Understanding Model Controls for Supply Planning

Understanding Model Controls for Supply Planning

This chapter provides an overview of model controls for supply chain planning and discusses how to:

Set up sourcing templates.

Define PeopleSoft Supply Planning user preferences.

Create planning bills of material (BOMs).

Create aggregate items.

Define forecast percentages.

Set up demand priority rules.

Set up business unit groups.

Define display templates.

Define display row types.

Define attributes in PeopleSoft Supply Chain Management.

Understanding Model Controls for Supply Planning

Understanding Model Controls for Supply Planning

When you set up attributes for PeopleSoft Supply Planning, you define attributes that control the planning models that are used by PeopleSoft Supply Planning as well as by other applications within PeopleSoft Supply Chain Management. This chapter describes the key setup pages and components and describes how they affect PeopleSoft Supply Planning.

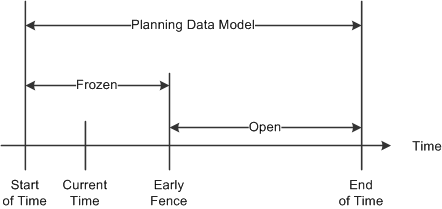

To reduce the size of a planning problem to a manageable set of data and functionality, use regions of time to define the scope of the plan. These regions of time are bounded by fences, which define the start and finish of these regions and influence solvers.

PeopleSoft Supply Planning automated processes, such as the Load Planning Instance process (PL_LOAD_OPT) and solver runs, use fences in the planning system to place boundaries on the magnitude of the planning problem, restrict the behavior of the solvers during certain time periods, and automate certain conditions at certain times. Manual processes, such as reschedules, are not constrained by fences (manual processes are, however, constrained by the start of time and the end of time fences).

Fences are attributes of a planning model, which you often define when running the Load Planning Instance process (usually by defining an offset time from a base time associated with a plan). The base time is equivalent to the current date time. Unless otherwise specified, offsets are defined in units of days.

This diagram illustrates the most common fences that are used in PeopleSoft Supply Planning, including time fences for use with frozen and open planning times:

PeopleSoft planning time fences

The region of time that is bounded by the Start of Time fence and the End of Time fence is the planning region. When you load an order into PeopleSoft Supply Planning from the transaction database, it may fall into this region if these options are true for:

|

Sales Order Schedule Line |

When running the Load Planning Instance process, you have an option to use either the request date or the schedule date as the target demand date in PeopleSoft Supply Planning. This option for sales orders determines which date the Load Planning Instance process uses for sales order inclusion in a plan. The specified date (dependent on the global option setting) must be in the planning region. The Load Planning Instance process selects all associated line and header information within the planning region. |

|

Transaction System Forecasts |

PeopleSoft Supply Planning considers forecast that is entered into the transaction system as a forecast quantity at a point in time. Generally, the forecast date time occurs in the planning region. However, the demand fence must be at or after the current time if the solver is to consider the forecast for inclusion in a plan. The Load Planning Instance process loads only those forecasts that can be used by the planning solvers. Demand fences are defined for each item within a business unit. |

|

Published Forecasts |

Forecasts values are produced by Demantra Demand Management. This forecast data is provided to PeopleSoft Publish Forecast tables that are available in the Advanced Planning component. You specify the name and date of a published forecast for use in Supply Planning. You can also import published forecasts from a third-party demand planning application. Published forecasts are bucketed (period) forecasts. Generally, the bucketed forecast date time occurs in the planning region. However, the demand fence must be at or after the current time if the solver is to consider the forecast for inclusion in a plan. The Load Planning Instance process loads only those forecasts that can be used by the planning solvers. |

|

Interunit Transfer |

If you include the source business unit in the planning instance, then the scheduled ship date exists in the planning region. If you include the destination business unit in the planning instance, then the scheduled arrival date exists in the planning region. These rules also apply to any planned interunit transfers. |

|

Material Stock Request |

The schedule ship date exists in the planning region. This rule also applies to any planned transfers. |

|

Purchase Order Line |

The scheduled arrival date exists in the planning region. |

|

Production Order |

The scheduled start and end dates must exist in the planning region. PeopleSoft Supply Planning assumes that any component demands that are associated with the production order occur between the production order start and finish dates. |

Prerequisites

Prerequisites

Before you set up planning data, you must set up PeopleSoft Supply Planning installation options, user preferences, and general option settings on these PeopleSoft Supply Planning-related pages:

Installation Options.

Set up installation options in the PeopleSoft Supply Chain Management (SCM) database.

Define Planning Attributes - Installation Options. Select the default planning instance, display template, order key separator, and starting sequence numbers for planned production, planned purchases, and planned transfers that are being committed from the planning instance.

See PeopleSoft Application Fundamentals PeopleBook Preface.

Setting Up Sourcing Templates

Setting Up Sourcing Templates

To set up sourcing templates, use the Sourcing Template component (PL_SRC_TEMPLATE).

Sourcing demand is the process that the PeopleSoft Supply Planning system uses to determine how the supply for an item's demand is going to be filled. The system sources demand using sourcing options. These options define parameters for manufacturing, purchasing, or transferring an item to meet demand. You define these options when you set up an item.

This section provides an overview of sourcing templates, lists common elements, and discusses how to:

Create sourcing templates.

Update transfer options.

Update purchase options.

Generate sourcing templates.

Understanding Sourcing Templates

Understanding Sourcing Templates

A sourcing template contains a sequenced list of sourcing options (purchase, transfer, or production) based on the item attributes that are defined in PeopleSoft Purchasing, PeopleSoft Inventory, and PeopleSoft Manufacturing. You can let the system load the options automatically, or you can set up sourcing templates manually and maintain the options. These templates are needed when multiple sourcing options exist for an item.

When you assign multiple sourcing options to a single item, you create a more flexible planning situation by providing more information to source demand. Material availability, resource capacity, and lead time can create exceptions that influence the sourcing selection. When you provide several options, the system has more opportunities to find an option that resolves an exception. For example, if a purchase option does not have adequate lead time, PeopleSoft Supply Planning can go to the next prioritized option to determine whether it can use that option to meet the demand.

The Define Sourcing Templates page enables you to review sourcing options before creating a plan, reduce processing time, and prevent the Create Sourcing Templates batch process job from overwriting those templates that you want to maintain manually.

