Understanding Serial Genealogy

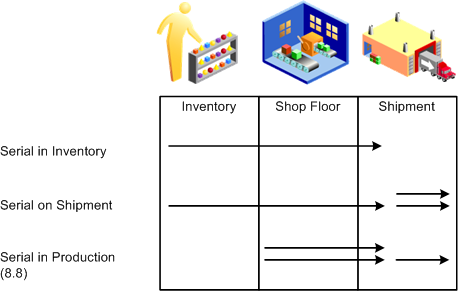

This diagram illustrates PeopleSoft and serial processing prior to Release 8.9

With PeopleSoft Manufacturing, you can trace the location and constituent components of finished goods items and trace source and usage of component parts during the production process.

Serial genealogy tracks the source and destination of any serialized item. A serialized item may be used in a serialized assembly, scrapped, used in a higher level serialized assembly that is then shipped to a customer.

Serial IDs may be associated with the production IDs at any time during the manufacturing process.

For rework or teardown production IDs, you do not manually associate serial IDs to the assembly. The serial association occurs when you issue the assembly that is to be reworked or torn down through the picking process or kit issues.

In addition to associating a serial ID with the assembly item, you can associate component serial IDs with an assembly serial ID.

You can correct errors by disassociating the serial ID from the assembly or disassociating the component from the assembly serial ID.

In addition, we provide an inquiry that displays the genealogy of a serialized item through multiple levels of BOMs. This inquiry also displays the transaction information associated with the serialized item.

Note: Serial genealogy is tracked with single output production orders (IDs) only.

Serial genealogy is not tracked on:

Production schedules.

Production IDs with multiple outputs such as co-products or by-products.

Components with an quantity code of per order.

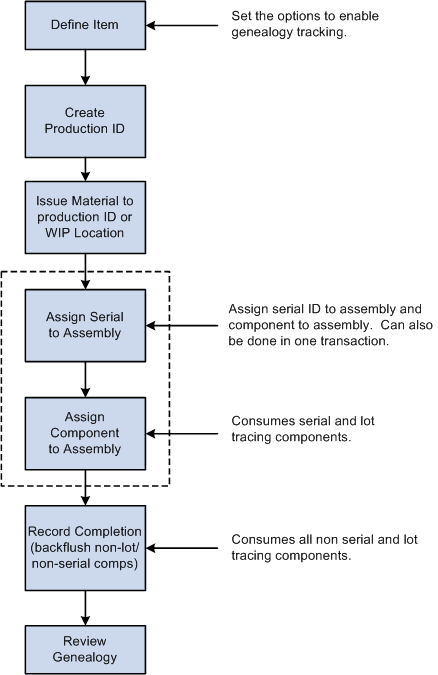

This diagram illustrates the serial genealogy process flow from setting the options on the item definition, to creating the production ID, issuing material, assigning serial IDs to assembly, assigning components to assembly, recording completions, and reviewing genealogy: