| Oracle® Retail Advanced Inventory Planning Order Management User Guide Release 14.1 |

|

Previous |

| Oracle® Retail Advanced Inventory Planning Order Management User Guide Release 14.1 |

|

Previous |

The scaling of purchase orders is performed during AIP batch. This process produces scaled receipt plans or purchase orders after replenishment batch has produced the constrained and unconstrained receipt plans.

Every warehouse has a limitation on inbound capacity due to the number of truck slots, and the time and labor that is required to unload a truck. Smoothing in the scaling module will attempt to address the scenario where the inbound warehouse capacity can be broken down by a grouping of SKUs, usually of a supplier.

Setting a warehouse capacity within a scaling group will limit the total scaling group orders into a warehouse on a particular day. To do so, delivery days which have orders in excess of the capacity must be pared-down; not by simply decreasing orders but rather by pushing the orders forward to earlier delivery days. Pushing the orders will cause a domino or waterfall effect as they are pushed one ATP day at a time until enough days are encountered that can absorb the excess receipts. The waterfall method is intended to help ensure that a small number of items are not pushed out many days or weeks making them excessively overstocked.

The capacities can only be enforced if there are days able to absorb the excess. Therefore this process is most successful when the retailer's warehouse inbound plan has peak times with proportionally large or sustained valleys.

The smoothing push of orders on days exceeding the capacity is a precursor to supplier minimum scaling and container scaling. By performing the push first, more days are likely to have already met any supplier minimum. Additionally it ensures that containers are only built and scaled once. Nevertheless, the downstream processes must not allow the warehouse maximums capacity to be broken when attempting to scale.

AIP produces an actionable receipt plan based on forecasted demand and stock availability. The receipt plan is actionable because it accounts for/is constrained by receiving calendars, order multiples, and lead times. This is sufficient for retailers who wish to replenish purely based on immediate need. However, a number of retailers negotiate contracts with vendors which either require a minimum purchase or provide financial benefit to the retailer for meeting an agreed minimum purchase (usually specified as a cost, quantity, weight or volume).

The combination of supplier/SKU/destination order quantities that count toward meeting the minimum are heavily dependent upon the business driver behind the minimum and the vendor itself.

In certain scenarios a vendor may have multiple manufacturing or distribution locations created as separate entities in the retailer's merchandising and financial systems and therefore the agreed minimum may be addressed by orders for multiple vendors.

In another scenario the minimum purchase may be required in order for the vendor to sufficiently offset the cost associated with setup and production. In this case the vendor dictates the total production value regardless of where each order is being shipped.

Another important reality to consider is proper transportation management. Transportation management is generally treated as a separate business process from replenishment planning. However, some of the costs associated with the transportation of products may be reduced if the retailer orders quantities that make full use of available container capacity.

AIP is in a unique position to address vendor minimums and to make use of container capacity because of its forward-looking plan. Since AIP has visibility to the future planned need it can make intelligent decisions about what items to select to meet the minimum. AIP can use the future plans to identify what the actual expected need is in the short term, whereas a system which does not have future visibility would have to make an arbitrary decision about which SKUs are ordered to meet the minimum.

The Supplier and Container Scaling functionality is designed to enable retailers to pool orders together to achieve higher efficiencies in their purchasing and logistics functions. The scaled-receipt plans or scaled orders are a list of order quantities by supplier, SKU-Pack, warehouse-chamber, and delivery date. These order quantities are a result of comparing supplier and container constraints to total order quantities for each release day and pulling orders forward, where necessary, to meet the constraints. When scaling is complete the pre-smoothed, pre-scaled totals are visible in Order Management for viewing and comparing to the final order quantities which will reflect any smoothing and scaling that occurred.

This section provides information on:

A container group is a grouping of suppliers, SKUs, and warehouses derived from the scaling group specified by the user. The container group is derived by the Container Assignment method set on the scaling group.

Table 4-1 Container Assignment Methods

| Container Assignment Method | Description |

|---|---|

|

Same as Scaling Group |

Indicates the container group and scaling group assignments are identical. |

|

Expand Scaling Group |

Indicates that scaling group assignments are placed in a container group such that each unique source/destination combination is placed in its own container group. |

Figure 4-1 illustrates the conversion.

Scaling groups and therefore container groups are effective by batch run and do not change over the horizon. Container Groups inherit container scaling properties from the scaling group.

