Defining Work Centers

To create and maintain work centers and their associated resources, conversion codes, text, locations, departments, and distribution types by business unit, use the Work Center Definition component (WORK_CENTERS). To define overhead rates, use the Overhead Rates component.

See PeopleSoft Cost Management Documentation

If you have enabled PeopleSoft Workflow and when you add a new work center, or when you change any attribute in an existing work center, the system optionally sends the Workcenter Change workflow notification to the roles that you've defined, such as an engineering manager or cost accountant.

This section discusses how to:

Define work center attributes.

Define work center resources.

Define work center planning options.

Associate conversion codes with work centers.

Associate conversion overhead codes with work centers.

View work center where-used data.

|

Page Name |

Definition Name |

Navigation |

Usage |

|---|---|---|---|

|

Define Work Center - Definition |

EN_WORK_CENTER |

|

Define and maintain work centers for use on routings. |

|

Define Work Center - Text |

EN_WORK_CENTER_TXT |

|

Enter up to 254 characters of text to associate with the work center. |

|

Define Work Center - Attachments |

EN_WC_ATT |

|

Attach work center-related documents. Click the Get Attachment button to launch the multimedia object that is associated with the work center. Select the type of media that you want to attach and enter the file name. |

|

Define Work Center - Resources |

EN_WC_RESOURCE |

|

Define work center resources. |

|

Define Work Center - Planning Opts (planning options) |

EN_AGGREG_WC |

|

Define the planning options associated with the work center. |

|

Define Work Center - Conv Code (conversion code) |

EN_WC_CONCODE |

|

Associate conversion codes with the corresponding labor and machine rates for the work center. |

|

Define Work Center - Conv Ovhd Codes (conversion overhead codes) |

EN_WC_CONOHCODE |

|

Associate work center conversion overhead codes. |

Use the Define Work Center - Definition page (EN_WORK_CENTER) to define and maintain work centers for use on routings.

Navigation:

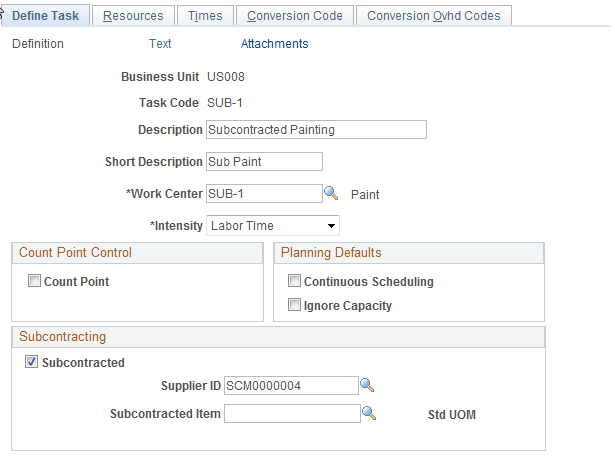

This example illustrates the fields and controls on the Define Work Center - Definition page. You can find definitions for the fields and controls later on this page.

Before defining routings, you can define a master dictionary of tasks or jobs that can be performed at work centers.

Field or Control |

Description |

|---|---|

Department |

(Optional) Enter the department code, which is informational only and is used for reporting purposes. |

Distrib. Type (distribution type) |

(Optional) Predefine distribution types within PeopleSoft Cost Management. When used in conjunction with the assembly completion transaction, the distribution types can determine the general ledger accounts when posting earned conversion costs, such as labor, machine, subcontracting, and overhead costs. The distribution type appears by default as the value defined in PeopleSoft Inventory for the transaction group for earned conversion costs. |

Average Daily Hours |

Enter the average number of hours that the work center is in operation each day. This field determines the operation's setup, fixed run, run rates, and post-production times in hours, when the time unit for an operation is expressed in days for planning and costing purposes. For example, suppose that you set the run rate for an operation to 100 units per day and the work center's average daily hours to 8 hours, the system converts this to 100 units per 8 hours. |

Default Queue Time |

Enter the default amount of time that a job must wait before it can be processed by this work center. The value is copied to a task when you create a task and specify queue time on the task. The system copies it to a routing when you assign a task to an operation sequence on the routing. |

Queue Time Unit |

Designate whether the default queue time is in Minutes, Days, or Hours. |

Note: If you change the average daily hours and the run rates on routing operations are expressed in units-per-day, revisit all routing operations that use the work center and adjust the run rates accordingly.

Note: The Default Queue Time field and the Queue Time Unit field do not appear if you use PeopleSoft Supply Planning.

