F Barcode Labels

This section describes the requirements for cartridge barcode labels used in Oracle's StorageTek tape libraries. All tape cartridges must have a proper barcode label. Mis-aligned, mis-oriented, or improperly-labeled cartridges may cause equipment damage.

Barcode Standards

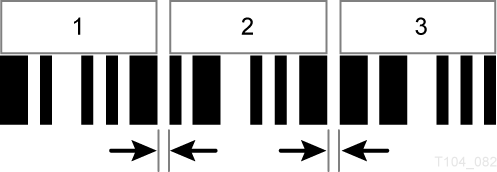

StorageTek libraries use labels based on the Code 39 barcode standard (refer to ANSI/AIM BC1/1995, Uniform Symbology Specification - Code 39). This standard uses discrete barcodes, meaning a fixed pattern of bars represents a single character. Each character is made up five black and four white, where three bars are wider than the others.For example, Figure F-1 represents the letter A using six narrow bars and three wide bars (two black and one white).

When multiple barcode characters are arranged together as a label, a narrow white bar is placed between the individual characters. This bar is called the inter-character gap.

Label Design

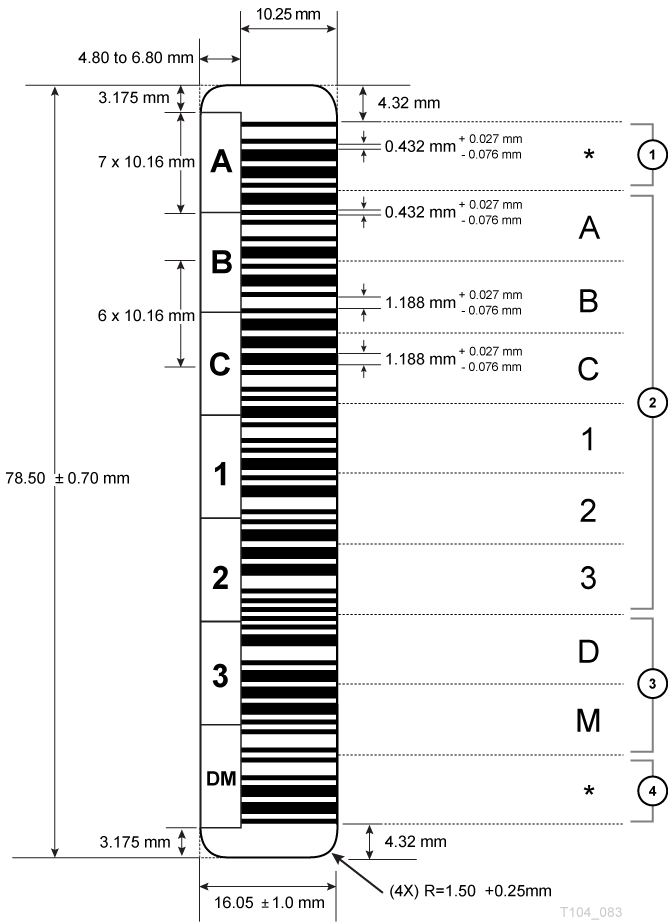

Each label must have a six-character volume serial ID (vol-id) and a one- or two-character media ID. The media ID identifies the cartridge type. The labels can only use the uppercase letters A through Z, the numbers 0 through 9, and an asterisk (*) for the start and stop character (for example, *ABC123L6*, where ABC123 is the vol-id and L6 is the media ID).

The StorageTek T-series cartridge labels made by Tri-optic use a dollar sign ($) as the start and stop character. Never use the asterisk or dollar sign as part of the customer-defined characters of a barcode. Barcode algorithms only decode the characters between the end stops, ignoring any characters outside. Refer to the table below for examples.

Table F-1 Start and Stop Character Placement

| Actual Barcode Label | After Decoding | Result |

|---|---|---|

|

*ABC123L6* |

ABC123L6 |

Correct label |

|

*ABC*23L6* |

ABC |

Misplaced stop character |

|

*ABC1234L6 |

Unreadable |

No stop character |

Figure Legend:

-

Start character

-

Volume ID

-

Media ID

-

Stop character

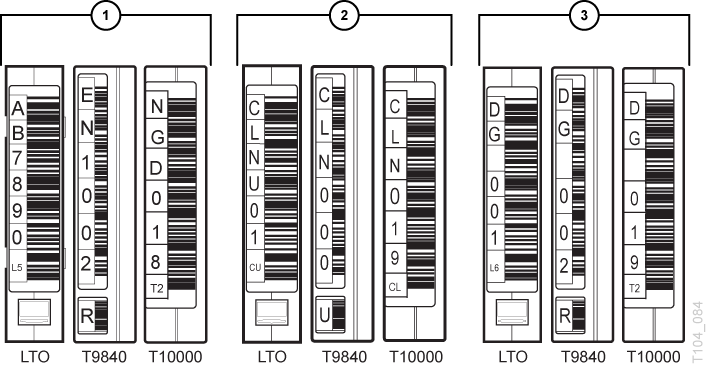

LTO

These cartridges require an eight-character label — a six-character vol-id and a two-character media ID. The media ID characters are:

