View Find Number and Suggested Operation Sequence of Item Structure Components in a Manufacturing Work Definition

Prior to this update, a product design engineer could add a component and its total quantity required per product when in a single level item structure. Subsequently, a manufacturing engineer could determine whether the component is required in more than one operation and assign a partial quantity to each operation in the work definition for a product. This multistep process requires manual coordination to implement the component split across multiple operations and later to synchronize quantity changes for the component.

Now you can view the find number that uniquely identifies a specific instance of a component in a standard item structure and its suggested operation sequence to facilitate the component assignment to a work definition operation. Find number allows the same component to be repeated in an item structure, which voids the need to split a component in a manufacturing work definition. Suggested operation sequence makes the product design engineer’s recommendations for operation sequencing visible to the manufacturing engineer. For example, a desktop computer is built with a left speaker and right speaker. The product design engineer adds the speaker twice in the item structure, with a unique find number and either the same or different suggested operation sequence for each instance of the speaker.

The following is a screenshot of the Edit Item Structure page showing component WM661 Thin Profile Speaker System that repeats in the item structure with unique find number and suggested operation sequence.

Find Number and Suggested Operation Sequence in Item Structure

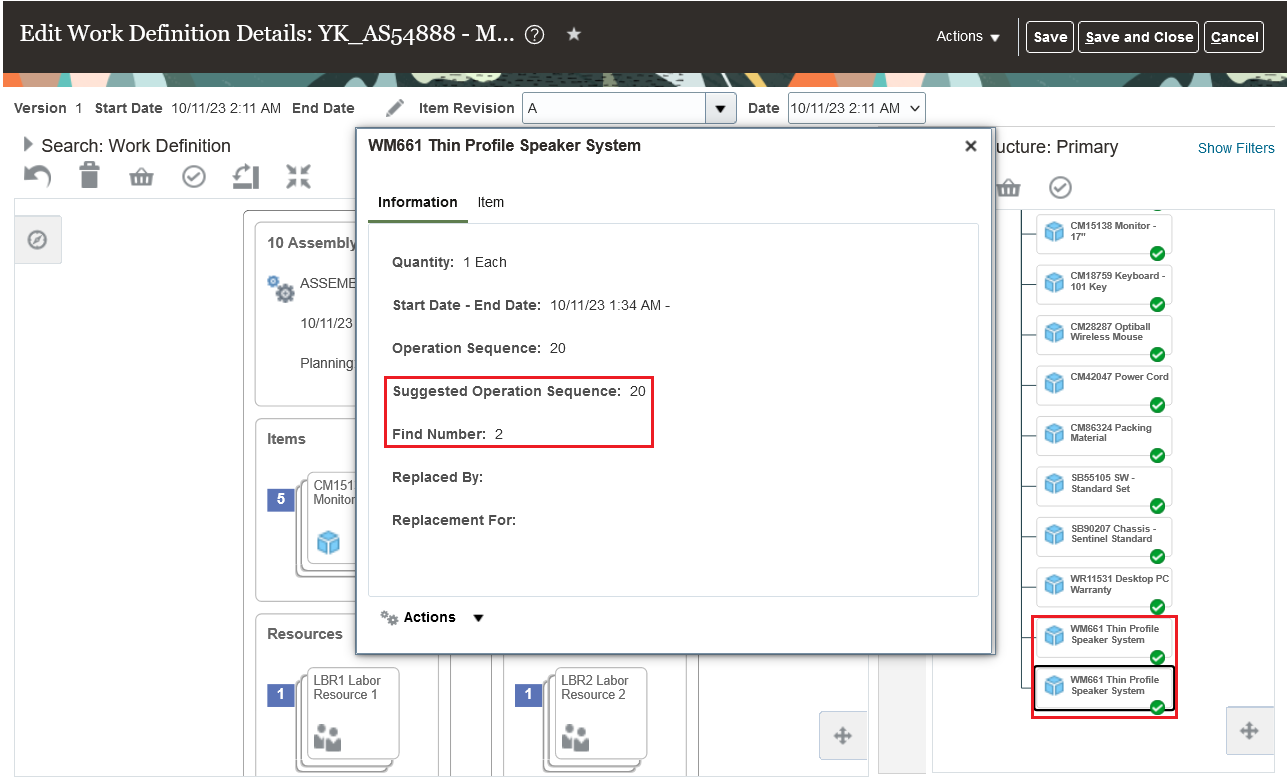

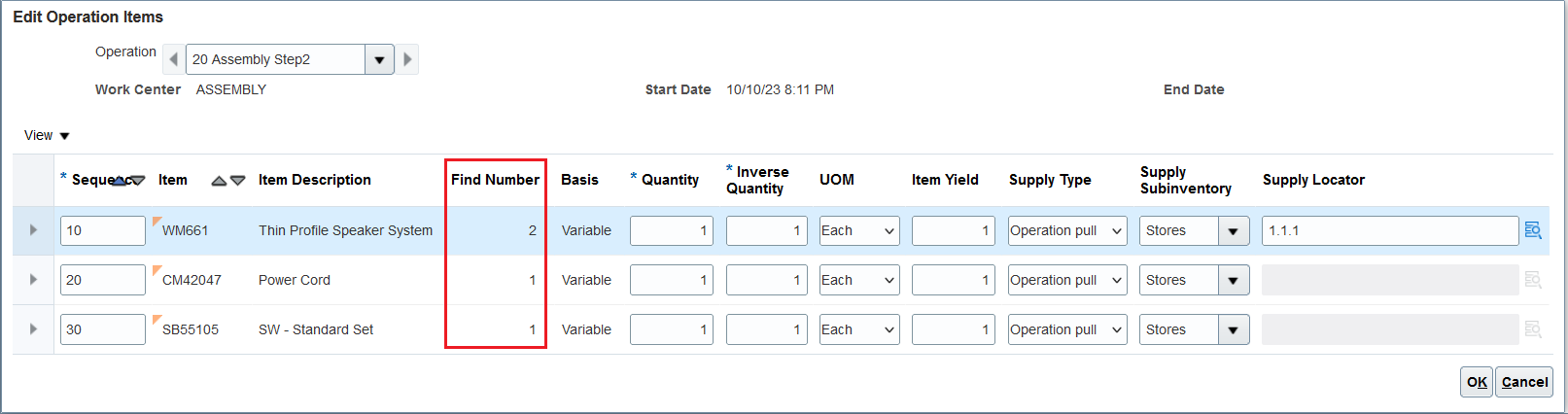

In the Edit Work Definition Details page, you can view the find number and suggested operation sequence by double clicking or right click on a selected item structure component to open the Item Information dialog with this information displayed. You can also view the find number of the item structure component in the Assign Operation Items and Edit Operation Items dialogs.

The following is a screenshot of the Item Information dialog for component WM661 Thin Profile Speaker System displaying the find number and suggested operation sequence.

Find Number and Suggested Operation Sequence in Item Information Dialog

The following is a screenshot of the Edit Operation Items dialog displaying the find number of the work definition operation items.

Find Number in Edit Operation Items Dialog

In a change management scenario, an update to the suggested operation sequence for an item structure component can be synchronized to the impacted work definitions by running the Process Item Structure Changes to Work Definitions scheduled process. However, the find number can't be updated after a component is saved in the item structure. Both find number and suggested operation sequence are read only fields when viewed in the work definition.

Application Desktop Framework Desktop Integration (ADFdi) Changes:

The Find Number and Suggested Operation Sequence columns have been added to the following worksheets when creating or updating operation items for discrete manufacturing work definitions:

- Operation Items for Standard Assemblies

- Operation Items for ATO Model

- Operation Items - Multilevel ATO