If the system finds a scaling group constraint specified (cost, volume, weight, pallets) for active smoothing, supplier scaling or container scaling, but is unable to find a related value for any one of today's assignments in the scaling group, effective on the constraint effective date, the scaling group assignments are flagged as invalid for scaling.

The original order quantities are saved for each order before scaling is performed. The data is used when viewing scaling group totals in Order Management. Orders for any assignments which have been flagged as invalid for scaling will not count towards the pre-scaling totals viewed in Order Management.

Smoothing is performed after the completion of all Replenishment and Reconciliation functionality and takes Constrained Receipt Plans (planned orders) as inputs. The smoothing module starts at the end of the smoothing horizon and works backward toward today. Smoothing for all days in the smoothing horizon is performed before supplier scaling and container scaling.

In order for the scaling module to perform smoothing for a scaling group the following must be true

Smoothing must be enabled at the global level and the scaling group.

The horizon day being smoothed must fall within the scaling group smoothing horizon.

There must be planned orders on the horizon day being processed. Days with no orders, either as a direct result of planning or of push/pull-forward will not be smoothed. In addition, orders will not be brought onto any day in order get up to the full warehouse capacity.

There must be one or more assignments in the scaling group that have all required dimensions defined.

The calculation of the dimensions of a quantity are the same across scaling whether it applies to a total order quantity, an order multiple, or any other quantity that is expressed in terms of cases.

All orders that have a delivery date of the smoothing day being processed are grouped by scaling group and warehouse, then the order totals of each group are calculated and summed using the standard calculations described previously. When partial pallet rounding is on and the quantity Unit of Measure (UOM) is pallets, the rounded pallet total is calculated by rounding each order line item to full pallets before adding it to the total.

If the order totals are less than the warehouse capacity constraints that are effective on the delivery date, then the warehouse capacity constraint is not broken and no smoothing will occur. If the order totals exceed the warehouse capacity, then some orders must be pushed earlier to reduce the orders to the warehouse receiving capacity. Orders are always pushed to their very next earliest delivery date.

Orders which meet all of the following criteria may be moved:

Orders for a supplier/sku-pack/warehouse in the scaling group which has a delivery date on the day being smoothed. The order must have an earlier delivery date to move to.

Orders where all or a portion of the order quantity can be moved and the new delivery date is not more days before the Pull-forward Days according to the original delivery date of any quantity being moved.

Orders that do not cross a stockless day from the original delivery date to the new delivery date. Orders may be moved from a stockless day to a non-stockless day as long it does not cross another stockless day in between, unless the system is configured to allow pulling across stockless days.

Orders that do not cross a Supplier Purchase Quantity (SPQ) week. Orders will not be moved into or out of an SPQ week.

If the order multiple changes between the order's original delivery date and the new move-to delivery date there must be a common multiple that is equal to or less than the order quantity.

All moved quantities are restricted to a multiple of the move-from and move-to order multiples. The least common multiple (LCM) is used. The LCM of two numbers is the smallest number that is a multiple of both. If the order multiple does not change then the LCM is the order multiple of both the move-from and move-to delivery dates.

If the total of the orders is greater than the warehouse receiving capacity, then the amount above and beyond the capacity is the excess. This is the target quantity that needs to move.

The push-forward quantity (PFQ) is the number of full cases of an item, in terms of the LCM, that is needed to meet the excess quantity target.

When partial pallet rounding is on the PFQ of an item with a partial pallet, it always includes the partial pallet first and then any additional full pallets needed to meet the excess quantity target. When moving a partial pallet, the excess is decreased by one pallet. However, the PFQ reflects the actual number of cases on the partial pallet.

In Figure 4-2, the receiving capacity has an excess of three pallets.

The PFQ cannot exceed the original order quantity but may be less than the original order quantity.

At this point the required number of cases of the item needed to achieve the target excess are known, however, the order quantity may be less than that target, or some of the order quantity may be unable to move without breaching the pull forward days limitation.

Because an order quantity can move multiple times, it is necessary to understand how many days the quantity composing that order has moved. For any particular order AIP will always move order quantities in order from those closest to their original delivery date to those farthest.

If you imagine that each delivery date has a queue with the original order quantity at the front of the queue when smoothing occurs, a quantity on the smoothing day is pulled from the front of the queue and added to the back of the queue of the next delivery date. When smoothing, the next delivery date is the quantity at the front of the queue that is moved first and then the next quantity in line as needed. This allows each days moved order quantity to be appropriately limited by the pull-forward days.

The available order quantity is the smallest value of the order quantity rounded down to the nearest multiple of the LCM, or the total quantities that can be moved without breaking the pull-forward days limit.

