Defining BOM Mass Maintenance Codes

To define manufacturing BOM mass maintenance codes, use the BOM Mass Maintenance (MBOM_MASS_MAINT) component.

This section provides an overview of BOM mass maintenance codes

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

EN_BOM_MMC_SRCH |

Identify the specific existing outputs or components to change. Specifying components also enables you to identify the BOMs that are impacted. |

|

|

Search - Dimensions Page |

EN_BOM_MMC_DIM_SP |

Enter component dimension search criteria. |

|

EN_BOM_MMC_REF_SP |

Enter reference designator search criteria. |

|

|

Search - Substitutes Page |

EN_BOM_MMC_SUB_SP |

Search for substitutes everywhere they are used. |

|

EN_BOM_MMC_VW_SP |

This display-only page allows you to view the number of assemblies that match the search criteria that you have entered and view matching BOMs. |

|

|

EN_BOM_MMC_NEW |

Specify new component values, once you have selected the set of components that you want to change on the Search page. |

|

|

EN_BOM_MMC_DIM2_SP |

Make mass changes to component dimensions. |

|

|

EN_BOM_MMC_REF2_SP |

Make mass changes to reference designators. |

|

|

EN_BOM_MMC_SUB2_SP |

Mass change a substitute everywhere it's used. |

|

|

EN_BOM_MMC_ADD |

Add components or outputs to assemblies. The system adds these components or outputs to each BOM identified by the values that you entered on the Search page. Use the Process BOM Mass Maintenance pages to designate, at a later time, the specific assemblies to be affected by these changes. |

|

|

Add - Dimensions Page |

EN_BOM_MMC_DIM3_SP |

Add component dimensions, if you are adding using the Component sequence type. |

|

Add - Reference Designators Page |

EN_BOM_MMC_REF3_SP |

Add reference designators, if you are adding using the Component sequence type. |

|

EN_BOM_MMC_SUB3_SP |

Add a substitute everywhere it's required. |

Use the BOM Mass Maintenance pages to create and maintain BOM mass maintenance codes. These pages enable you to specify multiple BOM component or output changes and additions, including substitute items. A MMC consists of search pages, which allow you to identify existing components that are to be impacted, Change pages that allow you to change instances of those specific components on specific BOMs, and add pages that allow for the introduction of new components and detail information. After you've used these pages to define MMC codes, you can implement the changes directly, using the Process BOM Mass Maintenance by MMC page.

Note: To maintain components en masse for revision-controlled BOMs, enter effective and obsolete dates for the revision on these pages, regardless of whether the revision is controlled by revision name or effectivity date.

Prior to accessing any MMC pages, you must select a business unit and a MMC. The MMC value can be generated automatically.

Important! Any MMCs created in PeopleSoft Manufacturing are available only in manufacturing, and MMCs created in PeopleSoft Engineering are available only in engineering.

Note: To provide greater flexibility when defining MBOMs, the Quantity field does not need to follow the quantity precision rules defined for the item. A warning is issued if you define a decimal quantity value for an item whose quantity precision value is a whole number. This is an example of when you may need the quantity precision flexibility. If 1 B0004 component is required to make 2 assembly A0001s, then when defining the BOM, the QPA for B0004 would be 0.5. If you applied the rounding rules to the QPA, then it would round the QPA for B0004 to 1, and thereby inflate the production costs.

Prior to making BOM mass maintenance changes, define:

The appropriate assemblies and BOMs.

Any revision-controlled items with automatic revisions if you plan to create automatic revisions.

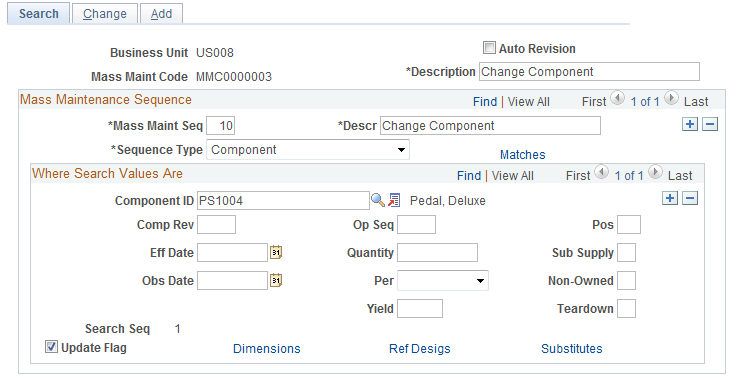

Use the Search page (EN_BOM_MMC_SRCH) to identify the specific existing outputs or components to change.

Specifying components also enables you to identify the BOMs that are impacted.