The system uses these sourcing options to create supply to meet demand for an item:

|

Production Option |

Defines the method that you use to produce an item (for example, the material and resources that are required to make a specific item). These options combine a BOM and routing code that can be effective-dated for seasonal mix variations and that originate from item maintenance settings at the business unit level. You can create a production option for each BOM and routing code combination. You can define the BOM code, the routing code, and production option usage at the business unit level. You can also maintain options for an item when the planning rates are not maintained at the routing level. Note. Production options are based on the definitions that exist for the BOM, routing, or item. If you change or add a new BOM, routing, or item attribute (lead-time usage or production control attributes, for example) you might need to regenerate the sourcing template to ensure that solvers make proper sourcing decisions. |

|

Transfer Option |

Defines transfer attributes, such as cost or transfer time, that are associated with transferring an item from one business unit to another. Create the option by defining transfer attributes for an item. You can define transfer options at the business unit level or at the item level. Items with a planned-by option defined as Distribution use the business unit transfer option if the item does not have a specific item-based transfer option. Note. Transfer options are based on the default transfer attributes for a business unit or the item transfer attributes. If you change or add a new transfer attribute, you might need to regenerate the sourcing template to ensure that solvers make proper sourcing decisions. |

|

Purchase Option |

Defines item and vendor attributes, such as cost, lead time, and order modifiers. You create the option by defining item and vendor relationships on the Item Purchasing Attributes page. Note. Purchase options are based on the purchase item attributes. If you change or add a new purchase item attribute, you might need to regenerate the sourcing template to ensure that solvers make proper sourcing decisions. |

Manually Creating and Loading Sourcing Templates

When you manually create a sourcing template on the Define Sourcing Templates page, you sequence the options and define a default option for use if the system cannot find an adequate option using prioritization. The system uses fixed-priority sourcing logic to determine which sourcing option to use to meet the demand, evaluating, in the order of priority, each sourcing option until an option meets all of the selection criteria.

The system evaluates several criteria to determine when to select a sourcing option. First, the sourcing option must be valid. For example, if effectivity dates apply to the option, the option must be effective.

Note. Effective dates apply only to production options in the Planning Instance tables.

The system also considers material and capacity availability when selecting sourcing options. If you specify material availability as a criterion, then all materials (consumed by the tasks of that routing) must exist at the time they are required. If you specify capacity as a criterion, then all aggregate resources (that are consumed by the tasks of that routing) must have available capacity at the time they are required. PeopleSoft Supply Planning considers material as a sourcing criteria.

If the system evaluates all of the sourcing options and no options meet the selection criteria, it uses the default option (identified by the PL_SRC_DEFAULT column in the PL_SRC_TMPL_INF component).

Generating Sourcing Templates Automatically

Use the Generate Sourcing Templates - Generate Templates page to load production, transfer, and purchasing options automatically into the sourcing template for one business unit group at a time. The priority of each option is based on lowest cost. After you load the sourcing options into the template, you can maintain the priorities and the default option manually.

Reviewing and Refining Sourcing Information

You can review an item's sourcing template and sourcing options by using the Review Sourcing Information inquiry component. This component displays the sourcing template for the item and the data from production, purchasing, and transfer options. Use these inquiry pages to review sourcing options to be sent to the planning engine.

Along with maintaining sourcing information at the planning-instance level, you can update the business unit sourcing template with the current planning instance sourcing template. A check box displays the setting of the Manually Maintained check box for the Business Unit sourcing template, which you can change. If you select the check box, the changes to the business unit sourcing template will not be overwritten the next time that you run the Generate Sourcing Template process.

Common Elements Used in This Section

Common Elements Used in This Section|

Apply Selected |

Select this check box on the Update Production page, the Update Transfer page, or the Update Purchase page and click OK to identify the option or options that you want to load when you return to the Define Sourcing Templates page. |

|

Associated BOM (associated bills of material) |

Displays the assigned primary items BOM that is used when you are generating supply for a co-product. When an item is a co-product on multiple primary BOMs, one of the primary items must be assigned as an associated primary BOM. If an item has an associated primary item that is different from itself and also has its own BOM, then the planning instance imports production options for both the item itself and the associated primary item. |

|

BOM (bills of material) |

Displays the BOM identifier for the production option within the template. Production options can be predefined or created based on defaults that are specified at the item attributes by unit level. |

|

Location |

Select a vendor location. When purchasing items from a vendor who has multiple locations, you can, for example, select a location with the shortest lead time. |

|

Min Order Qty (minimum order quantity) |

Displays the minimum quantity that can be placed on a production, transfer, or purchase order. |

|

Max Order Qty (maximum order quantity) |

Displays the maximum quantity that can be placed on a production, transfer, or purchase order. |

|

Order Multiple |

Displays the multiple that the system uses to determine an order quantity. For example, if you have a demand for 28 and the multiple is 10, then the system generates a planned purchase order for 30. Note. Minimum and maximum order quantities must be in multiples of the order multiple if you specify an order multiple. |

|

Routing |

Displays the routing identifier for the production option within the template. The system populates this column only when routings are being used. |

|

Ship VIA |

Identifies the method that is used for shipping the item. |

|

Source BU (source business unit) |

Identifies the business unit that is shipping the item. |

|

Unit Cost |

Displays the cost to produce a single unit of the item that is defined in the sourcing template. When generating sourcing templates automatically, the system uses the cost as the basis for prioritizing sourcing. A lower item cost corresponds to a higher sourcing priority. |

|

Vendor |

Identifies a specific vendor, as defined on an item or vendor definition in PeopleSoft Purchasing. |

|

Vendor SetID |

Displays the setID in which the vendor information was defined in PeopleSoft Purchasing. |

Pages Used to Set Up Sourcing Templates

Pages Used to Set Up Sourcing Templates

Creating Sourcing Templates

Creating Sourcing Templates

Access the Define Sourcing Templates page (Supply Planning, Define Planning Attributes, Sourcing Templates, Define Sourcing Templates).

|

Manually Maintained |

Select to identify this sourcing template as a manually maintained template. If you select this check box, the Generate Sourcing Template batch job does not overwrite any options in the template. If you no longer need to maintain this sourcing template manually, deselect this check box. The next time that you run the Generate Sourcing Template batch job, the system overwrites the current sourcing template, including the options that you have defined. |

|

Refresh Current Template |

Click to replace the existing sourcing options with the current available default sourcing options. When prompted, click Yes to refresh with the current sourcing options; click No to keep the sourcing options as they appear on the page |

|

Update Production |

Click to access the Update Production page, where you can select production options for the item. |

|

Update Transfer |

Click to access the Update Transfers page, where you can select transfer options for the item. |

|

Update Purchase |

Click to access the Update Purchase page, where you can select purchase options for the item. |

