Creating Production IDs

The first step in defining a discrete manufacturing order is to create a production ID. Once you've generated a production plan, manually enter any discrete production or rework orders for those items that were not included in the new production recommendations from PeopleSoft Supply Planning.

When you change any information on an existing production ID, the system optionally sends the Production ID Change workflow notification to selected roles that you defined. These roles could include a planner, buyer, or a production control manager.

You can create production IDs for production, rework, or teardown orders.

If you want to automatically create operation and component lists, you must define BOMs and routings for the end item.

This section discusses how to define and maintain Production ID

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

SF_PRDNID_MAINT |

Create and maintain a single production ID for production, rework, or teardown orders. |

|

|

Production Start Date/Shift or Production Due Date/Shift Page |

SF_PRDN_DUE_SBP |

Display production start date and shift information or production due date and shift information for the selected production ID. |

|

EN_PDO_SEL_SP |

Select a different BOM and routing code combination that you want to use for the production ID. |

|

|

Process/Output Options Page |

SF_PRNT_OPT_SP |

Select the print options for printing production documents at save. |

|

SF_TRDN_PID_SEC |

Locate the original production ID used to create the teardown item. This page is used for teardown orders only. |

|

|

PL_PLAN_ATTRIB |

Freeze the production ID's component list and operation list in the PeopleSoft Supply Planning system. |

|

|

SF_PRDNID_STATIC |

View production ID and scheduling data. |

|

|

Production ID Text Page |

SF_PRDNID_TEXT |

Associate text with any production ID. |

|

SF_PRDN_OUTPUT |

Maintain and display production output information. |

|

|

Traceability Page |

SF_PRDN_TRC |

View the assembly serials that have been associated with the production ID. You can only access this page if the serial IDs have been associated with the production ID. |

|

SF_TRANSHIST |

View production transaction history. |

|

|

Production History Details inquiry Page |

SF_TXN_HIST_SP |

View transaction history details based on the selection criteria. |

|

Production ID Comp Transfers Page |

SF_COMP_TRANSFER |

Transfer components between production IDs to cover shortages. Correct errors after a production ID split. |

|

Production Detail Page |

SF_PID_SEC |

View production details. |

|

Production by Area Summary Page |

SF_PA_SCH_SUMMARY |

Add, modify, and view all production for a specific production area. |

|

Production by Area Details Page |

SF_PA_SCH_DT_MAINT |

Add, modify, and view production details for all production for a specific production area. |

|

Production by Area (inquiry) Page |

SF_PA_SCH_SUM_INQ |

View all production in a specific production area. Define at least one production schedule or production ID. |

|

Production Selection Page |

SF_PRDN_ITEM_SEL |

Access production, rework, and teardown information for a specific item. View production IDs, production schedules, or a combination of both. Define at least one production ID or production schedule for an item. |

|

Production List Page |

SF_PRDNID_ITEM_VW |

Access production, rework, and teardown information for a specific item. View production IDs, production schedules, or a combination of both. Use this page to see the status of production for a production area at the operation level. Define at least one production ID or production schedule for an item. |

|

Production for an Area/Item - Production Detail Page |

SF_PRDNINQ_STATIC |

Display production, rework, or teardown details associated with any production ID displayed on the Production for an Item inquiry page. |

|

Operation Detail Page |

SF_PRDN_DATA_DTL |

View operation list details. |

|

Production Output Page |

SF_PRDID_ITEM_OUT |

View output information for a specific item. Define at least one production ID for an item. |

|

Production Text Page |

SF_PRDNINQ_PRTXT |

View text associated with any production ID. |

|

Production Inquiry - Production Selection Page |

SF_PRDN_SELECTION |

Define production criteria for the production inquiry. |

|

Production Inquiry Page |

SF_PRDN_MAINT_INQ |

View production information for a particular production ID. Enter production information on the Production Selection page before accessing this page. |

|

Production Detail Inquiry Page |

SF_PRDN_STAT_INQ |

Display additional details for the selected production. |

|

Production Output Page |

SF_PRDN_OUTPUT_INQ |

View output information for production IDs. |

|

Production Text Inquiry Page |

SF_PRDN_TEXT_INQ |

Display text associated with the selected production. |

|

Production Output Mix Inquiry - Production Selection Page |

SF_COMP_OUT_SEL |

Enter the search criteria for the production ID whose component and output data you want to display. Define at least one production ID with multiple outputs. |

|

Prdn Op Summary (production operation summary) Page |

SF_COMP_OUT_SUM |

Display production operation sequence data at a summary level, including task and work center information. |

|

Prdn Output/Component Details Page |

SF_COMP_OUT_DTL |

Display specific production component and output ID production data by operation sequence at a detail level. |

|

Production Report Selection Page |

RUN_SFS2004 |

Generate a production report for a range or all actual start dates, selected production statuses, and a range or all production IDs. |