Navigation:

This example illustrates the fields and controls on the BOM Mass Maintenance Code - Search page. You can find definitions for the fields and controls later on this page.

Before you associate any changes or additions to an MMC, you can use the Search page to identify which specific outputs, components, or component revisions to change on the BOM.

When adding components, use the Search page to further identify the BOMs to which the new component should be added. For example, you may want to add component ID LT5001 only on BOMs that already have a component ID called LT5000 and a 12/31/97 obsolete date or perhaps where you already have component ID LT5000 and LT5001 defined. Similarly, you can use the Search page to further identify to which BOMs the new output should be added.

Note: On these pages, the fields that appear vary, depending on the choice of values in the required Sequence Type field. The page examples that you see are based on the value Component having been selected in the Sequence Type field. However, if you select Output, the system doesn't display the component ID, component revision, quantity, yield, position, if the item is supplied by a subcontractor, if the item is non-owned, or if it is a teardown item. It also does not display the dimensions, reference designators, and substitutes. Instead, it displays the output item, output type, output quantity, resource allocation percentage, and cost allocation percentage fields.

Field or Control |

Description |

|---|---|

Auto Revision |

Select this check box to apply schemes for this mass maintenance code that automatically update revisions when a change event occurs. You actually generate the automatic revisions when you run the mass maintenance functionality. |

Mass Maint Seq (mass maintenance sequence) and Descr (description) |

Enter a mass maintenance sequence number and its description. The mass maintenance sequence number enables you to set up more than one set of changes for a single mass maintenance code. The sequence number determines the order in which the changes are applied. Note: The maximum number of sequence numbers that you can enter for a specific mass maintenance code is 20. |

Sequence Type |

Select Component or Output. If you select Component, enter the component search values. This optionally includes standard BOM fields such as Component ID, Comp Rev (component revision), Op Seq(operation sequence), Eff Date, (effectivity date), Obs Date (obsolete date), and quantity Per. The system searches for values that meet, at the same time, all of the criteria that you enter. Note: The effective date and obsolete date that you enter indicates the precise date on which the component becomes effective or obsolete on the BOM. If you select Output as the sequence type, then you can, optionally, select the output item and output type. You can also enter an output quantity, resource percentage, and cost allocation percentage. If you don't want to change a specific component, then leave the Component ID field blank, and select criteria based on the other fields. If you leave any field on the Component Search page blank, the system searches for BOM components without considering the blank search field. For example, if you leave Component ID blank and just enter a yield of 50, then all components with a yield of 50 are selected. To search for multiple components or outputs within a sequence, use the Where Search Values Are group box to enter "and" searches for more than one component or output on a BOM. |

Update Flag |

While searching for BOMs that contain multiple components or outputs, you may only want to actually make changes to a subset of all components or outputs. Select this check box to indicate which components or outputs you want updated by the Mass Maintenance process. |

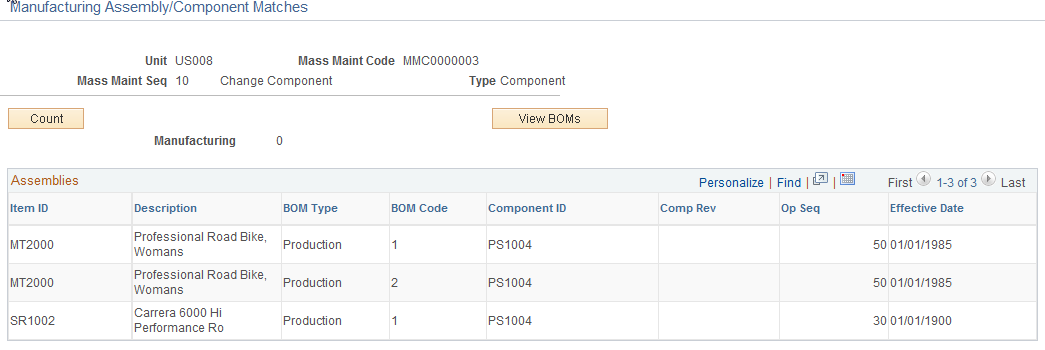

Use the Manufacturing Assembly/Component Matches page (EN_BOM_MMC_VW_SP) to this display-only page allows you to view the number of assemblies that match the search criteria that you have entered and view matching BOMs.

Navigation:

Click the Matches link.

