Entering Continuity Set Information (WCNT)

Overview: A continuity set item comprises a series of items that are sold together, but delivered at regular intervals. Intervals can be days or months.

Unit demand (continuity program ordered) is tracked at the component item level and continuity set level.

Example: The continuity program is made up of 12 different types of flowers that will be delivered every month for one year. Someone orders the "Flower of the month" continuity program for $200.00. Units ordered for the flower continuity set increases by 1, units for flowers increase by 12 (for each month). Dollars ordered increases for either the continuity item or the components, depending on whether the customer is charged at first ship or at each interval. Charging at first shipment tracks dollars on the continuity item and not the component. Charging at each interval tracks dollars and units at the component level.

In this topic:

• Work with Continuity Items Screen

• Work with Continuity Item Screen (Defining Components)

• Change Continuity Details Screen

Work with Continuity Items Screen

How to display this screen: Enter WCNT in the Fast path field at the top of any menu or select Work with Continuity Items from a menu.

INR0730 DISPLAY Work with Continuity Items 2/13/98 16:55:05 The KL Mail Order Company

Opt Item COLR SIZE OTHR Charge Type Interval Type

Type options, press Enter. 4=Delete 5=Work with

CON85757 2 M FRUIT SAMPLER FL67 1 M FLOWERS EVERY MONTH F6867 2 M MAGAZINE

F3=Exit F6=Create F12=Cancel F21=Print list F24=Select Company |

I

Field |

Description |

Item |

The continuity set item number. Alphanumeric, 12 positions; optional. |

Clr Size Wdth |

The SKU elements. SKU elements should be entered in conjunction with the item number to further narrow the scan. Alphanumeric, one 14 position field (full SKU) or three 4 position fields (split SKU); optional. |

Charge type |

A code to indicate how the customer is charged. 1 = Charge at first shipment 2 = Charge at each shipment Numeric, 1 position; optional. |

Interval type |

A code to indicate the interval or time between deliveries. D = Days M = Months Numeric, 1 position; optional. |

Screen Option |

Procedure |

Create a continuity set item |

Press F6 to advance to the Create Continuity Screen. |

Delete a continuity set item |

Enter 4 next to a continuity set item to delete it as a continuity set. Note: Deleting a continuity item from this screen does not delete it as an item in the Item file. |

Work with continuity set item components, intervals, or charge types |

Enter 5 next to a continuity set item to advance to the Work with Continuity Item Screen (Defining Components). |

Purpose: Use this screen to create a continuity set item.

How to display this screen: Press F6 at the Work with Continuity Items Screen.

CNR0002 ENTER Create Continuity 2/13/98 17:04:15 The KL Mail Order Company

Continuity Item . .

F3=Exit F12=Cancel |

Field |

Description |

Continuity item |

A continuity set item/SKU. You must first define the item in the Item file before defining its attributes, such as components and shipment intervals, as a continuity set item. The item code you enter must have the Kit type field set to C. Item: alphanumeric, 12 positions (item); required. SKU: alphanumeric, one 14-position field (full SKU) or three 4-position fields (split SKU); required if the item has SKUs. |

Instructions: Enter an item code to advance to the Work with Continuity Item Screen (Defining Components).

Work with Continuity Item Screen (Defining Components)

Purpose: Use this screen to add, change or delete continuity component items associated with a continuity set item (as defined by a C in the Kit type field for the item).

How to display this screen:

• Press Enter at the Create Continuity Screen.

• Enter 5 next to an a continuity item at the Work with Continuity Items Screen.

• Enter 14 an a continuity item at the Work with Items Screen or Work with SKUs Screen.

• Press F19 an a continuity item at the Display Item/Warehouse Information Screen.

INR0728 DISPLAY Work with Continuity Item 11/12/02 17:27:14 Alisa Company

Item: BOOK CLUB LEGAL THRILLER SERIES

Charge Type . 2 1=Charge at first shipment, 2=Charge at each shipment Interval Type M M=Months, D=Days

Opt Item COLR SIZE OTHR Qty Int CG# Avail (All Whs)

Type options, press Enter. 2=Change 4=Delete

BOOK 1 1 1 1 88 THE FIRM BOOK 2 1 2 2 31 STREET LAWYER

F3=Exit F12=Cancel |

Field |

Description |

Charge type |

A code that represents how the customer is charged. 1 = first shipment only: the Order Entry detail line with the continuity set item on it has the price. 2 = each shipment: each Order Entry detail line will have a price. Alphanumeric, 1 position; required. |

Interval type |

A code that represents the interval or time between delivery of continuity component items. D = Days M = Months (30 days) Alphanumeric, 1 position; required. |