Sourcing

Select the Sourcing tab to view and maintain basic information about the sourcing template.

|

Default |

Select to use this sourcing option as the default value when the planning engine sources demand for the current plan. You can select only one sourcing option as the default for the template. The system uses the default option to source demand when no sourcing template entries meet the selection criteria. |

|

Priority |

Enter a numerical value that defines the priority that you want the planning engine to consider when using a sourcing option to meet demand. You can enter any positive number up to 999. The planning engine (solver dependant) considers all of the sourcing template options (production, transfer, and purchase) using their priority in ascending sequence until it finds a template that can meet the demand without creating planning exceptions. If the planning solvers cannot find a template without exceptions, then it uses the default template. |

|

Option Type |

Defines whether the demand is supplied by production, purchase, or transfer. |

|

Minimum Quantity |

Defines the minimum demand quantity that should be considered when selecting this sourcing option. For example, if the demand is 10 but the minimum quantity is 50, then the sourcing option will not be considered when generating supply. |

|

Maximum Quantity |

Defines the maximum demand quantity that should be considered when selecting this sourcing option. For example, if the demand is 100 but the maximum quantity is 80, then the sourcing option will not be considered when generating supply. |

Production

Select the Production tab to view and update information related to bills of material.

Purchase

Select the Purchase tab to view and update information related to purchasing and vendors.

Transfer

Select the Transfer tab to view and update information related to material transfers.

Updating Transfer Options

Updating Transfer Options

Access the Define Sourcing Templates - Update Transfers page (click Update Transfers on the Define Sourcing Templates page).

|

Defines the usable output from the transfer. The value is expressed as a percentage. The transfer yield is used in PeopleSoft Supply Planning to inflate the planned quantity on transfers to account for any loss that occurs during transport. |

Updating Purchase Options

Updating Purchase Options

Access the Define Sourcing Templates - Update Purchase page (click Update Purchase on the Define Sourcing Templates page.

Vendor Details Tab

Select the Vendor Details tab.

|

Standard Price |

Displays the standard price for the item. The system uses this value as the default price in transactions for which another price, such as a vendor price or a contract price, is not defined for the item. |

|

Lead Time Days |

Displays the purchasing lead time that is specified for the vendor or item or vendor relationship. This value represents the amount of time that is required to get inventory from the vendor. |

Order Modifiers Tab

Select the Order Modifiers tab.

|

Defines the usable output from the purchase. The value is expressed as a percentage. Purchase yield is used in planning to inflate the planned quantity on purchases to account for any loss that may occur during the purchase process. |

Generating Sourcing Templates

Generating Sourcing Templates

Access the Generate Sourcing Templates - Generate Templates page (Supply Planning, Define Planning Attributes, Sourcing Templates, Generate Sourcing Templates).

Sourcing Options

Identifies options to update and include in the sourcing templates that are being generated. You can select all options or any combination of options, but you must select at least one option. Options that are not selected remain in any currently existing templates. For example, if you select the Purchase Options check box only, then transfer and production options remain unchanged in any template that they belong to when the templates are refreshed. The system refreshes purchase options for the items that you select in the Item Option group box. These sourcing options are available:

|

Purchase Options |

Select to include purchase options, which define item and vendor attributes such as cost, lead time, and order modifiers. You create the option by defining item and vendor relationships in the PeopleSoft Supply Chain Management database on the Define Items and Attributes - Purchasing Attributes component. |

|

Production Options |

Select to include production options, which include a combination of a BOM and routing code that can be effective-dated for seasonal mix variations. The option defines which materials and resources are required to make a specific item. |

|

Transfer Options |

Select to include transfer options, which define transfer attributes such as cost or transfer time, that are associated with transferring an item from one business unit to another. You create the option by defining transfer attributes for an item. |

Item Option

Define which items you want to include in Create Sourcing Template processing. Options are:

|

All |

Select to include all items with defined sourcing options in the processing. This is the default option. |

|

Range |

Select to specify a range of items to be included in the processing. Use the adjacent fields to define a from and to item ID range. These adjacent fields are required if you select the Range option. The system creates sourcing options for those items that are within the range only. |

|

Only New Items |

Select to include only those items that have been established since the last sourcing template was created. When you select this field, the Date Added field becomes available for entry, where you must enter a date from which you want the system to consider new items. |

|

Date Added |

Enter the date from which you want the system to consider new items. The system generates sourcing templates for any items that were established after this date. This is a required field if you select Only New Items. |

|

Run |

Click to run the Generate Sourcing Templates process (PLS5000). PeopleSoft Process Scheduler runs the process at user-defined intervals. |

Defining PeopleSoft Supply Planning User Preferences

Defining PeopleSoft Supply Planning User PreferencesThis section discusses how to assign user preferences.

Page Used to Define PeopleSoft Supply Planning User Preferences

Page Used to Define PeopleSoft Supply Planning User Preferences

Assigning User Preferences

Assigning User Preferences

Access the User Preferences page (Supply Planning, Define Planning Attributes, User Preferences).

|

Default Planning Instance |

Select a default planning instance for the corresponding user ID. |

|

Default Display Template |

Select a default display template for the corresponding user ID. |

|

Order Key Separator |

Select a default key separator for the corresponding user ID. The system uses order key separators to format the display for a single field that contains a line, schedule, and kit number for sales orders and quotes in PeopleSoft Supply Planning grids. |

Creating Planning BOMs

Creating Planning BOMs

To create planning BOMs, use the Planning BOM Maintenance component.

This section provides an overview of planning BOMs and discusses how to define planning BOMs.

Understanding Planning BOMs

Understanding Planning BOMs

A planning BOM is an artificial grouping of related items that you can use to forecast demand. Using a planning BOM, you can facilitate the master scheduling and material planning processes by reducing the number of items that the planner needs to forecast.

On the Planning BOMs page, you can create and maintain at the summary level all components that make up a planning BOM for a group of assembly items or product families in a specific business unit.

Note. To define an item for use as the parent ID on a planning BOM, you must define the item as a planning item. To define an item as a planing item, you must select Planning in the Source Code field on the Define Business Unit Item - Manufacturing: General page.

You can also use a planning BOM to split the forecast among multiple items. For example, you might forecast item SR1001 at 50 percent of the forecast, item SR1002 at 30 percent, and item SR1003 at 20 percent.

