Extracting and Reviewing Planning Violations

This topic provides an overview of planning violations.

|

Page Name |

Definition Name |

Usage |

|---|---|---|

|

SPL_DMD_VIOLATIONS |

Extract demand violations for orders pegged to low level orders with violations. |

|

|

PL_REVIEW_ERRORS |

Establish plan violation criteria and filters and retrieve violations that prevent a material or capacity plan from being feasible. |

|

|

PL_RVW_ERR_FILTERS |

Specify selection criteria to narrow the number of violations that the system displays on the Violations summary page. |

|

|

PL_RVW_ERR_ITEM |

Review violations for negative quantity on hand or safety stock. |

|

|

PL_RVW_ERR_DELAYED |

Review delayed demand violations for customer orders, transfers, and extra demand. |

|

|

PL_RVW_ERR_WC |

Review work center overload capacity violations. |

|

|

PL_RVW_ERR_SUPPLY |

Review violations related to unavailable supply for existing and planned demands. |

|

|

SPL_DMD_V_INQ_SRCH |

Specify search filters and retrieve violations generated by the Extract Demand Violations process. |

|

|

SPL_DMD_V_INQ_DTL |

Review violations for end demands and for planned transfers and production pegged to a lower level supply order with a violation. |

The Violations component displays violations within the planning instance that are visible to the planning solvers. Violations are available as realtime data, which requires that the planning instance be loaded into a planning engine at the time that violations appear (except at the end of a solver run, when you can generate a summary report for any remaining violations).

When accessing the Violations component, the system initially displays all of the violations. These are separated by planning object type on a summary page. Before filtering, the Filtered column totals on the Violations page match the column totals for each type of error. After you apply filtering criteria, the filtered count may be less than the total count. If you specify multiple filter criteria, the system includes only the violations that meet all of the filter criteria.

From the Review Planning Violations Summary page, you can navigate to access more detailed error information.

Delayed Demand

Delayed demand violations occur for end demands (forecasts, sales orders and material stock requests) that cannot be met on time. If you use the Material Solver, it schedules all end demands at their scheduled dates and therefore, never creates violations in the delayed demand violation section. Instead, all planning problems generated by the Material Solver are reported in the unfulfilled demand violations section.

If you use the Feasible Solver and want to view delayed demand violations, then you must select the Allow Rescheduling box on the Feasible Solver page. If you do not check the Allow Rescheduling box, the system will report all demand violations in the unfulfilled demand violations section.

Unfulfilled Demand

Unfulfilled demand violations occur for lower level demands (not end demands) on items that cannot be met on time. The system determines the unfulfilled demand error classification (production, purchase, or transfer) based on the default sourcing option that you select for an item. If you do not define a default option for an item, the system bases the unfulfilled demand error classification on the item's make or buy option.

The system orders demands for an item according to:

Demand date (earliest to latest).

Priority (highest to lowest).

Quantity (smallest to largest).

Sequence number (smallest to largest).

The system can filter to show all Unfulfilled Violations or consider Reschedule Tolerance and show demands not met by supplies within tolerance.

Extracting Higher Level Demand Violations

When you run a solver, the system automatically reports delayed and unfulfilled demand violations. However, if you use the Material solver or the planning instance contains frozen demands, you may need to extract higher level demand violations.

If you run the Material solver, it reports demand violations at the lowest level demand in the supply chain that has the violation and does not identify the higher level demands that are affected. For example, suppose you are building an assembly on a production order to fulfill a requirement from a sales order; and a purchase order for a component used to build the assembly is late. In this case, the system will report an unfulfilled demand violation for the component. It does not report a violation for the production order or the sales order.

To view violations for higher level demands, you must run the Extract Demand Violations process. After you run this process, you can view the demand violations in the Demand Violations component. The systems stores these violations and their associated orders in a table named SPL_VIOLATIONS. When you transfer the planning instance to PeopleSoft Supply Chain Management, the system also transfers the SPL_VIOLATIONS table so that you can exclude these orders from the commit process.

Use the Extract Demand Violations page (SPL_DMD_VIOLATIONS) to extract demand violations for orders pegged to low level orders with violations.

