Edit Time-Phased Safety Stock Quantities in a Supply Plan

Edit Time-Phased Safety Stock Quantities in a Supply Plan

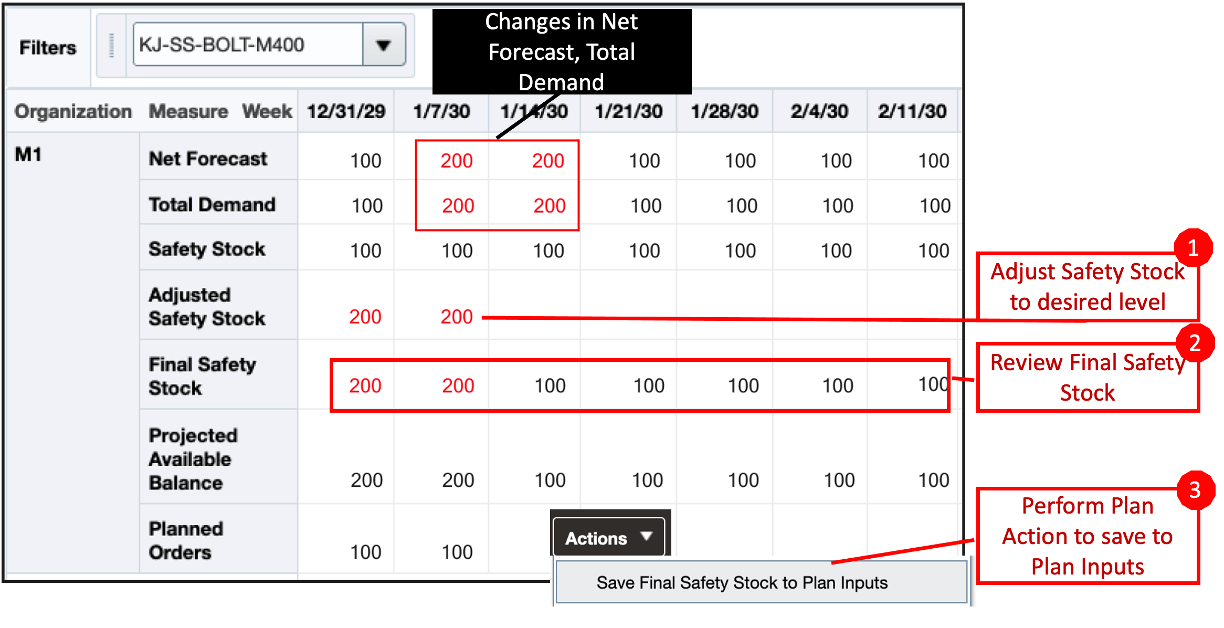

In a variety of situations, your planners might want to manually adjust safety stock levels that vary over time. This update allows you to verify current safety stock levels and determine if adjustments are necessary. You can update the new Adjusted Safety Stock measure. The new value is used in the next run of the supply plan to ensure that there’s enough stock to honor the new safety stock level if there are no supply constraints.

Two new seeded measures work together to help you edit the safety stock measure in a supply plan: Adjusted Safety Stock and Final Safety Stock.

Editing the Safety Stock in a Supply Plan

To set the desired safety stock level, edit the Adjusted Safety Stock measure. Save the plan and review the changes in the Final Safety Stock measure. The Final Safety Stock measure is recalculated with the updated Adjusted Safety Stock wherever present or with the original Safety Stock quantity, where there are no adjustments for the respective time buckets. The Save Final Safety Stock to Plan Inputs plan action saves the values for all the time buckets in the plan's horizon to the plan inputs.