Page Used to Define Planning Bills of Material

Page Used to Define Planning Bills of Material

Defining Planning BOMs

Defining Planning BOMs

Access the Planning BOMs page (Supply Planning, Define Planning Attributes, Planning Bills of Material).

|

BOM Quantity (bill of material quantity) |

The BOM quantity acts a scaling device that enables you to enter a structure when the planning item's specifications are in a base that is greater than 1 unit. |

|

Component ID |

Select the name of the component to use in the planning BOM. The component can be a planning item. |

|

Effective Date and Obsolete Date |

Define the effective dates for the components of the planning item. |

|

Quantity |

Define the component quantity (expressed in terms of a percentage) of the planning item. The forecast amounts at the parent level are multiplied by the quantity for the component to determine the forecast to be associated with the component. |

Creating Aggregate Items

Creating Aggregate Items

To create aggregate items, use the Aggregate Items component.

Use aggregate items to consolidate demand for multiple items when consuming forecast for a planning item. The aggregate parent and child items typically correspond to the parent and component items on a planning BOM. These two separate structures, planning BOMs (to allocate forecasts) and aggregate items (to sum demand), enable you to place forecast on alternate items that are not included in the current demand stream.

Note. Aggregate items do not always correspond to forecast families. The aggregate parent must always be a planning item. You can create hierarchies of aggregate items.

This section discusses how to create aggregate items.

Page Used to Create Aggregate Items

Page Used to Create Aggregate Items|

Page Name |

Definition Name |

Navigation |

Usage |

|

Aggregate Items |

PL_AGG_DMD_ITEM |

Supply Planning, Define Planning Attributes, Aggregate Items |

Creating Aggregate Items

Creating Aggregate Items

Access the Aggregate Items page (Supply Planning, Define Planning Attributes, Aggregate Items).

|

Item ID |

Select an item to include in the corresponding aggregate parent item. |

|

Description |

When you select a value in the Item field, the system displays the item's description. |

Defining Forecast Percentages

Defining Forecast Percentages

To define forecast percentages, use the OM Forecast Percentage component.

This section provides an overview of forecast percentages and discusses how to define forecast percentages.

Understanding Forecast Percentages

Understanding Forecast Percentages

PeopleSoft Supply Planning uses forecast percentage to allocate the forecast that is defined for a product (defined in the PeopleSoft Order Management business unit) among multiple PeopleSoft Inventory business units.

In PeopleSoft Order Management, you can define forecasts at the product and order-management business unit level. A single product and PeopleSoft Order Management business unit combination might correspond to an inventory item that is held at multiple PeopleSoft Inventory business units. Forecast percentages map the product at the PeopleSoft Order Management business unit to one or more inventory items at the PeopleSoft Inventory business unit level to enable PeopleSoft Supply Planning to use inventory items.

You can link a PeopleSoft Order Management business unit to more than one PeopleSoft Inventory business unit. This table lists how you can allocate the forecast percentage:

|

Order Management Business Unit |

Inventory Business Unit |

Forecast Percentage |

|

GBR01 |

GBR01 |

50 percent |

|

GBR01 |

GBR02 |

25 percent |

|

GBR01 |

CAN01 |

25 percent |

Page Used to Define Forecast Percentages

Page Used to Define Forecast Percentages

Defining Forecast Percentages

Defining Forecast Percentages

Access the Forecast Percentages page (Supply Planning, Define Planning Attributes, Forecast Percentages).

|

Forecast Percentage |

Enter the percent to allocate a specific forecast percentage to the business unit or product and business unit combination. The percentage can be any number. Even if you define more than one effective-dated percentage, the system does not require that the percentages total 100 percent; totals can also exceed 100 percent. |

Setting Up Demand Priority Rules

Setting Up Demand Priority Rules

To set up demand priority rules, use the Demand Prioritization component.

PeopleSoft Supply Planning enables you to define a set of rules to prioritize the distribution of demand when demand exceeds the available supply of inventory or capacity. The system uses these demand priority rules to determine the order in which you fulfill independent demand.

This section provides an overview of demand priority rules and discusses how to set up demand priority rules.

Understanding Demand Priority Rules

Understanding Demand Priority Rules

In PeopleSoft Supply Planning, you define the demand prioritization rules that are specific to a business unit that you model. The Load Planning Instance process uses the demand priority rules to generate the priority for a given independent demand. When the priority is established, the system passes the independent demands with different priority codes to the planning instance. A demand priority code can range from 1 to 999, with 1 being the most important. The priority value of 0 is reserved for the system. The planning solvers use the demand priority code to determine which independent demand to fulfill first so that higher priority demands are fulfilled before lower priority demands in situations in which enough available supply or capacity is not available to meet the various demands.

Note. Demand priorities are considered by the Feasible solver only. The Material solver does not consider demand priorities.

Page Used to Set Up Demand Priority Rules

Page Used to Set Up Demand Priority Rules|

Page Name |

Definition Name |

Navigation |

Usage |

|

Demand Priority Rules |

PL_PRIO_DEMAND |

Supply Planning, Defining Planning Attributes, Demand Priority Rules |

Setting Up Demand Priority Rules

Setting Up Demand Priority Rules

Access the Demand Priority Rules page (Supply Planning, Defining Planning Attributes, Demand Priority Rules).

|

Priority Rank |

(Required) Define the priority to be assigned to each independent demand that satisfies a given priority rule. The lower the value that you select, the higher the priority. The highest value is 999, which is the lowest possible priority, and the lowest value is 1, which is the highest possible priority. A priority rank value of 0 is reserved for the system. |

The Demand Source represents the source of independent demand to which the prioritization rule applies.

|

Buying Agreements |

A buying agreement is a schedule between you and the customer who is defining terms and conditions. Buying agreements enable you to define beginning dates, ending dates, and maximum amounts; specify the minimum dollar value per order placed, as well as the maximum and minimum line item ordering quantities for each line item; define certain shipping defaults for all sales orders, as well as all products and product groups to be included; define special pricing terms for a customer or customer group; generate sales orders automatically when customers know in advance when products are needed; create sales orders in situations in which shipment scheduling is unknown; and create rebates and penalties. |

|

Forecasts |

The total expected sales to all customers that you can maintain at the product, inventory-item, or planning-item level. At the planning-item level, sales are forecasted by families and exploded to inventory items through planning bills of material. |

|

Interunit Transfers |

Outbound transfers that represent independent demand in the planning model. |

|

Quotations |

An order management quotation is considered a demand and sent to PeopleSoft Supply Planning when the quotation success percentage is over the planning success percentage on the load planning instance run control. |

|

Sales Orders |

Represents a scheduled shipment on a line on a customer order from the order management system. |

|

Stock Requests |

Material stock requests that come from inventory but that are not transfers. A stock request might refer to an internal or external fulfillment. |