This example illustrates the fields and controls on the Manufacturing Assembly/Component Matches page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Count |

Click this button to view the number of assemblies that match the search criteria that you entered. The page displays MBOM totals. These values are the number of MBOMs that will be affected, assuming that you plan to perform mass maintenance processing for all BOMs in the business unit that meet the search criteria. The actual MBOMs to be changed can be determined by assembly list, by range, when the mass maintenance code is applied later. Note: If you anticipate that a large number of BOMs are going to be affected by the search criteria, click the Count button before attempting to view the BOMs, to avoid viewing too much data online. |

View BOMs |

Click this button to view manufacturing assembly matches to the criteria that you entered. This display of assembly matches lists the assemblies that can be affected by this mass maintenance sequence. When the mass maintenance code is applied later, this list of assemblies can be further restricted, by supplying a range of assemblies, a specific list of assemblies, or an ECO that contains assemblies with BOM changes. If you selected Output as the sequence type on the Search page, the assembly matches display the output item and output type instead of the component ID. |

Use the Search - Reference Designator page (EN_BOM_MMC_REF_SP) to enter reference designator search criteria.

Navigation:

Click the Ref Desigs link.

For a given sequence, you can search using multiple reference designators. If you enter more than one reference designator, the system searches for BOM components, using a logical "and" between reference designators. To search references designators using an "or" logical, use multiple sequences.

Use the Component Substitutes - Search page (EN_BOM_MMC_SUB_SP) to search for substitutes everywhere they are used.

Navigation:

Click the Substitutes link.

You can narrow the search by using all or any combination of the substitute item search criteria.

Field or Control |

Description |

|---|---|

Sub Item (substitute item) |

Enter a value to search for a specific component substitute on a BOM. To search for a specific component substitute with a particular priority, then enter both the sub-item and the priority. To search for a specific component substitute with a particular conversion rate, enter both the sub-item and the conversion rate. |

From Date and To Date |

Enter values for these fields to narrow the search. |

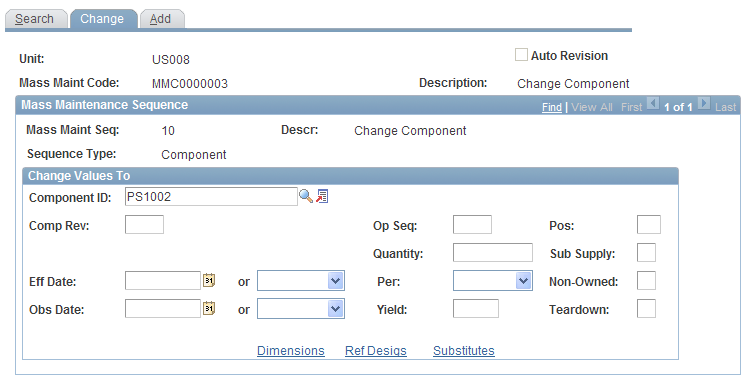

Use the Change page (EN_BOM_MMC_NEW) to specify new component values, once you have selected the set of components that you want to change on the Search page.

Navigation:

This example illustrates the fields and controls on the BOM Mass Maintenance Code - Change page. You can find definitions for the fields and controls later on this page.

Use this page to change values or obsolete the components specified on the Search page.

Field or Control |

Description |

|---|---|

Component ID |

Enter a new value if you intend to change the Component ID field. Note: This would typically be done for correcting BOMs. If you intend to keep the history of a component change, you should leave this field blank. |

Output Item and Output Type |

If you selected Output, you can enter the required output change to data on this page. The effectivity dates operate in the same manner as they do for a component sequence type. |

Using Automatic Revisions and Effectivity Dates

Field or Control |

Description |

|---|---|

Eff Date (effective date) and Obs Date (obsolete date) |

These values determine the specific effectivity date changes mass maintenance will make to the BOM for the searched components. For example for obsolete components, leave the effective date value blank, and specify an obsolete date or use the second field next to the Obs Date field to derive an obsolete date for the component. In the second field you can select Prior Date or Schd Date for the obsolete date. If you select Schd Date for the effective date, at process time, the system translates this into the process run date. |

Obs Date (obsolete date) |

Select one of these values:

|

Auto Revision |

If this check box is selected, and you specify the schedule date for both the effective date and the obsolete date. The system displays a warning that the component will be effective for only one day. |

Note: You can enter only one effective date. Therefore, if you specify a calendar date and then select Schd Date, the system clears the calendar date. Similarly, if you select a Schd Date and then enter a calendar date, the system clears the scheduled date. The Obs Date fields operate in the same manner.

