Establishing Manufacturing Business Units

To define business unit options for a manufacturing business unit, use the Manufacturing Business Unit (MG_BUSIN_UNIT) component. To define manufacturing business unit options, use the Manufacturing Business Unit Options (MG_BUS_UNIT_OPT) component.

Prior to using PeopleSoft Manufacturing, define the manufacturing business units and set parameters such as default rate maintenance and BOM online verification. If you are using PeopleSoft Engineering, you also define how you want to manage engineering BOMs.

There are several ways that you can set up PeopleSoft Manufacturing to run an enterprise. Your selections affect which pages you can access, how you maintain or present data, and how transactions work.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

BUS_UNIT_MFG1 |

Define manufacturing business units. |

|

|

BUS_UNIT_OPT_MG |

Set up manufacturing business unit options. |

|

|

BUS_UNIT_OPT_MG_2 |

Set up manufacturing business unit production options. |

|

|

EN_REVISION_SCHEME |

Define automatic revision schemes at the manufacturing business unit level. |

|

|

EN_BOM_MSG_DFLT |

Set manufacturing business unit defaults for BOM messages received from a third-party product data management system. |

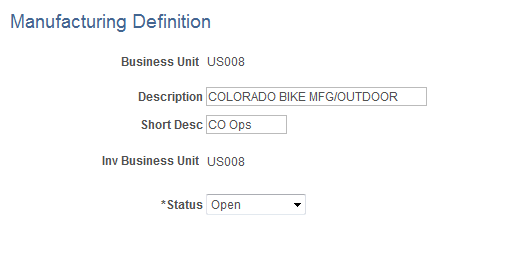

Use the Business Unit Definition page (BUS_UNIT_MFG1) to define manufacturing business units.

Navigation:

This example illustrates the fields and controls on the Manufacturing Definition page. You can find definitions for the fields and controls later on this page.

Important! Manufacturing business units must be identical to PeopleSoft Inventory business units to link the manufacturing and inventory processes.

To define a manufacturing business unit:

Enter values in the Description field and the Short Desc (short description) field for the manufacturing business unit.

The Inv Business Unit (inventory business unit) field is display-only.

Indicate whether the facility status is Open or Closed.

Note: You must set the facility status to Open to manage production or add BOMs or routings.

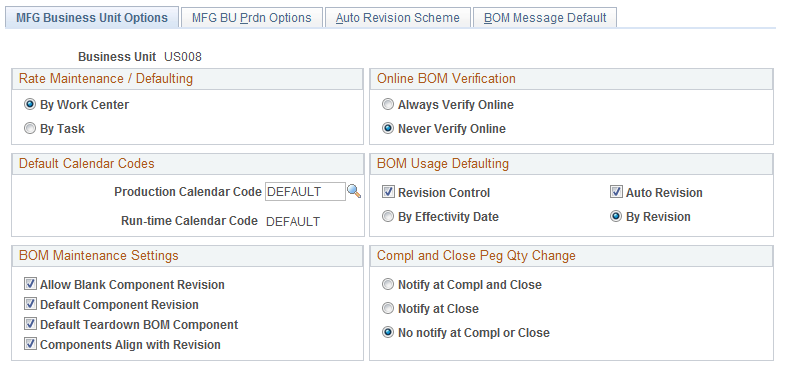

Use the MFG Business Unit Options page (BUS_UNIT_OPT_MG) to set up manufacturing business unit options.

Navigation:

This example illustrates the fields and controls on the Manufacturing Options - MFG Business Unit Options page. You can find definitions for the fields and controls later on this page.

Rate Maintenance/Defaulting

Use the Rate Maintenance/Defaulting group box to enter conversion rates for work centers or tasks.

If you determine that labor, machine, and overhead rates and costs are to be tracked by department or cost center, select By Work Center; all tasks assigned to the work center will use the same conversion rates and overhead rates. If you determine rates and costs are to be tracked by crew or resource, select By Task. With this option, each task can have a unique conversion and conversion overhead rate.

For example, if you select By Work Center, then you can access the conversion code fields on the work center pages but not on the task pages.

Online BOM Verification

Specify how to handle online verification for production BOMs. If you use PeopleSoft Engineering, you can also specify how to handle online verification for engineering BOMs:

Field or Control |

Description |

|---|---|

Always Verify Online |

Runs the process online during BOM maintenance. |

Never Verify Online |

Runs the verification as a deferred process. |

Note: When BOMs are complex and deep, select Never Verify Online to improve BOM maintenance performance, and run the BOM verification process from the BOM Verification page.