The PFQ is the smaller value of the order need calculated previously and AvailableQty.

Of the possible orders, only a portion of them may be needed to reduce the days total orders. Orders are sorted in the following order for selection as needed:

Difference between current delivery date and new delivery date.

Orders that are not comprised of a moved order quantity followed by those that have received a moved order quantity.

Total value of PFQ.

Total order quantity in units (not limited by the PFQ or any other restrictions).

For the orders being delivered on the smoothing date select, from the prioritized list, the order with the minimum value that meets or exceeds the excess quantity. If the excess cannot be met by moving a single order, then the largest are selected. Repeat the calculation of excess, PFQ, and order selection until there is no more excess on the smoothing date.

Scaling is performed after completion of Smoothing, if enabled. Scaling has two distinct modules—Supplier Scaling (SS) and Container Scaling (CS). For each day the supplier scaling module runs before container scaling.

In order for the scaling module to perform scaling for a scaling group/container group the following must be true:

The module must be enabled at the global level and the scaling group/container group level.

The horizon day being scaled must fall within the scaling group or container group scaling horizon.

There must be planned orders on the horizon day being processed. Days with no orders, either as a result of pull-forward or sufficient inventory, will not be scaled.

There must be one or more assignments in the scaling group/container group that have all required dimensions defined.

This section provides information on calculating dimensions for Supplier Scaling.

The calculation of the dimensions of a quantity are the same across scaling whether it applies to a total order quantity, an order multiple, or any other quantity that is expressed in terms of cases.

All orders that have met their lead time on the release day being processed are grouped by scaling group, then the order totals are calculated and summed using the standard calculations described previously. When partial pallet rounding is on and the quantity UOM is pallets, then the rounded pallet total is calculated by rounding each order line item to full pallets before adding it to the total.

If all order totals are equal to or greater than the supplier scaling constraints that are effective on the release date then all supplier minimums are satisfied. If one or more supplier scaling constraints are not met, pull forward orders to meet the remaining unmet constraints.

Orders which meet all the following criteria may be pulled forward:

Orders for a supplier/sku-pack/warehouse in the scaling group which has a release date on the day being scaled. The release schedule for the supplier/sku-pack/warehouse must have a delivery date with a lead time that results in release/ordering on the day being scaled. The new delivery date must also be earlier than or the same date as the order's original delivery date.

Orders with an existing delivery date where the date to which they could be pulled forward is not more than the pull-forward number of days before the existing delivery date.

Orders that do not cross a stockless day from the original delivery date to the new delivery date. Orders may be pulled from a stockless day to a non-stockless day as long as it does not cross another stockless day in between, unless the system is configured to allow pulling across stockless days.

Orders that do not cross a Supplier Purchase Quantity (SPQ) week. Orders will not be pulled into or out of an SPQ week.

If the order multiple changes between the order's original delivery date and the new pull-to delivery date, there must be a common multiple that is equal to or less than the order quantity.

All pull-forward quantities are restricted to a multiple of the pull-from and pull-to order multiples. The LCM is used. The LCM of two numbers is the smallest number that is a multiple of both. If the order multiple does not change, then the LCM is the order multiple of both the pull-from and pull-to delivery dates.

If more than one minimum has been defined, the system will compare the two to determine which is farthest from being met. The remaining amount of a minimum not yet achieved is the remaining need. The remaining need compared to the minimum provides a percentage by which to compare various minimums.

The supplier minimum with the largest remaining need percentage is the primary target of each pass of the order selection.

The PFQ is the number of full cases, in terms of the LCM, that is needed to meet the remaining need of all minimums. The PFQ cannot exceed the original order quantity but may be less than the original order quantity.

Table 4-2 Calculation Steps for PFQ

| Step | Description | Example |

|---|---|---|

|

1 |

Calculate the value of one LCM for each constraint value. |

|

|

2 |

Calculate the number of full LCMs needed to meet each constraint. |

|

|

3 |

The actual need to meet all constraints is the maximum number of LCMs. |

LCMsActual = Max(LCMCostNeed, LCMPalletNeed, |

|

4 |

The need in terms of cases is the number of LCMs needed multiplied by the LCM which is a number of cases. |

|

|

5 |

The available quantity is the smaller value of the order quantity rounded down to the nearest multiple of the LCM, or the order quantity limited by pull-forward days. |

|

|

6 |

The PFQ is the smaller value of the OrderNeed, AvailableQty, and available warehouse receiving capacity on the new delivery date. |

Not applicable |

Of the possible orders, only a portion of them may be needed to meet the supplier minimums. Orders are sorted in the following order for selection as needed:

Earliest original release date to latest release date.

