Setting Up Preventive Maintenance Loops

To set up preventive maintenance loops, use the Maintenance Loop (WM_PM_MAINT_LOOP) component.

This section provides an overview of preventive maintenance loops and discusses how to create a preventive maintenance loop and search for a specific asset.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

WM_PM_MAINT_LOOP |

Create a preventive maintenance loop to perform routine maintenance tasks on groups of homogeneous assets or groups of heterogeneous assets. |

|

|

Asset Information Page |

WM_WO_ASSET_SEC |

Review details about the selected asset. |

You set up preventive maintenance loops to enable you to schedule and generate one or more work orders to perform a preventive maintenance service operation on a group of multiple similar and dissimilar, but related, assets.

Important! You must select the Multiple Asset Per Work Order check box in the appropriate work order business units to enable you to create work orders using a loop.

Preventive maintenance loops are set up for groups of:

Assets that are similar, or more specifically, homogeneous.

Homogeneous assets are assets for which all the assets that are listed in the loop grid share the same default asset classification parameters based on the level of specification in the loop's header. You must specify, at a minimum, the asset type and asset subtype in the loop header. For example, if you specify the asset type (fleet) and asset subtype (truck), then you can set up a loop that includes trucks from different manufacturers that are associated with job templates that are also generic in nature. In other words, the job templates and underlying task templates are not applicable for specific makes and models of trucks. Continuing the previous vehicle example, a 3000-mile checkup job template could include a task to change the oil and a task to rotate the tires, and it could be applied to vehicles from any manufacturer. In this case, you do not have to assign a job template to each individual asset. Instead, you can assign a job template in any schedule that you set up for this type of loop. When the Preventive Maintenance Process generates a work order based on this loop, the resource requirements and data that are associated with the template that is specified in the preventive maintenance loop schedule applies to all of the assets.

Assets that are dissimilar, or heterogeneous.

Heterogeneous assets are assets that are set up together in a preventive maintenance loop that are related to one another in some way, but do not fall under the same asset categories (asset type, subtype, manufacturer, and model). For example, an organization may use a group of different kinds of equipment to perform a specific kind of job and want the service maintenance on each piece of equipment in the group to occur at the same time to avoid having to take individual pieces of equipment in the group offline at different times. An example of heterogeneous assets would be a pickup truck from one manufacturer, a dump truck from another, and a cement mixer from a third. You may want to schedule them to be serviced on a specific day every six months. In this case, you must assign a relevant work order job template to each type of asset.

Important! You can use a heterogeneous loop only for a single maintenance situation.

You can also create a preventive maintenance loop that contains a list of homogeneous assets and heterogeneous assets. For example, you may require the use of five pickup trucks (homogeneous), a dump truck, and a cement mixer for certain kinds of jobs. You set them up in a preventive maintenance loop so that they can be scheduled for maintenance at the same time and same interval. In this case, you must assign a work order job template to the heterogeneous assets in the list (the dump truck and cement mixer). However, you can either specify a work order job template in the schedule to apply to the homogeneous assets (the pickup trucks), or specify the same work order job template in the Override Job Template field for each homogeneous asset that is listed in the loop. If you specify an override job template value for one or more assets in a loop, then you can usually use the loop in only one maintenance situation.

You use the Preventive Maintenance Process to generate work orders based on preventive maintenance loop schedules that have heterogeneous assets.

Using the previous example, you set up a loop with heterogeneous assets:

|

Loop's Assets |

Work Order Job Template |

|---|---|

|

Manufacturer A, Pickup Truck 1 |

Monthly Truck Service Job Template attached to Schedule. |

|

Manufacturer A, Pickup Truck 2 |

Same as above. |

|

Manufacturer A, Pickup Truck 3 |

Same as above. |

|

Manufacturer A, Pickup Truck 4 |

Same as above. |

|

Manufacturer A, Pickup Truck 5 |

Same as above. |

|

Manufacturer B, Dump Truck |

Monthly Dump Truck Maintenance Job Template. |

|

Manufacturer C, Cement Mixer |

Monthly Cement Mixer Maintenance Job Template. |

The work order job template, Monthly Truck Service, contains three work order tasks: Rotate Tires, Change Oil, Check Brake Fluid.

The work order job template, Monthly Dump Truck, contains four work order tasks: Rotate Tires, Change Oil, Check Brake Fluid, and Clean Truck Bed.