Adjusted Safety Stock and Final Safety Stock Measures

Saving the Final Safety Stock for Future Use

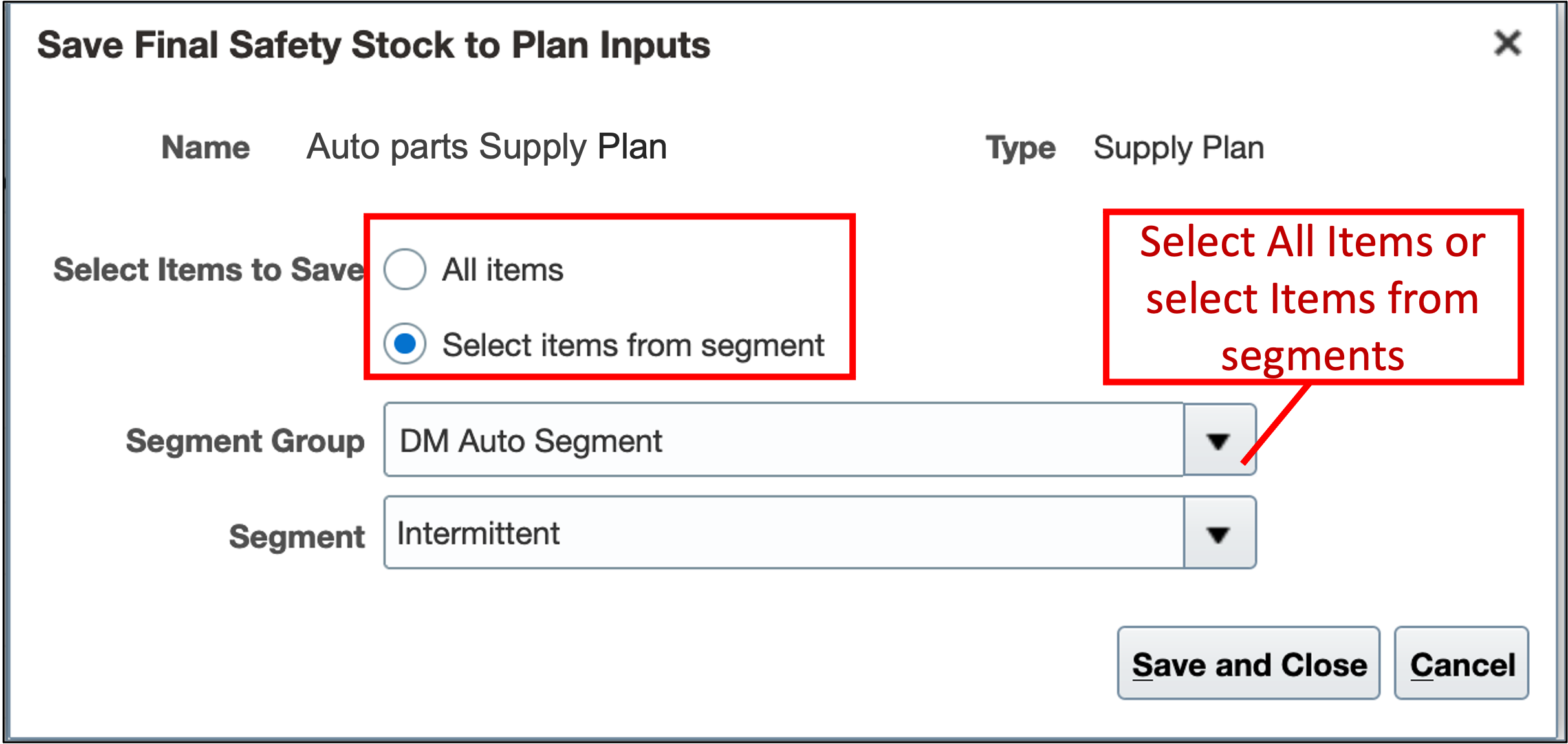

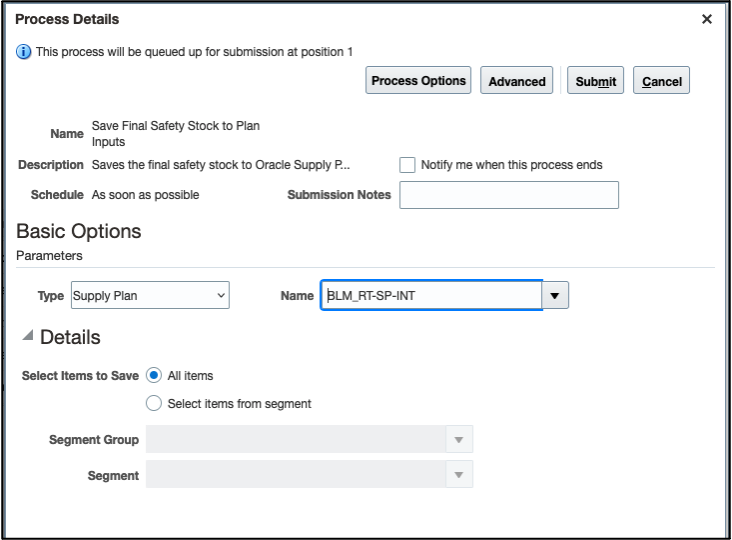

The Final Safety Stock measure can now be saved and used as a plan input for all plans that include that item on subsequent plan runs. You can run the Save Final Safety Stock to Plan Inputs scheduled process from the plan Actions menu. Alternatively, you can run it as a scheduled process in an automated mode. You can save the safety stock adjustments for all or specific segments (item-organization combinations), as shown in the following illustration.