See the product documentation for PeopleTools: Workflow Technology

Field or Control |

Description |

|---|---|

Op Seq (operation sequence) |

The operation step in the manufacturing process where the components are required. |

Prdn Start Date (production start date) |

Date production is or was to have started. |

Prdn Due Date (production due date) |

Date production is or was due to be completed. |

Prdn Due Shift (production due shift) |

Shift that the production is or was due to be completed. |

Expected Yield |

The aggregate yield percentage for the production order when all operation yields are combined. |

Source Cd (source code) |

End item source code. Options are Make or Buy. |

Task Code and Description |

Task code number and description of the task being performed. |

Sub (subcontracted operation) |

Indication that the operation step is a subcontracted operation. |

Work Center |

Work center where the operation step is performed. |

Configuration Code |

Indication that the output or component is a configured item. |

Output Qty (output quantity) |

Output production quantities based on per assembly or per order setting. |

Per |

Quantity qualifier. Options are Asy (assembly) or Ord (order). |

Res % (resource allocation percentage) |

Percentage that determines how much of the BOM batch quantity the primary and co-product represents. It is used during completions to determine what percentage of the components should be consumed for the primary and co-product. The total resource allocation percentage should always equal 100 percent. |

Qty (quantity) |

Component quantity required based on per assembly or order. |

Sched Qty (schedule quantity) |

Quantity required for the production start or production end quantity. |

Issue Qty (issue quantity) |

For components using the issue or replenishment material issue method, this is the quantity consumed from the WIP location for the component and is charged to WIP. For components using the kit method, this is the quantity issued directly to the production ID. |

Orig Comp ID (original component ID) and Description |

Original component if the current component is a substitute item. |

Use the Production ID Maintenance page (SF_PRDNID_MAINT) to create and maintain a single production ID for production, rework, or teardown orders.

Navigation:

Select a Production Type.

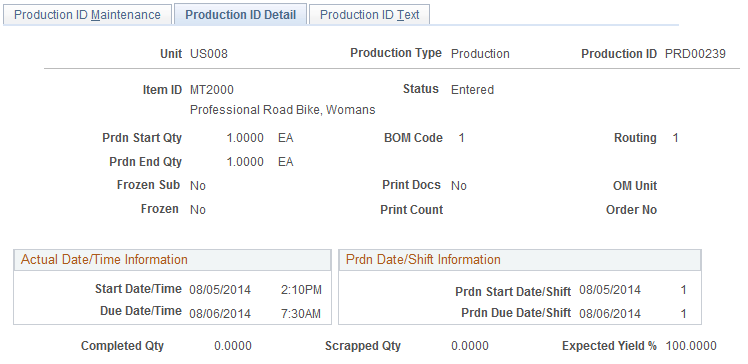

This example illustrates the fields and controls on the Production ID Maintenance page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Status |

You can add a production ID with a production type of Production in either the Entered, Firmed, or Released status. You can add a rework or teardown production ID with a Firmed or Released status only. |

Note: Pend Cmpl (pending complete), Completed, Clsd/Labor (closed for labor), and Clsd/Acctg (closed for accounting) are used when tracking and closing production, but they are not used when creating or maintaining a production ID.

Maintaining Production ID Information

Field or Control |

Description |

|---|---|

Production Area |

Select to indicate where this production will take place. Once you select a production area, you can view the items produced in that production area by selecting an item ID. You cannot add a production ID for an item that has not previously been defined in the production area selected. Additionally, you must have selected to maintain production IDs for the production area and item combination. The production area and item combination must have an Active status to add a new production ID. |

Item ID |

Select one of the items produced in the production area. You can change the item for any production ID in the Entered or Firmed status. If the production ID has a status of Released, you can change the item for any production as long as subcontracted purchase orders have not been generated against the production ID. If you change the item ID:

Note: If you need to change the item ID for In Process production, you can split the production ID into a new production ID—moving the remaining quantity in process—and simultaneously specify a new item. When adding a production ID for an item with item status of Hold or Discontinue, you'll receive a warning message. However, there is no warning for rework or teardown production type. If the production ID for an item has a status of Hold, the system gives you the option to cancel that order at save time. |

