Support Infer UOM for Additional Transactions

Support Infer UOM for Additional Transactions

With this release, we are providing expanded capabilities to operate in UOMs from vendor barcodes across different transactions resulting in in higher picking and warehouse productivity.

To support UOM in further transactions, we are adding the following:

- qty-uom parameter in RF Manual Putaway to Active and the Ordered UOM parameter in RF Sort and Receive.

- Support Infer UOM from the item barcode scanned in several transactions

- A new hotkey CTRL-K: Switch UOM in several transactions, allowing you to swap the UOM in the SKU and quantity scan screen.

RF MANUAL PUTAWAY TO ACTIVE

The qty-uom parameter has been added to RF Manual Putaway to Active (rf.inbound.cwrfputawayactive), allowing you to enter the quantity in terms of 'Cases,' ‘Packs,' or 'Infer UOM from Item Barcode' This way, you don’t have to count the quantity in terms of the item's primary UOM if the operations are predominantly handled in terms of 'Cases,' 'Packs,' or 'Infer UOM from Item Barcode' inside the warehouse, saving you time.

The following table shows the corresponding behavior for the 'qty-uom' parameter and the existing parameter 'quantity-entry-mode':

| 'quantity-entry-mode' | 'qty-uom' | System Behavior |

|---|---|---|

| <Blank> | <Blank> |

The system moves the quantity according to the item's Primary UOM <Existing behavior> |

| <Blank> | Packs |

During Item Standard/Vendor Barcode scan, the system retrieves the the Pack Quantity from the scanned IBLPN and defaults the same in the quantity entry field. So the move quantity should correspond to the Pack Quantity. |

| Scan SKU | Packs/Cases |

In the SKU prompt, when scanning the Item Standard/Vendor Barcode, the moved quantity should be incremented by the IBLPN Pack Quantity. If the IBLPN-SKU inventory has Pack Quantity = 0, then during sku scan the system displays the error "No %s qty defined." |

| <Blank> | Cases |

During Item Standard/Vendor Barcode scan, the system retrieves the Case Quantity from the scanned IBLPN and defaults the same in the quantity entry field. So the move quantity should be the same as the Case Quantity. |

| Scan SKU | Cases |

In the SKU prompt, when scanning the Item Standard/Vendor Barcode, the moved quantity should be incremented by the IBLPN Case Quantity. If the IBLPN-SKU inventory has Case Quantity = 0, then upon sku scan the system displays the error "No %s qty defined." |

| <Blank> | Infer Uom from Item Barcode |

During Item Vendor Barcode scan, the system retrieves the UOM and Pack/Case Quantity of the Item Barcode and defaults the same in the quantity entry field. So the move quantity should be the same as the Pack/Case Quantity. Upon Item Std Barcode scan, the system should compute the move quantity according to the item's Primary UOM (Existing behavior.) |

| Scan SKU | Infer Uom from Item Barcode |

In the SKU prompt, when scanning the Item Vendor Barcode, the moved quantity should be incremented by the Item Barcode UOM Pack/Case Quantity. |

SORT and RECEIVE

To provide users the option in RF Sort and Receive (rf.inbound.cwrfsortandrecv) to receive in terms of the underlying shipped UOM, we’ve added the new value 'Ordered UOM' to the 'qty-uom' screen parameter.

- Upon scanning the SKU, if the qty-uom parameter is set to orderered uom, then the SHIPPED_UOM_CODE is taken from the underlying shipment detail for the SKU scanned to display the UOM in the quantity screen.

- If SHIPPED_UOM_CODE is blank, then the system falls back to the display in terms of item_primary UOM from item_facility or from item.

The following table describes the behavior for the different values:

| qty_uom | Behavior |

|---|---|

|

Units/Blank |

The Quantity entry screen displays UOM of "Units" or the underlying Primary UOM of the item facility or item. In SKU Scan Mode, each scan of SKU will increment the quantity by 1 value of the underlying Primary UOM. |

|

Packs |

The Quantity entry screen displays UOM of "Packs" or the underlying PACK UOM associated with the item (Pack_UOM.) |

|

Cases |

The Quantity entry screen displays UOM of "Cases/Cs" or the underlying Case UOM associated with the item (Case_UOM.) |

|

order-uom |

The Quantity entry screen displays the UOM code based on the UOM_CODE passed on from the corresponding shipment detail/purchase order detail and creates the corresponding Inventory in the corresponding item's primary UOM. |

SUPPORT INFER UOM FROM ITEM BARCODE SCANNED

We’ve added a new screen parameter infer-uom-from-item-barcode to support Infer UOM from the item barcode scanned in the following transactions:

- RF Repack OBLPN (rf.outbound.cwrfrepackoblpn)

- RF Pick IBLPN (rf.outbound.cwrfpickiblpn)

- RF Distribute OBLPN (rf.outbound.cwrfdistributelpn)

This allows users to scan the quantity in terms of different UOM such as cases, packs, and units, based on the inventory composition and not the Allocation UOM. Especially for unit allocation, you can easily scan the move quantity in terms of packs/cases, without the need to hastily compute the unit quantity, and improve the process time.