Default Calendar Codes

To indicate a default production calendar for the manufacturing business unit, select Production Calendar Code. You create calendar codes and their associated calendars using the Calendar Code Definition page. The first calendar code and associated calendar that you create for the business unit is the default for this field. It is treated as the primary production calendar for the business unit. If a calendar code is not associated with a work center—or if the calendar code associated with the work center is not effective yet or is obsolete—the system uses the calendar defined here to schedule production.

The Run-time Calendar Code field is display-only. It indicates which calendar code is used as the default production calendar for the business unit.

When you associate a different calendar code than the current runtime calendar code, the system optionally sends a workflow notification to selected roles that you define. This workflow notification indicates to the user (such as a production control manager) that the calendar originally used for scheduling is not in sync with the calendar code specified for the business unit.

If you do not define a calendar code and an associated calendar for the business unit—or if the production calendar associated with the business unit runs out—PeopleSoft Manufacturing uses the default five-day work week. A five-day work week is defined as Monday through Friday, with one shift. You set it up using the Work Week Definition page.

BOM Usage Defaulting

The BOM Usage Defaulting group box enables you, at the business unit level, to indicate whether you maintain BOMs:

In PeopleSoft Manufacturing and PeopleSoft Engineering.

By revisions.

By effectivity dates (and whether revisions can be automatically generated for revision controlled items).

Field or Control |

Description |

|---|---|

Revision Control |

Select to generate BOMs by revisions. |

Auto Revision |

Select to automatically generate revisions. |

By Effectivity Date |

Select to maintain BOMs by effectivity date. |

By Revision |

If you are maintaining BOMs by effectivity date, you can specify an effective revision that equates to an effectivity date. |

While the value that you define here (at the business unit level) is the default at the item setup level, you can overwrite this at the item level.

To automatically create revisions to items, use the mass maintenance functionality in PeopleSoft Manufacturing or PeopleSoft Engineering. You can use either of these features:

BOM Mass Maintenance by Mass Maintenance Code (MMC)

BOM Mass Maintenance by Engineering Change Order (ECO)

The mass maintenance process creates revisions for those items that have both revision control and automatic revision selected. In other cases, the process functions as a regular mass maintenance process without creating automatic revisions.

Use the Auto Revision Scheme page in this component to define the scheme that the system uses to generate automatic revisions.

BOM Maintenance Settings

Field or Control |

Description |

|---|---|

Allow Blank Component Revision and Default Component Revision |

Select these two check boxes to define component revision default settings that affect the BOM Maintenance pages. The check boxes only apply to revision-controlled items. In addition, they operate independently of each other. Therefore, there are four possible combinations of settings. |

Default Teardown BOM Component |

Select to indicate business unit settings for teardown components. You can only select this check box for teardown production orders. If you select this check box, the system indicates that the components are teardown outputs on the BOM Maintenance Component Details page when you add or change components on a BOM. Note: This check box only affects teardown components with a source code of Make or Buy. If teardown components are selected on a BOM, the system copies the components to the output list when you create a teardown production order, based on the BOM code. |

Components Align with Revision |

Select to indicate that any component existing on a BOM for a revision-controlled assembly must be associated with one of the assembly revisions. This is the default setting, and it is the most common setting for revision-controlled environments. However, if the environment requires a change to the BOM structure without rolling the revision of the parent assembly, then deselect this option to enable you to do so. This can be required in outsourcing scenarios where you are the contract manufacturer and are required to adhere to customer-specified revision in manufacturing. When this option is deselected, you can introduce a new component against the current revision of the assembly as of the current date versus the start date of the current revision for the assembly. In this scenario, the components required to build the assembly for the revision-controlled item are based on the revision specified, including any additional component changes up to the date specified when creating the component list. Note: In addition to deselecting this option, you must also set the assembly item's business unit item-attributes manufacturing setting for BOM usage to By Effective Date so that new components for that assembly can be created for dates not associated with the assembly revision. |

Compl and Close Peg Qty Change

This group box controls how often pegging notifications are sent to a user or group of users when changes are made on a production ID. PeopleSoft Manufacturing has a number of common circumstances that could cause excessive pegging notifications to be generated. For example, normal scrap activity during the completions process could result in quantity reduction notifications. Completing serial controlled items would generate a receipt notification for every serialized item. The close process generates close notifications for every order closed.