|

Demand Priority Family |

(Optional) A planning priority family represents an item or a group of items that can be used as criteria for prioritization. You define demand priority families in PeopleSoft Inventory. |

|

Reservation Status |

(Optional) Select Reserved if the corresponding order has been reserved against available and projected quantity on-hand at the business unit and item level. Otherwise, select Unreserved.This field value is available only if you select Sales Orders, Inter-Unit Transfers, or Stock Requests in the Demand Source field. |

|

Customer Group |

(Optional) Select to identify as a customer allocation group, a group corresponding to one or more ship-to customers. This field is available only if you select Sales Orders, Quotations, or Buying Agreements in the Demand Source field. |

|

Priority |

(Optional) Enter an order priority value between 1 and 999. For a given priority rule, all sales orders with an order priority that is less than or equal to the value in this field are considered to match this parameter. For example, if you enter a value of 100 here, the system considers all sales orders with an order priority of 100 or less as matching this parameter. This field is available only if you select Sales Orders in the Demand Source field. |

|

Destination Unit |

(Optional) Select a value to prioritize demand for a specific destination business unit. This field is available only if you select Inter-Unit Transfers in the Demand Source field. |

Note. To create a priority rule, you must define a value for the Priority Rank field, and enter a value in at least one of the remaining fields on this page.

Setting Up Business Unit Groups

Setting Up Business Unit Groups

To set up business unit group codes, use the Group Codes component.

A business unit group represents all of the business units that you want to include in a planning instance. You must define at least one business unit group for PeopleSoft Supply Planning. If in the business operations you require only one business unit, define the business unit group with a single business unit.

This section discusses how to set up business unit groups.

Note. PeopleSoft Supply Planning business unit groups are defined with inventory business units only.

Page Used to Set Up Business Unit Groups

Page Used to Set Up Business Unit Groups

Setting Up Business Unit Groups

Setting Up Business Unit Groups

Access the Business Unit Group Definition page (Supply Planning, Define Planning Attributes, Business Unit Groups).

Business Units Tab

Select the Business Units tab.

|

Business Unit |

Add the business units that you want to include in the plan unit group. The system displays a description that is adjacent to the business unit. |

|

MFG BU (manufacturing business unit) |

Indicates whether the corresponding inventory business unit is also defined as a manufacturing business unit. This field is not available for entry. |

Options

Select the Options tab.

|

Round Component Demand |

Select to limit component demand quantities to the precision that is associated with the item based on its standard unit of measure. This option is applicable for Manufacturing business units only. |

|

Available Inventory Balances |

Select to include quantity on hand for this business unit. |

|

If quarantine quantities are not included in the quantity on hand in PeopleSoft Inventory, select to include quarantine quantities in the quantity on hand in PeopleSoft Supply Planning. If quarantine quantities are included in the quantity on hand in PeopleSoft Inventory, select to exclude quarantine quantities in the quantity on hand in PeopleSoft Supply Planning. |

|

|

Allow Substitution |

Select to allow solvers to do component substitution to resolve constraints. This option is available for Manufacturing business units only. |

|

Create Substitute Supply |

Select to allow solvers to create a new supply for substitute components to resolve constraints. If you do not select this option, the substitute algorithm may use on-hand quantities only. This option is available when you select the Allow Substitution option only. |

|

Check Substitute First |

Select to allow solvers to use substitute components before using alternate sourcing options. If you do not select this option, a solver determines alternate sourcing options prior to attempting to use substitutes when resolving a constraint failure. This option is available only when you select the Allow Substitution option. |

Defining Display Templates

Defining Display Templates

To define display templates, use the Workbench Template Maintenance component.

This section includes an overview of display templates and discusses how to define display templates.

Understanding Display Templates

Understanding Display Templates

PeopleSoft Supply Planning delivers standard display templates to enable you to set up default templates that you can use to define row type, graph, period duration, and other display defaults on workbenches and review pages.

These sections list the standard display templates in PeopleSoft Supply Planning:

Allrows

The Allrows template includes all display row types.

Supplier Schedule

The Supplier Schedule template includes row types for the following Buyer Based display types:

Vendor Scheduled Purchases.

Vendor Planned Purchases.

Distribution Plan

The Distribution Plan template includes row types for:

Item Based display types:

Starting On Hand.

Actual Forecast.

Net Forecast.

Independent Demand.

Dependent Demand.

Total Demand.

Scheduled Receipts.

New Planned Orders.

Planned On Hand.

Intransit Inventory.

Safety Stock.

Capacity Based display types:

Available Capacity.

Required Capacity.

Unused Capacity.

Utilization percentage.

Overloaded Capacity.

Buyer Based display types:

Starting On Hand.

Vendor Scheduled Purchases.

Vendor Planned Purchases.

Other Supply.

Total Demand.

Planned On Hand.

Master Plan

The Master Plan Template includes row types for:

Item Based display types:

Starting On Hand.

Actual Forecast.

Net Forecast.

Independent Demand.

Dependent Demand.

Total Demand.

Planned On Hand.

Available To Promise.

Cumulative ATP.

Scheduled Receipts.

New Planned Orders.

Capacity Based display types:

Available Capacity.

Required Capacity.

Unused Capacity.

Utilization Percentage.

Overloaded Capacity.

Buyer Based display types:

Starting On Hand.

Vendor Scheduled Purchases.

Vendor Planned Purchases.

Other Supply.

Total Demand.

Planned On Hand.

Material Plan

The Material Plan template includes row types for:

Item based display types:

Starting On Hand.

Net Forecast.

Customer Orders.

Stock Requests.

Transfer Demand.

Production Demand.

Extra Demand.

Total Demand.

Scheduled Receipts.

New Planned Orders.

Planned On Hand.

Capacity Based display types:

Available Capacity.

Required Capacity.

Unused Capacity.

Utilization percentage.

Overloaded Capacity.

Buyer based display types:

Starting On Hand.

Vendor Scheduled Purchases.

Vendor Planned Purchases.

Other Supply.

Total Demand.

Planned On Hand.