Field or Control |

Description |

|---|---|

Prdn Start Qty (production start quantity) |

Displays the quantity required at the beginning of the production process. This quantity may be entered, or it may be calculated when the end quantity is entered. If calculated, this quantity will be rounded up at each operation to account for any operation yield. You can change the production start or production end quantity for a production ID with a status of Entered, Firmed, Released, or In Process. Changing the production quantity reschedules the actual start or due date and time of the production ID. |

Prdn End Qty (production end quantity) |

Displays the quantity expected at the end of the production process. This quantity may be entered or it may be calculated when the start quantity is entered. If calculated, this quantity will be rounded down at each operation to account for any operation yield. Production end quantity may be changed when operation yields are maintained. As production is reported against the production ID, the end quantity is updated to reflect actual production yields. |

Expected Prdn Qty (expected production quantity) |

Displays the quantity expected at the end of the production process. This is the expected quantity at the time production was started. It is not updated to reflect actual production variances, but it is updated if the production ID quantity is manually changed. |

Note: Whether the quantity is a whole number or a decimal depends on the item's unit of measure and quantity precision combination defined in PeopleSoft Inventory.

Note: The production start quantity and production end quantity may not be the same due to operation yield allowances.

Once you add the production ID, keep these points in mind when you change the production start or production end quantity:

If the production ID is Firmed or Released, the system recalculates the component's scheduled quantities.

If the production ID is In Process and you increase or decrease the order quantity, the system adjusts the component's scheduled quantities to reflect the new order quantity and marks the production ID as changed so that PeopleSoft Supply Planning reschedules the operations during the next planning run.

If you have decreased the production quantity and have already issued components, you might have a surplus of components at the WIP location.

If you have decreased the production start or production end quantity and already kitted material to the production ID, a usage variance results at accounting close time if the excess material is not returned to stock.

If you change the production quantity and the production ID is released and backward scheduled, the system automatically recalculates the actual start date and time.

If you change the production start or production end quantity and the production ID is released and forward scheduled, the system automatically recalculates the actual due date and time.

In this case, the system prompts you to delete the existing component list.

If you select Yes to the Component List for Production ID prompt, the system deletes the component list and then creates a new component list for the production ID, based on the BOM in effect on the new production due date.

If you select No, the system uses the existing component list for production.

If you change the production quantity, and the production ID is Firmed or Released, and subcontracted purchase orders have been created, the system sends a purchase order change request to PeopleSoft Purchasing, indicating a change in production start or production end quantity.

Note: If a subcontracted operation has more than one purchase order, the system will not automatically create change requests. You will need to manually create the change requests.

You cannot decrease the production quantity to a quantity less than the quantity that has already been completed to stock.

Warning! A warning is issued if you decrease the production start quantity to a quantity less than the number of serial IDs associated.

Field or Control |

Description |

|---|---|

BOM Code and Routing Code |

The values appear by default for the production area and item combination effective for the area and item as of the current date. Change the BOM and routing codes if alternate routings are used for this production ID. Only the BOM and routing codes for the item and the selected production type are available. For example, suppose that you select the Rework production type, you can only select rework BOMs or rework routings if either are defined. Rework and teardown routings are optional. If you do not select a rework or teardown routing, the system does not create an operation list for the production ID, and you need to manually enter the actual start date and time and actual due date and time. For teardown production, the production BOM (or an original production ID) is used to determine the teardown output list. The end item is copied to the component list. |

Rtg Itm (routing item) |

Displays the item whose routing is used to manufacture, rework, or tear down the end item. Each assembly item can have its own unique primary and alternate routings or reference another item's primary and alternate routings. |

Due Date/Time |

If you change the due date and time for the production ID so that a different BOM and routing combination is used, a warning message appears enabling you to accept the new BOM and routing combination. |

Note: Effectivity dates apply only if you use the Production Option Maintenance component to define the valid BOM and routing combinations.

BOM and routing combinations can be viewed in the Production Option Maintenance component.

Select valid production options (predefined BOM and routing combinations) for the item. If you select the Valid Production Options only option on the Item Attributes by Unit - Manufacturing page, then only the predefined combinations can be entered or selected.

Field or Control |

Description |

|---|---|

|

Click the Production Option button to access the Production Option Selection page. |

Note: If you create a component list and there are operations linked to the components that do not exist on the routing, the system treats those components as linked to the first operation sequence. This is similar to how the system handles a component with a 0 operation sequence. Unmatched output by-products, on the other hand, are linked to the last operation.

Once you add the production ID, keep these points in mind if you make any changes to the routing code:

The system recalculates the production ID's actual start or due date and time based on the new routing's lead times and scheduling parameters.

