Entering Stockroom Feedback

When items are not put away according to the original putaway plan, use the Stockroom Feedback component to record what actually occurred in the stockroom.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

PUTAWAY_FEEDBK_INV |

Enter the actual putaway information when at least some items in a staging ID are not put away according to the original putaway plan. |

|

|

ChartField Overrides Page |

PUTAWAY_DETAIL_INV |

Override the credit accounting information for the received item. |

Use the Stockroom Feedback page (PUTAWAY_FEEDBK_INV) to enter the actual putaway information when at least some items in a staging ID are not put away according to the original putaway plan.

Navigation:

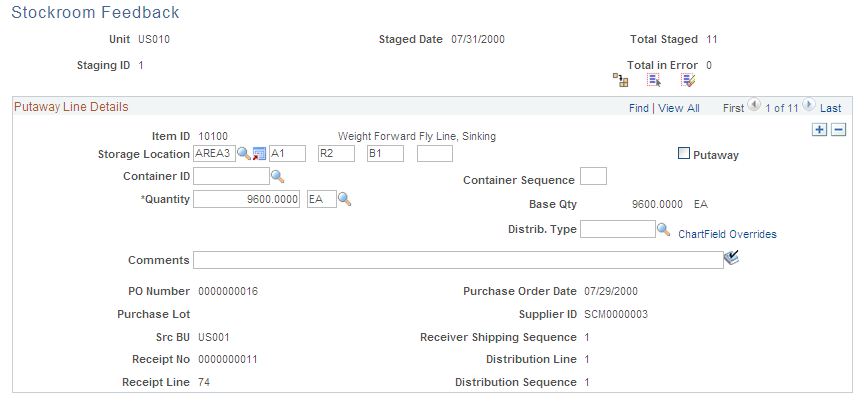

This example illustrates the fields and controls on the Stockroom Feedback page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Staging ID |

If Canceled appears after the staging ID, the items are the result of a canceled order that was picked but not shipped. If Short Shipment appears after the staging ID, the items are the result of a short shipment. In both cases, you must now put the items away again. |

Total Staged |

The number of items staged. |

Total in Error |

The number of items that were in error during the staging process. Staged items with errors do not appear on this page. |

Error Detail |

Click to access the Correct Staged Errors page, where you can correct staging errors. All staging errors should be corrected before you run the Complete Putaway process. If this link is not available, no errors need correction. |

Putaway Items |

Click to run the Complete Putaway process for all items in this staging ID that are ready to be put away. If you have not selected at least one row for putaway, the system issues an error. |

Select All and Deselect All |

Select or deselect the Putaway check box for all rows. |

Putaway Line Details

Field or Control |

Description |

|---|---|

Storage Location |

If the item was not stored in the location specified on the putaway plan, enter the correct material storage location. Note: The business unit's default display options determine how many location levels appear for new rows. If you are entering a material storage location that requires additional levels, enter the storage area, then refresh the page to display the remaining levels for that area. |

Putaway |

Select to indicate that the item was physically put away in the material storage location that appears. When you run the Complete Putaway process, the system updates the quantity for the location. |

Container ID and Container Sequence |

Enter a container ID to assign the item to a container. If you are assigning the item to an existing container, leave the Container Sequence field blank. If the business unit allows automatic generation of container IDs, you can assign multiple items to the same new container by defining the container ID as NEXT and entering a container sequence number. The system puts all items with the same container sequence into the same container. |

Lot ID |

Enter a lot ID if the item is lot-controlled. If the business unit does not allow the automatic addition of new lots, create the new lot before adding a lot ID here. |

Config Code |

Select the appropriate configuration code if the item is also configured. |

Serial ID |

If the item is serial-controlled, the assigned serial ID appears. This field is display-only and cannot be changed here. |

Quantity and Base Qty (base quantity) |

Enter the received quantity and select a stocking UOM. If the stocking UOM differs from the standard UOM, the system converts the entered quantity to the standard UOM and displays the base quantity. For serial-controlled items, the quantity must be 1 and the stocking UOM must be the same as the standard UOM. You cannot modify the UOM for serial-controlled items or for items staged from PeopleSoft Manufacturing. To split the item quantity across material storage locations, insert a line in the scroll area. The new receiving line displays the item data from the selected line with the quantity set to 0 and no material storage location information. To ensure that the Complete Putaway process works correctly, enter the second material storage location on the new receiving line and adjust the quantity on both rows before saving your changes. |

Distrib. Type (distribution type) |

You cannot change the distribution type for items staged from PeopleSoft Manufacturing. |

ChartField Overrides |

Click this link to access the ChartField Overrides page (PUTAWAY_DETAIL_INV) where you can override the credit accounting information for the received item. ChartField overrides are not available for interunit receipts or for items staged from PeopleSoft Manufacturing. |

Comments |

Enter a comment using up to 254 characters. These comments are informational only. |

PO Number, Purchase Lot, Src BU, Receipt No, Receipt Line, Purchase Order Date, supplier ID, Receiver Shipping Sequence, Distribution Line, and Distribution Sequence |

Displays values that come from a purchase order if the transaction source is Purchasing. Otherwise these fields are not displayed. |

Note: The Complete Putaway process can only be launched from the Stockroom Feedback page if you have specified a server name under Set Up Financials/Supply Chain, Common Definitions, User Preferences, Define User Preferences, Inventory.

Note: Because you use this page to provide feedback on what you have already stocked, you might receive warnings from PeopleSoft Inventory when you save the data on this page. For example, if you put an item into a material storage location that contains the identical item (including lot ID, serial ID, and staged date, if applicable) with an inventory status of Rejected, or if the putaway location is suspended or shut down for cycle counting, you receive a warning instead of an error.