Entering Picking Feedback Using an Electronic Data Collection System

The Inventory Picking EIP is an asynchronous inbound service operation that receives picking feedback data for released demand lines into PeopleSoft from an electronic data collection system. The data is stored in the transaction log using any one of three transaction codes: Pick Location (0301), Complete Pick Batch Line (0302), and Complete Pick Batch (0303).

You enter transaction details manually on the Picking page or use the Inventory Picking EIP. When you save the transaction, PeopleSoft Inventory inserts the information into the transaction log. You then run the Inventory Picking process (IN_FUL_PFB), which retrieves data from the transaction log, processes the transaction, updates the staging tables, and identifies the material ready for the Picking Confirmation process. If errors occur, you can use the Transaction Maintenance component to correct the errors and resubmit the transaction.

The auto-processing option that enables the orders to be sent to the confirmed, shipped, or depleted state is set on the Inventory Picking process page.

Note: If your environment includes inventory transfer transactions from electronic data collection systems, such as keyboard wedges or the Inventory Transfer EIP, then you should verify that the Inventory Transfers process (IN_TRANSFER) has been run before processing any inventory picking transactions. Processing your picking data before the completion of any pending bin-to-bin transfer transactions can drive quantity in the material storage location negative and generate errors.

See Picking to Stage.

Setting Up the Inventory Picking EIP

PeopleSoft delivers the service operations in PeopleSoft Integration Broker with a default status of Inactive. You must activate each service operation before attempting to send or receive data from a third-party source or another PeopleSoft system, such as CRM.

To set up the Inventory Picking EIP within PeopleSoft Integration Broker and Enterprise Components, use the information in the table below and refer to the setup instruction in the PeopleSoft Supply Chain Management Integrations, "Implementing Integrations" topic, Setting Up Service Operations section.

|

Service Operation |

Direction and Type |

Handlers |

Chunking Available? |

Integrates With |

|---|---|---|---|---|

|

INVENTORY_PICKING |

Inbound Asynchronous |

InventoryPicking |

No |

Electronic data collection systems |

See Setting Up Service Operations.

See PeopleTools : Integration Broker

Pick Location Transaction

The Pick Location transaction enables you to report that items were picked from a specific storage location. You can use this transaction alone, or you can combine it with the Complete Pick Batch Line and Complete Pick Batch transactions.

Use this transaction to:

Enter all picking results for a pick batch ID with no allocations created (pull pick plan).

Enter any exceptions from a pick batch ID with allocations created (push picking plan).

An item that was allocated on the picking batch ID but cannot be picked as planned creates an exception condition. For example, suppose that 20 items were allocated from storage location A to an order line on a pick batch ID with allocations created. Now suppose that you can pick only 15 items from location A, and you pick the last 5 items from location B. You must then enter two Pick Location transactions, one for the 15 items from location A, and a second for the 5 items from location B.

You can also use the Pick Location transaction for order lines on a pick batch ID with allocations created with no exceptions. In fact, procedural requirements at many sites require that you enter a transaction each time that you pick an item from any location, whether or not you followed the picking plan.

For Pick Location transactions, the value in the SEQ_NBR field should always be 1.

Note: If you enter a Pick Location transaction for an order line on a pick batch ID with allocations created, you must enter a Pick Location transaction for all items picked on that line. The existence of a Pick Location transaction tells the system that you are overriding the original picking plan. In this case, only quantities reported on the Pick Location transactions are confirmed.

Complete Pick Batch Line Transaction

Use the Complete Pick Batch Line transaction to report that an order line is ready for processing; the system does not process picking feedback until all picking activity for the line is complete. You can also use this transaction to remove a line from a picking plan; if you have not entered any Pick Location transactions for the order line, you can clear the line by setting the complete flag to Complete Pick Batch Line.