Segment Selection for Save Final Safety Stock to Plan Inputs

For Items with the Safety Stock Planning Method as Quantity, the safety stock in the plan inputs will persist. It can be overridden by subsequent changes to the Adjusted Safety Stock measure on the planning page. You can also make changes using the file-based data import (FBDI). The latest changes to safety stock, either by interface updates to the Adjusted Safety Stock or FBDI updates to the Safety Stock directly, will persist.

The values to the Adjusted Safety Stock measure continue showing until a complete refresh of the plan is performed via the Refresh with current data run plan option.

Running the Plan with a Full Refresh

The Final Safety Stock, which is saved to plan inputs, will now be used on subsequent plan runs for items that use the Safety Stock Quantity as an Item attribute.

Running the Plan with a Replan

For the items that have the Safety Stock Planning Method as Safety Stock Quantity, the plan will use the Adjusted Safety Stock quantity overrides and replan the supplies accordingly. You can iteratively replan and review the supply plan output changes without saving the safety stock adjustments to Plan Inputs. To do so, use the Run plan action with the Do not refresh with current data refresh option.

For the items that have Days of Cover as an Item attribute or those Items that use Statistical Safety Stock based on the Safety Stock Planning Method plan option, safety stock will be recalculated based on the respective methods. The adjusted safety stock quantity won't be considered for these items as the safety stock planning method isn't Safety Stock Quantity.

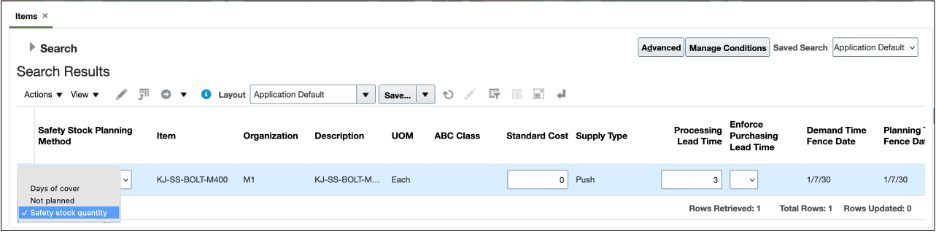

Using with Items that Have Days of Cover as a Safety Stock Planning Method Attribute

At certain times, you may want to override the safety stock calculated for items that use Days of Cover as a Safety Stock Planning Method attribute. Even for such items that have the Safety Stock Planning Method as Days of Cover, you can still edit the Adjusted Safety Stock quantity and save the Final Safety Stock quantity to Plan Inputs. However, to use those quantities in the next plan run, you need to change the item's Safety Stock attribute to Quantity from Days of Cover in the Items table. You can then use the Final Safety Stock generated as a Plan Input to be used in subsequent plan runs. However, in this case, the Adjusted Safety Stock quantity won’t be used in a subsequent replan without refreshing the current data.

Safety Stock Planning Method in the Items Table

Safety Stock Planning Method as Statistical Safety Stock for End Items

When using the plan option Safety Stock Planning Method to use Statistical safety stock for end items also, you can still edit the Adjusted Safety Stock quantity and save the Final Safety Stock quantity to Plan Inputs. However, to use those quantities in the next plan run, you need to change the Safety Stock Planning Method to User-specified values for all items in the plan’s options. You can then use the Final Safety Stock generated as a Plan Input in subsequent plan runs. However, in this case, the Adjusted Safety Stock quantity won't be used in a subsequent replan without refreshing the current data.