Work Center Calendar Code

Field or Control |

Description |

|---|---|

Calendar Code |

You can associate a calendar code with the work center. Use the Calendar Code Definition page to define calendar codes. If you intend to use a production calendar, as opposed to a five-day work week definition, define at lease one calendar code and the associated calendar. You can define alternate calendar codes with alternate calendars. A calendar code entered here indicates that the work center has different hours of operation from the business unit. If you enable PeopleSoft Workflow and change a work center calendar code, the Work Center Calendar Code Change workflow notifies the planner of the change. The planner may want to reschedule production. |

Run-time Calendar Code |

Displays which calendar code is used for scheduling the work center. |

When you associate a calendar code that is different from the current runtime calendar code—or when you associate a calendar code for the first time—the system optionally sends a workflow notification to selected roles that you have defined. This workflow notifies the role, such as a production control manager, that the calendar originally used for scheduling is not synchronized with the calendar code that is specified for the work center.

Work Center WIP Location

You can select the WIP location to which material associated with the operation is delivered for use in production. This is also the WIP location from which material is consumed upon operation or assembly completion (if the component, production area, or item's issue method is set to Issue or Replenish.)

Field or Control |

Description |

|---|---|

Owned and Non-Owned |

Indicate a WIP location for both owned and non-owned inventory. The system can only issue owned components to (and consume them from) owned WIP locations. Likewise, the system can only issue non-owned material to (and consume it from) non-owned locations. Consigned inventory is issued to non-owned WIP locations. Once consumed, it is considered owned. If you never use consigned inventory, maintain non-owned inventory, or issue non-owned inventory to production, you can leave these fields blank. |

Note: If you use consigned components, you must define both an owned location and a non-owned location. Consigned components are consumed from a non-owned location but, once consumed, can only be returned to an owned location.

Use the Define Work Center Resources page (EN_WC_RESOURCE) to define work center resources.

Navigation:

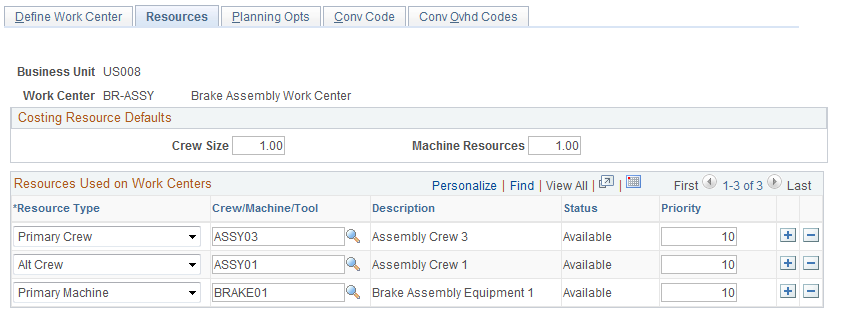

This example illustrates the fields and controls on the Define Work Center Resources page. You can find definitions for the fields and controls later on this page.

Costing Resource Defaults

Field or Control |

Description |

|---|---|

Crew Size |

(Optional) Enter the number of people at the work center. This value appears by default from the primary crew specified in the work center definition. |

Machine Resources |

(Optional) Enter the number of machines at the work center. If multiple machines exist in the work center and you want to factor their costs into an item's cost, enter that factor here. |

Although these are optional fields, the system uses the crew size and machine resources information when it calculates standard labor and machine costs for items in the standard cost calculations.

In some cases, the system also uses crew size and machine resources when it calculates the per unit cost of an item, as well as the earned labor and machine amounts in PeopleSoft Manufacturing. The system only uses crew size and machine resources in labor and machine cost calculations if the value of the labor and machine rate is defined as a rate per hour, rather than a rate per unit. If the value is per unit, it's expected to be factored in and the system doesn't include it in the calculation. However, if the rate is per hour, the system uses the crew size in the calculation.

The system only uses crew size and machine resources for runtime labor and machine calculations. Setup times, for example, are typically of fixed duration and amount. Therefore, it is assumed that you have already factored in crew size and machine resources when you define them.

To better understand an item's cost calculation and the earned labor cost calculations, consider these equations. For setup time operations, the item's cost calculation equation is:

When calculating earned setup costs in PeopleSoft Manufacturing, the system calculates the setup cost for the production quantity. It does not divide by the average order quantity.

For runtime operation, the cost calculation equation differs, depending on whether the labor or machine rate is a rate per unit or rate per hour. If it's a rate per unit, then the applicable per unit item cost equation is the labor or machine rate per unit. To calculate the earned labor or machine run cost, the system uses this equation:

If the labor or machine rate is a rate per hour, then the applicable per unit item cost equation is as follows:

Field or Control |

Description |

|---|---|

Labor |

(Crew size) × (Labor

rate for run) × (Run time [in hours]) = Labor run cost

|

Machine |

(Machine resources)

× (Machine rate for run) × (Run time [in hours]) = Machine run cost

|

To calculate the earned labor or machine run costs in production, the system multiplies the per unit cost by the quantity completed at the operation.