The manner in which this transaction handles the order line depends upon the complete flag setting and whether a Pick Location transaction has already been processed for the line. If you have not entered a Pick Location transaction, you can automatically pick all allocated quantities as planned by setting the complete flag to Pick Line as Planned. If you entered a Pick Location transaction for the order line, the Complete Pick Batch Line transaction uses only the picked quantities reported on the Pick Location transaction to process the order line.

Suppose that 20 items were allocated from location A to an order line on a pick batch ID with allocations created, but you could pick only 15 items from location A; you picked the remaining 5 items from location B. Suppose that, instead of entering two Pick Location transactions, you only entered a transaction for the 5 items picked from location B. If you now enter a Complete Pick Batch Line transaction, only those 5 items recorded in the Pick Location transaction are processed, leaving a shortage of 15 items. If partial quantities are not allowed for the order line, the system rejects the Complete Pick Batch Line transaction. If partial quantities are allowed for the order line, the system either cancels or back orders the remaining 15 items, depending upon how you set the line's backorder rule.

Complete Pick Batch Transaction

The Complete Pick Batch transaction enables you to report that all picking activity for a picking plan is complete and all order lines are ready for processing. This transaction processes order lines in the same manner as the Complete Pick Batch Line transaction; the only difference is that the system processes every line on the picking plan that has not already been completed by one of the other two transaction types.

The Complete Pick Batch transaction is a good way to report the picking activity for environments in which there are very few exceptions to the picking plan. For example, suppose that you generate a pick batch ID with allocations created, requiring you to pick items to fill 100 order lines. As long as there are no exceptions to the picking plan, you can enter a single Complete Pick Batch transaction for the entire plan. If you set the complete flag to Pick Batch as Planned, the system automatically processes all order lines as planned.

Note: You do not need to use this transaction if all order lines on the picking plan have already been completed on one of the other two transactions.

Examples of Picking Transactions Using Electronic Data Collection

The three electronic data collection picking feedback transactions provide users in different environments control over how and when the picking feedback program processes the picking information. The examples in this section illustrate some of the ways in which you can use the picking transactions.

Examples of All Lines Picked As Planned

These examples show some ways in which the different transactions and complete flags can be used to report that all lines on a picking plan were picked as planned. The tables in the examples illustrate the fields scanned and the complete flag used for each transaction on each line.

For these examples, assume pick batch ID 1000 has two lines, and line one has two storage locations. On line one, the pick quantity is 10 for storage location A and 5 for storage location B. On line two, the pick quantity is 10.

|

Transaction |

Pick Batch ID |

Line Number |

Location |

Pick Quantity |

Complete Flag |

|---|---|---|---|---|---|

|

0301 |

1000 |

1 |

A |

10 |

0 - Process Location |

|

0301 |

1000 |

1 |

B |

5 |

1 - Pick Line Complete |

|

0301 |

1000 |

2 |

B |

10 |

1 - Pick Line Complete |

Since both pick lines ended with the complete flag 1 - Complete Pick Batch Line, the picker is finished providing picking feedback. In this example, the procedural requirement was for the picker to scan all the information for each line and location.

|

Transaction |

Pick Batch ID |

Line Number |

Location |

Pick Quantity |

Complete Flag |

|---|---|---|---|---|---|

|

0301 |

1000 |

1 |

A |

10 |

0 - Process Location |

|

0301 |

1000 |

1 |

B |

5 |

0 - Process Location |

|

0302 |

1000 |

1 |

1 - Pick Line Complete |

||

|

0301 |

1000 |

2 |

B |

10 |

0 - Process Location |

|

0302 |

1000 |

2 |

1 - Pick Line Complete |

Since both pick lines ended with the complete flag 1 - Complete Pick Batch Line, the picker is finished providing picking feedback. In this example, the procedural requirement was for the picker to scan all the information for each line and location.

