Navigate to IoT Digital Twin from Dispatch List for Real Time Monitoring of Automation Equipment Data

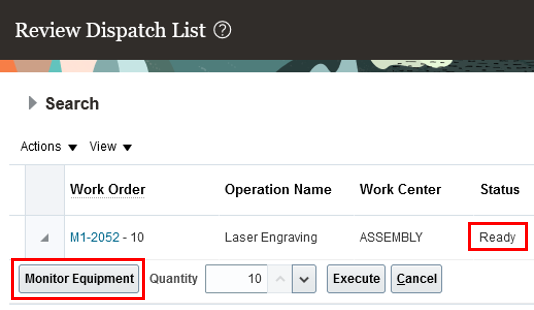

Real-time sensor data monitoring through IoT communication during manufacturing execution provides a clear visibility of work in progress and performance of connected equipment. With this update, you can now monitor the real time status of an automation equipment and the data produced while executing an operation. You can navigate from the Review Dispatch List page to the equipment's Digital Twin view in Oracle Production Monitoring, part of Oracle IoT Intelligent Applications. This navigation is available for work order operations that have quantities in ready and in process dispatch statuses. You can navigate to the equipment's Digital Twin view in Oracle Production Monitoring by clicking on the Monitor Equipment button as shown in the following screenshot:

Monitor Equipment Button to Nnavigate to Digital Twin View of the Automation Equipment in IoT Production Monitoring

In the IoT Digital Twin view, you will be able to view the start and complete information of work order operations real time, and monitor the telemetry data from an automation equipment for the corresponding work order operation. You will also be able to determine if the automation equipment is currently available or busy to start execution of a new work order.

The ability to navigate to IoT Digital Twin view directly from the Review Dispatch List page saves time for operators from switching to multiple screens to obtain information about work order execution status and equipment performance.

Steps to Enable

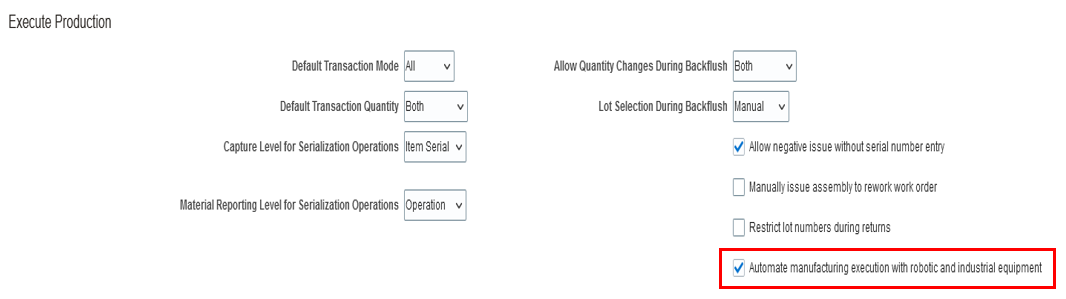

Enable the Enable synchronization to IoT Production Monitoring plant parameter, and then enable the Automate manufacturing execution with robotic and industrial equipment parameter to be able to use this feature.

Plant Parameter to Automate Manufacturing Execution Through Bidirectional Communication with Robotic and Industrial Equipment

Key Resources

- Refer to the Navigate to IoT Digital Twin from Dispatch List for Real Time Monitoring of Automation Equipment Data readiness training.