The system copies the resources to the task when you enter the work center for the task. It copies the resources to the routing when you specify the task for an operation, or, if you are not using tasks, when you specify the work center for the routing operation. If you choose not to define resources, you can enter the crew size and number of machines used in the work center here.

Resources Used on Work Centers

Field or Control |

Description |

|---|---|

Resource Type and Crew/ Machine/Tool |

Select a type and resource to associate with the work center. You can only associate one Primary Tool, Primary Crew, and Primary Machine with the work center, but you can designate unlimited Alternate Crews, Machines, or Tools. A primary resource is the preferred resource to be used in production. You can assign tools, crews, and machines to multiple work centers. |

Status |

Indicates the availability of a resource for this work center. |

Priority |

Enter a whole-number ranking to indicate which resource has preference over others when considering multiple resources. The lower the priority assigned to a resource, the more likely it is that the resource will be chosen. You can manually specify a priority for the task resource or work center resource. The priority appears by default onto the routing. The primary resource for tool, crew, and machine automatically changes to a priority of 10. Other resources of like type automatically change to a priority of 20. The priority setting enables you to designate the order in which PeopleSoft Supply Planning uses resources. |

If you use PeopleSoft Supply Planning, you must enter at least one resource in the resource list (crew or machine) at each work center. PeopleSoft Supply Planning only uses the priority that you define on the routing.

Note: To specify a resource on a task or routing, first associate it with the work center in which the task or operation is performed.

Changing the resources for a work center does not change the resources for any routing operation that is using the work center. Furthermore, you cannot delete a work center resource if it is being used on a task or routing.

The system only copies primary resources when it copies routings to production.

Use the Define Work Center - Planning Opts (planning options) page (EN_AGGREG_WC) to define the planning options associated with the work center.

Navigation:

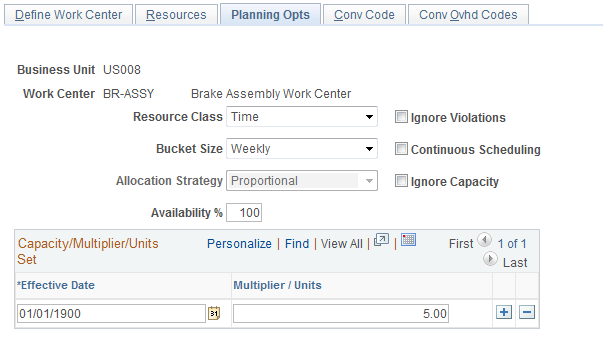

This example illustrates the fields and controls on the Define Work Center - Planning Opts page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Resource Class |

Because work centers are modeled as aggregate resources in PeopleSoft Supply Planning, define each work center as either an aggregate resource by time or an aggregate resource by unit. Values are:

|

Bucket Size |

Enter the summation period, the period over which you are aggregating. Values are Daily, Weekly, and Monthly. The default is Weekly. |

Allocation Strategy |

Enter a value to specify how you plan to spread the time and unit over the bucket size. Values are Start, Finish, and Proportional. This determines whether if the task is stretched across two or more buckets—in its entirety—is placed in the first bucket, the last bucket, or spread proportionally across all buckets. The default is Proportional. |

Availability % |

Define a percentage of the total capacity time that the resource is available for use. You might take into consideration scheduled maintenance or include a buffer for unexpected repairs when you define the percentage. You can change the resource availability percentage for all the aggregate resources. The default is 100. |

Ignore Violations |

Select to prevent the solvers from analyzing and resolving capacity issues impacting the work center. When this check box is selected, capacity issues—although not recognized by the solvers—will appear in the PeopleSoft Supply Planning Violations workbench if they are before the capacity fence defined for the planning instance. By selecting the Ignore Violations check box on noncritical work centers, you enable the solvers to ignore these work centers and focus on critical work centers for capacity repair. Select this check box to generate what-if scenarios. |

Continuous Scheduling |

Select to complete the corresponding operation in a single run of continuous valid calendar time, with no gaps allowed between shifts. This field is used as a routing operation default. |

Ignore Capacity |

Select to prevent solvers from considering the corresponding operation as required capacity for the work center. This field is used as a routing operation default. |

Capacity Multiplier/Units Set

This is used by the system to determine the available capacity on a work center. Because these sets are effective-dated, you can use the Capacity Multiplier/Units grid to vary the work center's available capacity over time.

If you define the work center as an aggregate resource by time, the system uses the capacity multiplier to represent the number of identical work centers that exist for scheduling purposes.