Page Used to Define Display Templates

Page Used to Define Display Templates|

Page Name |

Definition Name |

Navigation |

Usage |

|

Define Display Templates |

PL_WBENCH_TEMPLATE |

Supply Planning, Define Planning Attributes, Display Templates |

Defining Display Templates

Defining Display Templates

Access the Define Display Templates page (Supply Planning, Define Planning Attributes, Display Templates).

|

Default Template |

Select to use this template as the default template when you access the Material or Capacity Workbench if no user default or installation default is identified. |

|

System Data (Locked) |

PeopleSoft Supply Planning provides the ALLROWS template as part of the system data. When this check box is selected, you cannot change rows in the corresponding template. |

|

Display Type |

Define the template as Item Based, Capacity Based, or Buyer Based. The value that you select here determines which fields are available in the Row Type ID field. You define row types for each display type on the Define Display Row Types page. Display types indicate the workbench in which you can use any given row type. For example, an item-based display template is available in the Material Workbench only. You can use capacity-based display types in the Capacity Workbench only, and buyer-based display types in the Buyer Workbench. |

|

Default Number of Periods |

Enter the default number of buckets the system displays on each workbench initially. |

|

Default Graph Type |

Select the graph type that the system uses initially. |

|

Beginning Start Date |

Define the start date of the first bucket. Values are Beginning of Period, in which the start date falls on a specific Start Date Entered. Initially, the system uses Beginning of Period as the default value. Templates with capacity-based display types always use Beginning of Period. |

|

Template to Copy |

To copy an existing template, select from the available options and click the Copy Template button. |

|

Default Period Duration |

Select a default period duration that the system uses for buckets. |

|

Default Decimal Positions |

Enter the default decimal precision that the system uses for quantity buckets. |

Row Type List

|

Row Type ID |

Select a row type that you want to appear on workbenches and review pages. You can add as many rows as available for the corresponding display type. You can set up lists of available row types for each display type on the Define Display Row Types page. |

|

Sort Order Number |

Define the order in which the row types appear on the workbench or review page when displayed. |

|

Include in Chart |

Select this option to include the row type in generated graphic representations. |

Defining Display Row Types

Defining Display Row Types

PeopleSoft Supply Planning enables you to create and maintain lists of available template rows for each workbench type.

This section discusses how to define display row type lists.

Note. If you add new row types, you must also add the corresponding logic for calculating the row type on workbench and review pages. Predefined row types are delivered with calculations.

Page Used to Define Display Row Types

Page Used to Define Display Row Types|

Page Name |

Definition Name |

Navigation |

Usage |

|

Define Display Row Types |

PL_WBENCH_ROWTYPES |

Supply Planning, Define Planning Attributes, Display Row Types |

Defining Display Row Type Lists

Defining Display Row Type Lists

Access the Define Display Row Types page (Supply Planning, Define Planning Attributes, Display Row Types).

|

Description |

Enter a long and short description of the row that you want to make available for the corresponding workbench type. |

PeopleSoft Supply Planning delivers row types for these display types:

Item-based.

Capacity-based.

Buyer-based.

PeopleSoft Supply Planning delivers these item-based row types:

|

Actual Forecast |

Displays the actual, unconsumed forecast for the corresponding period. |

|

Available to Promise (ATP) |

Determines the projected available inventory that has not been committed to customer orders. PeopleSoft Supply Planning uses this algorithm: ATP = Planned Receipts + Scheduled Receipts − Actual Demand − Carryover Demand Planned Receipts + Scheduled Receipts = Total Supply row type Total Orders row type + Dependent Demand row type = Actual Demand Carryover demand occurs when ATP is driven below 0 in a time bucket. If this occurs, supply is consumed from an earlier time bucket. ATP is reported as a negative number in the first bucket if carryover demand is not satisfied. PeopleSoft Supply Planning does not print ATP and cumulative ATP in the past due bucket (as it does not apply). |

|

Buying Agreements |

Displays the demand quantity for this item that is generated by buying agreements |

|

Cumulative ATP |

Cumulative or running total of ATP. |

|

Dependent Demand |

Displays the demand quantity that occurs when the item is required to meet demands of another transfer, planned transfer, production, or planned production order. |

|

Excess Inventory |

The maximum amount of inventory that is allowable. The planned inventory on hand should never exceed this number. Excess is the defined excess level as of the end of the corresponding period. When you are summarizing multiple items, excess is the summarized excess levels for all items at the end of the corresponding period. Note. When planned inventory on hand exceeds the excess inventory, PeopleSoft Supply Planning reports the violation in the exceptions inquiry only. The planning solvers do not solve for this condition. |

|

Extra Demand |

Displays demand quantity that you enter directly into a planning instance in the form of extra demand. |

|

Independent Demand |

Displays the total demand quantity from sales orders, quotes, buying agreements, stock requests, and extra demand. |

|

Intransit Inventory |

Interunit transfers that have been shipped but not received. Appears in the destination business unit only. |

|

Net Forecast |

Displays the forecast quantity that remains after the actual forecast has been consumed by actual demand. |

|

New Planned Orders |

The sum of planned production, purchases, and transfers for an item in a period. |

|

Periods Of Supply |

A forward-looking calculation of a period's planned on-hand balance, which determines how many days into the future a period's planned on-hand balance covers the total demand. When planned on-hand quantities are not enough to cover all of the total demand for a particular bucket, PeopleSoft Supply Planning prorates the number of days by the ratio of the planned on-hand quantity that is available over total demand. When not enough total demand is available through the periods reported, the Periods of Supply bucket displays 99999. |

|

Planned On Hand |

Displays the cumulative projected inventory balance from the beginning of the planning horizon. This includes the prior period's ending on-hand balance plus the total supply, minus the total demand for the current period. |

|

Planned Production |

Displays the suggested production orders that were created for this period when you generated the supply plan solution. |

|

Planned Production Demand |

Displays the component demand for this item that was caused by other planned production orders in the planning instance. |

|

Planned Purchases |

Displays the suggested purchase orders that were created for this period when you generated the material plan. |

|

Planned Transfer Demand |

Displays the demand for this item that was caused by planned transfer orders in the planning instance. |

|

Planned Transfers |

Suggested transfer orders that were created by PeopleSoft Supply Planning. |

|

Production Demand |

Displays the total amount of demand (component demand) from planned production and scheduled production for this time period. |

|

Production Supply |

Displays the scheduled receipts from manufacturing for this time period. The receipts are in the form of production orders. |

|

Projected On Hand |

Displays the cumulative projected inventory balance from the beginning of the planning horizon. This includes the prior period's ending on-hand balance plus the known supply, minus the total demand for the current period. The projected on-hand does not include planned supplies in the calculation. |

|

Purchase Supply |

The scheduled receipts from vendors for this period. The receipts are in the form of purchase orders. |

|

Safety Stock |

The defined safety stock level that is expected for the item as of the end of the corresponding period. When you are summarizing multiple items, the safety stock represents the sum of safety stock levels for the items that are being summarized as of the end of the corresponding period. |

|

Sales Orders/Quotes |

Displays the quantity of orders that were generated by customers, including real orders and any quotes that have been included in the planning instance. |