Item |

Item to be included as a component of the continuity set item. Each item represents a shipment. Validated against the Item file. Cannot be a set, variable set, or another continuity set item. Alphanumeric, 12 positions. Create screen: required. Change screen: display-only. |

Color Size Wdth |

The SKU elements used to further define the item. Note: If the component item has SKUs, the specific SKU element must be specified. The SKU scan will not display in Order Entry. Alphanumeric, one 14-position field (full SKU) or three 4-position fields (split SKU). Create screen: required (if SKUed item). Change screen: display-only. |

Qty |

The number of units of this item that are included in the continuity program. Numeric, 5 positions; required. |

Int (Continuity Interval Number) |

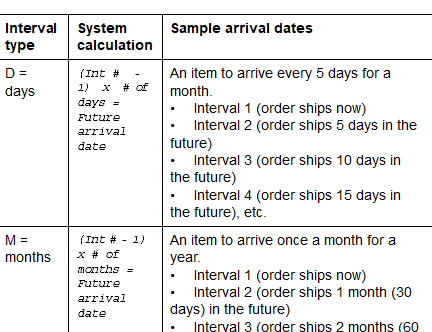

The interval number is used to determine when this item/SKU should be shipped. The first shipment is interval 1, the second shipment is interval 2, etc. Future arrival date: The future arrival date is calculated by subtracting 1 from the interval number and then either multiplying it by the number of months or days (depending on the interval type defined for the item/SKU). Based on the Interval type, the system performs the following future arrival date calculations: |

|

|

|

You can also default a future ship arrival date to a continuity item by entering its status code in the Future Orders Item Status (E52) system control value. The future arrival date that defaults for the item is taken from the date defined in the Default Future Orders Arrival Date (E53) system control value. You may wish to use these system control values to set a starting future arrival date for the continuity item; the system uses this starting date to calculate the future arrival dates for each continuity item. Example: A continuity item contains 2 items: 1 item that ships in the first interval and another item that ships in the second interval. When you add the continuity item to the order, the system defaults the date defined in the Default Future Orders Arrival Date (E53) system control value to the future arrival date for the item that ships in the first interval. The system uses this date to calculate the future arrival date for the item that ships in the second interval. Each component item/SKU defined constitutes a shipment. Numeric, 5 positions; required. |

CG # (Continuity Coordinate Group Number) |

Group number assigned to certain component items in the continuity program to ensure that they ship together. Items with the same coordinate group number should also have the same interval. Coordinate group 999: Do not use coordinate group number 999 when coordinate grouping sets. This number is reserved for the accessory coordinate group. Coordinate group 999: • Does not coordinate group items that are assigned to coordinate group number 999 on the same order together. Example: If an order contains an in stock item assigned to coordinate group 999, an out of stock item assigned to coordinate group 999, and another in stock item that is not assigned to a coordinate group, the system will print a pick slip for the two items that are in stock instead of holding the item assigned to coordinate group 999 until the other item assigned to coordinate group 999 is available. • Prints a pick slip for items assigned to coordinate group 999 only if there are other shippable items on the order. However, if the items assigned to coordinate group 999 are the only items on the order remaining to ship, the system will print a pick slip for the items. Example: If an order contains an in stock item assigned to coordinate group 999, another in stock item assigned to coordinate group 999, and an out of stock item that is not assigned to a coordinate group, the system will not print a pick slip for the in stock items until the out of stock item is available. Numeric, 2 positions; optional. |

Avail |

The total quantity available for the component item. Note: If you advanced to this screen from the Display Item/Warehouse Information Screen, the available quantity reflects the selected warehouse only; otherwise, the quantity reflects all allocatable warehouses. Numeric, 7 positions; display-only. |

Adding component items to a continuity set item: Enter each item code and the SKU information, if the item has SKUs. Each time you enter an item, the system validates the information and displays the item below the entry fields.

Screen Option |

Procedure |

Change a continuity component item |

Enter 2 next to an item to advance to the Change Continuity Details Screen. |

Delete a continuity component item |

Enter 4 next to a component item to delete it from the continuity set. Note: Deleting a continuity set does not delete the set item or components, just the association (link) between the two. |

Change Continuity Details Screen

To change: Enter 2 next to an item at the Work with Continuity Item Screen (Defining Components) to advance to the Change Continuity Details screen.

At this screen you can change any information except the component item number. See Work with Continuity Item Screen (Defining Components) for field descriptions.

| Entering Variable Set Information (WVST) | Contents | SCVs | Search | Glossary | Reports | Solutions | XML | Index | Entering Finished Goods Information (WFGD) |

ME05_04 CWDirect 18.0.x 2018 OTN