This table lists the automatic revision impact that the second set of Eff Date and Obs Date fields have on both the revisions and the dates reflected on the BOMs. This example applies only to items that have been defined as revision-controlled on the Define Business Unit Item - Manufacturing: General page. Also, there is an example of how the dates will change on the BOM if the schedule date is 06/15/03 and the newly created revision is the latest revision for the item.

|

Change Obsolete Date to |

None |

Scheduled Date |

Prior Date |

|---|---|---|---|

|

When Effective Date = None |

Creates new automatic revision. There is no BOM component effectivity date change. Example: Both of the dates in the Eff Date and Obs Date fields are unchanged. |

Creates new automatic revision. The system changes the obsolete date on the selected BOMs to the obsolete date of the newly added automatic revision. Example: The value in the Eff Date field is unchanged; the value in the Obs Date field is 12/31/2099. (The obsolete date of the new revision added on 6/15/03). |

Creates new automatic revision. The system changes the obsolete date on the selected BOMs to the obsolete date of the revision just prior to the newly added automatic revision. Example: The value in the Eff Date field is unchanged; the field value in the Obs Date field is 06/14/03 (one day before new revision is active). |

|

When Effective Date = Schd Date |

Creates new automatic revision. The system changes the effective date of the BOM. Example: The value in the Eff Date field is 06/15/03. (This is the start date of new revision.) The obsolete date is unchanged. |

Creates new automatic revision. The system changes the BOM effective date to the Mass Maintenance Code process run date. The system changes the obsolete date on the selected BOMs to the obsolete date of the new revision. Example: The value of the Eff Date field is 06/15/03. (This is the start date of new revision.) The value in the Obs Date field is 12/31/2099. |

This combination is not allowed, because it would cause the effective date of the component to be after the due date. You must select another combination. |

As you can see from this table, with the exception of the schedule date and prior date combination, all scenarios are valid and lead to the automatic generation of revisions for revision control and automatic revision items.

This table lists items that have not been defined as using automatic revisions.

|

Change Obsolete Date to |

None |

Scheduled Date |

Prior Date |

|---|---|---|---|

|

When Effective Date = None |

There is no component effective date mass change. Example: Both of the dates in the Eff Date and Obs Date fields are unchanged. |

The system changes the obsolete date on the selected BOMs to the Mass Maintenance Code process run date. Example: The value of the Eff Date field is unchanged; the value of the Obs Date field is 06/15/03. |

The system changes the obsolete date on the selected BOMs to the date prior to the Mass Maintenance Code process run date. Example: The value in the Eff Date field is unchanged; the value in the Obs Date field is 06/14/03. |

|

When Effective Date = Schd Date |

The system changes the BOM effective date to the Mass Maintenance Code process run date. Example: The value in the Eff Date field is 06/15/00; the value in the Obs Date field is unchanged. |

The system changes the BOM effective date and the obsolete date to the Mass Maintenance Code process run date. Example:The Eff Date field is 06/15/00; the value in the Obs Date field is 06/15/00. |

This combination is not allowed. You must select another combination. |

Use the Change - Dimensions page (EN_BOM_MMC_DIM2_SP) to make mass changes to component dimensions.

Navigation:

Click the Dimensions link.

Enter the existing dimension on the Component Dimensions - Search page (optional), and then enter a new value on the Component Dimensions - Change page. Both pages are accessed by clicking buttons on the appropriate page. Entering the existing dimension on the Component Dimensions - Search page is necessary only when it needs to be part of the search criteria. For example, to change the weight for all occurrences of component LT5000 to 10, enter 10 on the Change page. If it should be changed only where its current weight is 9, then enter 9 on the Search page and 10 on the Change page.

Use the Change - Reference Designators page (EN_BOM_MMC_REF2_SP) to make mass changes to reference designators.

Navigation:

Click the Ref Desigs link.

To add, change, or delete reference designators, specify the reference designators on the Reference Designators - Search page only if it needs to be part of the search criteria.

Otherwise, use the Reference Designators - Change page to specify an Action of Add, Change, or Delete. When adding, specify only the new reference designator; when deleting, specify only the reference designator to be deleted; and when changing, specify the current and new reference designators.

Use the Change - Substitutes page (EN_BOM_MMC_SUB2_SP) to mass change a substitute everywhere it's used.

Navigation:

Click the Substitutes link.