Navigation:

Note: You only need to run the Extract Demand Violations process if you want to view higher level demand violations in the Demand Violations component or if you want to identify higher level orders with demand violations when you commit planning updates. The system displays the information generated by this process in the Demand Violations component, not in the Violations component.

Field or Control |

Description |

|---|---|

Planning Instance |

Select the planning instance for which you want to extract demand violations. |

Start Planning Engine and URL |

Select to start the planning engine for the corresponding planning instance. If the planning engine is already running, the system ignores this option and uses the domain on which the planning engine is currently running. If you select Start Planning Engine and the planning engine is not currently running, the system starts the planning engine for the corresponding planning instance using the domain that you specify in the URL field. If you specify no domain, or if the planning engine fails to start on the domain that you specify in the URL field, the system uses the default URL that you define on the Planning Engine Domains page. |

Run |

Click to extract demand violations using the PeopleSoft Process Scheduler. |

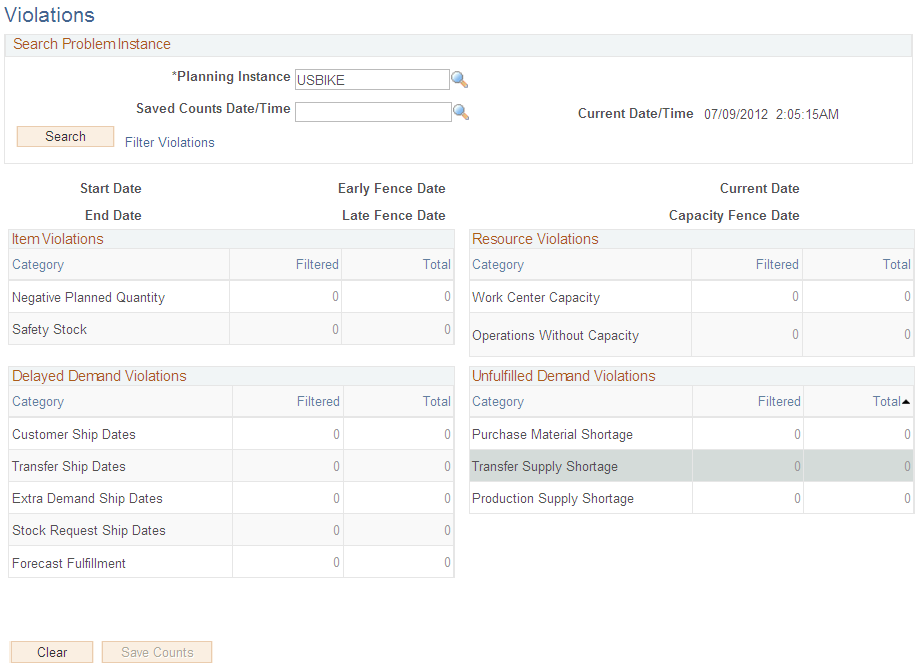

Use the Violations page (PL_REVIEW_ERRORS) to establish plan violation criteria and filters and retrieve violations that prevent a material or capacity plan from being feasible.

Navigation:

This example illustrates the fields and controls on the Violations Page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Saved Counts Date/Time |

Select a previously saved set of violation counts for review. You can save summary violation counts at any time, including before or after solver runs. When you save violation counts, the system retains the totals only. Additional details for saved counts are not available. |

Search |

Click to perform a new search using the filters that you defined. |

Filter Violations |

Click to access the Violations - Filter Violations page, where you can specify selection criteria to narrow the number of violations that the system displays on the Violations summary page. |

Start Date |

The beginning time boundary. Used with the end of time, this region defines the time period within which the system recognizes orders and changes. Solvers do not recognize times before the start of time. |

End Date |

The concluding time boundary. Solvers do not recognize orders or changes after this date. |

Current Date |

The current date and time for the planning instance. This fence is used to define various time offsets respected by the planning solvers. |

Early Fence Date |

The beginning time of the interval within which solvers process the elements of the material- and capacity-feasible plans and calculate constraint violations. |

Item Violations

Field or Control |

Description |

|---|---|

Negative Planned Quantity |

An item has a negative planned quantity on hand between the item's early fence and the late fence. The system calculates the violation if the item's histogram quantity falls below zero at any time between the current time and the late fence. Note: The system counts an item with negative planned quantity only once, even if the item has multiple occurrences of negative planned quantity on hand. |