The work order job template, Monthly Cement Mixer, contains two work order tasks: Lubricate Drum Turning Mechanism and Clean Drum.

A preventive maintenance loop schedule is set up to perform the maintenance monthly.

The Preventive Maintenance Process generates a work order based on the loop schedule. The requirements are applied to each work order task in the work order based on the tasks that are in the work order job templates.

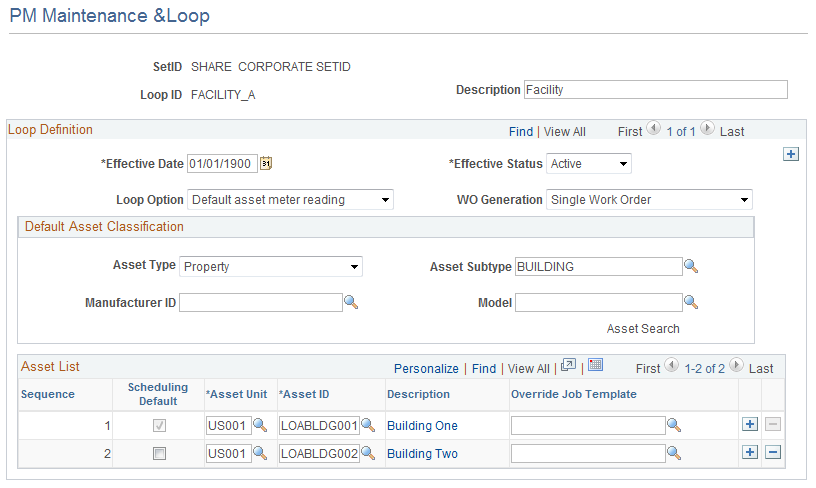

Use the PM Loop page (WM_PM_MAINT_LOOP) to create a preventive maintenance loop to perform routine maintenance tasks on groups of homogeneous assets or groups of heterogeneous assets.

Navigation:

PM Loop page

Loop Definition

Field or Control |

Description |

|---|---|

Effective Date |

Enter the date to create a preventive maintenance loop. |

Effective Status |

Select the status for the loop definition. It can be either Active or Inactive. |

Loop Option |

Select one of the two given options:

|

WO Generation |

Select one of the two given options:

|

Default Asset Classification

Field or Control |

Description |

|---|---|

Asset Type, Asset Subtype, Manufacturer ID, and Model |

Specify the asset classification values that are common to the homogeneous (similar) assets within the loop, such as Fleet and Auto. You must also select asset IDs for each asset that is listed in the Asset List grid for both homogeneous and heterogeneous (dissimilar) assets. The asset IDs that you select must either fall within these selected default asset characteristics, or be associated with an override template. If you select only heterogeneous asset IDs in the Asset List grid, and you select an override template for each asset ID, then you do not have to select any asset characteristics (asset type, asset subtype). Note: For homogeneous assets, you must, at a minimum, specify both asset type and asset subtype. If you also choose to identify a model, you must also identify the manufacturer ID. You cannot skip over a member in the asset category hierarchy. |

Asset Search |

Click to access the Asset Search page. Note: You must specify an asset type and asset subtype at a minimum to perform the search. |

Asset List

The Asset List grid lists the homogeneous (similar) assets that you copied from the Asset Search page. You can also select individual (heterogeneous) assets and their associated business units directly in the grid.

Field or Control |

Description |

|---|---|

Scheduling Default |

Select to indicate which asset's actual meter reading controls the scheduling of all of the assets in the Asset List. For example, if you have three different odometer readings for three cars, you must select one for the Preventive Maintenance Process to use to perform the calculations that are necessary to determine whether to create a work order. Note: The first asset in the list is selected by default. However, you can override this default and select the check box for another asset. You can identify only one asset as the scheduling default. |

Description |

Click to access the Asset Information page that contains details about the selected asset in the row. |

Override Job Template |

Select a work order job template to associate with each heterogeneous asset in the grid. This association with a work order job template is required for all heterogeneous assets in the Asset List grid. You must specify a job template in this field for any asset that has classification parameters that are different from the classification parameters that are specified on the loop header for homogeneous assets. You may optionally select a work order job template to associate with each homogeneous asset that is listed in this Asset List grid. If you specify a template here for a homogeneous asset, it overrides any template that is set up in the Loop Schedule. If this field is left blank for homogeneous assets, then the template that is specified in the Loop Schedule for this loop ID is used when the work order is created. |