Scenario 1: Using Auto Processing in Demand Fulfillment

The demand fulfillment features in PeopleSoft Inventory provide a wide variety of options, giving you the flexibility to design the methods that best fits your needs. This scenario uses an auto-ship example to illustrate the unit of work concept within the auto-processing method. Auto-processing is useful in environments where stock is readily available and the pick plans are predictable.

The auto-processing methods enable you to combine and run multiple fulfillment steps together, and the system enforces all the rules and restrictions of each fulfillment step included. Auto processing does not string together multiple programs in process-scheduled jobs; auto processing is a single fulfillment engine process. The selection criteria in the first fulfillment step are used to build the unit of work (the demand lines selected). The purpose of the auto-processing feature is to process the same unit of work moving from the first step in the process to the last step requested.

Auto-Processing From the Unfulfilled State

If you are designing an auto-processing flow that starts with Unfulfilled demand lines and moves them through the Releasable state to the Released, Confirmed, Shipped, or Depleted states, then you must predefine an Order Release run control. Within the auto-processing flow, the order release step is the only fulfillment step where additional parameters are needed. The fulfillment engine uses some of the parameters on the predefined Order Release run control in order to have the necessary instructions to process the unit of work sent to it from the reservations process.

Selection of the Unit of Work

The selection criteria in the first fulfillment step are used to build the unit of work (the demand lines selected). In the following example, the selection criteria on the Reserve Materials run control are used to build the unit of work since it is the first step in auto-process flow. Any selection criteria entered on the Order Release Request run control are ignored. If a demand line fails to be advanced to the Releasable state by the Reserve Materials process, then it is not part of the unit of work passed to the Order Release process. For example, if the Reserve Materials process selects 50 order lines and was able to move 45 lines to the Releasable fulfillment state, then the Order Release process would try to process the same 45 lines and place them in the Shipped fulfillment state using information from the predefined Order Release run control.

If you want the fulfillment engine to use separate selection criteria for each process, then you should not use auto processing. Instead, you can define a PeopleSoft job with two processes in it: Reserve Materials and Order Release Request. Create a run control ID with the same name for both of these processes. The Order Release Request run control should have all the selection criteria required at order release time. In this scenario, the reservations process runs and completes, moving the requested demand lines to a Releasable state. Next, the Order Release process starts up from the beginning and selects only the demand lines that meet the Order Release selection criteria. Since there are two separate selection criteria, the processes would not have the same unit of work. The Order Release process could include the same or different demand lines than the reservations process; it might pick up more or less lines.

To process the same set of demand lines (unit of work) from the Unfulfilled state to the Shipped state using auto processing, complete the following setup steps:

Define an Order Release run control for auto-processing to the Shipped fulfillment state.

Define a Reserve Materials run control for auto-processing to the Releasable fulfillment state and then pick up the Order Release run control to take the demand lines to the Shipped fulfillment state.

Once you have completed this setup, use the following steps to ship stock:

Run the Reserve Materials process using the predefined run control. This process instance uses auto-processing to move Unfulfilled demand lines to the Shipped state and yet still requires the lines to meet the rules and restrictions of each fulfillment step.

Use the picking plan generated by the Order Release process to physically pick the stock from the material storage locations used by the system. If stock is picked from a different material storage location than what is named on the picking plan, then use the Undo Fulfillment Request process to return the demand line to the Released state where you can alter the picking location and then process the demand line again to the Shipped state.

Generate any shipping documents needed. If necessary, these documents can be produced when the demand lines are in the Unfulfilled state.

Run the Deplete On Hand Quantity (Depletion) process to complete the final step in order fulfillment by depleting the PeopleSoft Inventory business unit for the shipped stock and marking the demand lines as depleted.

In this scenario, you review one method of using auto processing. This example does not represent all possible methods. For more information about the direct processing and auto processing methods, see the "Understanding Order Fulfillment Processing" topic.