Safety Stock |

The system generates a violation if an item has a planned quantity on hand below safety stock between the item's early fence and the late fence. Note: The system counts an item with stock violations only once, even if the item has multiple occurrences of safety stock violations. |

Delayed Demand Violations

Field or Control |

Description |

|---|---|

Customer Ship Dates |

The target ship date on a customer order cannot be met, and the order will ship late. The system generates a violation if the planned ship date is after the target ship date. |

Transfer Ship Dates |

The scheduled ship date on a transfer cannot be met and the transfer will be supplied late. The system generates a violation if the planned ship date is after the scheduled ship date. |

Extra Demand Ship Dates |

The target demand date on an extra demand required cannot be met and the extra demand will be supplied late. The system generates a violation if the planned schedule date is after the schedule ship date. |

Stock Request Ship Dates |

The target ship date on a material stock request cannot be met and the material stock request will be shipped late. The system generates a violation if the planned ship date is after the schedule ship date. |

Forecast Fulfillment |

A forecast demand cannot be met on the forecast date. The system generates a violation if the forecast demand has been canceled or satisfied at a later time. |

Resource Violations

Field or Control |

Description |

|---|---|

Work Center Capacity |

A work center is overloaded. The system generates a violation if the work center's aggregate utilization exceeds the resource aggregate capacity between the global early fence and the capacity fence. Note: The system counts a work center capacity violation only once, even if the work center has multiple periods where it is overloaded. |

Operations Without Capacity |

A production operation occurs at a work center for which the work center capacity has been exceeded. The system generates a violation only for production operations for which no or partial work center availability exists. For example, if an operation occurs in an overloaded capacity bucket and the operation only consumes available capacity, the system does not generate a violation. The system sorts which operation steps use the available capacity according to:

By sorting based on operation start date and time, the system first allocates available capacity to operations that may have started in a previous capacity bucket. |

Unfulfilled Demand Violations

Field or Control |

Description |

|---|---|

Production Supply Shortage |

Demand has no supply for items where the default sourcing option is a production option. The system generates a violation if the supply for any demand on an item (for which the default sourcing option is a production sourcing option) does not exist or would occur after the demand date. If an item has no default sourcing option, the system considers the sourcing type a production sourcing option if the item's make or buy option is Make. |

Purchase Material Shortage |

Demand has no supply for items where the default sourcing option is a purchase option. The system generates a violation if the supply for any demand on an item (for which the default sourcing option is a purchase sourcing option) does not exist or would occur after the demand date. If an item has no default sourcing option, the system considers the sourcing type a purchase sourcing option if the item's make or buy option is Buy. |

Transfer Supply Shortage |

Demand has no supply for items where the default sourcing option is a transfer option. The system generates a violation if the supply for any demand on an item (for which the default sourcing option is a transfer sourcing option) does not exist or would occur after the demand date. |