To assign a component that repeats multiple times in the item structure to a work definition operation using ADFdi, you must perform a search, then assign the item with the unique find number returned in the search results. You can copy the suggested operation sequence to the operation sequence field if the operation assignment is accurate or enter the correct operation sequence for the item.

File-based data import (FBDI) Changes:

The Find Number column has been added to the following worksheets in the FBDI work definition templates when importing operation items for discrete manufacturing or process manufacturing work definitions:

- Template: WorkDefinitionTemplate.xlsm

- Work Definition Operation Items - Standard Items

- Work Definition Operation Items - ATO Model

- Template: ProcessWorkDefinitionTemplate.xlsm

- Work Definition Operation Items

To assign a component that repeats multiple times in the item structure to a work definition operation using FBDI, you must specify the find number of the item in addition to its operation sequence and material sequence. Otherwise, the find number is an optional field. Use the latest template after upgrade to 24A.

REST API Changes:

The Find Number attribute has been added to the Work Definition Requests REST API when creating discrete manufacturing or process manufacturing work definitions. To assign a component that repeats multiple times in the item structure to a work definition operation using REST, you must provide the find number of the item in addition to its operation sequence and material sequence. Otherwise, the find number is an optional field.

With find number and suggested operation sequence, you can streamline the coordination between product development and manufacturing engineering, model the material requirements for production more accurately, and complete work definitions more quickly for use in planning, production, and costing.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- In Product Lifecycle Management, you can specify the following fields for a component in an item structure:

- Find number is a required field. You can’t update the find number in an item structure after the component is saved.

- You can't use find number to add the component multiple times if the item structure type is model or option class.

- Suggested operation sequence is an optional field and defaults to blank.

- You can update the suggested operation sequence in an item structure after the component is saved and upon collaboration with the manufacturing engineer to understand the sequence of operations for making a product.

- In Manufacturing, both find number and suggested operation sequence are read-only fields.

- Any subsequent changes to the operation sequence for the assigned component in the work definition is not automatically synchronized back to the suggested operation sequence in the item structure.

- You can't view the find number and suggested operation sequence for item structure components in a work order. At this time, the quantities of the same component with different find numbers and the same basis type in an operation are aggregated upon work order creation.

- You can't disable this feature in Manufacturing regardless of whether you opt in to the Add Find Number and Suggested Operation Sequence for Structure Components feature in Product Lifecycle Management.

Key Resources

- Readiness training Add Find Number and Suggested Operation Sequence for Structure Components (Product Lifecycle Management Update 24A).

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- Manage Work Definitions (WIS_MANAGE_WORK_DEFINITIONS_PRIV)

The privilege was available prior to this update.