Planning Logic for Axle Weight for Rail Equipment

In 24B, the Metrics to quantify the axle weight and load imbalance were defined and applied to the appropriate shipments. In 24C, the logic to determine the placement of coils within the rail equipment was added so to satisfy the metrics. The logic does not optimize the load, but stops when the first feasible solution is discovered. This means that the imbalance from front to back is within tolerance. It also means that the axle weight threshold has not been exceeded. The imbalance default is 1.0 which is perfection but client is able to provide their own criteria.

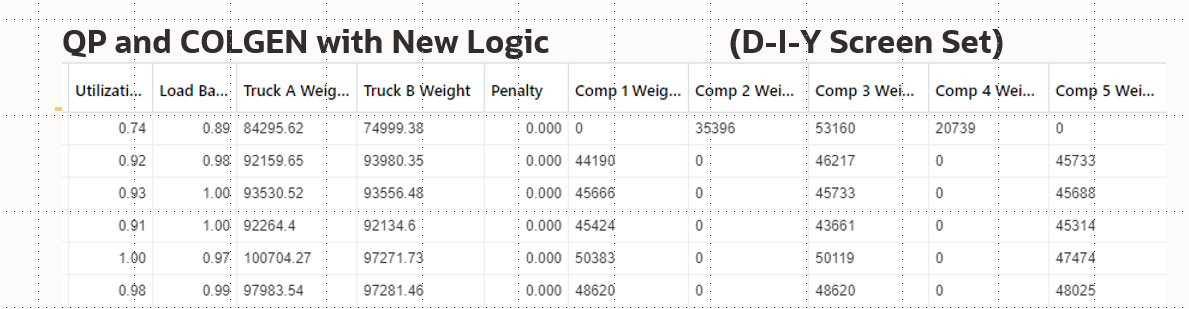

The Quick Packing and Column Generation logic, which is used for the Loading Point logic was modified for this additional requirement as the Loading Point logic also applies.

The reason why this is significant is that the shipper must certify to the rail carrier that the load has been packed in conformance with regulations. Truck shipments are managed and certified by the driver. so there is no need for OTM to determine coil placement on trucks.

Steps to Enable

New Container Optimization (Conopt) Parameters must be set to invoke the logic. RAIL AXLE WEIGHT AWARE PACKING is required to activate the logic. The RAIL AXLE WEIGHT IMBALANCE THRESHOLD is used to set the threshold.

Tips And Considerations

This is NOT for trucks. Rail Cars or Wagons are symmetrical in construction. Trucks are not.

A tip is that the client should customize a screen set using "Attributes" to display the Compartment weights for display. An agent is required to populate the attribute fields.

Rail Axle Weight Client Defined Screen Set