Support Pallet Putaway to Multiple Locations using Putaway Cart Transaction

To improve the Putaway process for palletized inbound LPNs (IBLPNs), we have introduced a new option in the RF Build Putaway Cart transaction that allows you to use an existing pallet as a cart. This enhancement removes the need to move already palletized IBLPNs onto a separate cart, saving time, reducing operational costs, and minimizing the risk of damage during extra handling.

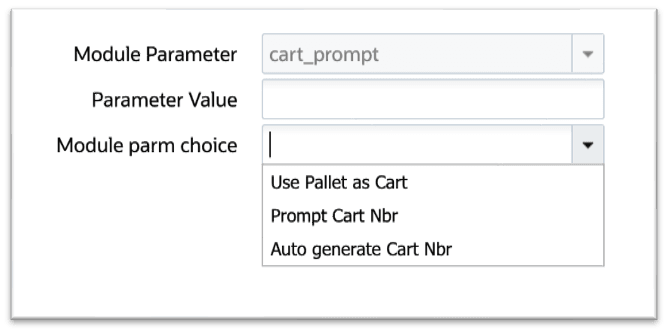

A new option, Use Pallet as Cart, has been added to the cart_prompt module parameter for the RF Build Putaway Cart transaction:

| Module Parameter | Parameter Type | Parameter Value / Choice |

|---|---|---|

| cart_prompt | Selection | Use Pallet as Cart, Prompt Cart Number, Auto Generated Cart Number |

When this option is selected, the system treats the scanned pallet as the cart during the Putaway process.

Module Parm Choice

FOR EXAMPLE:

- Instead of creating a special cart to move items around, workers can now just use the pallet that already holds the items.

- This makes things quicker and simpler, especially when items are already sitting on a pallet.

- Some rules that normally apply to carts (like max number of items or compatibility checks) are skipped in this mode because they don’t make sense when you’re using an existing pallet.

HOW TASKS ARE CREATED:

- The system figures out where to put the items based on smart rules.

- If only some of the items on the pallet can be stored, the system asks the user if they still want to move the whole pallet.

- If the user agrees, it creates a task. If not, it saves the plan but doesn’t start the task yet.

- All updates (like where the pallet is and what it holds) are tracked and logged.

LOCK DOWN THE PALLET AND ITS ITEMS DURING PUTAWAY

Once a Putaway Task is created for a pallet (used as a cart):

- You can no longer move or use that pallet or its assigned items through other screens or actions (like sorting, moving, or receiving).

- This protects the process from accidental or conflicting actions.

If someone tries to:

- Move the pallet elsewhere, the system will display an error "Pallet has a Putaway cart Task. Cannot proceed".

- Move or depalletize assigned items the system will display an error "LPN is in a putaway cart. Cannot proceed with scan".

NOTE: Items on the pallet that are not yet assigned to the task can still be moved.

When that happens:

- The item is removed from the pallet.

- All pallet and cart information is cleared from it.

- The system logs this activity.

- Once the Putaway Task is finished or canceled, everything is unlocked and can be used again normally.

This locking behavior is applied to RF devices, UI screens, and API calls like:

- Receiving, sorting, locating, palletizing.

- Moving items or closing tasks.

- APIs that deal with pallets, LPNs, or putaway location selection.

TRACK PALLET MOVEMENT BY ZONE

When the pallet (as a cart) is moved to a new drop zone, the system:

- Logs this move in history.

- Keeps accurate records of where the pallet has gone.

HANDLE LEFTOVER INVENTORY AND SCAN BEHAVIORS

If not all items on the pallet are used in the task:

At the end, prompt the user to drop the leftover items in a specific location.

- You can scan a valid drop spot.

- System will show an error if it’s not a valid drop location.

- You can skip the scan if needed.

As soon as an item is fully stored, the system:

- Removes all pallet and cart info.

- Logs the move.

- Clears it from the cart.

