Understanding Inventory Material Storage Structures

You can configure the system to reflect the physical layout of your warehouse and to establish rules governing the storage and movement of materials within the warehouse.

For each business unit, you define material storage locations made up of storage areas and storage levels. A material storage location is a division of a business unit used to store material and to track inventory transactions. Your material storage locations might include shipping and receiving docks, staging areas, warehouse zones, inspection areas, and quality control departments. Each material storage location contains a storage area that can be divided into a maximum of four levels, with each level representing a physical subdivision of the area. For example, you might have a three-level warehouse area consisting of 15 aisles, with 10 cabinets per aisle and 5 shelves per cabinet. The combination of a storage area and that area's most detailed storage level constitutes a material storage location. Each material storage location is identified by area and level.

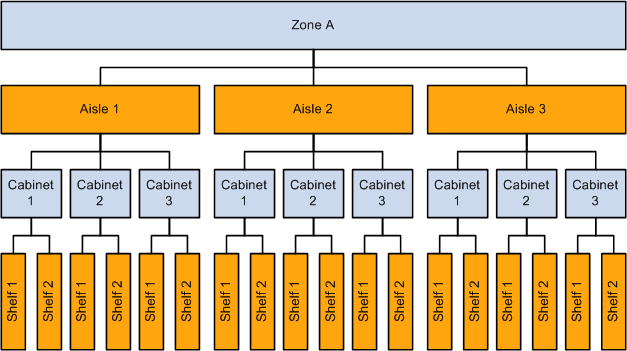

The following diagram illustrates the hierarchical relationship between material storage locations, storage areas, and levels. Zone A is the storage area. The aisles constitute level one, the cabinets constitute level two, and the shelves make up level three. The combination of storage areas and levels create a material storage location where stock can be placed or retrieved.

Establishing Storage Structures

You can design a different level structure for different areas of your warehouse; tailoring individual structures to fit business needs and the physical layout of your business unit. You might want a four-level structure for a primary storage area consisting of aisles, cabinets, shelves, and drawers, and a two-level structure for a staging area containing rows of pallets. In certain cases (if you have a bulk storage area containing only one item, for example), you might want to set up a material storage location with a storage area but no levels.

You define default material storage location attributes for a SetID on the Inventory Options page. You then define attributes for individual storage areas on the Storage Areas page and for material storage locations on the Material Storage Locations page.

Closing Storage Structures

When storage areas and material storage locations no longer physically exist in your warehouse, you can mark them for closure in the system records. The Closed check box, available on both the Storage Areas and Material Storage Locations pages, enables you to indicate that the structure is no longer active and is ready to be deleted from the system. To close an entire storage area, select the Closed check box on the Storage Areas page; when you save the page, PeopleSoft Inventory automatically closes all material storage locations defined with that area. To close a specific material storage location, use the check box on the Material Storage Locations page. You can also use the Select All and Deselect All buttons to mark all locations on the page as closed or to unmark all locations.

Important! Closure is permanent. After you save either page, you cannot reopen the closed storage structure. If you want to inactivate a material storage location temporarily, use the Suspend option.

The following conditions must exist before you can close a storage structure. If any condition is not met, PeopleSoft Inventory issues an error message and cancels the close.

For storage areas only, all material storage locations assigned to a storage area are empty (there is zero on-hand and zero reserved quantity in the PHYSICAL_INV record).

If the area is not empty and you want to close it, transfer all of the stock to another storage area.

For material storage locations only, the material storage location is empty.

If the material storage location is not empty and you want to close it, transfer all of the stock to another location.

The storage area or material storage location is not associated with a production area, production replenishment location for an item, or work center in PeopleSoft Manufacturing.

Before you can close the material storage location, you must use either the Production Area Summary page or the Defining Production Area/Item Detail page to disassociate the location from the production area.

There are no open transactions involving the area or material storage location.

No open transactions can exist in the following tables:

Manufacturing Production (SF_PRDN_AREA).