-

L3 = Generation 3

-

L4 = Generation 4

-

L5 = Generation 5

-

L6 = Generation 6

-

L7 = Generation 7

-

L8 = Generation 8

-

LT = Generation 3 WORM

-

LU = Generation 4 WORM

-

LV = Generation 5 WORM

-

LW = Generation 6 WORM

-

LX = Generation 7 WORM

-

LY = Generation 8 WORM

-

CU = universal cleaning

T9840 and T9940

These cartridges require a six-character vol-id label plus a separate one-character media ID label. Only Tri-Optic Corporation, American Eagle Systems/Wrightline, or Imation Corporation can print these labels. The media ID characters are:

-

R = T9840 data

-

U = T9840 A/B/C cleaning

-

Y = T9840 D cleaning

-

P = T9940 data

-

W = T9940 cleaning

T10000

These cartridges require an eight-character label — a six-character vol-id and a two-character media ID. The media ID characters are:

-

T1 = T10000 A/B data

-

T2 = T10000 C/D data

-

TS = T10000 A/B sport

-

TT = T10000 C/D sport

-

CT = cleaning (A and B only)

-

CL = universal cleaning

Cleaning and Diagnostic Labels

Cleaning and diagnostic cartridges require unique labels to distinguish them from data cartridges. The first three alphanumeric characters in the vol-id determine the type of cartridge.

-

Cleaning cartridges — use

CLNnnnfor the vol-id plus the cleaning-specific media ID, whereCLNis the cleaning cartridge identifier andnnnis a sequence of numbers (for example,CLN001CUcould be an LTO cleaning cartridge label). -

Diagnostic cartridges — use

DG[space]nnnplus the media ID, whereDG[space] is the diagnostic cartridge identifier, andnnnis a sequence of numbers (for example,DG 001L6could be an LTO6 diagnostic cartridge label).

Applying a Label

Caution:

Mis-aligned, mis-oriented, or improperly-labeled cartridges may cause equipment damage.Guidelines for applying the labels include:

-

Inspect and clean the cartridge. Wipe all dust, dirt, and moisture using a lint-free cloth. Use a safe cleaning solution (such as isopropyl alcohol) to clean the cartridge exterior housing.

-

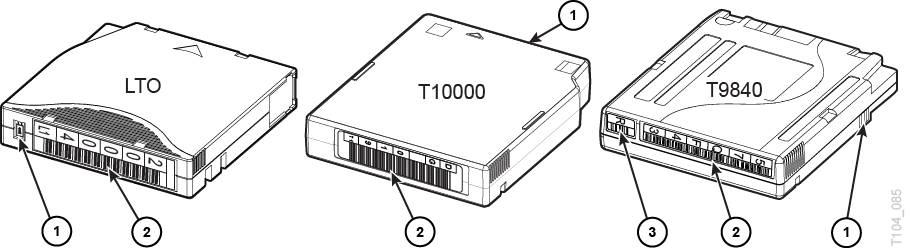

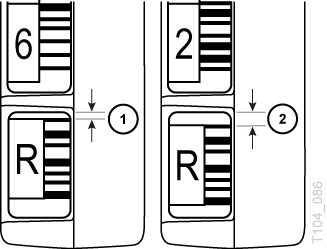

Ensure the cartridge and label are oriented correctly. Orient the label with the barcode below the human-readable characters and the cartridge with the hub-side down. For LTO cartridges, hold the cartridge so that the write-protect switch is toward you. For a T10000 cartridge, ensure the write-protect switch is away from you. For a T9840 cartridge, ensure the write-protect switch is on the right side.

-

Apply the labels with in the recess on the cartridge as straight as possible. Ensure the edges of the label are parallel to the edges of the cartridge. The label must not overlap the edge of the recessed area.

-

For T9840 and T9940 labels, align the vol-id label and media ID label.

-

For best adhesion, apply the label within one year of purchase.

Figure Legend:

-

Write-protect switch

-

Cartridge label

-

Separate media ID label (T9840 and T9940 only)

T9840 and T9940 Label Issues

All media ID labels must have a correctly sized white area above and below the barcode. If the white area is too small, the radius of the label die can cut into the first black bar of the barcode, causing barcode read errors.

Figure Legend:

-

White area is too small

-

Correctly sized white area

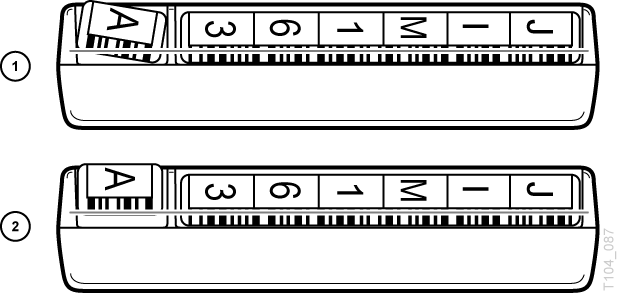

The media ID label must be aligned with the vol-id label. Ensure the media ID label is not rotated or off-center from the vol-id label.

Figure Legend:

-

Rotated media ID label

-

Off-center media ID label

Label Care

Proper label care is required to prevent barcode read errors or damage to the equipment:

-

Keep the barcode intact. Do not mark or damage the barcode label or place any kind of tape across the label.

-

Remove old labels completely before applying a new label. Do not apply a new label on top of an old one.

-

Do not use sharp instruments to seat or remove a label.