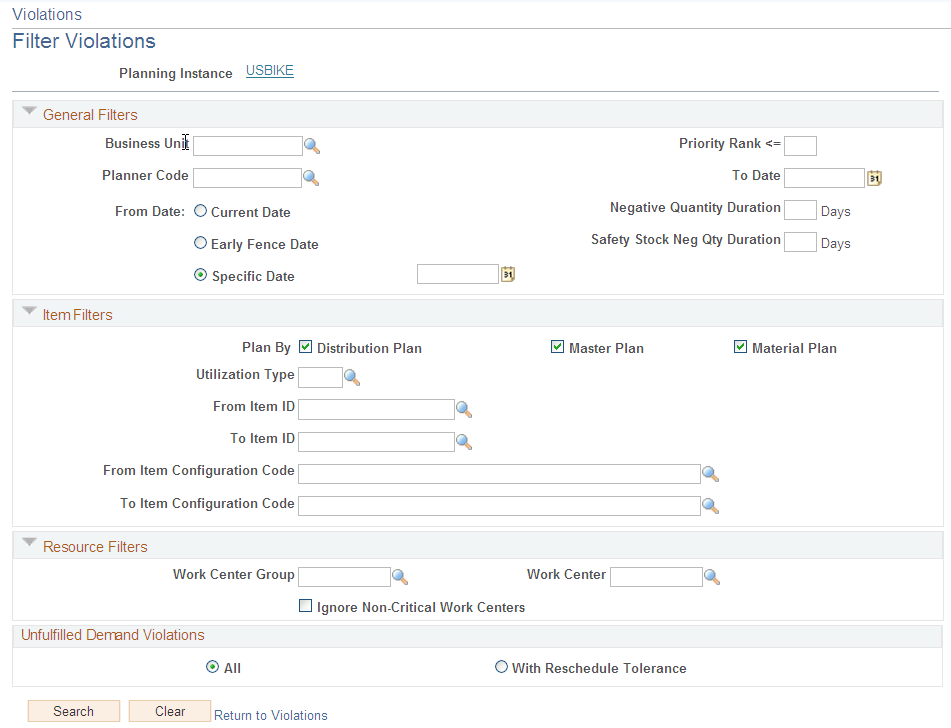

Use the Violations - Filter Violations page (PL_RVW_ERR_FILTERS) to specify selection criteria to narrow the number of violations that the system displays on the Violations summary page.

Navigation:

Click the Filter Violations link on the Violations page.

This example illustrates the fields and controls on the Filter Violations Page. You can find definitions for the fields and controls later on this page.

Field or Control |

Description |

|---|---|

Business Unit |

Select violations for the specified inventory business unit only. For interunit transfers, the system uses the source business unit. |

Planner Code |

Select violations for items associated with a specific planner code only. |

From Date and To Date |

Select violations in the date range specified only. For item violations and capacity violations, the system selects only those violations where the occurrence falls within the date range for the item. For delayed demands, the system selects violations only if the target ship date is in the date range. For unfulfilled demands, the system selects violations only if the demand date is in the date range. Define the from date as an early fence date, current date, or as a specific date. If you specify no date range, the system uses the late fence date as the to date when calculating for violations. |

Priority Rank |

Applies to unfulfilled demand violations and delayed demand violations only. Select violations if the item's demand priority rank is equal to or higher than the specified priority. Note: Small priority rank numbers (those numbers closer to zero) have higher demand priorities. |

Negative Quantity Duration |

Select only the negative quantity violations in which the duration is greater than or equal to the number of days specified in this field. |

Safety Stock Neg Qty Duration (safety stock negative quantity duration) |

Select only the safety stock violations in which the duration is greater than or equal to the number of days specified in this field. |

Planned By |

Select only those violations that are associated to items with these specified planned-by types: distribution plan, master plan, and material plan. |

Utilization Type |

Select only those violations with items that are associated with the utilization type. |

From Item ID and To Item ID |

Select only those violations with item codes in the specified range. |

From Item Configuration Code and To Item Configuration Code |

A non-active field that is related to a deprecated product. |

Work Center |

Select capacity violations that occur on the specified work center. The work center filter applies to operations without capacity and aggregate capacity violations only. |

Work Center Group |

Select capacity violations that occur on work centers in the specified work center group. The work center group filter applies to operations without capacity and aggregate capacity violations only. |

Ignore Non-Critical Work Centers |

Select the check box to ignore capacity violations for Non-Critical Centers. |

Unfulfilled Demand Violations

Field or Control |

Description |

|---|---|

All |

Shows all Unfulfilled Violations. This is the default selection. |

With Reschedule Tolerance |

Select to display Unfulfilled Violations, without considering demands which are satisfied by supplies within tolerance. |

Note: The system determines the aggregate capacity error total according to the total count in the Operations without Capacity Filtered column on the Violations page. For example, suppose that after applying the item filter, the operations without capacity all occur on the same work center (and the total in the corresponding Filter column equals 1), then the work center capacity total error count equals 1.

Field or Control |

Description |

|---|---|

Return to Violations |

Click to return to the Violations page without performing a search. |

Search |

Click to apply the filtering criteria and review the results on the Violations page. |

Clear |

Click to delete all of the previously entered filter criteria. |

Use the Violations - Item Violations page (PL_RVW_ERR_ITEM) to review violations for negative quantity on hand or safety stock.

Navigation:

Click any amount total in the Filtered or Total column in the Item Violations group box on the Violations page.

