Creating and Modifying Replenishment Requests

The Calculate Replenishment Parameters process (IN_RPL_PRM) computes item replenishment parameters such as reorder point, safety stock, and economic order quantity (EOQ). Each of these calculations is based on an item's average daily demand. All replenishment parameter calculations use the historical item demand for the calculation period. The results of the Calculate Replenishment Parameters process appear on the Setup Item Replenishment page. Fractional results will be rounded if the item's precision indicates whole numbers.

You can run either the IN Replenishment Options process (IN_REPLEN_AE) or the IN Replenishment multiprocess job (REPLN_AE) from the Create Replenishment Requests page.

The IN Replenishment Options process compares the available on-hand quantity, plus any on-order quantity, with the replenishment point set for each item and generates a replenishment request for any item with quantity equal to or below the reorder point.

The IN Replenishment multiprocess job (which includes the IN Replenishment Options process and the Fixed Bin Replenishment Notify process (IN_WFFBREPL)) works in conjunction with the Fixed Bin Replenishment workflow to transfer stock to fixed picking locations in which the item has fallen below the optimal quantity.

Note: Whether calculated by the Calculate Replenishment Parameters process or entered manually, replenishment parameters must be defined on the Setup Item Replenishment page before using the Create Replenishment Requests page to generate replenishment requests. Items that you want included must have a replenishment class assigned, and the Not Included In Replenishment option must be clear.

Important! To avoid duplicate replenishment requests, the Create Replenishment Requests process does not create a replenishment request if a previous replenishment request with a status of Ready already exists for the item, regardless of the reorder quantity. If you do not have PeopleSoft Purchasing installed, cancel these requests manually on the Manage Replenishment Requests page.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

REPLEN_PRM_REQ_INV |

Define options for the Calculate Replenishment Parameters process. |

|

|

REPL_OPT_REQ_INV |

Generate replenishment requests by specifying business unit and replenishment class and then running the Create Replenishment Requests process. |

|

|

REPLEN_REQUIST_INV |

Modify replenishment requests created by reorder point and ad hoc replenishment methods. |

|

|

Replenishment Requests Selection Page |

REPL_RQST_SRCH_INV |

Search for the replenishment requests that you want to review and modify by clicking the Search button on the Manage Replenishment Requests page or the Review Replenishment Requests inquiry page. |

|

Sort Page |

REPL_RQST_SORT_INV |

Sort returned replenishment requests by clicking the Sort Display link on the Manage Replenishment Requests page or the Review Replenishment Requests inquiry page. |

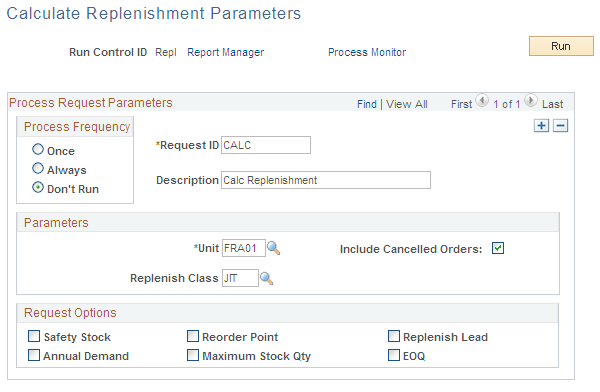

Use the Calc Replenishment Parameters page (REPLEN_PRM_REQ_INV) to define options for the Calculate Replenishment Parameters process.

Navigation:

This example illustrates the fields and controls on the Calculate Replenishment Parameters page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Replenish Class |

Enter a value to calculate the replenishment parameters for items belonging to a specific class. If this field is blank, the replenish lead time will be calculated for all items where the replenish class is not blank. For all other calculations, a blank replenish class on the run control page means to calculate for all items. |

