Use Maintenance Schedule Optimizations

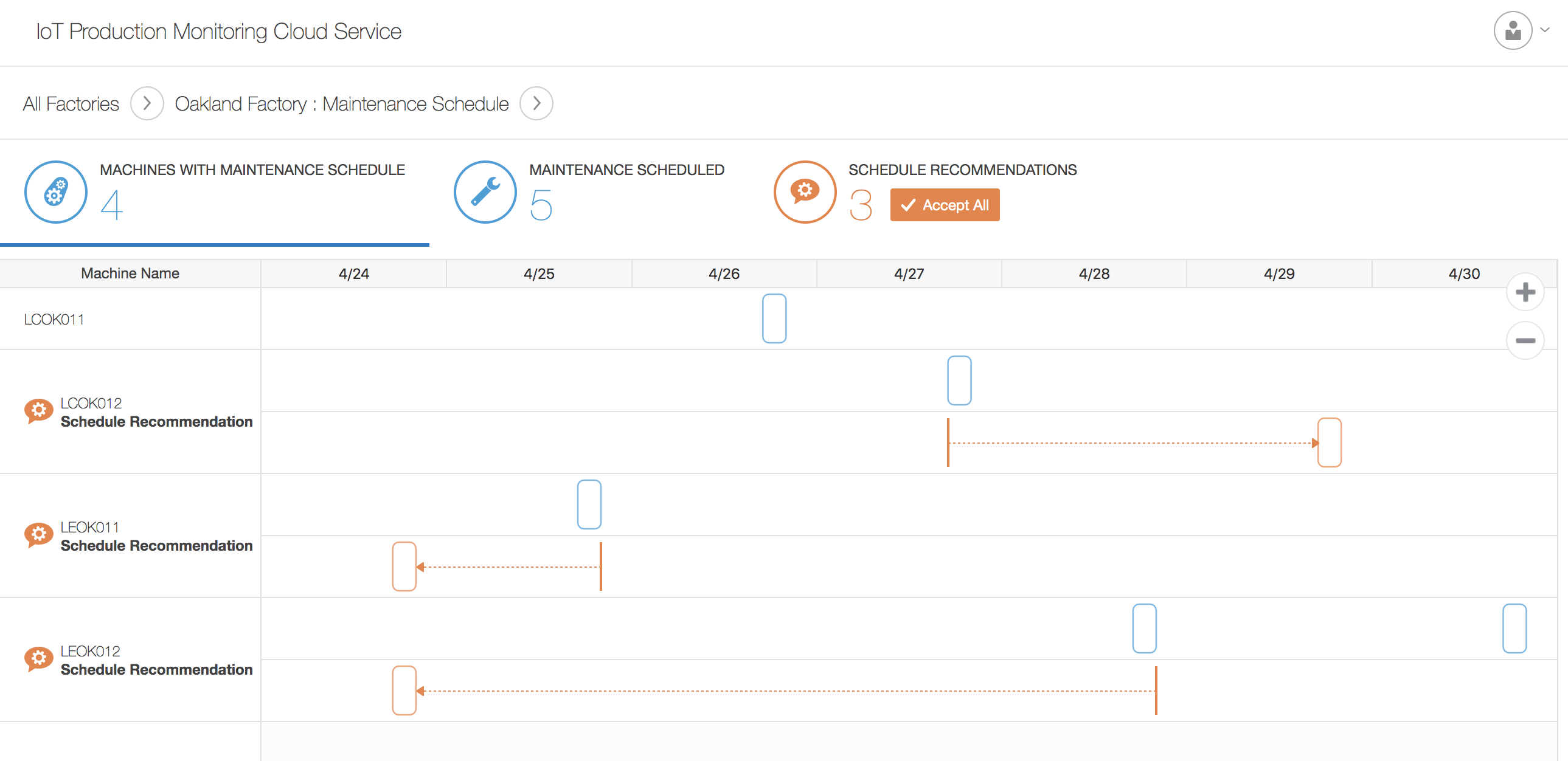

Oracle IoT Production Monitoring Cloud Service helps recommend an optimal preventive maintenance schedule that addresses high probability machine failures while minimizing product delivery delinquencies.