Field or Control |

Description |

|---|---|

Item ID |

Click any value in this column to access the Material Workbench - Summary page, where you can analyze the material plan for the item and resolve item violations manually. |

First Violation Date |

Displays the date that the first shortage or safety stock violation occurs. |

First Duration (Days) |

Displays the number of days the first error is in violation. |

First Shortage Quantity |

Displays the shortage quantity (the maximum deviation from the safety stock level) when the first violation occurs. |

Maximum Shortage Quantity |

Displays the maximum deviation from the safety stock level for the item. |

Use the Violations - Delayed Demand Violations page (PL_RVW_ERR_DELAYED) to review delayed demand violations for customer orders, transfers, and extra demand.

Navigation:

Click any amount total in the Filtered or Total column in the Delayed Demand Violations group box on the Violations page.

Common Information

Field or Control |

Description |

|---|---|

Order |

Displays the order number. For example, depending on the order type, this field might display a sales order number, quote number, or buying agreement number. Click any value in this column to access the corresponding Refine Plan Details page for the order type. For example, suppose that the order type is Material Stock Request, you can click the order ID value to access the Refine Plan - Stock Requests page, where you can maintain information about internal and external demand orders on an inventory business unit, such as planning parameters, dates, and quantities. |

Order Tab

Select the Order tab.

Field or Control |

Description |

|---|---|

Order Type |

Displays the type of demand for the corresponding item. |

Planning Start Date/Time |

Displays the current date PeopleSoft Supply Planning intends to ship the order. |

Original Start Date/Time |

Displays the date and time the transaction system intended to ship the order. |

Details Tab

Select the Details tab.

Field or Control |

Description |

|---|---|

Demand Quantity |

Displays the demand quantity for the corresponding order line. |

Priority Rank |

Displays a numeric value ranging from 1 (highest priority) to 999 (lowest priority) used by the planning engine to determine the order in fulfilling the demand. The system reserves 0 as a priority value. |

Customer Tab

Select the Customer tab.

Field or Control |

Description |

|---|---|

Ship To Customer |

Displays the customer ID that identifies where the order is to be shipped. The customer name appears in the adjacent field. |

Use the Violations - Resource Violations page (PL_RVW_ERR_WC) to review work center overload capacity violations.

Navigation:

Click any amount total in the Filtered or Total column in the Resource Violations group box on the Violations page.

Field or Control |

Description |

|---|---|

Work Center |

Click any work center ID in this column to access the Capacity Workbench, where you can analyze the capacity plan and resolve capacity violations manually. |

First Period Start Date/Time |

Displays the starting date of the period with the first capacity overload occurrence. |

First Overloaded Quantity |

Displays the overload amount for the first capacity overload occurrence. |

Buckets Overloaded |

Displays the number of buckets with capacity overloads. |

Maximum Overloaded Quantity |

Displays the maximum overload amount for the capacity planning period. |

Use the Violations - Unfulfilled Demand Violations page (PL_RVW_ERR_SUPPLY) to review violations related to unavailable supply for existing and planned demands.

Navigation:

click any amount total in the Filtered or Total column in the Unfulfilled Demand Violations group box on the Violations page.

Common Information

Field or Control |

Description |

|---|---|

Order Type |

Displays the type of demand for the corresponding item. |

Order |

Displays the order number. For example, depending on the order type, this field might display a sales order number, quote number, or buying agreement number. Click any value in this column to access the corresponding Refine Plan Details page for the order type. For example, suppose that the order type is Material Stock Request, you can click the order ID value to access the Refine Plan - Stock Requests page, where you can maintain information about internal and external demand orders on an inventory business unit, such as planning parameters, dates, and quantities. |

Order Tab

Select the Order tab.

Field or Control |

Description |

|---|---|

Operation Sequence |

Displays where you need components in the manufacturing process. PeopleSoft Production Management uses the work center associated with each operation and the WIP location associated with each work center to determine where to deliver components. The component's issue method in combination with the operation sequence determines when and where the material is delivered. It determines how the system updates inventory in the WIP location, as well as the quantity issue on the component list. When the operation sequence is set to zero or an invalid operation sequence is specified, it is assumed that the component item is to be used for the first operation. |

Details Tab

Select the Details tab.