PeopleSoft Manufacturing offers three options for controlling the number of pegging notifications generated during the completions and close processes:

Notify at Compl and Close: Enables all normal pegging notifications including order quantity changes and closing of production.

Notify at Close: Enables normal notifications in the production close process and suppresses order quantity change notifications during compl

No Notify at Compl or Close: Suppresses close notifications during the close process and suppresses quantity change notifications during completions.

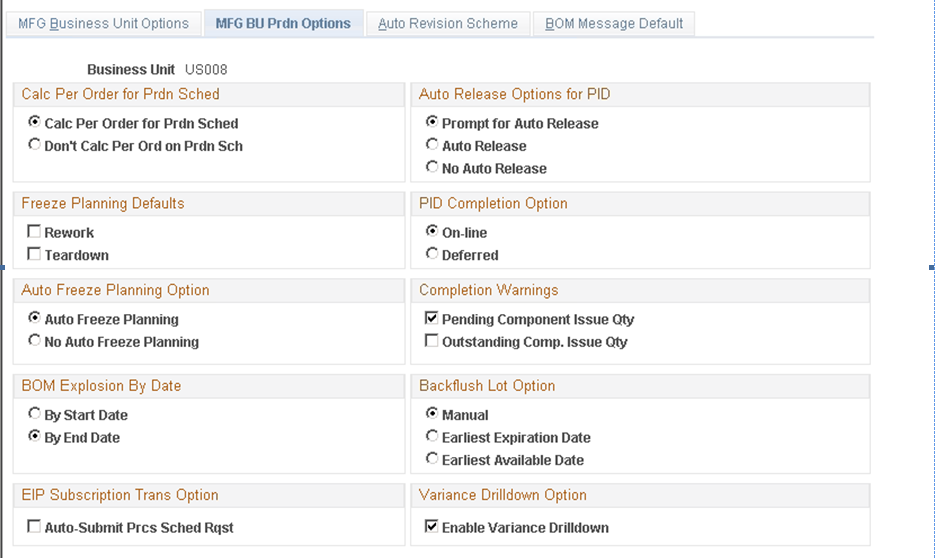

Access MFG BU Prdn Options page (Set Up Financials/Supply Chain, Business Unit Related, Manufacturing, Manufacturing Options, MFG BU Prdn Options).

This example illustrates the fields and controls on the Manufacturing Business Unit Production Options page. You can find definitions for the fields and controls later on this page.

Calc Per Order for Prdn Sched

Use the Calc Per Order for Prdn Sched (calculate per order for production schedule) group box to indicate if you want the system to update the pending issue quantity for any component on a production schedule's component list whose quantity is per order.

Select Calc Per Order for Prdn Sched if you want the pending issue quantity for a component set to the per order amount each time that you record a completion on a production schedule. This means that the per order quantity will be consumed from the work-in-progress (WIP) location with each backflush, unless you use the Edit/Issue Components page to zero-out the pending issue quantity.

Select Don't Calc Per Ord on Prdn Sched (don't calculate per order on production schedule) if you do not want the pending issue quantity automatically filled. Selecting this option means that you must use the Edit/issue Components page whenever the components order quantity should be consumed from the WIP location following a backflush.

Auto Release Options for PID

Use the Auto Release Option for PID to indicate how to you want to handle the releasing of production IDs on the shop floor for the manufacturing business unit. You can select from any of these options:

Field or Control |

Description |

|---|---|

Prompt for Auto Release |

The system prompts you to release the selected production ID (with a status of Entered or Firm) when recording completions, scrap, or editing components. Click Yes to automatically release the production ID and streamline the production process. Click No to select an alternate production ID if one was selected in error. |

Auto Release |

The system automatically releases selected production IDs with a status of Entered or Firmed from the Record Completions/Scrap and Edit Issue Components pages. You are not prompted to release the production ID. |

No Auto Release |

The system does not allow you to automatically release production. You must use the Production ID Status Change page or the Production Status Change page to release production for the manufacturing business unit. |

Freeze Planning Default

Use the Freeze Planning Default group box to indicate if new rework or teardown orders for this business unit should be frozen. The Planning engine does not reschedule frozen orders to repair capacity violations.

Select Rework to freeze all new rework orders.

Select Teardown to freeze all new teardown orders.

Note: The system creates new production orders in the unfrozen status.

Use Planning Attributes to override this default check box. You can also manually unfreeze an order in the Planning engine and rerun a solver to reschedule the order.

See Frozen Production.