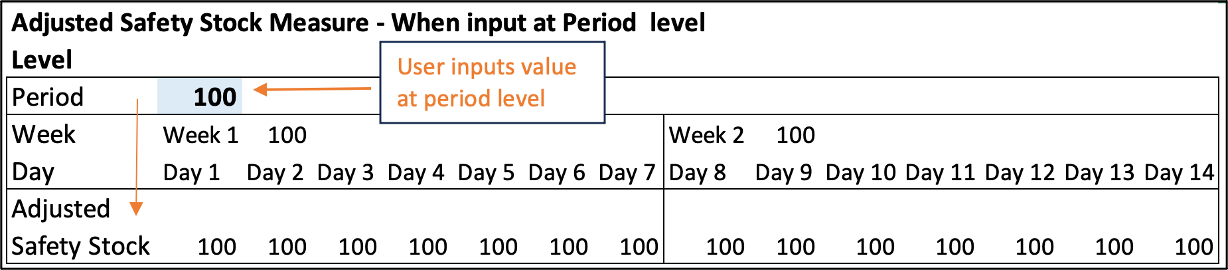

Examples of Disaggregation across levels in the Hierarchy

The Adjusted Safety Stock measure follows the disaggregation rule of Equal when disaggregating data across the time hierarchy. The Illustration below shows the disaggregation of user input values in the time hierarchy.

User Inputs Value at Period Level

In the preceding example, the Adjusted Safety Stock input at the month level is repeated for every week and each day of the week in that month.

Aggregation Across Time Hierarchy

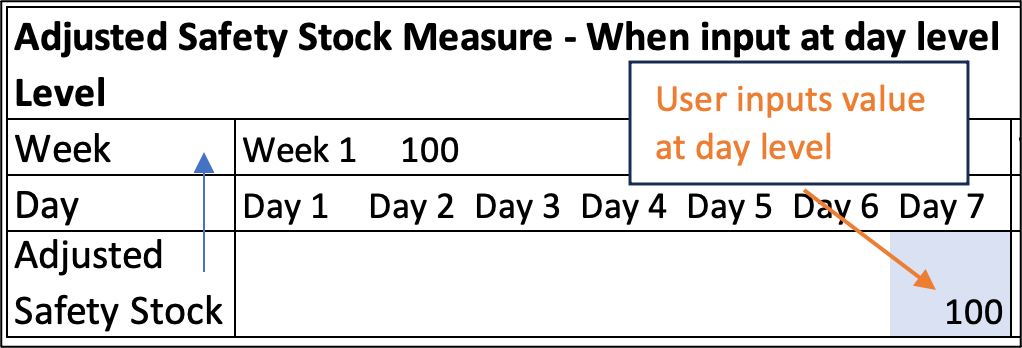

While aggregating from lower levels on the time hierarchy, the Adjusted Safety Stock measure uses the aggregation rule of Last. For example, in the illustrated example below, the user inputs a value of 100 at the day level. Upon aggregation, the value for the parent, week level, retains the same value.

Aggregation in the Time Hierarchy

Disaggregation Across the Product Hierarchy

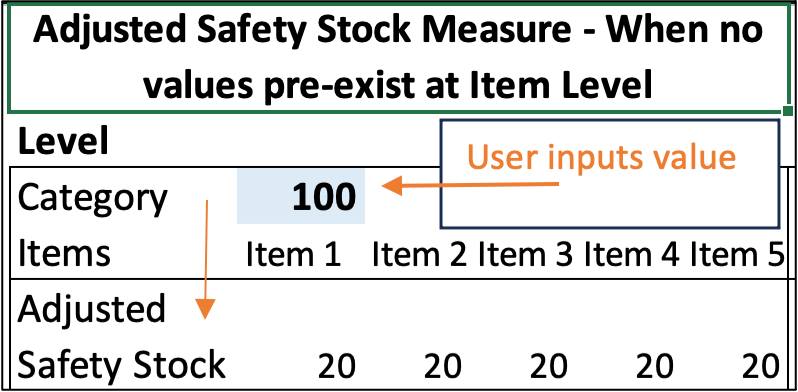

Proportional disaggregation is used for members in the product hierarchy. In the following illustration, no preexisting values exist at the item level and the disaggregation is proportionate.