|

Transaction |

Pick Batch ID |

Line Number |

Location |

Pick Quantity |

Complete Flag |

|---|---|---|---|---|---|

|

0302 |

1000 |

1 |

3 - Pick Line as Planned |

||

|

0302 |

1000 |

2 |

3 - Pick Line as Planned |

Since both lines were picked as planned with the Complete Pick Batch Line transaction, and the complete flag was set to 3 - Pick Line as Planned, the picker is finished providing picking feedback. In this example, the picker was not required to scan all the information for each line and each location.

|

Transaction |

Pick Batch ID |

Line Number |

Location |

Pick Quantity |

Complete Flag |

|---|---|---|---|---|---|

|

0303 |

1000 |

4- Pick Batch as Planned |

This example completes the entire batch as planned on the picking plan. The picker was not required to scan all the information for each line and location.

Examples of a Line Not Picked and a Partially Picked Line

These examples show some ways in which the different transactions and complete flags can be used to report that line two on a picking plan was not picked as planned. The tables illustrate the fields scanned and the complete flag used for each transaction on each line.

For these examples, assume pick batch ID 1000 has two lines, and line one has two storage locations. On line one, the pick quantity is 10 for storage location A and 5 for storage location B. On line two, the pick quantity is 10.

|

Transaction |

Pick Batch ID |

Line Number |

Location |

Pick Quantity |

Complete Flag |

|---|---|---|---|---|---|

|

0301 |

1000 |

1 |

A |

10 |

0 - Process Location |

|

0301 |

1000 |

1 |

B |

2 |

1 - Pick Line Complete |

|

0302 |

1000 |

2 |

B |

0 |

1 - Pick Line Complete |

Both pick lines ended with the complete flag 1 - Complete Pick Batch Line; therefore, the picker is finished providing picking feedback. In this example, the procedural requirement was for the picker to scan all the information for each line and location that was picked but not for the line that was not picked.

Entering the partial quantity on line one along with a complete flag of 1 - Complete Pick Batch Line ensures that the line will be picked short, assuming that partial quantities are permitted. If partial quantities are not permitted, the Inventory Picking process rejects the transaction.

The 0 quantity used in pick batch line two causes the line to be processed with a quantity picked equal to 0. If the cancel back orders flag for the line is set to Y, no quantity ships and the line is canceled. If the cancel back orders flag is set to N, a back order is created for the full quantity on the line.

To pick line two on a subsequent picking plan, use the Complete Pick Batch Line transaction with a complete flag of 1 - Complete Pick Batch Line, rather than using the Pick Location transaction. This clears the line from the current pick batch and makes it available to be printed on a new picking plan.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

BCT_INV_PICKING |

Enter picking feedback using an electronic data collection system. |

|

|

BCT_INV_REQPICK |

Define run control parameters for the Inventory Picking process (IN_FUL_PFB). This run control page process both the INVENTORY_PICKING and SHIPPING_NOTIFICATION transactions. |

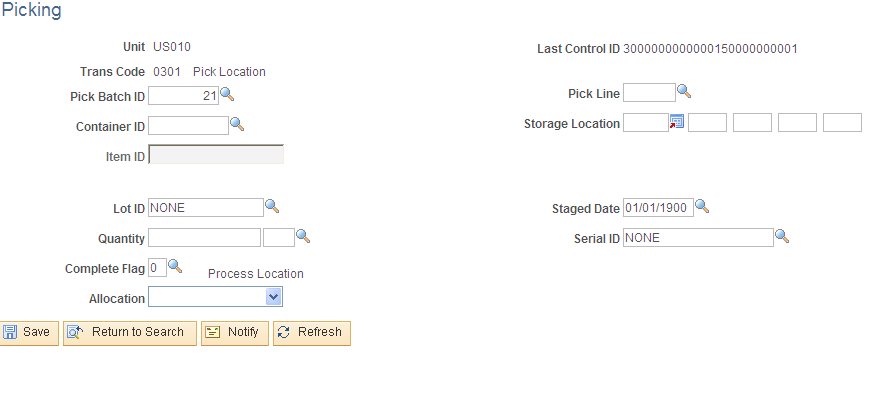

Use the Picking page (BCT_INV_PICKING) to enter picking feedback using an electronic data collection system.

Navigation:

This example illustrates the fields and controls on the Picking page. You can find definitions for the fields and controls later on this page.

Note: The business unit defaults established on the Inventory Display Options page govern whether lot, serial, staged date, and configuration fields appear upon entry to this page. Any fields for which the default flag has been set to Yes always appear. Any fields for which the default is No appear when you save or refresh the page, and only if they apply to the item in question.

Field or Control |

Description |

|---|---|

Pick Line |

This field is unavailable for the Complete Pick Batch transaction. |

Container ID, and Storage Location |

For the Pick Location transaction, enter the storage location or container from which to pick. Note: The business unit's default display options determine how many storage location levels appear upon entry to this page. If you are entering a storage location that requires additional levels, enter the storage area, then refresh the page to display the remaining levels for that area. |

Item ID |

This field is available only for the Pick Location transaction. The item ID appears automatically, based on the pick batch and pick line information. If substitutes are permitted for the order line, you can select a substitute item. |

Quantity |

For the Pick Location transaction, enter the quantity and UOM to be picked. If the UOM Conversion Flag specifies using the entered UOM, select a stocking UOM; if the conversion flag is set to convert the entered UOM to the standard UOM, enter any valid UOM for the item. |

Complete Flag |

Indicates that a pick batch line is ready to be processed and informs the system how to process the pick batch or pick batch line. The default value is 0 for the Pick Location transaction, 1 for the Complete Pick Batch Line transaction, and 2 for the Complete Pick Batch transaction. 0 - Process Location: No additional processing is required, and the line is left open. This entry is only valid for the Pick Location transaction. 1 - Pick Line Complete: The pick batch line is processed using only the quantities entered on Pick Location transactions for this line. If the line does not have a Pick Location transaction processed against it, it is cleared from the picking plan and becomes eligible to be placed on a new picking plan. On a pick batch ID with allocations created, any allocations that have not been confirmed by Pick Location transactions are brought to 0. If the full quantity ordered for the line was not picked, and if the cancel back order option for the line is not active, a back order is created upon shipment. This is not a valid entry for the Complete Pick Batch transaction. 2 - Pick Batch Complete: All demand lines that do not have Pick Location transactions processed against them are cleared from the picking plan. These lines are eligible to be placed on a new picking plan. Demand lines that have Pick Location transactions entered against them are handled in the same manner as Pick Line Complete lines. On a pick batch ID with allocations created, any allocations that have not been confirmed by Pick Location transactions are brought to 0. If the full quantity ordered for the line was not picked, and if the cancel back order option for the line is not active, a back order is created upon shipment. 3 - Pick Line as Planned: On a pick batch ID with allocations created, the line is processed as planned, provided that no Pick Location transactions have been entered against the line. This entry is only valid for the Complete Pick Batch Line transaction. 4 - Pick Batch as Planned: On a pick batch ID with allocations created, all lines without Pick Location transactions entered against them are processed as planned. Demand lines for which Pick Location transactions have been entered are handled in the same manner as Pick Line Complete lines. |

Allocation |

For transaction code 0301, this field indicates the type of allocation applied to the demand line. This value is stored in the ALLOCATE_SOURCE field of the DEMAND_PHYS_INV record. The options are:

|

When you save the page, PeopleSoft Inventory inserts the transaction into the transaction log and clears the page, so you can enter a new transaction.

Use the Inventory Picking (process) page (BCT_INV_REQPICK) to define run control parameters for the Inventory Picking process (IN_FUL_PFB).

This run control page process both the INVENTORY_PICKING and SHIPPING_NOTIFICATION transactions.

Navigation:

This example illustrates the fields and controls on the Inventory Picking process page. You can find definitions for the fields and controls later on this page.

This page is used to process the INVENTORY_PICKING transactions.