PID Completion Option

Use the PID Completion Option group box to indicate when you want to run the completions process for the business unit. You can select one of these options:

Field or Control |

Description |

|---|---|

On-Line |

This option indicates that you process completions online. The update process runs immediately and calculates associated production costs—earned labor and machine hours, conversion codes, and overhead conversion costs. It also consumes components and routes completed material to storage locations or other production. |

Deferred |

This option indicates that you are running the completions process at a later time. All associated production costs are calculated when you run the Completions Update process. |

Auto Freeze Planning Option

You can set up the autofreeze planning option so that the system automatically freezes operations for production based on specified events in the manufacturing process. This enables PeopleSoft Supply Planning to reschedule production based on particular operations. You can also freeze or unfreeze operations manually while maintaining the operation list.

Select Auto Freeze Planning to have the system to freeze production operations when you've recorded any of these transactions for that operation:

Actual hours

Operation completions

Operation scrap

Setup complete

By-product or co-product completions

The system does not automatically freeze an operation if you've recorded material consumption for that order (issue, kit, or edit components) unless you've also recorded completions for that operation. Select No Auto Freeze Planning if you do not want the system to automatically freeze production operations.

Completion Warnings

Use these check boxes to indicate the situations in which warnings should be sent during the completions process:

Field or Control |

Description |

|---|---|

Pending Component Issue Qty |

Select this check box to send warnings if there are pending component issue quantities during a backflush. Pending quantities can be caused to incomplete lot IDs, negative quantities when the business unit does not allow negative quantities, or other causes. |

Outstanding Comp. Issue Qty |

Select this check box to send warnings if there are outstanding component issue quantities. This warning occurs if you are completing quantity at the last operation sequence and at least one component's total issue quantity is less than the scheduled quantity. |

These same fields are defined at the item-level of a production area using the Item Detail - Detail page (Production Control, Define Production, Production IDs/Schedules, Production Area, Item Detail, Detail).

BOM Explosion By Date

Field or Control |

Description |

|---|---|

By Start Date or By End Date |

Select to indicate whether the BOM explosion for creating a new production component list should be based on the production start date or end date. |

Backflush Lot Option

Use this group box to define the backflush lot selection rule at the business unit level. The backflush lot selection rule enables you to determine which lot IDs are selected for consumption when a backflush is performed for a production ID or production schedule. The option selected on this page can be overridden for an individual item within the business unit using the Define Business Unit Item - Manufacturing: General page.

The options for the backflush lot selection rule are:

Field or Control |

Description |

|---|---|

Manual |

(default) Select this option to require the user to enter the specific lot IDs consumed during backflushing. The system does not automatically select any lot IDs |

Earliest Expiration Date |

Select this option to have the system select the lot IDs for consumption based on the lot expiration date. The system first selects the lots with the earliest expiration date. |

Earliest Available Date |

Select this option to have the system select the lot IDs for consumption based on the lot available date. The system first selects the lots with the earliest available date. |

Note: Before changing the backflush lot selection rule, it is recommended that you process all pending transactions in the staging tables (BCT tables) that impact production completion. Changing the backflush lot selection rule can impact how these BCT transactions are processed.

See Automatically Consuming Lot-Controlled Stock During a Backflush.

EIP Subscription Trans Option

Select the Auto-Submit Prcs Sched Rqst check box to automatically launch the Completions Update (SFPDCDRV) process after the completion of the Inbound File Publish (EOP_PUBLISHF) process (with the file identifier MFG_PRODUCTION). However, running the Completions Update process after every completions inbound message can slow performance.

Deselect this check box if you want to run the Completions Update process at a later time. Use the Process Scheduler's scheduling functionality to determine when you want to run the Completions Update process.

Variance Drilldown Option

Select the Enable Variance Drilldown check box to capture detailed production variance data in the Production Variance Detail record (SF_VARS_DETAIL) ) and the Configuration Variance Detail record (SF_CFGVAR_DET ) during the Close Production process (SFS1100). Information about how production variances are calculated can then be viewed in the Production Variance Drilldown- Review Variances page (Production Control, Close and Analyze Production, Production Variance Drilldown). When applicable, the Reopen Production process (SFS1200) can reverse postings in the Production Variance Detail record and the Configuration Variance Detail record. In addition, after the Cost Accounting Creation process has been run, the Posted Variance Drilldown page (Cost Accounting, Inventory and Mfg Accounting, Analyze Production Costs, Posted Variance Drilldown) can be used to view the accounting lines related to the production variances. Links on both the Production Variance Drilldown – Review Variances page and the Posted Variance Drilldown page enable you to drill down into more detailed information or drill up into summary information.

