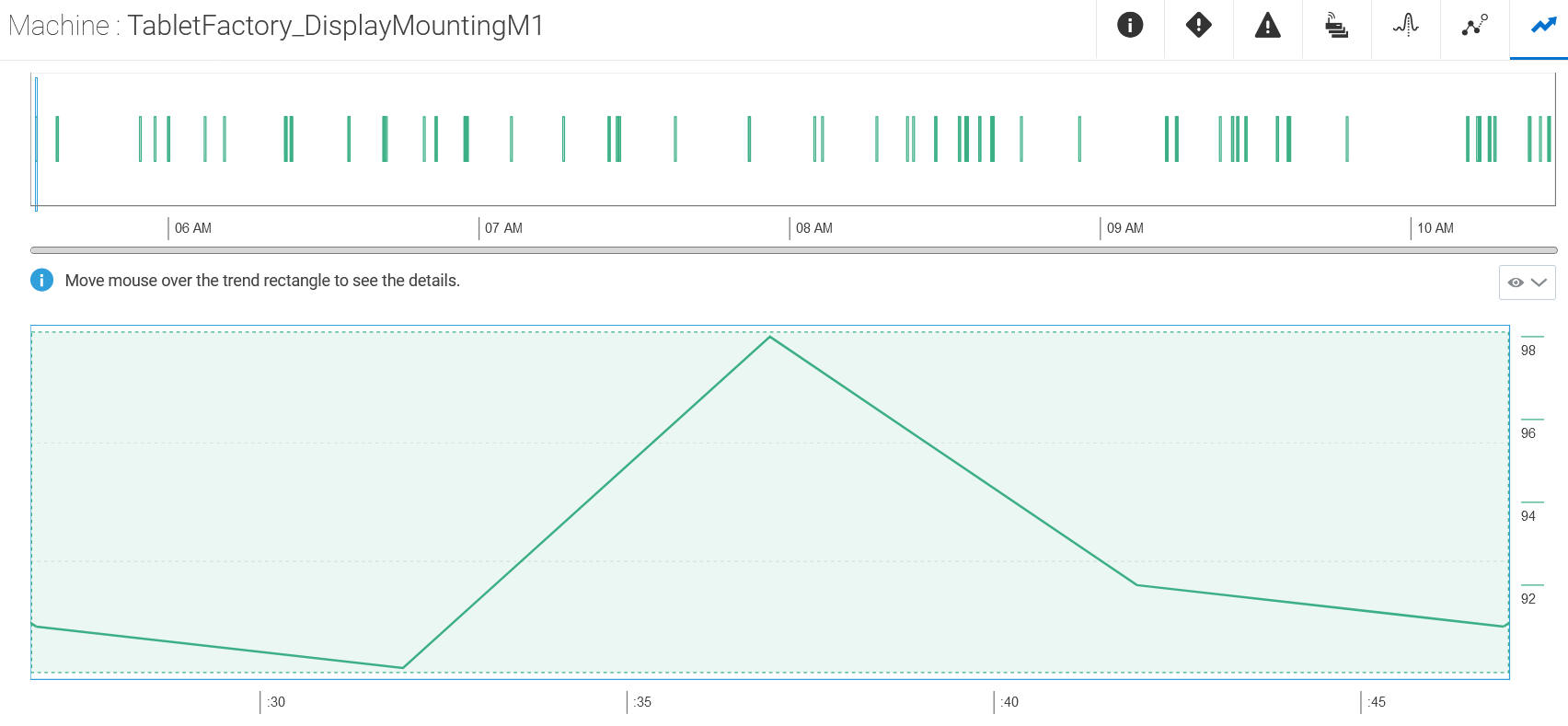

Use Statistical Trends for Machine Attributes

You can create statistical trends for your machine attributes using one or more Nelson Rules. These may help you analyze the consistency and predictability of your attribute values.

Trends use a set of Nelson Rules along with your machine type and attribute to be analyzed. For example, you may wish to analyze the trends for the pressure, temperature, or vibration sensor values of your machine. You can choose one or more of the following Nelson Rules that are relevant for your machine attribute:

- Nelson Rule 1: One point is more than three standard deviations from the mean.

- Nelson Rule 2: Nine, or more, points in a row are on the same side of the mean.

- Nelson Rule 3: Six, or more, points in a row are continuously increasing or decreasing.

- Nelson Rule 4: Fourteen or more points in a row alternate in direction, increasing then decreasing.

- Nelson Rule 5: Two or three points in a row are more than two standard deviations from the mean in the same direction.

- Nelson Rule 6: Four, or five, out of five points in a row are more than one standard deviation from the mean in the same direction.

- Nelson Rule 7: Fifteen points in a row are all within one standard deviation of the mean on either side of the mean.

- Nelson Rule 8: Eight points in a row exist, but none within one standard deviation of the mean, and the points are in both directions from the mean.