When you choose machine types for maintenance schedule optimizations, the system creates automatic failure predictions for the selected machine types, and uses this as an input when deciding on the optimum maintenance schedule for the machines. The automatic system predictions created by Oracle IoT Production Monitoring Cloud Service appear on the Predictions page.

Enhanced maintenance schedule optimization suggestions prioritize minimizing overall delinquencies over individual machine failures. So, for example, if you have multiple machines with high failure probabilities, the maintenance schedule optimization first works on minimizing overall delinquencies. It then focuses on reducing product delinquencies attributable to individual machines.

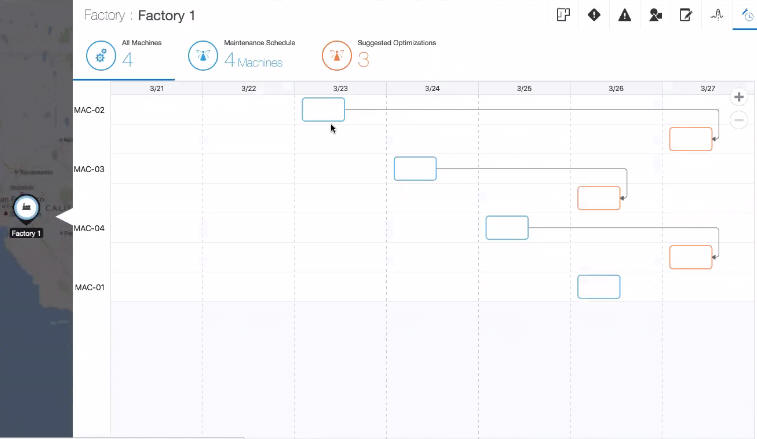

The Factory view includes the Maintenance Schedule tab where you can view the currently uploaded maintenance schedule and optimization suggestions.

In the following example, Oracle IoT Production Monitoring Cloud Service suggests pushing out the maintenance schedule for the first machine and pulling in the maintenance schedule for the other two machines, so as to reduce overall product delinquencies for the Oakland factory.

Note:

The factory must already have a production plan and maintenance schedule in place. See Understand Production and Maintenance Data and Upload Production and Maintenance Data for more information on uploading production and maintenance data.

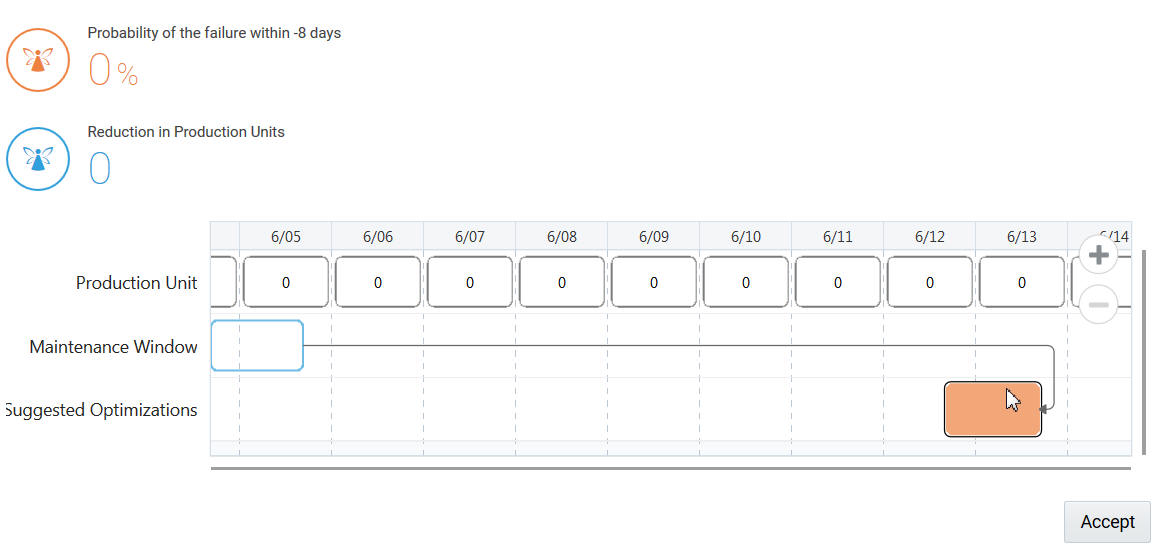

The system makes maintenance recommendations after analyzing the uploaded production data, such as production plan and product routing, and the maintenance schedule.