The configuration of the infer-uom-from-item-barcode parameter for RF Pick IBLPN and RF Distribute OBLPN corresponds to the configuration of the existing parameter 'item-barcode-scan' as follows, as Infer UOM will work only when there is a SKU prompt:

| item-barcode-scan | infer-uom-from-item-barcode | System Behavior |

|---|---|---|

|

<Blank> |

Yes / No |

No SKU scan is involved, system should compute the qty scan according to the Allocated UOM < Existing behavior > |

|

<Blank> |

No / <Blank> |

System should direct the qty scan based on the Allocation UOM < Existing behavior > |

|

Prompt SKU |

Yes |

Upon Item Barcode scan, retrieve the the UOM and Pack/Case Qty of the Item Barcode and default the same in qty entry field, hence the move qty should be as per the Pack/Case Qty |

|

Scan Each SKU |

Yes |

Upon Item Barcode scan, the moved quantity should be incremented by the Item Barcode UOM Pack/Case Qty |

For RF Repack OBLPN:

- If the infer-uom-from-item-barcode parameter is set to 'No', the system continues with the current behavior. For the item barcode scanned, the underlying UOM and conversion will not be considered.

- If the infer-uom-from-barcode parameter is set to "yes", then the scanned barcode picks up the UOM with Pack/Case Qty and defaults the same in the quantity entry field.

CTRL-K HOT KEY TO SWITCH UOM

There are scenarios where an IBLPN might contain different UOM (Units/Cases/Packs), or you may want to move inventory in terms of a different UOM from the same UOM class per the item's primary UOM, all within one RF screen.Now, you can switch UOMs within one RF screen. A new hotkey, CTRL-K: Switch UOM, allows you to swap the UOM in the SKU and quantity scan screen.

We’ve added the CTRL-K: Switch UOM hot key in the following RF transactions:

- RF Manual Putaway to Active (rf.inbound.cwrfputawayactive)

- RF Distribute Replenishment (rf.inbound.cwrfdistlpnreplen)

- RF Sort and Receive (rf.inbound.cwrfsortandrecv)

RF MANUAL PUTAWAY TO ACTIVE

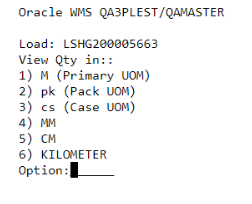

In RF Manual Putaway to Active, when you press CTRL-K: Switch UOM in the SKU scan screen before entering a SKU, the system displays a UOM selection screen with a list of the three standard SYSTEM class UOM: Units ( Primary UOM) , Packs (Pack UOM), and Cases (Case UOM) as follows:

After you select the desired UOM via Ctrl-K, the move quantity will be computed with the existing parameter 'quantity-entry-mode' as follows:

| 'quantity-entry-mode' | Ctrl-K selection | System behavior |

|---|---|---|

|

<Blank> |

(Primary UOM) |

System should compute the move quantity according to the item's Primary UOM < Existing behavior> |

|

<Blank> |

(Pack UOM) |

Upon SKU and Quantity scan, compute the putaway quantity= Scanned Quantity * Inventory Pack Quantity |

|

Scan SKU |

(Pack UOM) |

Upon SKU scan, compute the putaway quantity = Inventory Pack Quantity |

|

<Blank> |

(Case UOM) |

Upon SKU and Quantity scan, compute the putaway quantity= Scanned Quantity * Inventory Case Quantity |

|

Scan SKU |

(Case UOM) |

Upon SKU scan, compute the putaway quantity =Inventory Case Quantity |

|

<Blank> |

Not a Primary/Pack/Case UOM |

Upon SKU and Quantity scan, compute the putaway quantity= Scanned Quantity * UOM-Conversion Factor |

|

Scan SKU |

Not a Primary/Pack/Case UOM |

Upon SKU scan, compute the putaway quantity = UOM-Conversion Factor |

RF DISTRIBUTE REPLENISHMENT

In RF Distribute Replenishment, the "CTRL-K: Switch UOM" hotkey impacts the following operations:

- For a Replenishment wave:

- 'Distribute Replenishment' operation of a REPLEN-CASES task

- 'Distribute Replenishment' operation of a CONSOL_REPLEN task

- RF Putaway - 'Split LPN Into Active Locations' transaction that creates a REPLEN-CASES task: while performing the 'Distribute Replenishment' operation.

The following table shows the system behavior based on the Ctrl-K selection:

| Ctrl-K selection | System Behavior |

|---|---|

|

(Primary UOM) |

System should compute the move quantity according to the item's Primary UOM <Existing behavior> |

|

(Pack UOM) |

Upon SKU and Quantity scan, compute the move quantity = Scanned Quantity * Inventory Pack Quantity. |

|

(Case UOM) |

Upon SKU and Quantity scan, compute the move quantity= Scanned Quantity * Inventory Case Quantity |

|

Not a Primary/Pack/Case UOM |

Upon SKU and Quantity scan, compute the move quantity= Scanned Quantity * UOM-Conversion Factor |

RF SORT AND RECEIVE

In RF Sort and Receive, the following criteria apply:

- If the item Primary UOM is not of a System class, then the UOM selection screen will list all the UOM options from the same UOM class as the item's primary UOM. The Item Primary UOM, Pack UOM, and Case UOM will be identified accordingly.

Item Primary, Pack and Case UOM

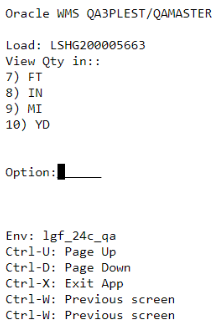

- If the UOM list is more than 6, you will have the option to view all of the UOMs via hot key 'Ctrl-U: Page Up' and 'Ctrl-D: Page Down'.

Page Up and Page Down

- You can select and enter the desired option by entering the listed UOM sequence number.

- If the selected UOM has Item Std Case/Pack UOM (For Example: BUNDLE (Case UOM) ), the system displays the quantity information with respect to the selected UOM.

Steps to Enable

You don't need to do anything to enable this feature.