For example, suppose that you define a work center as an aggregate resource by time with weekly buckets, and it has a capacity multiplier of 2, with an effective date of March 5, 2005. Then, beginning on March 5, 2005, PeopleSoft Supply Planning treats this aggregate resource as two identical work centers that it can use simultaneously for jobs. If the work center has 40 hours of available calendar time in a weekly bucket, then the available capacity for the bucket, based on a capacity multiplier of 2, would be 80 hours total. PeopleSoft Supply Planning uses this capacity multiplier to determine the work center's available capacity until the next capacity multiplier becomes effective.

If you define the work center as an aggregate resource by unit, the system uses the capacity units to represent the number of units that can be produced on that work center in an entire bucket (assuming a calendar of 24 hours per day, seven days per week, during the entire bucket).

For example, suppose that you define a work center as an aggregate resource by unit with weekly buckets. If this resource has capacity units of 100 with an effective date of April 10, 2005, then, beginning on April 10, 2005, PeopleSoft Supply Planning treats this work center as being capable of producing 100 units per week (based on a calendar of 24 hours per day, seven days per week). The actual available capacity for this work center is then calculated by factoring in the actual production calendar during each weekly bucket. If the work center has 40 hours of available calendar time in a weekly bucket, then the available capacity for the bucket, based on a capacity unit of 100, would be (100 units × 40 hours per week) ÷ (24 hours per day × 7 days per week) = 24 units. PeopleSoft Supply Planning uses these capacity units to determine the work center's available capacity until the next capacity multiplier becomes effective.

Use the Define Work Center - Conv Code (conversion code) page (EN_WC_CONCODE) to associate conversion codes with the corresponding labor and machine rates for the work center.

Navigation:

This example illustrates the fields and controls on the Define Work Center - Conv Code page. You can find definitions for the fields and controls later on this page.

Enter the conversion code that you want to associate with the work center.

Conversion Codes

The system copies conversion codes and their associated labor, machine, and overhead rates and costs into the item's routing when you assign the work center to a routing operation. The system uses the conversion codes to calculate the cost of the operation using the work center. Conversion costs are optional, but if you define them, the system can calculate the labor, machine, and overhead costs associated with manufactured items during cost roll-ups. When the routing is copied, the system uses PeopleSoft Manufacturing costs to calculate the earned labor, machine, and overhead costs that are added to the WIP inventory value when operation or end item completions are recorded.

Conversion Rates

The system displays the conversion rates from the Costing Conversion Rates page. The rates displayed are from the frozen conversion rate and costs that were updated during the last cost update and revaluation. When production costs are updated using a selected cost type and version, the system copies the conversion rates and conversion overhead rates—which are used to calculate the item cost—into a frozen conversion rate record. The system uses those frozen rates to calculate earned labor, machine, and overhead costs when end items are completed at operations or to stock.

Additionally, the system uses the rates to calculate the cost of end items scrapped during manufacturing. You must have a labor or machine rate or cost for each costing operation time type specified on the routing. For example, suppose that you enter a costing labor setup time on the routing. There must be a corresponding labor setup rate per hour for the system to calculate the operation cost and include it in the item's cost.

Use the Define Work Center - Conv Ovhd Codes (conversion overhead codes) page (EN_WC_CONOHCODE) to associate work center conversion overhead codes.

Navigation:

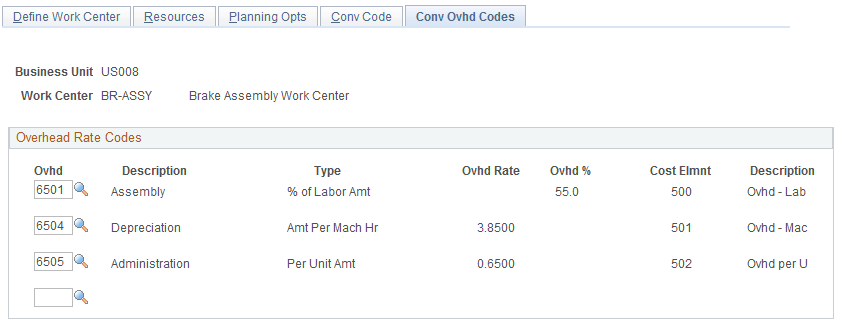

This example illustrates the fields and controls on the Define Work Center - Conv Ovhd Codes page. You can find definitions for the fields and controls later on this page.

Enter the overhead code that you want to associate with the work center. The system displays the overhead rates from the Conversion Ovhd Codes page. The rates appear from the frozen conversion overhead rates and costs that were updated during the last cost update and revaluation. When production costs are updated using a selected cost type and version, the system copies the conversion rates and conversion overhead rates—which are used to calculate the item costs—into a frozen conversion rate record. The system uses those frozen rates to calculate earned labor, machine, and overhead costs when end items are completed at operations or to stock. You can associate up to four codes with a work center.

Note: The system copies the overhead rates and costs into the item's routing when you assign the work center to a routing operation. The system uses these codes to calculate the cost of the operation that uses the work center.