Defining Items that Are to Use Production Options

This section discusses how to define items that will use production options.

|

Page Name |

Definition Name |

Navigation |

Usage |

|---|---|---|---|

|

Define Business Unit Item - Manufacturing: General |

GEN_ATTRIB_INV |

|

Define production option control information for an item. |

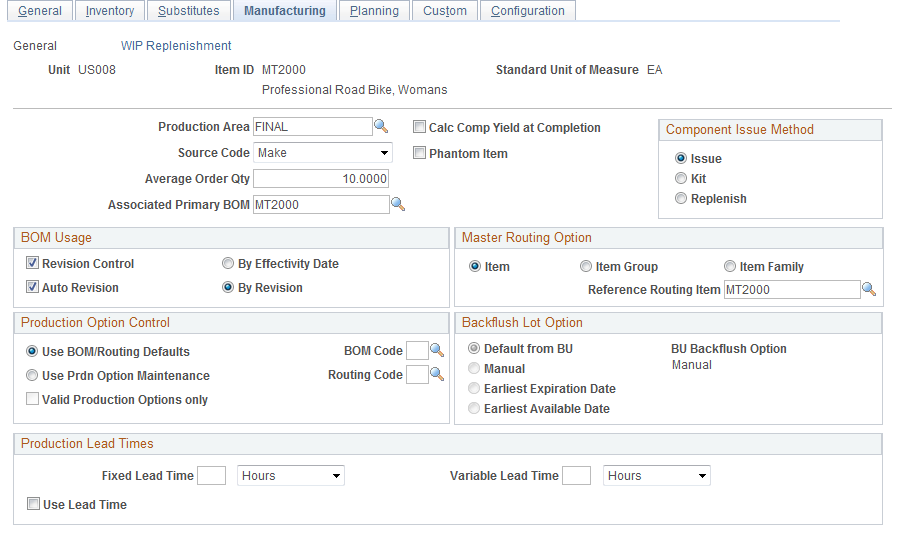

Use the Define Business Unit Item - Manufacturing: General page (GEN_ATTRIB_INV) to define production option control information for an item.

Navigation:

This example illustrates the fields and controls on the Define Business Unit Item - Manufacturing: General page. You can find definitions for the fields and controls later on this page.

Production Option Control

Field or Control |

Description |

|---|---|

Use BOM/Routing Defaults |

Use to create specific BOM and routing combinations for PeopleSoft Supply Planning. If you select Use BOM/Routing Defaults, you cannot access the production option maintenance pages for the item, but you can limit the production options that are created in PeopleSoft Supply Planning by using the BOM Code and Routing Code fields. |

Use Prdn Option Maintenance (use production option maintenance) |

If you select Use Prdn Option Maintenance for a specific item ID, you can access the specified item using the Production Option Maintenance component. With these pages, you can define specific BOM and routing combinations that can be extracted to PeopleSoft Supply Planning and used in PeopleSoft Manufacturing. You can define effective start and end dates for the combinations in addition to assigning the combinations to valid production areas. If you select Use Prdn Option Maintenance, select Valid Production Options only to use only predefined production options when creating production IDs. If any BOM or routing combination is valid, leave this blank. |

Note: You can only select Use Prdn Option Maintenance if no area or items have been defined for the specific item. If you have already assigned an item to a production area in PeopleSoft Manufacturing, you cannot select Use Prdn Option Maintenance for that same item on the Define Business Unit Item - Manufacturing: General page. You can, however, create production options by running the Autocreate Production Options process, which sets the item's Production Options group box to Use Prdn Option Maintenance rather than Use BOM/Routing Defaults.

Note: If you have marked an item to Use Prdn Option Maintenance, you must set the planning rates to be based on routings; you cannot select them to be based on lead time. If the item is already going to be produced based on lead times, you cannot select the Use Prdn Option Maintenance option on the Define Business Unit Item - Manufacturing: General page.

This table outlines the production options that you can create by entering various values in the BOM Code and Routing Code fields:

|

BOM Code and Routing Code Setting |

Production Option Created |

|---|---|

|

If both are blank. |

System creates a production option for every possible BOM and routing combination. |

|

If BOM Code field is not blank and Routing Code field is blank. |

System creates a production option for all routing codes with the specific BOM code selected. |

|

If Routing Codefield is not blank and BOM Code field is blank. |

System creates production options for all BOMs with the specific routing code selected. |

|

If both are not blank. |

System creates one production option for the single, specified BOM and routing combination. |

By selecting a specific BOM and routing code, you can limit the number of BOM and routing combinations that are extracted by PeopleSoft Supply Planning. For example, by selecting a specific BOM code and routing code, you eliminate all but this specific combination from consideration by PeopleSoft Supply Planning. At the other extreme, if you leave both fields blank, then PeopleSoft Supply Planning extracts all possible combinations.

This example illustrates various BOM and routing values and the production options that would be created by various BOM code and routing code settings.

If a specific item has BOM codes 1, 2, and 3 and routing codes 1 and 2, here are the numbers of production options created in PeopleSoft Supply Planning, based on the BOM Code and Routing Code field settings:

|

BOM Code |

Routing Code |

Production Options Created |

Total Combinations |

|---|---|---|---|

|

Blank |

Blank |

1-1, 1-2, 2-1, 2-2, 3-1, 3-2 |

6 |

|

1 |

Blank |

1-1, 1-2 |

2 |

|

Blank |

2 |

1-2, 2-2, 3-2 |

3 |

|

1 |

2 |

1-2 |

1 |

The number of production options created in PeopleSoft Supply Planning depends on the BOM and routing default values.

Note: Only routing codes that have the Copy Routing to Planning check box selected in the Routing Definition - Header: Description page are copied to PeopleSoft Supply Planning.

Note: You can only select Use BOM/Routing Defaults if there are no production options defined for the item. If production options exist, you must manually delete them first.

Also, if you select Use BOM/Routing Defaults, use the Production Area Maintenance set of pages to define area BOM and routing combinations.

|

Production Option Control Setting |

Steps Based on Control Setting |

|---|---|

|

Select Use Prdn Option Maintenance to:

|

|

|

Select Use BOM/Routing Defaults, if specific BOM and routing combinations are not required. Additionally, it's possible to limit the number of BOM and routing combinations extracted to PeopleSoft Supply Planning using the BOM and routing fields. |

|