|

Scheduled Production |

The total amount of demand from production, with statuses of Entered, Firmed, Released, Dispatched, and In-Process. |

|

Scheduled Production Demand |

Displays the total amount of demand (component demand) from scheduled production for this time period. |

|

Scheduled Purchases |

The sum of purchases, with statuses of Firmed and Open. |

|

Scheduled Receipts |

Displays the total quantity for this period from these row types: Scheduled Production, Scheduled Purchases, and Scheduled Transfers. |

|

Scheduled Transfer Demand |

Displays the total demand quantity for this period caused by scheduled transfers. |

|

Scheduled Transfers |

Displays the total amount of supply from transfer orders arriving at the destination business unit for this time period. |

|

Starting On Hand |

The cumulative inventory level at the beginning of the period. The history begins with the starting quantity for the planning horizon. |

|

Stock Requests |

Internal and external inventory orders (for noninterunit transfers only). |

|

Total Demand |

Defined as the sum of net forecast, customer orders, interunit orders, and dependent demand. The total demand consists of both independent and dependent demand. |

|

Total Supply |

Displays the total quantity of actual supply and new planned orders. |

|

Transfer Demand |

Displays the scheduled transfers to other business units in the form of transfer orders. |

|

Transfer Supply |

Displays the scheduled receipts from other business units in the form of transfer orders. |

PeopleSoft Supply Planning delivers these capacity-based row types:

|

Available Capacity |

The total capacity that is available for a period, measured in hours or units. |

|

Overload Capacity |

The amount that exceeds the available capacity (required capacity less available capacity when greater than zero). |

|

Required Capacity |

The amount of capacity that is consumed by production operations using a resource in a specific period, measured in hours or units. |

|

Unused Capacity |

Leftover capacity (available capacity less required capacity when greater than zero). |

|

Utilization Percentage |

The ratio between required capacity and available capacity when the available and required capacities are greater than zero. |

PeopleSoft Supply Planning delivers these buyer-based row types:

|

Vendor Scheduled Purchases |

Represents actual purchases for item and vendor or schedule group and vendor combinations. |

|

Vendor Planned Purchases |

Represents the total of planned purchases for item and vendor or schedule group and vendor combinations. |

|

Previous Schedule's Approved Quantity |

Displays the quantity on the last schedule that the supplier approved for supplier-scheduled items. |

|

Current Schedule's Required Quantity |

Displays a supplier scheduled item's current quantity. |

|

Other Supply |

Represents the combined total of all transfers, all production, all actual purchases not included in the item and vendor combination, and all planned purchases not included in the item and vendor combination. |

|

Total Demand |

Represents the combined total of net forecast, sales orders, quotes, buying agreements, transfers, stock requests, production demand, and extra demand. |

|

Starting On Hand |

The cumulative inventory level at the beginning of a defined period. The history begins with the starting quantity for the planning horizon. For past due buckets, this value is determined by the inventory quantity on hand. For all other buckets, this value is determined by the planned on-hand inventory from previous buckets. |

|

Projected On Hand |

Displays the cumulative projected inventory balance from the beginning of the planning horizon. This includes the prior period's ending on-hand balance plus the known supply, minus the total demand for the current period. The projected on-hand does not include planned supplies in the calculation. |

|

Planned On Hand |

Displays the cumulative projected inventory balance from the beginning of the planning horizon. This includes the prior period's ending on-hand balance plus the total supply, minus the total demand for the current period. |

|

Safety Stock |

The minimum quantity of stock that is planned to always be in inventory to protect against fluctuations in demand or supply. This value represents the safety stock effective on the end date of the period. |

|

Excess Inventory |

The maximum amount of inventory that is allowable. The planned inventory on hand should never exceed this number. This value represents the excess stock that is effective on the end date of period. Note. When planned inventory on hand exceeds the excess inventory, PeopleSoft Supply Planning reports the violation in the exceptions inquiry only. The planning solvers do no solve for this condition. |

Defining Attributes in PeopleSoft Supply Chain Management

Defining Attributes in PeopleSoft Supply Chain Management

Before using PeopleSoft Supply Planning, you must define attributes in other PeopleSoft applications within the PeopleSoft Supply Chain Management application suite. This section details the key setup pages and components and discusses how to:

Set up work center planning attributes.

Define and review manufacturing BOMs.

Define manufacturing routings.

Define item attributes at the business unit level.

Define planner codes.

Establish closure calendars.

Set up stocking periods.

Set up demand priority families.

Define transfer attributes.

Define purchasing attributes.

Define forecast sets.

Define forecast product information.

Create item forecasts.

Setting Up Work Center Planning Attributes

Setting Up Work Center Planning Attributes

A work center can consist of one or more people and machines; it can represent a logical grouping of machines, a department, or a cost center. For a routing, you can assign to each operation or task a work center where the operation or task takes place. You can also assign one or more resources (crew, machine, or tool) to each work center.

You create and maintain work centers and their associated resources, conversion codes, text, locations, departments, and distribution types in the Define Work Centers component. When you add a new work center, or when you change any attribute in an existing work center, the system optionally sends a workflow notification to the roles that you have defined, such as an engineering manager or cost accountant.

Set up PeopleSoft Supply Planning work center options on the Define Work Centers - Planning Opts (define work centers - planning options) page.

See Also

Defining and Reviewing Manufacturing BOMs

Defining and Reviewing Manufacturing BOMs

PeopleSoft Supply Planning uses manufacturing BOMs for determining material requirements for production. On the Manufacturing BOMs component, you can create and maintain (on a summary level) all components that make up a manufacturing BOM or outsourced material for a group of assembly items or product families in a business unit.

See Also

Defining Manufacturing Routings

Defining Manufacturing Routings

You can create and maintain routings using the Manufacturing Routings component, where you can define the routing code, operations, scheduling options, routing times, conversion costs, routing text, attachments, and the associated tasks, count points, work centers, and resources. You can specify a routing by business unit for any manufactured or purchased item. When you add a new routing, or when you change any attribute in an existing routing, the system sends a workflow notification to the roles—such as engineering manager or cost accountant—that you define.

See Also

Defining Item Attributes at the Business Unit Level

Defining Item Attributes at the Business Unit Level

Access the Define Business Unit Item - Planning page. (Items, Define Items and Attributes, Define Business Unit Item and select the Planning tab).

For each item, define information using the Define Items and Attributes - Define Business Unit Item - Planning pages:

On the Planning - General page, define planning information for an item, such as whether the item is planned by distribution planning, master planning, or material planning, or is not planned. You can also define the PeopleSoft Purchasing sourcing option. Options include Use Ship To Locations, Use Item Vendor by Region, or Spot Buy. You can only select one method.