Orders that are not comprised of a moved order quantity followed by those that have received a moved order quantity.

Total value of PFQ of the constraint with the largest remaining percentage need. Then, the total PFQ value of the next largest remaining need, if more than one constraint is defined.

Total order quantity in units (not limited by pull-forward days or any other restrictions).

Difference between original and new delivery date.

For the earliest available original release date select, from the prioritized list, the order with the minimum value that meets or exceeds the constraint with the largest remaining percent (that is, the order that gets closest to the constraint).

If the largest remaining percentage cannot be met by a single order then the largest is selected. If multiple orders have the same value, then repeat the selection for the next largest remaining percentage. Repeat the calculation of remaining need, and PFQ, and order selection until all supplier constraints are met.

The goals of Container Scaling are simultaneously:

Assign orders for a particular release date to the least number of containers.

Assign orders for a destination to the least number of containers.

Meet at least one of the minimum constraints in each container.

After the necessary Smoothing and Supplier Minimum Scaling has been performed, Container Scaling can be performed. The aim of Container Scaling (CS) is to break up orders, or portions of an order, into groupings that represent containers. The following rules are applied when assigning orders to containers:

An order may be assigned to more than one container.

A container assigned to an order will have at least one Order Multiple's worth of the order. This is because the Order Multiple is the smallest quantity of the product that can be moved and manipulated while ordering and packing containers.

The groupings of orders will not exceed any of the maximum constraints defined for the SG on the release date.

If any container is partially filled it must meet at least one of the specified minimums otherwise the system must look to future days to find orders that can be pulled forward to satisfy a container minimum.

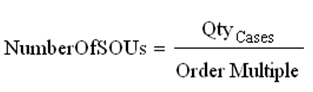

Orders for a CG that have a release day equal to the day being scaled must be built into a container no later than that release day. Order quantities are placed in a container by Smallest Ordering Unit (SOU). The purpose of breaking order quantities into their SOU is to enable the placement of orders into containers of a finite size, in the most efficient manner. Packing is most efficient when working with the most granular object. An SOU is the most granular quantity of a product that is manipulated in scaling. Once Orders are broken into SOUs, the size, in terms of the container group constraints, of each is then calculated so that when it is placed into a container, exactly how much of the constraint it consumes is known. The way in which SOUs are assigned to a container will follow a modified First Fit Decreasing method. The traditional First Fit Decreasing method requires that the SOUs be sorted in decreasing order of a single primary constraint in order to achieve the best results. However, it is important that the orders to a particular destination be placed into the same container when possible. Therefore, placement of SOUs will first consider destination, and then constraint size. Ultimately an SOU is placed on the first container found that has room and does not violate the container rules.

All orders that have met their lead time on the release day being processed are grouped by container group for building into containers.

Following is the process to group and sort SOUs to build into containers.

Break Orders into SOUs.

The order multiple is a quantity, in cases, that the order quantity must be a product of. That is, the order quantity (in terms of cases) must be evenly divisible by the order multiple. It is typically a number that is equal to half of a pallet or some multiple of a full pallet (one or more). Replenishment into-the warehouse is planned in terms of Order Multiples. It is deemed the smallest unit of quantity that can be ordered from the supplier, and therefore also placed in a container. All orders are broken into its component SOUs for loading into containers.

Each SOU that results from an order being broken down inherits a number of properties from the order from which it came—namely the Source, the SKU, the Pack-size, the Destination Chamber, the Delivery Date, and Release Date (the unique identifiers of the order it was derived from).

Each SOU has a case quantity equal to one Order Multiple.

|

Note: The order multiple that is effective on the order Delivery Date should be used. |

Calculate SOU Value.

In order to sort the SOUs, the constraint values of one SOU must first be known. After the orders are split into SOUs the amount of each constraint that the SOU contributes is calculated for the specified container constraints. The standard cost, weight, volume, and quantity calculations described previously are used here with a quantity value of one SOU.

Sort SOUs.

It is important that the orders to a particular destination be placed into the same container, when possible, in order to minimize the amount of stops/unloads. Placement of SOUs will first consider destination.

The SOUs must then be sorted according to the most constraining value so that the largest items are loaded first. The most constraining value is the one that the container typically achieves first. This may be any of the constraints that are enterable in AIP—Volume, Weight, Cost, Pallets, Cases, or Units. The primary container scaling constraint is specified by the user.