Disaggregation When No Preexisting Values Exist

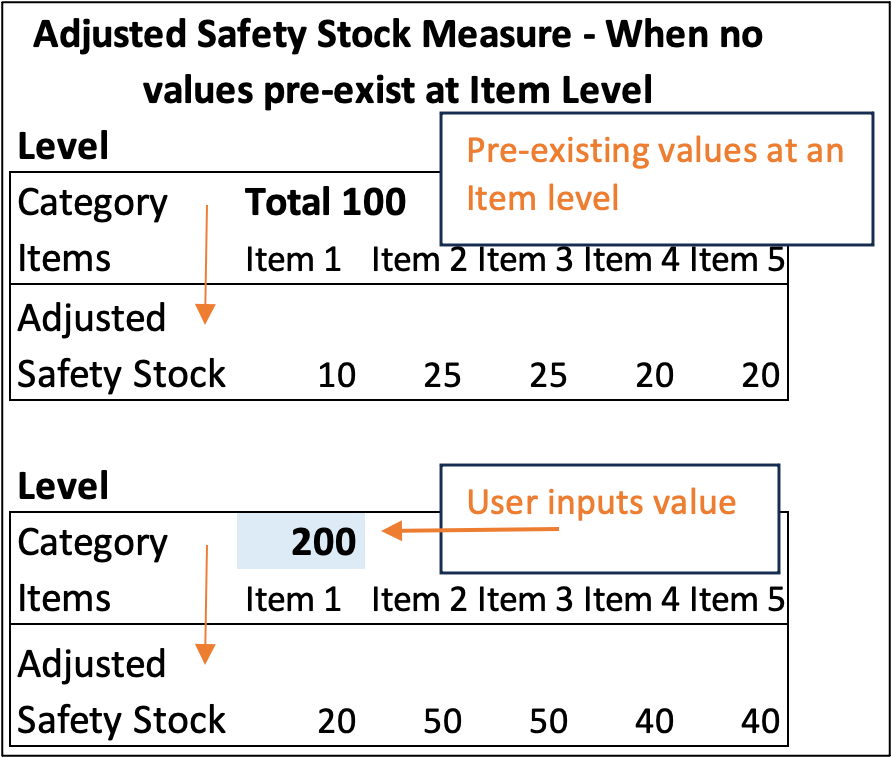

When disaggregating when previous values exist, planning considers the proportion of the preexisting values and disaggregates in the same proportion, as shown in the following illustration.

Disaggregation in Product Hierarchy When Values Exist

Aggregation in the Product and Organization Hierarchies

The aggregation in the Product and Organization Hierarchies follows the Sum rule. The values for all members at the same level are added to aggregate to the parent.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- Add the two new measures, Adjusted Safety Stock and Final Safety Stock, to the measure catalogs.

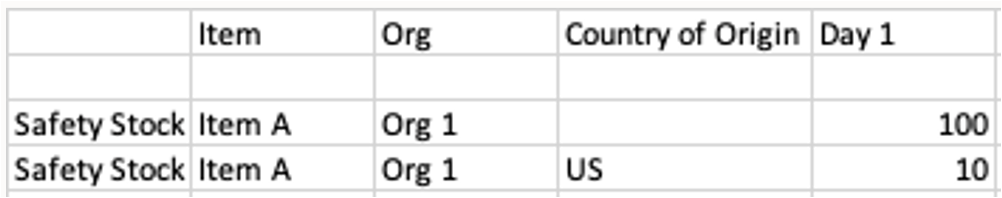

- The Adjusted Safety Stock, Final Safety Stock, and Safety Stock measures are dimensioned by Item, Organization, and Date. However, in the case of attribute-based planning Safety Stock measure alone can also be dimensioned by attribute, whereas the other two aren't dimensioned by attribute. See the following example.

Adjusted Safety Stock In Case of Attribute-Based Planning

In the preceding example, the Adjusted Safety Stock measure for Org 1 will override the Safety Stock of 100 but not the Safety Stock of Org 1 - US, where US (Country of Origin) is the attribute of Org 1.

-

For plans that have Safety Stock Planning Method as Do not plan safety stock, the plan would still contain the Adjusted Safety Stock and Final Safety Stock measures. However, they won't participate in the safety stock calculation.

-

To enable automated workflows, you can program the Save Final Safety Stock to Plan Inputs scheduled process.

Scheduled Process Dialog Box

Key Resources

- Watch the Edit Time-Phased Safety Stock Quantities in a Supply Plan demo.

Access Requirements

Users who are assigned these job roles have privileges that can access this feature:

- Supply Chain Planner

- Demand and Supply Planner

- Replenishment Planner

These privileges were available prior to this update.