Understanding Bills of Material for Style Items

A bill of material defines all the components that are included in the manufacture of a style item. For style items, you define the bill of material for the style item root level 0. The bill of material for the style item root level 0 cascades down to the lowest-level child style items.

Style items are multilevel items with complex bills of material, for example, 100 styles with 5 colors, 5 sizes, and 3 fits creates 7500 child style items. Each child style item has a different bill of material because the components are based on attributes, such as size and color. Thus, one style can have 75 different bills of material.

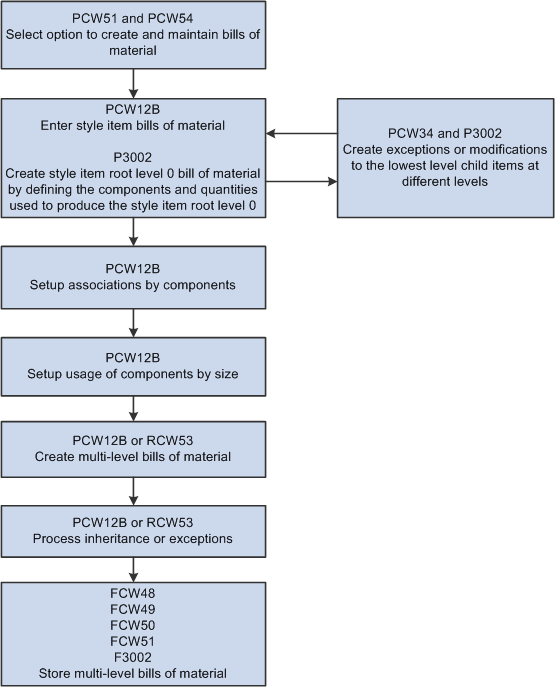

When defining the bill of material for the style item root level 0 for the first time, you must use either the Style Item Master program (PCW51) or the Collection Item Master program (PCW54). The Style Item Master and Collection Item Master programs provide access to the Bill of Material for Style Items program (PCW12B), which in turn calls the Bill of Material Revisions program (P3002) for bill of material entry and update.

The Bill of Material for Style Items program enables:

-

Creation of the style item root level 0 bill of material.

-

Generation of multilevel inheritance and exceptions.

-

Association of components based on attributes.

-

Definition of usage of quantities for the components based on sizes.

-

Copying a bill of material.

You can create bills of material for child style items on demand using the Bill of Material for Style Items program (PCW12B) or by batch using the Create BOM for Child Style Items program (RCW53).

The system provides visual assistance on the Work With Bill of Material for Style Items form (WCW12BA) as color coding in the column headings. The color of the column headings changes according to the following statuses:

-

Blue is status 0.

The color is blue after you create the bill of material for the style item root level 0 or any level of the style item but you have not yet created bills of material for the child style items.

-

Red is status 2.

The color is red after you make changes to the bill of material for the style item root level 0 or any level of the style item without re-creating the bills of material for the child style items.

-

Black is status 9.

The color is black when all updates to the bill of material for the style item root level 0 or any level of the style item have been proliferated to the child style items.

The system stores bill-of-material information for style items in the Bill of Material Association Header (FCW48) and Bill of Material Association Detail (FCW49) tables. The Bill of Material Master File table (F3002) is also populated with the multilevel bills of material.

This diagram illustrates the on-demand bill-of-material creation process for style items:

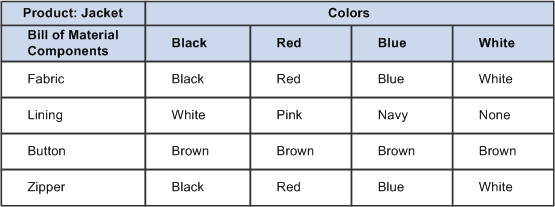

When creating the bill of material, you enter the components that you need without accounting for an attribute such as color. An example is a jacket that is made of fabric, a zipper, and a lining.

You then further define the bills of material by creating component associations, which is an automated process to:

-

Associate colors of components with style items.

-

Associate sizes of components with style items.

The system supports 9 levels of associations and up to 30 values. You use the Bill of Material for Style Items program to define associations. The bill of material associations are stored in the Bill of Material Association Matrix table (FCW50).

