Understanding Control Plans

Control plans identify specific quality control points or processes and provide an overall structure for data collection, reaction, and analysis. Control plans comprise these features:

Specific hierarchy field definitions that identify the process.

Measurement plans containing the characteristics that you want to monitor.

Attribute codes within categories to facilitate data annotation within reaction plans.

Traceability information for use in tracking and identifying product variation.

(Optional) Control limits that are used to maintain a predetermined level of process control.

Use the following steps to begin online quality data collection and control:

Establish a Quality business unit.

Create the quality function.

Define measurement plans.

Create the control plan.

Establish the relationship between each component so that you can record inspection data in the quality control environment.

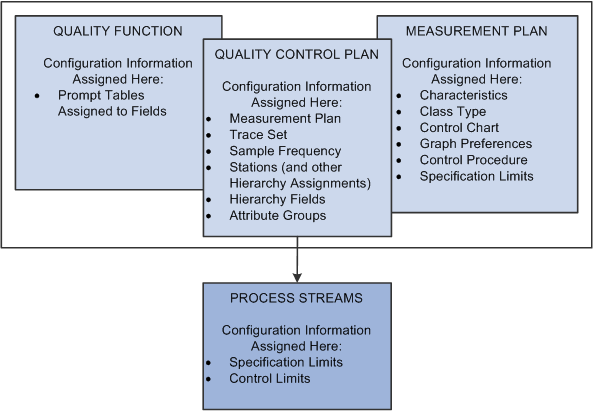

PeopleSoft Quality Control Plan Configuration

This diagram illustrates the Quality control plan configuration using a quality function, measurement plan, and control plan:

This diagram illustrates the Quality control plan configuration.

Quality Functions

A quality function is a set of fields that identify nonparametric information and map process-specific field information into Quality for process identification, data tracking, and analysis. Hierarchy fields define the actual process—stream—against which you collect and monitor data. Trace fields make it possible to collect associated information that is used for tracking purposes.

Measurement Plans

Measurement plans group characteristics that are used as quality indicators for a given process. Establish specific control methods, such as sampling, charting, and testing criteria, at this level.

Control Plans

The control plan brings together application, measurement, and control and response criteria for a specific product or process. PeopleSoft refers to a unique combination of hierarchy fields and a measurement plan as a control plan. The combination of fields and characteristics within the measurement plan is called a process stream. To this point, all elements of configuration that you establish are not yet applied to a specific process. The control plan provides the remaining element of configuration, defining the process and applying methods of inspection and control to that process.

When defining a control plan, you:

Reference a quality function to enter specific hierarchy field definitions that identify the process.

Assign a measurement plan to each individual hierarchy field combination.

Each characteristic that is associated with the plan then becomes a process stream with its own associated details.

Determine the method for data entry for each individual characteristic.

You can record data by subgroup or by sample for each characteristic.

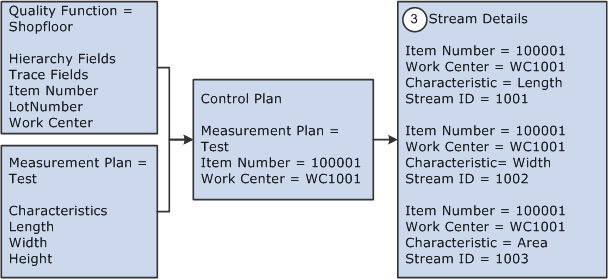

Relationship Example

This diagram illustrates the relationship between a quality function, measurement plan, and control plan within a quality configuration.