CONOPT Bulk Packing MIP

Added a Mixed Integer Program Solution (MIP) to the methodology to pack bulk commodities into compartments so that the packing more effectively uses the equipment.

To clarify, this applies to BULK COMMODITIES like liquids and solids (gasoline and corn for example) and the methodology for packing is very similar in concept to packing tiny boxes. Each unit of measure is a virtual cubic entity with no fixed shape. This is exactly like our Equipment Reference Unit in concept. The orders are COUNT SPLITTABLE and not BULK SPLITTABLE. Each compartment has a finite quantity with no decimals.

The business use case for this is to be able to build Muti-stop shipments and optimally pack the equipment with the selected orders.

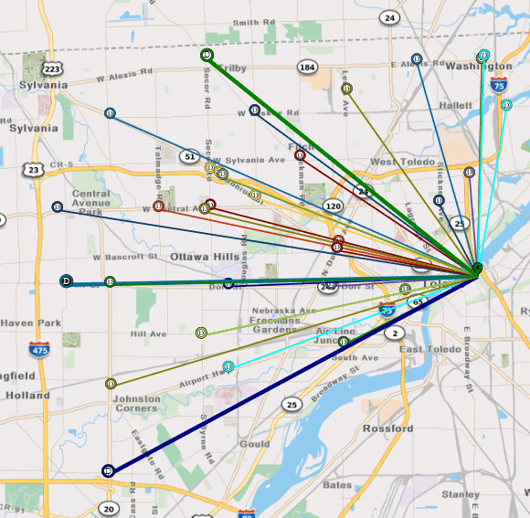

Order Map

The resulting shipments are intended to be efficient from the perspective of distance and time and vehicle utilization.

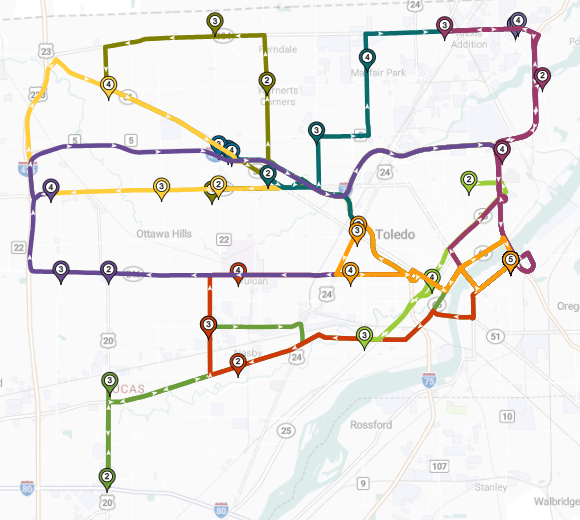

Shipment Map

The truck manifest should also be clearly defined with the work to be performed.

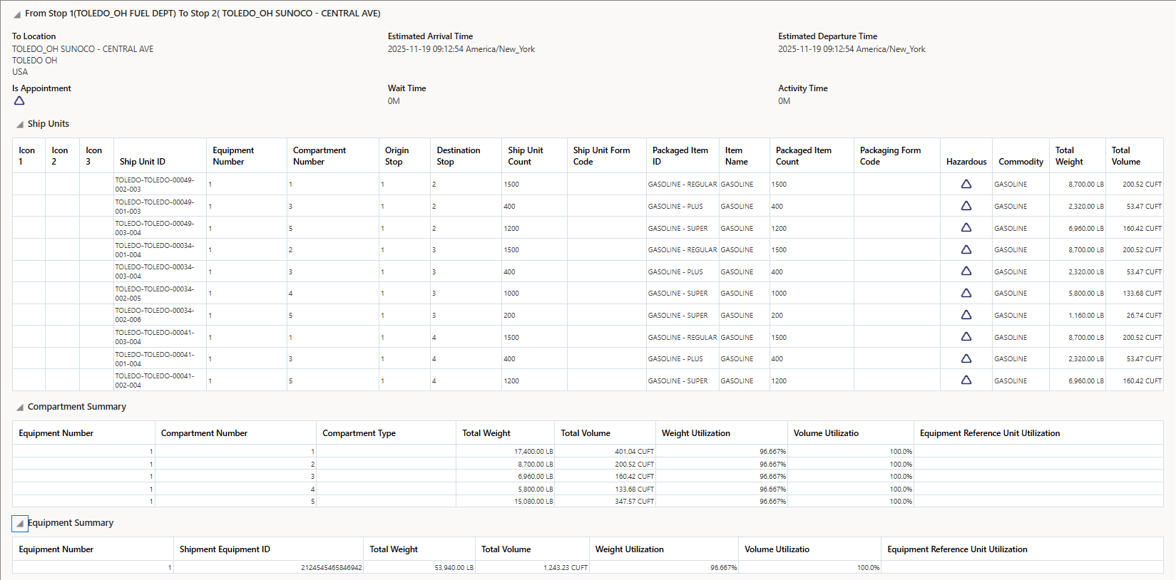

Shipment Manifest

Business Benefit: The primary reason to adopt a MIP approach was to avoid the typical greediness of heuristic solutions that relied upon sorting for compartments and items. Even with the Column Generation technique, the heuristic is used to provide the options. The MIP provides a superior solution. It will consider splitting quantities across compartments and will honor the strict mixing or non mixing requirements for bulk. Additionally, another enhancement was added to avoid multiple lines for the same item in the same compartment. This is an improvement in the packing solver architecture to recombine excessive splits. The end results is more consistent.