Field or Control |

Description |

|---|---|

Demand Quantity |

Displays the demand quantity for the corresponding order. |

Priority Rank |

Displays a numeric value ranging from 1 (highest priority) to 999 (lowest priority) used by the planning engine to determine the order in fulfilling the demand. The system reserves 0 as a priority value. |

Ship To Customer |

Displays the customer ID to which the order is shipped. The customer name appears in the adjacent field. |

Use the Demand Violations Search page (SPL_DMD_V_INQ_SRCH) to specify search filters and retrieve violations generated by the Extract Demand Violations process.

Navigation:

Supply Planning, Solve Plan, Analysis, Demand Violations

Field or Control |

Description |

|---|---|

Planning Instance |

Select violations for the specified planning instance. |

Business Unit |

Select violations for the specified inventory business unit only. For interunit transfers, the system uses the source business unit. |

Item ID |

Select violations for the specified item ID only. |

Planner Code |

Select violations for items associated with a specific planner code only. |

Configuration Code |

A non-active field that is related to a deprecated product. |

Planned By |

Select only those violations that are associated to items with these specified planned-by types: distribution plan, master plan, and material plan. |

Start Date and End Date |

Select violations in the date range specified only. The system selects violations only if the planning date is in the date range. If you specify no end date, the system uses the late fence date as the end date when searching for violations. |

Family |

Select violations for the specified item family only. |

Utilization Type |

Select only those violations with items that are associated with the utilization type. |

Category |

Select violations for the specified item category only. |

Search |

Click to apply the filtering criteria and review the results on the Demand Violations Detail page. |

Clear |

Click to delete all of the previously entered filter criteria. |

Order Type Filters |

Indicate whether you want to include violations that pertain to these orders types: sales orders/quotes, purchases, production, transfers, buying agreements, planned purchases, planned production, planned transfers, forecasts, stock requests and extra demand. |

Use the Demand Violations Detail page (SPL_DMD_V_INQ_DTL) to review violations for end demands and for planned transfers and production pegged to a lower level supply order with a violation.

Navigation:

Click Search from the Demand Violations Search page.

Note: You must run the Extract Demand Violations process before you can view information in the Demand Violations Detail page. If you make manual changes to the plan or run a solver after you initially run the Extract Demand Violation process, you should rerun the Extract Demand Violation process.

Note: The demand violations displayed by the system are potential problems in the plan. The Extract Demand Violations process uses a first in, first out sorting order for supplies and demands. Therefore, if you allocate supply using a priority scheme, the displayed demands with violations may not be the actual demands affected by the lower level supply problem.

Common Information

Field or Control |

Description |

|---|---|

Planning Due Date/Time |

Displays the planning due date/time of the order. |

Business Unit |

Displays the business unit for the order. For interunit transfers, the system uses the source business unit. |

Order Type |

Displays the type of demand for the corresponding item. |

Order |

Displays the order number. For example, depending on the order type, this field might display a sales order number, quote number, or buying agreement number. Click any value in this column to access the corresponding Refine Plan Details page for the order type. For example, suppose that the order type is Stock Request, you can click the order ID value to access the Refine Plan - Stock Requests page, where you can maintain information about internal and external demand orders on an inventory business unit, such as planning parameters, dates, and quantities. |

Line |

Displays the line, schedule and kit number for a sales order or buying agreement. For a stock request or a transfer, the system displays "IN" followed by the line, schedule and demand line number. |

Order Tab

Select the Order tab.

Field or Control |

Description |

|---|---|

Show Supply |

Click to access the corresponding Show Supply page, where you can view a list of orders, the outputs of which are used to satisfy the demands of the selected order. |

Show Demand |

Click to access the corresponding Show Demand page, where you can view a list of orders that use the items supplied from the selected order. |

Violations Count |

Displays the number of violations for lower level supply orders that are pegged to the order. |

Item Tab

Select the Item tab.

Field or Control |

Description |

|---|---|

Item ID |

Displays the item ID associated with the violation. |

Description |

Displays the description for the item ID. |

Configuration Tab

Select the Configuration tab.

Field or Control |

Description |

|---|---|

Configuration Code |

A non-active field that is related to a deprecated product. |