Understanding Outsource Operations for Style Items

The JD Edwards EnterpriseOne Apparel Management system enables the use of outside operations in which a particular operation is outsourced to a vendor. The outsource operation is for a service. For example, manufacturers in the apparel industry might outsource such manufacturing tasks as dyeing, cutting, and sewing.

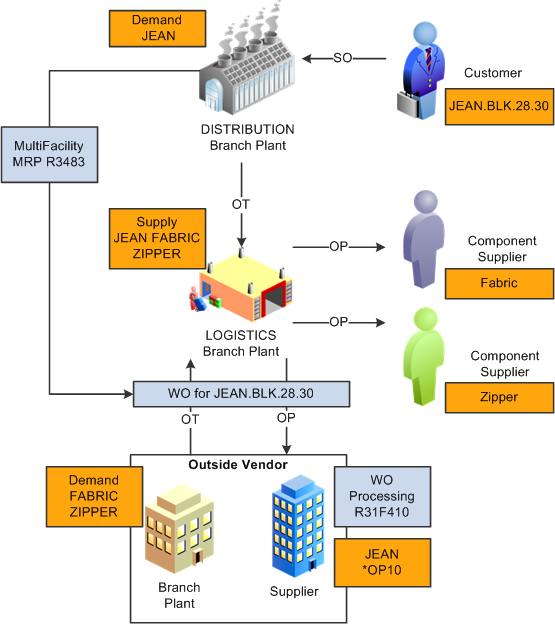

This diagram illustrates the outsource operations process for style items:

A specific operation sequence in the routing instructions is identified as an outside operation. For example, if routing sequence 10 of style item JEA301 is defined as an outside operation, then the system creates style item JEA301*OP10. Both the stocking type and line type for style item JEA301 are set to X (outside processing).

After defining the routing steps, the system creates the required documents, such as a purchase order, for the outside operations.

Each time a new vendor or style item is set up, you must complete setup activities such as creating all style items, bills of material, routings, prices, cost records, and branch/plant relationships. To enable outsourcing of style items, the system:

-

Creates and maintains the *OP item.

-

Copies bills of material and routings.

-

Creates Item Branch/Plant records for the style item root level 0, all child style items, and all components.

-

Updates the item supplier and country of origin.

You use the Exchange Rates for Style Item Outsource Operations program (PCW62) to define exchange rates between currencies for style items. The value in the From Currency Code field on the Exchange Rates for Style Item Outsource Operations Detail form is the default value from the Currency Code From processing option.

You use the Create Outsource Operation Details for Style Items program (PCW93) to create the outside operations for style items by copying from a source branch/plant to a target branch/plant. The Source Branch/Plant field represents the logistics branch/plant. The Target Branch/Plant field represents the outside vendor to perform the outside operations.

The Create Outsource Operation Details for Style Items program copies and creates a *OP outside operation for the target branch/plant only if an outside operation is in the source branch/plant. If the Job Type field on the routing instruction for the outside operation is blank, then no routing is created. Also, the code in the Outsource Operation Code field on the Style Item Outsource Operation Details form and the code in the Job Type field in the routing instruction must match. If the codes do not match, then the system does not create the *OP items. The system does not display an error message.

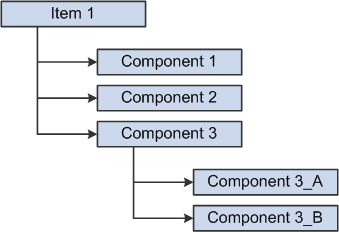

If you leave the Multi Level BOM processing option on the Process tab of the Create Outsource Operation Details for Style Items program blank, then the system copies the multilevel bill of material for the style item. However, the system does not copy the bills of material for the components of the style item that was copied. For example, a style item has the following bill of material:

Item 1 has a bill of material consisting of Component 1, Component 2, and Component 3. Component 3 has a bill of material consisting of Component 3_A and Component 3_B. Item 1 and Component 3 are style items with lower-level child style items.

On the Process tab of the Create Outsource Operation Details for Style Items processing options, the Bill of Material processing option is left blank to process bills of material and the Multi Level BOM processing option is left blank to process multilevel bills of material.

When the Create Outsource Operation Details for Style Items program processes Item 1, the system copies the bill of material of Item 1 from the source branch/plant to the target branch/plant. It also copies the child style item records of Item 1 from the source branch/plant to the target branch/plant. The system copies only Component 1, Component 2, and Component 3 in the bill of material.

The system does not copy the bill-of-material records for the child items of Component 3 to the target branch/plant. If you want the bill of material records for Component 3, then you must run the Create Outsource Operation Details for Style Items program to copy the Component 3 records to the target branch/plant.

The Copy to Outsource Operation Details for Style Items program (RCW93) enables you to create outside operation items (*OP items) for style items along with item cost, item price, and item location. The Copy to Outsource Operation Details for Style Items report prints the No Data Selected message on the report if no records exist in the FCW93 table corresponding to the data selection.

The Work Order Processing for Style Items program (R31F410) creates outside operation (*OP) purchase orders if the system is setup to automatically create the purchase orders.

The manufacturer sends the work to the outside vendor and the vendor completes the work and sends it back to the manufacturer. The outsource work is applied to internal work orders.