Include Cancelled Orders |

Select to include canceled orders in the demand history calculations. |

Safety Stock |

Select to calculate safety stock levels. Safety stock is equal to the Mean Absolute Deviation Safety Stock (MAD_SFTY_STK) multiplied by the Replenishment Lead Time for the item (REPLENISH_LEAD). The safety stock calculation uses the window of time between today's date and today's date minus the replenishment calculation period. After you run the Calculate Replenishment Parameters process, the system determines the Average Demand (AVG_DEM_QTY) by taking the sum of the Actual Demand (SUM_DEM_QTY) and dividing it by the Replenishment Calculation Period (REPL_CALC_PERIOD) for the item. Next, the system loops through each day of the calculation period, sums the Actual Demand (DEM_QTY) for the day, and subtracts the Average Demand (AVG_DEM_QTY) to result in the mean absolute deviation as an absolute value (MAD_DELTA_QTY). The Actual Demand (DEM_QTY) is the Sum of Quantity Base for all orders for an item on a specific schedule date. Then the system adds all of the deviations: the sum of the average absolute deviation (MAD_SUM_QTY) is equal to the sum of the mean absolute deviations (MAD_DELTA_QTY). Finally, the formula for safety stock is applied as follows:

From the window of BETWEEN TODAY & TODAY − (REPL_CALC_PERIOD) AVG_DEM_QTY = SUM_DEM_QTY

/ REPL_CALC_PERIOD

This portion loops for every day in the window regardless of DEM_QTY = 0 MAD_DELTA_QTY = |DEM_QTY

− AVG_DEM_QTY|

MAD_SUM_QTY = MAD_SUM_QTY

+ MAD_DELTA_QTY

MAD_QTY = MAD_SUM_QTY

/ REPL_CALC_PERIOD

MAD_SFTY_STK = Z_VALUE

* MAD_QTY

SAFETY_STOCK = MAD_SFTY_STK

* REPLENISH_LEAD

|

Reorder Point |

Select to calculate reorder points for the business unit. The Calculate Replenishment Parameters process calculates reorder points as follows: ((sum of the demand during calculation period * lead time) / calculation period) + safety stock. |

Replenish Lead |

Select to calculate the business unit's replenishment lead time. The Calculate Replenishment Parameters process calculates replenishment lead time for all items except those that have an Under Initialization, Pending Approval, or Denied Approval status. The process averages the difference between an item's PO date and its subsequent put away date. The PO date is required for this calculation. If the transaction date is before the PO date, the transaction will be ignored by the replenish lead calculation. |

Annual Demand |

Select to calculate the annual demand for the business unit. PeopleSoft Inventory calculates this value as follows: Sum of the demand from (today's date less 365 days) through today's date. |

Maximum Stock Qty (maximum stock quantity) |

Select to calculate the maximum on-hand quantity for the business unit. This calculation is computed as follows: (average daily demand for calculation period * (lead time + calculation period)) + safety stock. |

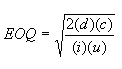

EOQ (economic order quantity) |

Select to calculate economic order quantities for the business unit This option will not be available if the EOQ option is not selected on the Setup Replenishment page. The Calculate Replenishment Parameters process calculates EOQ by using the industry standard calculation. In this formula, d equals the last calculated annual demand for an item, c equals order preparation cost of EOQ defined on the Setup Replenishment page, i equals annual inventory carrying cost percentage defined on the Setup Replenishment page, and u equals the item's standard or average cost, depending on the item's cost method. |

EOQ

Note: EOQ always calculates to zero unless the reorder point quantities option on the Setup Replenishment page is EOQ.

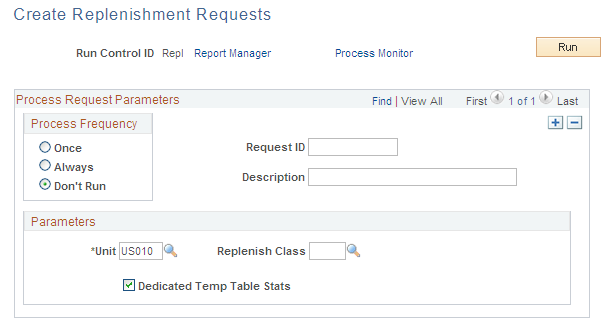

Use the Create Replenishment Reqs (AE) page (REPL_OPT_REQ_INV) to generate replenishment requests by specifying business unit and replenishment class and then running the Create Replenishment Requests process.