Note: The Production Variance Detail record and the Configuration Variance Detail record can become large and require regular purging.

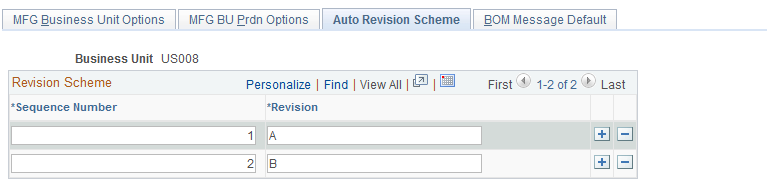

Use the Auto Revision Scheme page (EN_REVISION_SCHEME) to define automatic revision schemes at the manufacturing business unit level.

Navigation:

This example illustrates the fields and controls on the Manufacturing Options - Auto Revision Scheme page. You can find definitions for the fields and controls later on this page.

Note: This page is primarily intended for use during implementation of the system.

Revision Scheme

You generate automatic revisions by using the mass maintenance functionality. Before creating an automatic revision, however, the system must determine which scheme or sequence of revisions to use to create the next revision. On the Revision Scheme page, you create such a revision scheme by entering sequence numbers as well as an alphanumeric order for the revisions. The system uses this scheme to automatically increment sequenced assembly revisions. Each time new revisions are automatically generated, they follow the order defined in this list of sequenced revision names. For example, if the current revision for an item is C, then the next automatic revision will be D. If the current revision doesn't exist in the scheme, then the system creates the revision with the lowest non-existing sequence number. For example, if an item currently has revisions A, B, and X, then the next revision created for the item will be C.

You can insert interim revisions into the sequence scheme if needed. For example, if the sequence is 100, 110, 120, you can add a 115 between the 110 and 120 revisions. Changing the revision scheme does not update the sequence of revisions already in use on an item.

Note: You cannot enter duplicate sequence numbers or revisions numbers or letters. If you try to change or delete revision names that are already in use on a BOM, you receive a warning message.

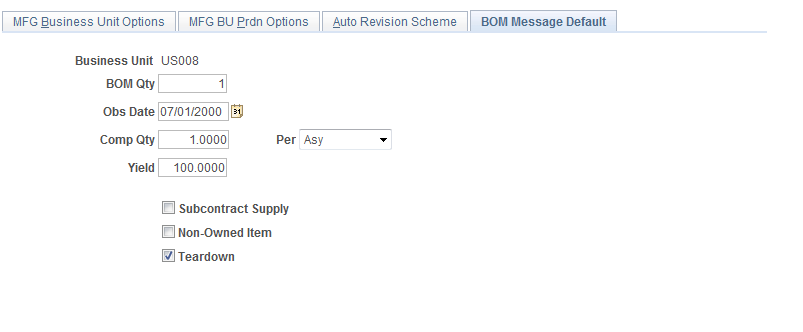

Use the BOM Message Defaults page (EN_BOM_MSG_DFLT) to set manufacturing business unit defaults for BOM messages received from a third-party product data management system.

Navigation:

This example illustrates the fields and controls on the Manufacturing Options - BOM Message Default page. You can find definitions for the fields and controls later on this page.

If you are using effectivity dates, enter the obsolete date for the components of the incoming BOM message.

Indicate the component quantity to assign to incoming BOM message components.

In the quantity Per field, enter whether you want the component quantity for incoming BOM messages to apply per assembly or per order. If you set the quantity per assembly—and when the system determines component requirements in PeopleSoft Supply Planning—the system divides the quantity-per by the BOM quantity and then multiplies that result by the demand or order quantity. If you set quantity Per field to Order, the system uses the quantity regardless of the demand quantity or order size.

Component yield is the expected percentage of usable components within a batch of components issued to production. If you know that components may be damaged during the issuing or assembly process, you can account for that loss here. Indicate the yield to be assigned to incoming BOM messages.

Select Subcontract Supply if you are subcontracting all or part of the manufacturing process and you want to assign this status to incoming BOM messages.

Select Non-Owned Item for incoming BOM messages if you do not own the component, and you want to indicate that the component is consigned to you or is supplied by a customer.

You can indicate if incoming BOM message components should be a potential output from a teardown order. When you select Teardown, the system designates the component as a teardown output.