On the Planning - Fences page, define planning time fences, planning message parameters, safety stock and excess stock parameters, lead times, new order fences, and other general information about how you will generate supply for inventory items.

Note. PeopleSoft Supply Planning generates recommendations for new orders, reschedules, or order cancellations and then routes these recommendations to PeopleSoft Inventory, Purchasing, Order Management, and Production Management. In many cases, the volume of changes number in the thousands. To help manage this activity more effectively, the system enables you to define a time fence and filters to control the message review and approval process.

On the Planning - Order Modifiers page, define transfer, purchasing, and manufacturing order quantities, order multiples, yields, and whether to use the purchase order modifier.

Note. For transfers, you can set up order modifiers on the Transfer Attributes page. The system uses the transfer order modifier values that you define on the Planning - Order Modifier page when you do not define values on the Transfer Attributes page. You can select the Include in Planning check box on the page to indicate that sourcing options will be created for this given item and business unit. You can also select to Include in Planning check box on the Transfer Attributes Defaults page.

Note. If you select the Use Purchase Order Modifier check box, the system uses the item's purchasing attributes defined on the Vendor's UOM and Pricing Information page.

For more information about the Planning page, see the PeopleSoft Managing Items 9.1 PeopleBook.

See Specifying Planning Information for an Item.

Defining Planner Codes

Defining Planner Codes

Use planner codes to filter information for most pages and processes in PeopleSoft Supply Planning. Define planner codes on the Planner Code page.

Establishing Closure Calendars

Establishing Closure Calendars

The PeopleSoft Inventory closure calendar enables you to specify when the business units are closed for various inventory and purchasing activities. You use the Closure Calendar page to schedule regular (standing) closure days or specific closure periods and associate these closures with shipping, interunit and RMA receiving, and internal warehouse activities. If the installation includes PeopleSoft Purchasing, you can also define calendar closures for purchasing receiving activities.

See Also

Establishing Operation Closure Dates

Setting Up Stocking Periods

Setting Up Stocking Periods

Set up time-phased safety stock and excess stock levels on the Stocking Periods page. The information that you enter on this page overrides any stocking-level information that you entered on the Define Business Unit Item - Planning: Fences/Lead Time page.

See Also

Setting Up Demand Priority Families

Setting Up Demand Priority Families

Group similar items to establish a common priority for all items within a single group on the Demand Priority Family page. This setup set enables the system to establish demand priorities in PeopleSoft Supply Planning.

See Also

Grouping Items in Demand Priority Families

Defining Transfer Attributes

Defining Transfer Attributes

Define item transfer attributes to plan transfer for items between business units. Using the Transfer Attributes page, you can define transfer attributes for individual items. PeopleSoft Supply Planning uses these attributes that you define on the Transfer Attributes page to help fulfill material needs. After you set up transfer attributes, you can use them to set up sourcing template transfer options for an item on the Define Sourcing Templates page.

See Also

Defining Purchasing Attributes

Defining Purchasing Attributes

If you are using PeopleSoft Purchasing, use the Define Items and Attributes - Purchasing Attributes component to enter data that PeopleSoft Supply Planning requires.

On the Purchasing Attributes page, define the lead time and the primary buyer for the purchased item.

On the Item Vendor page, define the vendors from whom you can purchase the corresponding item.

PeopleSoft Supply Planning recommends this vendor to PeopleSoft Purchasing for each planned order. If you do not specify a vendor for a purchased item, PeopleSoft Supply Planning creates a planned order without a vendor. In this scenario, you can use the purchase order load process to assign a vendor to the item. PeopleSoft Supply Planning ranks multiple vendors for the same item based on the values that you define in each vendor's corresponding Priority field.

Define a ship-to location that represents an Inventory business unit. When you set up a purchase option, you can define a ship to location as an attribute only if the item has purchasing attributes. If an item has purchase attributes defined but no ship to locations, the system assumes that the item can be ordered at any Inventory business unit.

See Also

Defining Purchasing Item Information

Defining Forecast Sets

Defining Forecast Sets

Whether you forecast products at the Order Management business unit level, forecast items at the Inventory business unit level, or use planning BOMs to forecast at the Inventory business unit level, you must define one or more forecast sets. Use the Forecast Sets page to define different versions of the forecast for PeopleSoft Supply Planning to create what-if scenarios with different versions of the material and capacity plan based on the different forecasts.

You might, for example, have three versions of a forecast: a conservative forecast, a most likely forecast, and an optimistic forecast. For each case, you can define forecast quantities by item. You use forecast sets for product forecasts in order management and item forecasts in inventory.

If you use Demantra Demand Management forecast data, you do not have to define forecast sets, because you obtain the forecasts from PeopleSoft Publish Forecast tables that are available in the Advanced Planning component. Demantra Demand Management provides a flat file (forecast.txt) of forecasts through the Process Integration Pack. Using the PeopleSoft Import Forecast routine, you can import the file into the Publish Forecast tables in PeopleSoft. After the import, the file is available for use by other PeopleSoft modules such as PeopleSoft Supply Planning, Inventory Policy Planning, and Inventory. To access the routine, select SCM Integrations, Advanced Planning, Demantra, Import Forecast.

See Also

Integrating with Oracle's Demantra Demand Management

Defining Forecast Product Information

Defining Forecast Product Information

In PeopleSoft Order Management, you can define product forecast information. PeopleSoft Supply Planning uses forecast sets to define different versions of a forecast. You associate products with forecast sets on the Forecast Products page.

See Also

Setting Up PeopleSoft Order Management Business Units

Creating Item Forecasts

Creating Item Forecasts

Use the Forecast Items page to associate items with forecast sets. You select a forecast set that you want to use in PeopleSoft Supply Planning. You set up forecast sets on the Forecast Sets page to create what-if scenarios with different versions of the material and capacity plan based on different forecasts.

Applying Security for Business Units and Planning Instances

Applying Security for Business Units and Planning Instances

The available options for business unit fields and planning instance fields within the Supply Planning pages can be restricted based on the use of the user ID level or permission list level security. With row-level support, you can implement security to restrict individual users or permission lists from specific business units, planning instances, or both. To establish security, you must first decide the level that you want, which key fields (business unit and planning instance) to secure, and whether security will be defined through user IDs or permission lists. For more information, see the PeopleSoft Application Fundamentals PeopleBook, "Security Your System" chapter.

See Securing Your System.