Navigation:

This example illustrates the fields and controls on the Create Replenishment Requests page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Replenish Class |

Enter a value to replenish items belonging to a specific replenishment class. Leave this field blank to replenish all items in the business unit that are marked for replenishment. Fixed bin replenishment ignores this field. |

Dedicated Temp Table Stats |

This process stores some of its temporary working data in dedicated temporary tables. This check box is defaulted to make it easier for database administrators to generate accurate table statistics for these types of tables. |

Use the Manage Replenishment Requests page (REPLEN_REQUIST_INV) to modify replenishment requests created by reorder point and ad hoc replenishment methods.

Navigation:

Field or Control |

Description |

|---|---|

|

Click to generate the Replenishment Register report, which lists all replenishment requests for the selected business unit. |

|

Change Status |

To change the status of all reorder point replenishment requests at once, select Canceled or Ready in the Replenish Status (replenishment status) field, then click this button. The PeopleSoft Purchasing Requisition Loader process does not pick up canceled replenishment requests. Note: The copy status feature does not change the status of ad hoc requests. |

User ID |

Because both reorder point and ad hoc replenishment requests are generated by PeopleSoft Inventory processes, the assigned user ID is SYSTEM. |

Source, Src BU, (source business unit) and Order No (order number) |

The default values come from the order that generated the ad hoc replenishment request. For reorder point replenishment requests, the location is the inventory business unit's location. |

Reorder Qty (reorder quantity) and Required By |

You can modify these fields before the system passes the information to PeopleSoft Purchasing. Note: If the business unit requires closure calendar validation and processing for receiving activities as defined on the Closure Calendar page, and you enter a required by date that is a defined closure date, you receive an error message. Click No to accept the closure date, or click Yes to reschedule. If you click Yes, the system returns the first valid future date defined for the function. |

Status |

Change the status of reorder point replenishment requests. Values are: Ready: The request is ready to be loaded into the PeopleSoft Purchasing system tables by the Requisition Loader process. Important! To avoid duplicate replenishment requests, the Create Replenishment Requests process does not create a replenishment request if a previous replenishment request with a status of Ready already exists for the item, regardless of the reorder quantity. If you do not have PeopleSoft Purchasing installed, cancel these requests manually on the Manage Replenishment Requests page. In Process: The request is currently being processed by the Requisition Loader process. Processed: The request has been moved into the PeopleSoft Purchasing system tables by the Requisition Loader process. Error: The Requisition Loader process found an error in the request that must be corrected before the request can be processed successfully. Canceled: The request was canceled manually and will not be picked up by the Requisition Loader process. Depending on the Request Cancel Method specified on the Setup Replenishment page, the system either deletes the request or leaves it in the system tables with a status of Canceled. If your installation does not include PeopleSoft Purchasing, the Create Replenishment Requests process deletes existing reorder point replenishment requests if the item no longer needs replenishment (regardless of the status). In this case, change the status to Canceled to delete the replenishment request, because the Request Cancel Method value on the Setup Replenishment page is always set to Delete. If PeopleSoft Purchasing is installed, the Requisition Loader process ignores previously processed replenishment requests; therefore, these requests do not need to be deleted. If PeopleSoft Purchasing is installed, the Create Replenishment Requests process might delete existing reorder point replenishment requests. If you change the status to Canceled, the order is either canceled or deleted, depending on the Request Cancel Method setting on the Setup Replenishment page. You can run purge routines to remove canceled replenishment requests from the system tables. |

Expected By and Required By |

The system calculates the expected by date by adding the replenishment lead days for the item (specified on the Setup Item Replenishment page) to the required by date. Note: If the business unit requires closure calendar validation and processing for receiving activities as defined on the Closure Calendar page, and the system encounters a closure date, it uses the previous valid receiving date to determine the required by date. |

Details |

Click to access the Maintain Requisitions page. |

Note: The display of fields on this page varies depending on the Reorder Quantity Option selected on the Setup Item Replenishment Page.

If the Reorder Quantity Option is Use Business Unit Default, the display of fields depends on the fields configured for the business unit on the Setup Replenishment Page.

Any change made to the item replenishment set-up will affect future transactions and will not have any retrospective effect on old replenishment records.