If the production ID is in the Firmed or Released status, changing the routing code also deletes the existing operation list.

The system creates a new operation list for the production ID using the routing code specified.

If the production ID is in the Firmed or Released status, you can change the routing code only if a subcontracted purchase order has not been generated against the production ID.

If the production ID is forward scheduled and the due date and time for production has changed based on the new routing, the system prompts you to delete the existing component list.

If you select Yes to the Component List for Production ID prompt, the system deletes the component list and creates a new one based on the BOM in effect on the new due date.

Field or Control |

Description |

|---|---|

Sch Method (scheduling method) |

If you are using the production start date as a basis for creating the schedule for the production ID, select Forward. If you are using the production completion date as a basis for creating the schedule for the production ID, select Backward. |

Start Date/Time or Due Date/Time |

If you selected a routing, enter only one of these dates. The system automatically calculates the other date once you define whether the production for this item is based on forward or backward scheduling. Keep these points in mind when entering a start date and time or a due date and time:

Note: If capacity and material availability are concerns, estimate the start and due dates when you create or maintain the production ID using PeopleSoft Manufacturing, and then schedule the production ID's start and due dates using PeopleSoft Supply Planning. |

Revision |

If a revision was specified for the area and item, it is displayed here. Otherwise, if the item is revision-controlled, the BOM revision in effect as of the due date for the order is used. Changing the revision is valid only if the item is revision controlled. Select an alternate revision if alternates have been specified. If you are changing the revision and the production ID is in Firmed or Released status, the system prompts you to replace the existing component list.

|

Prdn Doc Status (production document status) |

Indicates whether production documents have been printed. Values are:

|

Print at Save |

Select to print production documents for the production ID at save time. |

Action Menu |

Select any of these pages to access additional information:

|

Adding and Maintaining Production IDs Using a Weekly View

You can also maintain and view production IDs by using the Production by Area pages.

Use the Production Start Date/Shift or Production Due Date/Shift page (SF_PRDN_DUE_SBP) to display production start date and shift information or production due date and shift information for the selected production ID.

Navigation:

Click the Detail button next to the Start Date/Time or Due Date/Time fields.

The first or last minute of the production shift is based on these scenarios:

For Forward scheduling, the system uses the work center calendar for the routing's first operation, if one exists.

For Backward scheduling, the system uses the work center calendar for the routing's last operation, if one exists.

If work center calendars do not exist for the routing's first or last operation's work center, the system uses the production calendar, if one exists.

If a production calendar does not exist, the shift's start or end time specified for the five-day work week is used.

If you are changing the due date and time and a routing is specified, the system recalculates the start date and time.

Conversely, if you are changing the start date and time, the system recalculates the due date and time. The production start date and shift and the production due date and shift associated with the start date and time and due date and time are also determined.

If the production ID is in the Firmed or Released status and you replace the start date and time or due date and time, the system updates the operation list with each operation's new start and due dates and times.

If you are changing the due date or the due date changes as a result of a change in start date, the system prompts you to delete the existing component list.

If you select Yes to the Component List for Production ID prompt, the system deletes the component list and adds a new one based on the BOM in effect on the new due date.

If the production ID is in the Firmed or Released status and a subcontracted purchase order has been generated against the production ID, any changes that result in a change to the start date and time or due date and time may affect the purchase order due date.

The system displays a warning message when changes occur that result in a change to the start dates and times and the due dates and times.

Use the Teardown Original Production ID Search page (SF_TRDN_PID_SEC) to locate the original production ID used to create the teardown item.

This page is used for teardown orders only.

Navigation:

Click the Search button next to the Original PID field to access this page.

This example illustrates the fields and controls on the Teardown Original Production ID Search page: Production tab. You can find definitions for the fields and controls later on this page.

Note: If the production type is Teardown, the output list is based on the components used on a previous production ID or on the components designed as teardown outputs on the item's BOM.

Select Completion History, and if the serial ID and lot ID exist for the original order, select values.

You can also select a production due date range or configuration code from the available options. After you make the selections, click Search for a list of production IDs. If multiple production IDs were used to create the item, the system generates a list of production IDs, but it only selects production IDs with a status of In Process or later status with a production type of Production.

Production Tab

Select the check box next to the original production ID that you're tearing down.

Use the Update Production page (PL_PLAN_ATTRIB) to freeze the production ID's component list and operation list in the PeopleSoft Supply Planning system.

Navigation:

Click the Planning Attribute link.