SOUs within a Container Group are sorted by:

| Order | Description |

|---|---|

| 1 | Destination code, increasing. |

| 2 | Container Group Primary Constraint, decreasing. |

| 3 | Delivery Date, increasing |

| 4 | Parent Order of the SOU (this is equivalent to sorting by Source/SKU-pack. This is relevant to keeping multiple SOUs of the same parent order together). |

A container is a logical entity that contains groupings of SOUs. An SOU is simply some portion of a full order, therefore a container is a grouping of full or portions of Orders.

Containers will:

Know which container group's Scaling Group and release date it was created for.

Be uniquely identifiable from other containers built for the same Scaling Group and Release Date.

Know which Order's SOUs belong to it.

Have a pre-scaled order quantity set after supplier scaling but before any container scaling pull-forward occurs. This value is saved for later review by the user.

Have a Status of Open, Filled, Filled to Minimum, or Exceeded Max.

When building a container, the following rules and assumptions will apply:

A container is assumed to pick-up from all sources on the same release day.

A container is assumed to route to different destinations based on lead times of sku-packs contained within the container. However, AIP will not do any intelligent routing. The lead time between one source and one destination is assumed to take into account any routing time between destinations.

A container will not visit a destination twice. Therefore, if two SKUs delivered to a destination (from the same or different sources) have different lead times, they cannot be loaded in the same container.

Now that the SOUs have been appropriately sorted and the value of each has been calculated for each constraint, load the SOUs one-by-one by checking the open containers to determine if the SOU fits in the remaining space. Place the SOU into the first open container that has space, without exceeding any maximum constraints. If there are no containers open that the SOU fits into, open a new container.

Before any quantity can be placed in a container it must fit without exceeding the maximum container constraints, and the destinations being served by the container's orders are valid to be loaded with the SOU.

To see if the quantity fits in the open container:

Determine if any chambers of the destination's parent warehouse is already assigned to the container with a different lead time (delivery date). If so the quantity does not fit.

When partial pallet rounding is on and pallet quantity is a container constraint, decrease the current container total by the rounded partial pallet of any existing order quantity of the same order line item.

Example: Load 1.5 pallets of Grape - 24 into containers

Container 1: Quantity Maximum 22 pallets

Table 4-3 Example for Container Fit

| Supplier | SKU-pack | Warehouse | Delivery Date | Order Quantity (converted to pallets) | Pallet Rounded Order Quantity |

|---|---|---|---|---|---|

|

1000 - Beverage Corp |

Cola - 24 |

2 - East Coast |

12/31/2055 |

15 |

18 |

|

1000 - Beverage Corp |

Lime - 24 |

2 - East Coast |

12/31/2055 |

2.75 |

3 |

|

1000 - Beverage Corp |

Grape - 24 |

2 - East Coast |

12/31/2055 |

.5 |

1 |

Available Space = Pallet Rounded Order Quantity - Order Quantity (converted to pallets) = .5 pallets. Add .5 pallets to the current container totals when checking the available space for order item Grape - 24.

|

Note: Another .5 pallets of Grape-24 can be placed into Container 1 without exceeding the maximum capacity. |

Check the maximum container constraints against the current container totals plus the unrounded totals of the quantity being added. If the container totals exceeds any one of the maximum constraints when the quantity is added, that quantity does not fit.

|

Note: If an SOU does not fit in a newly opened container without exceeding the maximums, the SOU is excessively large for the container. The container maximums were likely entered wrong, or a SKU dimension is inaccurate. The SOU is placed into a new container and the status set to Exceeded Max. An alert is generated for the Scaling Group and earliest release date encountering the issue. |

After placing an SOU into a container, perform the necessary partial pallet rounding of the line item and then check the container maximums and tolerance to determine if at least one has been met. If so, set the container status to Filled and remove it from the list of open containers.

Once all SOUs for the release day have been placed into containers, check the open containers to determine if the minimums have been met. If no minimums are defined, or one of the minimums has been met then the container is full enough and can be closed. The container is set to a status of Filled to Minimum.

When all orders for the release date have been loaded into containers, additional orders must be pulled-forward to fill any open containers to the smaller value of the minimum or tolerance.

Orders which meet all the following criteria are potential candidates for pull-forward:

Orders for a supplier/sku-pack/warehouse in the container group which has a release date on the day being scaled. The Release Schedule for the supplier/sku-pack/warehouse must have a delivery date with a lead time that results in release/ordering on the day being scaled. The new delivery date must also be less than or equal to the order's original delivery date.