To avoid errors, use either the Production Area Summary page or the Item Detail page to disassociate the material storage location from the production area.

Data Collection Transaction (BCT_DTL).

To avoid errors, run all processes that affect the storage structure that you want to close.

Putaway Staging (STAGED_ITEM_INV and STAGED_INF_INV).

To avoid errors, run the Load Staged Items (INPSSTGE) and Complete Putaway (INPPPTWY) processes.

Purchasing Receipts (RECV_LN_ASSET).

To avoid errors, make sure no receipts have been assigned to the material storage location.

Shipments (IN_DEMAND tables).

To avoid errors, run the Deplete On Hand Qty (Depletion) process (IN_FUL_DPL).

Inventory Counts (COUNT_INF_INV and COUNT_INV).

To avoid errors, run the Stock Quantity Update process (INPOPOST) or cancel the open counting event.

Manufacturing Picking (SF_ISS_TRANSFER).

To avoid errors, use the Review Plan to remove the material storage location from any picking plans on which it appears.

Manufacturing Work Center (EN_WORK_CENTER).

To avoid errors, make sure that the material storage location is not designated as a work center WIP location. Use the Define Work Center page to disassociate the location from the work center.

When you close a material storage location that has been assigned as a default putaway, fixed picking, RMA, ship staging location, cross-docking, or pegging location, PeopleSoft Inventory issues a warning message and gives you the option of canceling the close. Once you save the close, the system automatically deletes the material storage location from all tables and issues a warning that you cannot reopen the location.

Closed storage areas and material storage locations do not appear as options on transaction pages, and you cannot perform transactions against them. You can, however, include them in the Inventory Purging process (IN_PURGE).

The PeopleSoft Inventory capacity-checking feature helps you manage storage capacity by identifying the best material storage locations for putaway transactions. In capacity-checking environments, transactions that update material storage location quantity balances also calculate and update the material storage location's current occupied capacity. For online transactions, the system issues a warning message if the transaction quantity exceeds the maximum capacity of the material storage location.

Note: For stock stored in containers, the capacity-checking calculations consider only the weight and volume of the stock occupying the container; they do not consider the container's weight and volume.

You activate cubic-capacity checking, weight-capacity checking, or both at the SetID level on the Inventory Options page; the options that you select become the default values for new material storage locations. You can deactivate capacity checking for individual material storage locations on the Material Storage Locations page. For example, although you might want to enable capacity checking for most locations, you should disable the feature for material storage locations with unlimited capacity (locations that are unlikely ever to be overfilled, such as staging locations).

Note: The system defines inspection locations as having unlimited capacity. You cannot activate capacity checking for material storage locations that are defined as inspection locations on the Material Storage Locations page.

You can always deactivate capacity checking for a given material storage location, but you can only activate it at the material storage location level if capacity checking is active for the SetID. Conversely, once capacity-checking storage locations are defined for a business unit, you cannot disable the feature at the SetID level until you disable it for all material storage locations in business units belonging to the SetID.

Weight Capacity Processing

Transactions that update a material storage location's weight capacity use the following processing steps:

Retrieve the weight established for the item.

Look first for the stocking weight defined on the Define Business Unit Item - Inventory: Weight/Volume page. If no weight is defined at this level, check for the stocking weight defined on the UOM Weight/Volume page, and finally for the stocking weight defined on the Define Item - General: Dimensions page. If there is still no weight information for the item, issue a warning that the weight cannot be calculated and checked against capacity.

Convert the item's weight to the unit of measure defined for the material storage location's weight on the Inventory Options page, using the conversion factor established on the Units of Measure page.

If no conversion factor exists, issue a warning that the weight cannot be calculated and checked against capacity.

Multiply the converted weight by the adjustment quantity and add the result to the occupied weight recorded for the location.

If the adjustment quantity for the material storage location is positive, compare the calculated weight with the maximum weight capacity established for the location on the Material Storage Locations page.