Steps to Enable and Configure

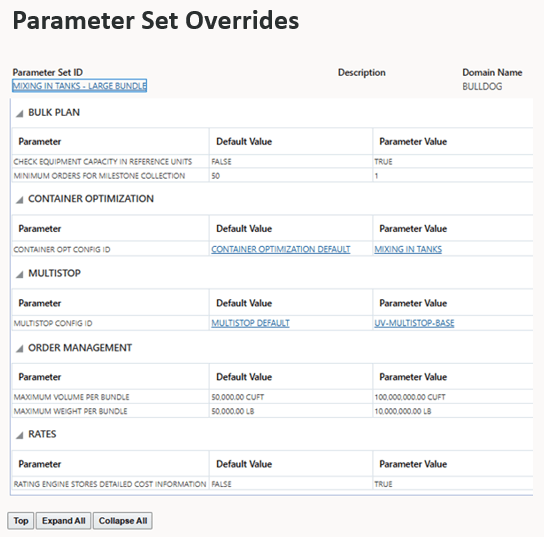

The Parameter Set and Logic Configuration needs to be configured to use this new enhancement.

Parameter Set

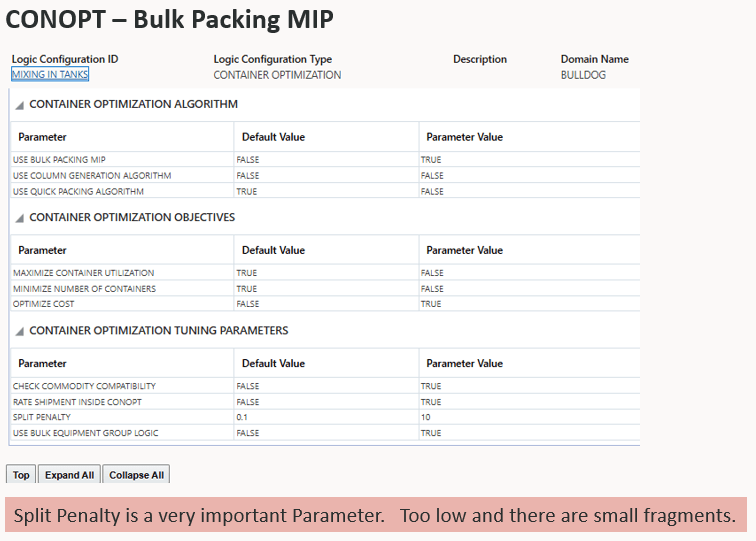

The Conopt Logic Configuration.

Conopt Logic Configuration

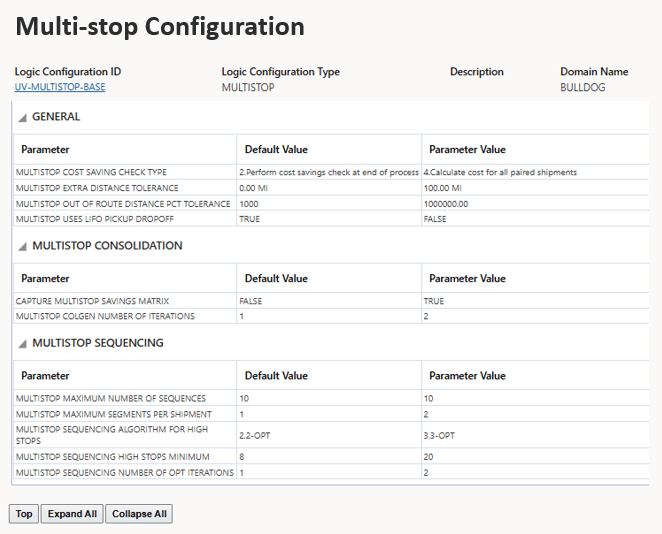

Multi-stop

Tips And Considerations

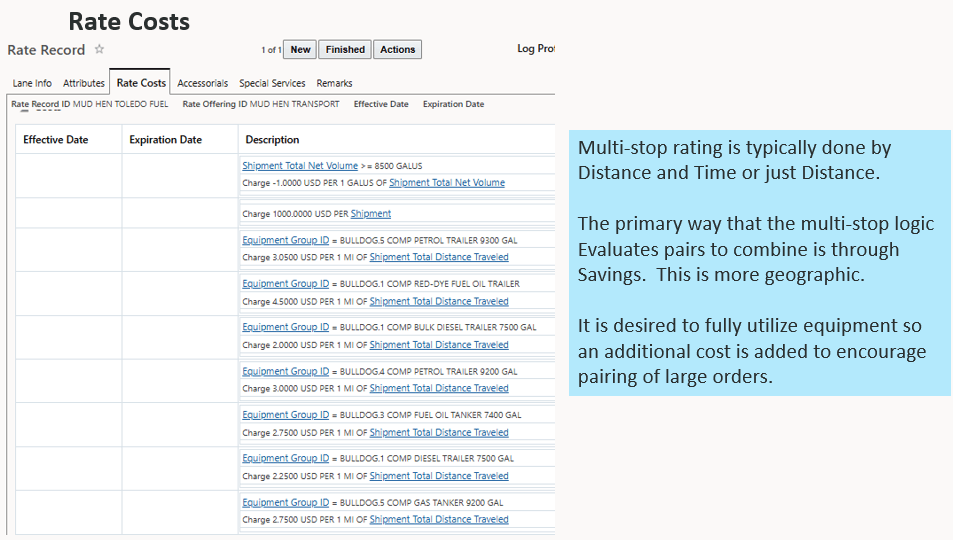

Configuration is straight forward. Remember that Conopt is being used by Multi-stop to evaluate the pairings of stops based on savings. Since typical multi-stop rates are based on distance and time, the stop pairing is heavily influenced by these factors. The addition of a new rate condition too favor utilization will help to fill the trucks, especially when the region is very compact.

Multi-stop Rates