SMARTER NAVIGATION AFTER PALLETIZING ITEMS

The system now allows warehouse staff to automatically jump to the next after they finish palletizing items, saving them from extra steps.

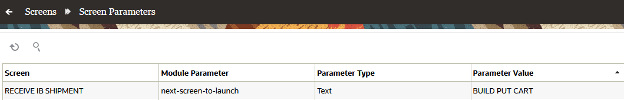

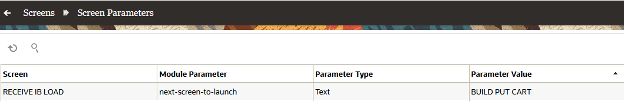

A new parameter "next-screen-to-launch" has been added to the RF Palletize screen.

A new screen parameter next-screen-to-launch has been added to the RF Palletize (rf.inbound.cwrfpalletizeplt) module.

Receive IB Shipment

Receive IB Load

| Module Parameter | Parameter Type | Comment |

|---|---|---|

| next-screen-to-launch | Text |

This parameter provides an option to automatically invoke a next RF screen after End Pallet. Currently, this enhancement supports screens from the rf.inbound.cwrfbuildputawaycart module. The intended screen name should be configured in the Parameter Value. |

This tells the system which screen to open next, such as the Build Putaway Cart screen. It only works for certain screens, and if it’s set up incorrectly, the system will show a clear error message.

When a pallet is completed ("End Pallet") and the settings are correct:

- The system automatically opens the RF Build Putaway Cart screen, treating the pallet as the cart.

- The pallet ID is automatically filled in and processed without needing to scan again.

NOTE:

-

If auto-assign task is enabled on RF Build Putaway Cart:

-

The system will automatically invoke the Execute Task screen.

-

After task execution, the system will navigate back to the RF Palletize pallet prompt screen.

-

-

If auto-assign task is disabled:

-

After displaying the message “Putaway cart task creation submitted for processing”, the system will navigate back to the RF Palletize pallet prompt screen.

-

A new next-screen-to-launch parameter has been introduced. This allows the system to determine the next screen based on broader contextual factors such as transaction type, user role, or workflow status, rather than being tied solely to weight and dimension data.

If the system is set up with a "next screen" (specifically, the RF Build Putaway Cart screen), the flow now behaves based on what type of item was received:

IF A FULL PALLET IS RECEIVED:

- The system automatically launches the Build Putaway Cart screen, treating the pallet as a cart.

- No need to scan the pallet again—it auto-fills.

- It follows the "Use Pallet as Cart" logic.

IF AN LPN (INDIVIDUAL BOX) IS RECEIVED:

- The system launches the Build Putaway Cart screen and asks the user to enter or scan a cart number.

- This uses the "Prompt Cart Number" flow.

Whether the system automatically creates and assigns a Putaway Task after this depends on how it's set up:

- If auto-assign is OFF: The system will display a confirmation message and completes the setup.

- If auto-assign is ON: The system runs all necessary checks and immediately opens the task for execution.