This example illustrates the fields and controls on the Component Substitutes - Change page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Action |

Select one of these values:

Adding, changing, and deleting component substitutes works in a similar fashion as the reference designators, except that you have more information to maintain. If adding a new substitute, specify all the required new values. If deleting a substitute, specify as many of the current values as necessary to perform the delete. If you are changing substitute information, enter the current and new values. For example, to delete all occurrences of LT5001 as a substitute, then enter only LT5001 as the substitute item. To delete only the substitute LT5001, if it has priority 1, then enter LT5001 as the substitute item and 1 as the priority. |

Current Values

Field or Control |

Description |

|---|---|

Substitute Item ID |

This is the current default value that comes from the business unit. |

Priority, Conversion Rate, From Date, and To Date |

If deleting a substitute, specify as many of the current values to perform the deletion. For example, to delete all occurrences of LT5001 as a substitute, then only enter LT5001 as the substitute item ID. If you only want to delete the substitute LT5001 if it has priority 1, then enter LT5001 as the substitute item ID and 1 as the priority. If changing substitute information, enter the current values. |

New Values

Field or Control |

Description |

|---|---|

New Substitute Item |

Enter the value for the new substitute component. If you're adding a new substitute, you must specify all of the required new values. |

New Priority, New From Date, New To Date, New (conversion), and Rate |

If you want to change the parameters of the new substitute item, enter values where applicable. Otherwise, any values that you don't specify here for the new substitute item priority, effective dates, and conversion rate remain unchanged on the BOM. You can also change the parameters for the original item here. Enter only the fields that you want to change. |

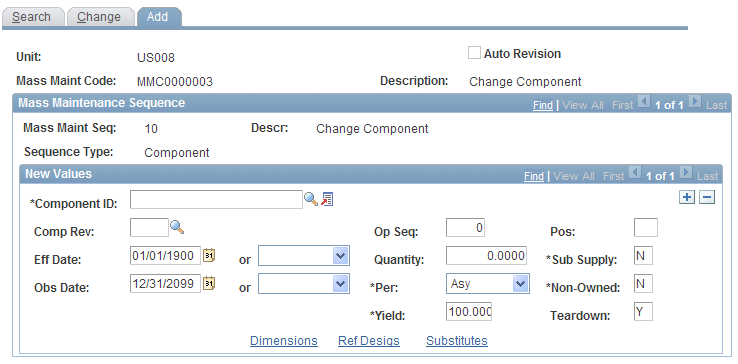

Use the Add page (EN_BOM_MMC_ADD) to add components or outputs to assemblies.

The system adds these components or outputs to each BOM identified by the values that you entered on the Search page. Use the Process BOM Mass Maintenance pages to designate, at a later time, the specific assemblies to be affected by these changes.

Navigation:

This example illustrates the fields and controls on the BOM Mass Maintenance Code - Add page. You can find definitions for the fields and controls later on this page.

Note: Automatic revision operates only for those items that are defined as using automatic revisions with the Define Business Unit Item - Manufacturing: General page.

Field or Control |

Description |

|---|---|

Component ID |

Enter a component if you selected Component as the sequence type on the BOM Mass Maintenance Code - Search page. Enter associated values that you want to add to the selected BOMs that meet the search criteria specified with the Component Search page. You can add multiple components per Mass Maint Seq (mass maintenance sequence) code. You can also add a placeholder item as a component. If the MMC is later applied to manufacturing BOMs that don't allow placeholders, the process indicates that BOM change as an exception, and the BOM won't be changed. |

Output Item and Output Type |

If you selected a Output as the sequence type on the BOM Mass Maintenance - Search page, you must enter values and any additional required output data. |

Note: The values that you select on these pages are subject to the same validation checks that apply to any MBOM component or output value. Some of these checks occur when you create the mass maintenance code, and the remaining validation checks occur when the MMC is applied.

Use the Add - Substitutes page (EN_BOM_MMC_SUB3_SP) to add a substitute everywhere it's required.

Navigation:

Click the Substitutes link.

This example illustrates the fields and controls on the Component Substitutes - Add page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

|

Click the Copy Substitute Push button to display all valid substitute items for the business unit. |

To add all valid substitute items for the business unit, click OK.

If you don't want to add all valid substitute items for the business unit, enter each individual substitute item that you want to add. In addition, enter the priority, from date, to date, and conversion rate for each substitute.

Note: Substitute items must be unique for the item. You can't enter the same item twice as a substitute with different dates. For example, substitute A with effective dates from 01/01/99 to 02/01/99 and substitute A with effective dates from 02/01/00 to 08/30/00 couldn't be substitutes for the same item. In this case, define a different substitute for the second set of effective dates.

Example: Mass BOM Changes

To better understand how you can use these three pages to effect desired mass change, let's look at an example.

To make a component obsolete on several BOMs and introduce another component in its place:

Create an MMC code by entering the search criteria (with the Search page) that identifies the component you want to make obsolete.

Then, on the Change page, specify the date that the component is to become obsolete (or select an effective date or obsolete date value).

Add the new component information on the Add page.

This includes required information such as the operation sequence and effective date for the new component.

If the new component requires dimension/reference designator/substitute information, add the information (with the reference designator/reference designator/substitute button), as required.

Run the Process BOM Mass Maint by MMC page.