Field or Control |

Description |

|---|---|

Frozen Substitutes |

Select to freeze substitutes in PeopleSoft Supply Planning. When you send the production ID to PeopleSoft Supply Planning, the Planning engine does not include substitute components. |

Frozen Production |

Select to freeze the production ID in the PeopleSoft Supply Planning system. This means that when you send the production ID to PeopleSoft Supply Planning, the Planning engine does not reschedule the production ID. Set a default at the manufacturing business unit level to create all new rework or teardown orders with a frozen status, indicating that you do not want PeopleSoft Supply Planning to reschedule those orders. |

Use the Production ID Detail page (SF_PRDNID_STATIC) to view production ID and scheduling data.

Navigation:

This example illustrates the fields and controls on the Production ID Detail page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Frozen Production |

Indicates whether a decision was made to hold or firm up the due date for this production ID by PeopleSoft Supply Planning. Change production information using the Production ID Maintenance page. If you change production information and the status is Yes, the system displays a warning message indicating that the production ID has been frozen by PeopleSoft Supply Planning and the change results in the production ID being rescheduled. You can continue or cancel the changes. If you change this information, the production ID is no longer frozen and the status changes to No. |

Frozen Substitutes |

Indicates whether the system has frozen substitutes in the PeopleSoft Supply Planning system. This means that when you sent this production ID to PeopleSoft Supply Planning, the Planning engine did not include substitute components. |

OM Business Unit (Order Management business unit), Sales Order No and Configuration Code |

These fields display sales order information if the production ID results from a sales order configured in PeopleSoft Order Management. |

Print Count |

Indicates the number of times that production documents have been printed for the production ID. |

Prdn Doc Status (production document status) |

Indicates whether production documents have been printed. |

Completed Qty (completed production start or production end quantity) |

Indicates whether assemblies have been completed to stock, routed to another WIP location, or issued directly to another production ID. |

Scrapped Qty (scrapped quantity) |

Indicates the number of assemblies that have been scrapped in process. |

Use the Production ID Outputs page (SF_PRDN_OUTPUT) to maintain and display production output information.

Navigation:

If you're adding a new production ID, the Production ID Outputs page is not available until after you save the page.

Select View Outputs from the Action Menu on the Production ID Maintenance page.

This example illustrates the fields and controls on the Production ID Outputs page. You can find definitions for the fields and controls later on this page.

Output List

Field or Control |

Description |

|---|---|

Output Type |

Values are:

|

Op Seq (operation sequence) |

Operation step in which the output is generated. For primary and co-products, this is always the last operation. By-products and teardown outputs can be generated at any intermediate operation. If the operation sequence is 0 or does not exist on the operation list, it is assumed the output is generated at the last operation. |

Output Sched Qty (output scheduled quantity) |

Output quantity based on the scheduled quantity but adjusted for scrap. The format for this display-only field may depend on the item's unit of measure and quantity precision combination defined in PeopleSoft Inventory. For example, suppose that item ID A0007 has a unit of measure of EA and a natural round, whole number combination. In that case, only whole numbers entered appear.

|

Release Type |

This field is used by PeopleSoft Supply Planning and indicates if the entire quantity of an end item at an operation should be completed at the end of the operation. Select None for no incremental release. Select Over Time to indicate that you want a specified quantity of end items to be on hand before completions occur. |

Release Offset |

This field is used by PeopleSoft Supply Planning and works with the Over Time option of release type. Enter the quantity of end items to be on hand before completions occur. |

Peg to Demand |

Click this link to access the Pegging Workbench page to peg the production ID to a sales order. |

Show Pegged Demand |

Click this link to access the Pegging Inquiry page to view any pegged orders. |

Adding Unplanned By-Products

Field or Control |

Description |

|---|---|

|

Click the Add button to add an additional (unplanned) by-product. You can add or change Recycle, Teardown, or Waste by-products on the production ID; however, you cannot add or change primary items or co-products. Note: You can only add teardown outputs to a Teardown type production ID. Similarly, you cannot add recycle or waste outputs to a Teardown production ID. However, you can change the output quantity, operation sequence, and Per field for any by-products. |

Output Qty (output quantity) |

Whether you can enter a whole number or a decimal depends on unit of measure and quantity precision combination that was defined for the item in PeopleSoft Inventory. |

Res % (resource percentage) |

Indicates the resource percentage for the primary and co-products. |

Important! Only by-products such as recycle or waste products can be added or changed. You cannot change or add primary items or co-products.

If you are maintaining a rework production ID, the output page lists only the reworked item as the end item. You cannot define co-products or by-products with rework.

(production option button)

(production option button)