If the new occupied weight exceeds the capacity of the material storage location, issue a warning.

When saving the page, update the material storage location's occupied weight with the calculated weight.

Volume Capacity Processing

Transactions that update a material storage location's cubic capacity use the following processing steps:

Retrieve the item's height, length, and width.

Look first for the stocking dimensions defined on the Define Business Unit Item - Inventory: Weight/Volume page. If no volume is defined at this level, check for the stocking dimensions defined on the UOM Weight/Volume page, and finally for the stocking dimensions defined on the Define Item - General: Dimensions page. If there is still no volume information for the item, issue a warning that the volume cannot be calculated and checked against the cubic capacity.

Convert the item's dimensions to the unit of measure defined for the material storage location's dimensions on the Inventory Options page, using the conversion factor established on the Units of Measure page.

If no conversion factor exists, issue a warning that the volume cannot be calculated and checked against the cubic capacity.

Multiply the converted item dimensions by the adjustment quantity and add the result to the occupied volume recorded for the material storage location.

If the adjustment quantity for the material storage location is positive, compare result with the maximum cubic capacity calculated from the dimensions established for the location on the Material Storage Locations page.

If the new occupied volume exceeds the cubic capacity of the material storage location, issue a warning.

When saving the page, update the material storage location's occupied volume with the calculated volume.

Capacity Processing in Negative Inventory Environments

The occupied weight or volume of materials in a material storage location cannot be driven negative. In negative inventory environments, the system uses only the portion of the adjustment quantity that reduces the item quantity to zero to calculate the location's occupied weight or volume. For example, if you store 10 each of an item in a given material storage location and enter an adjustment for -12 each, the system uses -10 of each item to calculate the occupied weight or volume. Any transaction that drives the item quantity negative drives the occupied weight and volume for the material storage location to zero.

Online Capacity Recalculation

If you ignore warnings that capacity cannot be calculated because there is not enough data available to calculate weight or volume, the occupied weight and volume fields for the material storage location will not be accurate. If you supply the missing information (conversion factor, item weight, dimensions, and so forth) after the warning is issued, future transactions are accounted for correctly, but the occupied weight and volume of the material storage location does not reflect the transactions that occurred before the required data was available.

To update the capacity for the material storage location correctly, calculate the capacity online using the Volume/Weight Capacity Checking page. Select the Calc Capacity at save time (calculate capacity at save time) option, click OK, and then save the Material Storage Locations page.

Note: Each time you recalculate the occupied capacity of a material storage location online, you must select the Calc capacity at save time option. Once the capacity of the location is recalculated and updated, the system clears the check box.

To optimize material handling, prevent product contamination, and define dedicated areas of your warehouse, you may want to ensure that only one item ID is stored in a given material storage location. You can define single-item storage as an attribute of either the item or the material storage location.

You can specify on the Define Business Unit Item - Inventory: Shipping/Handling page whether an item should be isolated. Items marked for isolation can be put away or transferred only to empty material storage locations or to locations containing stock with the same item ID. Once stock marked for isolation has been transferred to an empty material storage location, you cannot use that location for stock with any other item ID until the quantity in the location has been fully depleted.

You can also use the Volume/Weight Capacity Checking page (accessed from the Material Storage Locations page) to restrict a material storage location to holding a single item ID. Specifying single-item storage as an attribute of the material storage location enables you to segregate items by location in one area of your warehouse, but store them together (in a kitted container for manufacturing, for example) in another area of the warehouse.

If you define single-item storage for a location, you can specify which item ID the location should contain. The system then permits only stock matching that item ID to be put away or transferred to the location. If you do not specify an item ID for a single-item material storage location, the first putaway or transfer transaction to the empty material storage location defines the only item ID that the location can contain until the item quantity has been fully depleted. After the material storage location has been emptied, stock with another item ID can be put away or transferred to the location.