You associate the bill of material with colors, such as black fabric, black lining, and black zipper. This diagram shows an example of color associations for a bill of material:

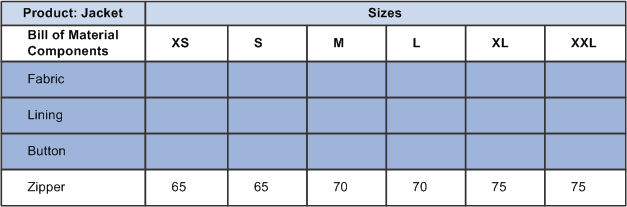

You can also associate the size of components with style items. This diagram shows an example of size associations for a bill of material:

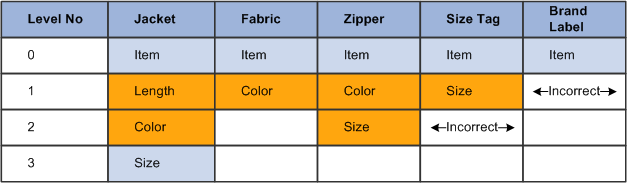

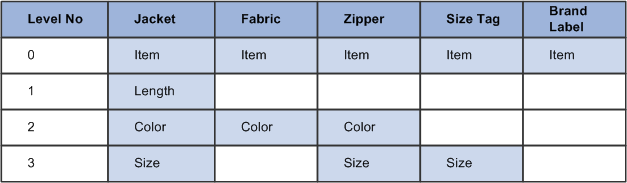

Bill of material associations cannot be made based on level numbers. This diagram illustrates the errors that occur when you attempt to create associations by level number:

Bill of material associations must be based on column position. This diagram illustrates associations by column position:

See Working with JD Edwards EnterpriseOne Inventory Management for Apparel Management.

When you enter the quantity for components on the bills of material, you enter the quantity that is used for the majority of the bills of material. The bills of material for the lower-level child style items inherit the associations from the style item root level 0. Once you generate bills of material for the lowest-level child style items, you can use the Bill of Material Exception program (PCW34) to define exceptions at the desired level of the style item's bill of material. For example, an exception might be a different quantity of fabric based on size, a blue skirt with a black button, or using a 1/2 cm size button on a size extra small (XS) skirt.

After associations are created, you define usage. In usage, you define the quantity of components based on style item size and not by level in the style item structure. For example, component quantity is associated with sizes such as extra small (XS), small (S), and such. The quantity entered for the style item root level 0 is the default value for usage, but you can override the values. The bill of material usage is stored in the BOM Usage table (FCW51).

The style item root level 0 is always passed from the entry points of the Style Item Master (PCW51) and Collection Item Master (PCW54) programs to the Bill of Material for Style Items program, regardless of the level from which it was called. You use the Bill of Material Exception program to select the level of the style item to modify. The system also supports the use of substitute items.

You can run the Create BOM for Child Style Items program (RCW53) in batch to create the BOMs for the lowest-level child style items.

The creation of BOMs for child style items is different than the item creation process for style items. When you create BOMs for style items, the system creates BOM records for the lowest-level child style items only. The system does not create a BOM for items at an intermediate level because BOMs are not needed for intermediate-level style items. You can use the Bill of Material Exception program to create a BOM for an intermediate-level style item. The system uses the BOM of an intermediate-level style item to track exceptions to apply to lower-level style items.

In the manufacture of some style items, not all components are on the bill of material. For example, in the apparel industry, thread is generally not part of the bill of material. Thread is considered as a base foundation item and is purchased in bulk.

The bill of material is used to derive the cost of the style items. The JD Edwards EnterpriseOne Apparel Management system uses the base manufacturing cost functionality in Oracle's JD Edwards EnterpriseOne Product Costing and Manufacturing Accounting systems in the JD Edwards EnterpriseOne Manufacturing and Supply Chain Management suite from Oracle.

To maintain bills of material for style items, Oracle recommends that you perform maintenance through the Style Item Master and Collection Item Master programs to enable inheritance and maintain links between parent and child style items

When you copy a bill of material that already has multilevel bill-of-material definitions, the system copies the definitions for levels other than level 0. When you copy a style item with a different item structure, the system automatically disables the Copy associations and usages option and copies only the FCW48 and F3002 records.

When you delete a bill of material at the parent level, the Bill of Material for Style Items program deletes all records for the style item root level 0 and child style items from the FCW48, FCW49, FCW51, and F3002 tables. You use the Create BOM for Child Style Items program for both the deletion and creation of bills of material. When deleting bills of material, you define a version of the Create BOM for Child Style Items program in the processing options of the Style Item Master program. The version of the Create BOM for Child Style Items program defined in the Style Item Master program must have a specific data selection set.