Maintenance recommendations for an individual machine are created after factoring in the machine's probability of failure and the production cost, or delinquency, associated with each day. A machine is marked as High/Medium/Low failure machine based on its probability of failure. For machines that do not have a failure probability value, no recommendations are provided.

The maintenance schedule optimization for individual machines uses the following logic:

- For high failure probability machines with a failure probability percentage above 70%, the earliest two possible maintenance days are found, and the day with the lowest cost is recommended.

- For medium failure probability machines with a failure probability percentage between 25% and 70%, the application tries to retain the originally scheduled day after rescheduling the high failure machines. If this day is not available then the system chooses the previous day or next day, depending upon the lowest cost. If these days are not available, then the application chooses the next closest day with the lowest cost.

- For low failure probability machines with a failure probability percentage between 25% and 70%, the application looks for the furthest possible days and chooses the one with the lowest associated cost.

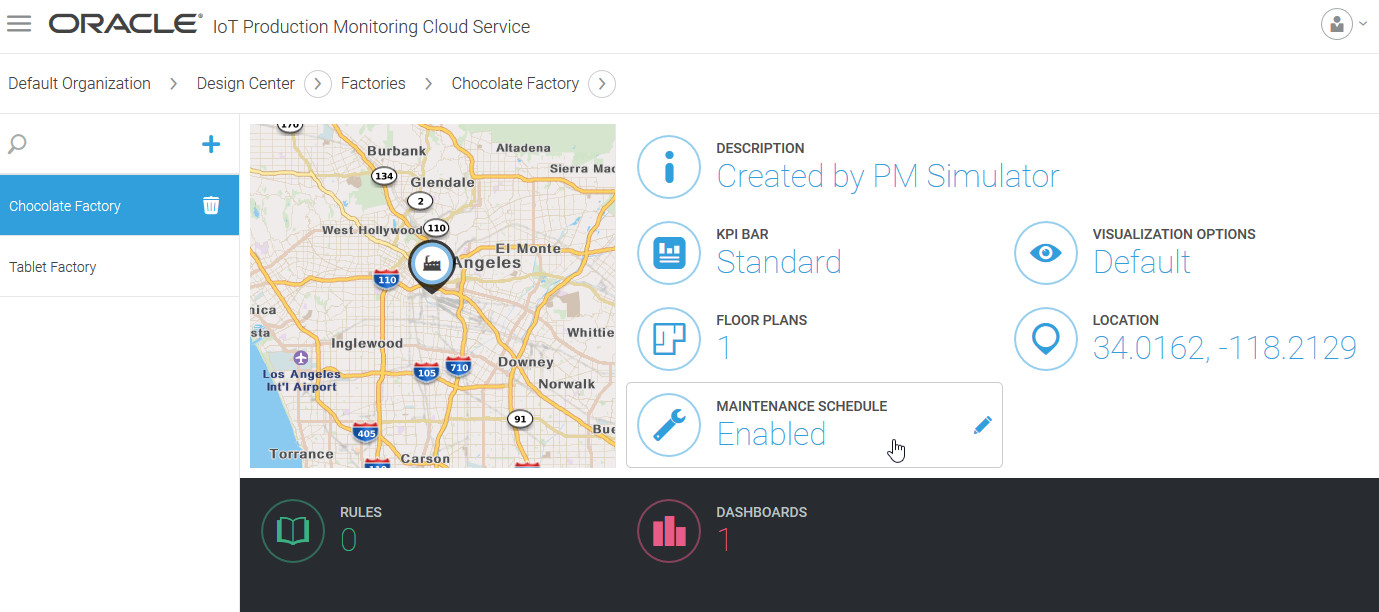

Configure the Factory Maintenance Settings

You can edit maintenance settings, such as selecting the machine types for maintenance optimization, from the Factory settings page.

View and Optimize the Maintenance Schedule

Use the Maintenance Schedule tab of the Factory view to look at, and to optimize, the maintenance schedules for the various machines in a factory.

Note:

You can upload the maintenance schedule form the Uploads ![]() page in Menu > Design Center > Organization > Uploads.

page in Menu > Design Center > Organization > Uploads.