Orders with a existing delivery date where the date to which they could be pulled forward is not more than the pull-forward number of days before the existing delivery date.

Orders that do not cross a stockless day from the original delivery date to the new delivery date. Orders may be pulled from a stockless day to a non-stockless day as long it does not cross another stockless day in between, unless the system is configured to allow pulling across stockless days.

Orders that do not cross a Supplier Purchase Quantity (SPQ) week. Orders will not be pulled into or out of an SPQ week.

If the order multiple changes between the order's original delivery date and the new pull-to delivery date, there must be a common multiple that is equal to or less than the order quantity.

All pull-forward quantities are restricted to a multiple of the pull-from and pull-to order multiples. The LCM is used. TheLCM of two numbers is the smallest number that is a multiple of both. If the order multiple does not change, then the LCM is the order multiple of both the pull-from and pull-to delivery dates.

If more than one minimum, or a minimum plus a tolerance, has been defined, the system will compare each to determine which is closest to being met. The remaining amount of a minimum or tolerance not yet achieved is the remaining need. The remaining need compared to the minimum (or tolerance) provides a percentage by which to compare various minimums. The minimum or tolerance with the smallest remaining need percentage is the primary target of each pass of the order selection.

In an effort to pull-forward the smallest quantity of an order that will meet one constraint, the PFQ is the smallest number of full cases, in terms of the LCM, needed to meet the smallest remaining need. The PFQ cannot exceed the original order quantity but may be less than the original order quantity.

Table 4-4 Calculation Steps for PFQ

| Step | Description | Example |

|---|---|---|

|

1 |

Calculate the value of one LCM for each constraint value. |

|

|

2 |

Calculate the number of full LCMs needed to meet each constraint. |

|

|

3 |

The actual need to meet all constraints is the maximum number of LCMs. |

LCMsActual = Max(LCMCostNeed, LCMPalletNeed, |

|

4 |

The need in terms of cases is the number of LCMs needed multiplied by the LCM which is a number of cases. |

|

|

5 |

The available quantity is smaller value of the order quantity rounded down to the nearest multiple of the LCM, or the order quantity limited by pull-forward days. |

|

|

6 |

The PFQ is the smaller value of the OrderNeed, AvailableQty, and available warehouse receiving capacity on the new delivery date. |

Not applicable |

Of the possible orders, only a portion of them may be needed to meet the container minimum. Orders will always be pulled from the earliest original release date to latest. For a particular release date the orders will first be broken into two subsets. The first will contain orders for destinations already in the container. The second will contain all the other possible orders. The first subset is exhausted before selecting orders from the second.

Orders within each subset are sorted in the following order for selection as needed:

Orders that are not comprised of a moved order quantity followed by those that have received a moved order quantity.

Total value of PFQ of the constraint with the smallest remaining percentage need. Then, the total PFQ value of the next smallest remaining need, and so forth, if more than one constraint is defined.

Total order quantity (not limited by PFQ or any other restrictions).

Difference between original and new delivery date.

From the sorted list, select the order with the smallest PFQ value that meets or exceeds the constraint with the smallest remaining percentage need (that is, the order that gets closest to the constraint). If the smallest remaining percentage cannot be met by a single order then the largest PFQ is selected.

The selected order and PFQ must meet the same load criteria as those required orders/SOUs with a release date equal to the scaling date. However, in this case of the PFQ doesn't fit without exceeding a maximum, the PFQ is reduced until it fits or it is 0. That is:

Determine if any chambers of the destination's parent warehouse are already assigned to the container with a different lead time (delivery date). If so, the order cannot be loaded.

Check the maximum container constraints against the current container totals plus the totals of the quantity being placed. When partial pallet rounding is on and pallet quantity is a container constraint, decrease the current container total by the rounded partial pallet of any existing order quantity of the same order line item. If the container totals will exceed any one of the maximum constraints when the quantity is added, then that quantity does not fit. Reduce the quantity by the number of cases equal to one LCM until the order fits or is 0.

After placing an order line item into a container, perform the necessary partial pallet rounding of the line item and check the container constraints and tolerance to determine if at least one has been met. The container status is set to Filled if a maximum or tolerance is met, or Filled to Minimum if a minimum is not met. Remove the container from the list of open containers.

Repeat the calculation of remaining need, and PFQ, and order selection until the container is not open or there are no more valid orders. Repeat the process for each open container.