Prerequisites

This topic discusses how to set up prerequisite tasks.

With PeopleSoft Inventory, there is a single point of entry for all items that you use within PeopleSoft Manufacturing. Unlike your production environment, where an item must be approved before it can be accessed within the system, PeopleSoft Engineering can make use of inventory items defined in a pending or approved state, as long as item business unit attributes are defined. For example, when associating an item with a BOM, you can (within PeopleSoft Engineering) immediately access pending items on ECOs and EBOMs.

In addition to using items in a pending state, PeopleSoft Engineering enables you to use placeholder items within BOM maintenance prior to formal component item definition. Placeholder items enable you to define EBOM structure and component information before you enter component item information into the system.

To use pending items or cost component items within PeopleSoft Engineering, you must first define business unit attributes for the items.

The system won't transfer an item from engineering to manufacturing unless the item status is Active.

Note: The content in this section is only part of what you need to know to define business unit attributes for items. Other relevant information, because it's common to many applications, is located in the PeopleSoft Application Fundamentals. Product documentation

You can maintain item BOMs by:

Revisions

Effectivity dates

When you define your assembly items, use the BOM Usage group box to determine whether you manage your BOMs by using revisions.

You can indicate that you automatically generate revisions for the item. While you can define at the business unit level that all items in your business unit use automatic revisions by default, you can at the item level change that setting for specific items. Prior to using automatic revisions, you must set up a revision scheme with the Manufacturing Options component.

You can maintain revisions, including associated text, documents, and attachments. The item revisions that you create apply to EBOMs and MBOMs.

You can choose how to handle EBOM Online Verification and define component revision default settings on the MFG Business Unit Options page.

Note: When EBOMs are complex and deep, you should select Never Verify Online to improve EBOM maintenance performance, and then run the EBOM verification process from the EBOM Looping Verification page.

There are some conceptual differences between single-output BOMs (one primary item) and multiple output BOMs (at least one co-product is defined). When you create a multiple output BOM with a primary and at least one co-product, consider these points regarding single-output and multiple output BOMs.

Single-Output BOMs

BOM quantity is a scaling device field that enables you to enter a product structure when the assembly specifications are in a base greater than one unit. With BOM quantity, you determine the assembly quantity to which the component's quantity per assembly (QPA) or per order is applied:

If the BOM quantity is greater than 1, enter the component quantity in terms of the BOM quantity.

If the BOM quantity is set to 1, the component quantity is the amount of the component required to make one unit.

Use BOM quantity for batched bills or when you know that you will only make a certain quantity of an item at a time.

Multiple Output BOMs

When you define multiple outputs (co-products) for a BOM, you are indicating that:

At least two end-items are coming out of production, one of which is the primary item.

The item ID that is specified for the BOM represents a batch item, in addition to representing the primary item to be completed.

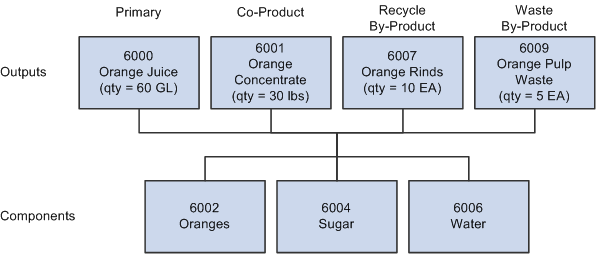

The following diagram illustrates a BOM structure that is defined for item ID 6000, or, in other words, item ID 6000 is a batch item. The output for batch item 6000 includes primary item 6000, as well as co-product 6001, recycle by-product 6007, and waste by-product 6009:

BOM with multiple outputs

When used on a multiple output BOM, BOM quantity represents the in-process quantity for the BOM item ID as a batch item (as opposed to the item ID as a primary item).

For example, when the BOM structure has a BOM quantity defined as 150, the in-process units of the batch are 150. This also indicates that routing times (planning and costing), as well as rates, are in terms of a single batch unit.

Also, when creating production (IDs or schedules), you must also define the production quantity in terms of batch units. For example a production ID is added for 150 of the batch item 6000 to produce 60 gallons of 6000 and 30 pounds of 6001.

Multiple Output BOMs: Using Yield by Operation

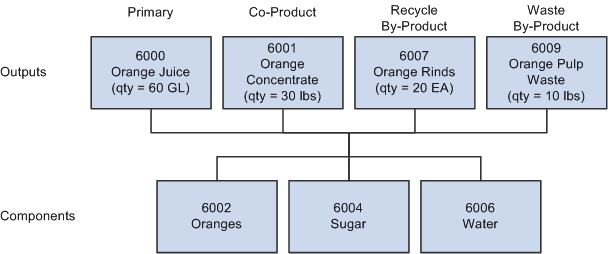

The following diagram illustrates the effect of yield by operation on a BOM. This example shows the impact of a 50 percent yield for one operation.

Note: When using yield by operation, the ending quantities for the by-products (recycle or waste) are based on the operation start quantity, not the BOM (batch) quantity.

BOM with multiple outputs using yield by operation

Assign associated primary BOMs if you plan to define BOM co-products.

See Prerequisites.

Copy and delete options control copying engineering BOMs (EBOMs) and engineering routings (ERTGs) to manufacturing.

If you plan to use the Documentum embedded document management system to access revision, assembly, and component documents, use the Component Options page to define which function buttons are available on the EBOM document management pages.