Access the Order Release Request process page (Inventory, Fulfill Stock Orders, Picking, Order Release Request):

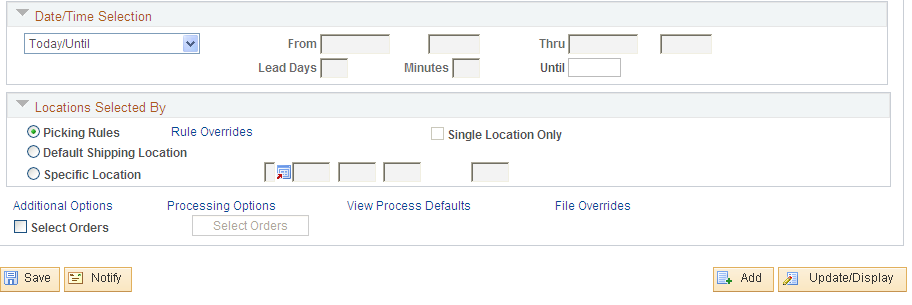

This example illustrates the fields and controls on the Order Release Request process page. You can find definitions for the fields and controls later on this page.

This example illustrates the fields and controls on the Order Release Request process page (2 of 2). You can find definitions for the fields and controls later on this page.

On the Order Release Request page, define a new run control to be used for auto processing (auto-ship). You name this run control AUTO_SHIP and give it the following settings:

The Action field uses the option of Create Allocations, Make Suggestions, or Release Only.

The Auto Process field uses the option, Advance to Shipped.

The Auto Pick check box is selected.

The Output Options group box is used to select picking output. Select the Picking Plan check box to generate a pick plan report listing the material storage locations to be picked.

The Locations Selected By group box can be used to determine the manner in which the Order Release process suggests material storage locations from which to pick stock.

The Additional Options link can be used to define picking plan options and bar code information.

The File Overrides link can be used to review or change the file directory and file name for the picking extract file, item usage labels, or carton labels.

The fulfillment engine does not use any selection criteria defined on this run control, including:

The Selection Criteria group box.

The Date/Time Selection group box.

The Select Orders section at the bottom of the run control.

Access the Reserve Materials process page (Inventory, Fulfill Stock Orders, Stock Requests, Reserve Materials Process) :

This example illustrates the fields and controls on the Reserve Materials process page (1 of 2). You can find definitions for the fields and controls later on this page.

This example illustrates the fields and controls on the Reserve Materials process page (2 of 2). You can find definitions for the fields and controls later on this page.

On the Reserve Materials page, define a new run control that uses auto-processing. In this scenario, use the auto-ship method to select Unfulfilled demand lines and move them to the Released state where the Order Release process selects the lines and moves them to the Shipped state. You name this run control AUTO_SHIP and complete the following information:

Enter the selection criteria for the unit of work.

The selection is based on the search criteria entered on the fields from Business Unit to Product ID. In the page shot above, you have selected demand lines in the inventory business unit of US010 with a scheduled shipment date between September 1st and 5th of 2009 that use the carrier ID FAST.

In the Auto Release Option field, select an option to advance the demand lines to the Released state.

In the page shot above, you have chosen the field value of Advanced to Released. In this case, you must also enter a value in the Release Run Control field.

You could have chosen the field value of Use Auto-Processing Default for the Auto Release Option field. If you had chosen this option, then the system would use the default options for the Reserve Materials process defined under the Auto-Processing Options tab of the Setup Fulfillment-Fulfillment Task Options page (business unit level) or the Fulfillment Engine Options page (SetID level).

In the Release Run Control field, select an Order Release run control that you have defined for this auto-processing flow.

In this example, enter AUTO_SHIP, the Order Release run control defined in the first step. You have chosen the field value of Advanced to Released in the Auto Release Option field, therefore; Enter a predefined run control for the Order Release process. This run control contains the parameters to be used when auto-processing orders after the Reserve Materials process.