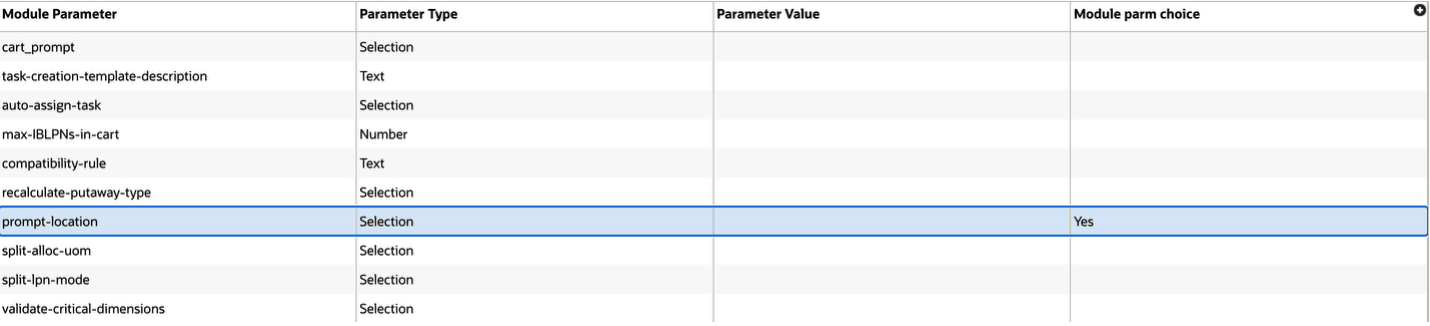

A new screen parameter called prompt-location is added to the RF Build Putaway Cart module. This setting controls whether the system should ask the user to scan a Drop Location after creating a Putaway Task.

Module Parameter - prompt-loaction

NOTE: This only applies when auto-assign-task is NOT enabled.

When you complete building a putaway-cart:

- The system will ask for a drop location scan after the task is created.

- It validates the scanned location:

- If the location doesn’t exist, display an error ‘Invalid location type’.

- If it’s not a Drop Location display error an ‘Invalid Location’.

- Also checks if the location can accept the items (for example, space, SKU rules, attributes) and shows any relevant validation errors.

- If valid:

- The scanned location is saved as the Current Location on the task.

- Task status is set to "Ready", not “In Drop” or “Between Zones” since it’s not part of a task zone movement.

NOTE: If prompt-location = No, the system will not ask for a Drop Location scan.

CHANGE IN DEFAULT TASK ORDERING CRITERIA

When the system creates a Putaway Task and no specific ordering rule is defined in the task creation template, it will now default to ordering task details based on the destination location’s "Putaway Sequence" in ascending order, instead of the old default, which was cart position number.

The system’s default ordering criteria for Putaway Task creation templates has been changed from:

- Ascending - Container cart_position_nbr to Ascending - Destination Location Putaway Sequence

This updated default ensures that:

- Tasks are grouped and ordered by Destination Location Putaway Sequence.

- The RF operator scans a location once and completes all associated putaway actions for that location before moving to the next.

- Split LPN allocations with multiple items assigned to the same location are grouped together in task details, reducing redundant LPN and location scans.

NOTE: In the RF Putaway Cart program (used to execute Putaway tasks), enhance the Cart prompt screen to display the current location code of the cart/task.

Steps to Enable

RF BUILD PUTAWAY CART - USE PALLET AS CART

- Launch the Mobile App and navigate to the Build Putaway Cart screen.

- At the Pallet prompt, scan or manually enter the Pallet Number (e.g.,PLTTEST1).

- Based on allocation status, the system handles one of the following three scenarios:

- If all IBLPNs on the pallet are allocated for putaway: The system prompts: "All IBLPNs allocated for putaway. Proceed with Putaway Task creation?"

- Press Ctrl-A to accept and create the Putaway Cart task using the Pallet Number as the Cart Number.

- Or press Ctrl-W to cancel.

- If all IBLPNs on the pallet are allocated for putaway: The system prompts: "All IBLPNs allocated for putaway. Proceed with Putaway Task creation?"

- If none of the IBLPNs are allocated for putaway: The system prompts: "No IBLPNs allocated for putaway. No task will be created."

- Press Ctrl-W to exit or proceed based on operational needs.

- If some IBLPNs on the pallet are allocated: The system prompts: "X of Y IBLPNs allocated for putaway. Proceed with Putaway Task creation?"

- Press Ctrl-A to accept and create a partial Putaway Cart task for allocated IBLPNs.

- Or press Ctrl-W to cancel.

- If accepted, move the pallet (acting as the cart) to the Drop Zone location.

You can continue to move pallet to other task zones or drop locations as per the tasks created. After completing all putaway tasks, exit the RF application by pressing Ctrl-X.