Gain Insights on Lead Times for Shipment to Receipt

Provide recommendations to adjust the assumptions for lead times for shipment to receipt for buy items based on actual performance.

Previously, you could use the lead time learning feature to receive alerts about major deviations in the actual supplier lead times when compared to those times specified in the approved supplier list (ASL) or supplier item record. The lead time specified is usually the expected lead time for the supplier to ship an item from a supplier site. In some situations, you might have modeled the entire lead time, including the shipment-to-receipt lead times in the ASL or supplier item record.

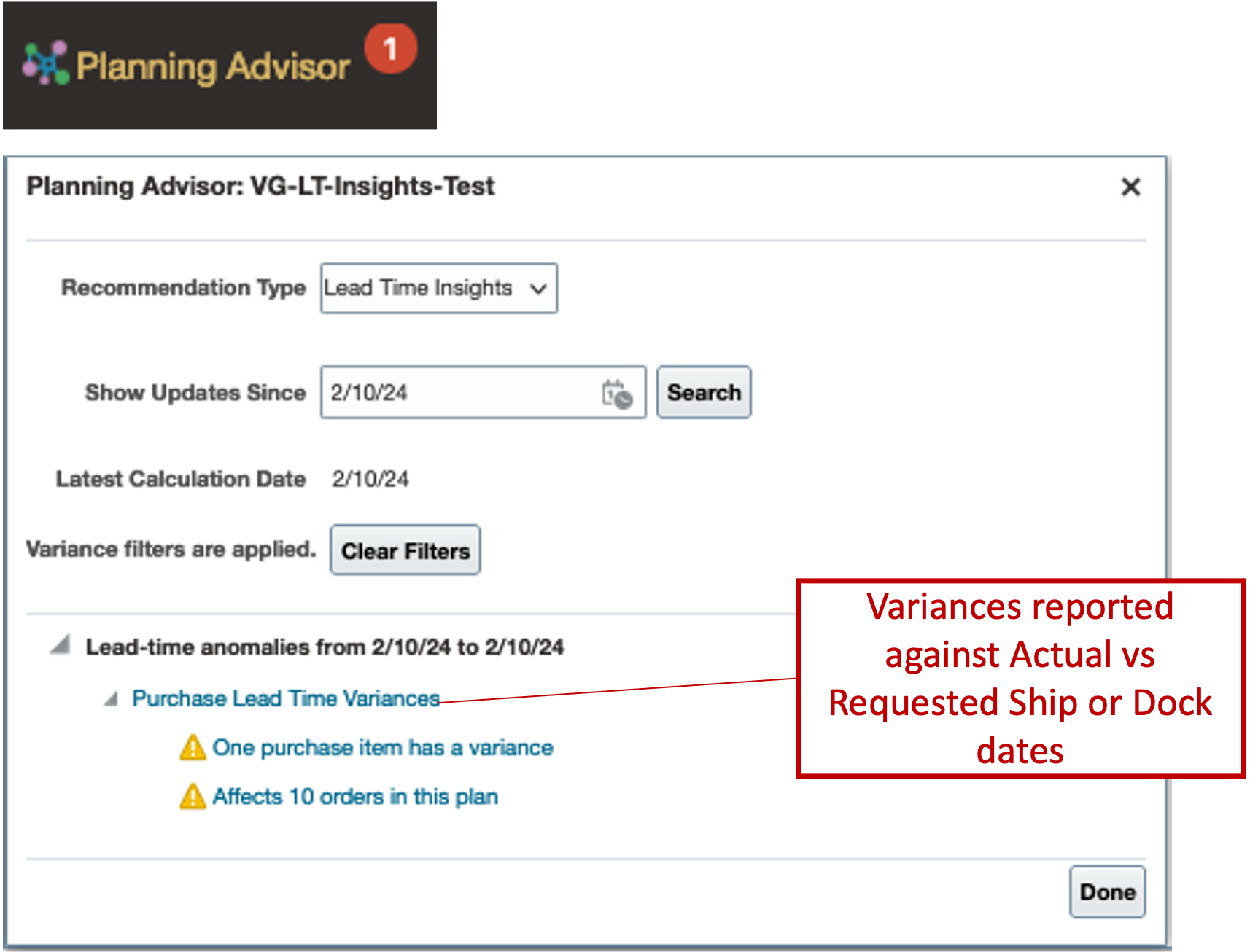

With this update, you can now capture the historical lead times in this situation as well and provide visibility to those item supplier combinations where your modeled lead times deviate significantly from the historical record. The computations of variance and other lead time metrics have been enhanced to examine the actual ship dates, requested ship dates, actual receipt dates, and requested dock dates, depending on whether your supplier manages the transportation or otherwise. These metrics use Planning Advisor to help alert you to situations when reality is deviating from your modeling assumptions so you can proactively take mitigation actions.

Planning Advisor Dialog Box

There’s an enhancement in the lead-time reporting calculations to address bulk and blanket order-based purchase orders where the lead time is recorded against the same order, but each instance of delivery is tracked for its lead time.

- The variances now reported consider if the shipment was delivered by means of Buyer-managed Transportation (BMT) in your purchase order history to arrive at the variance calculation as follows:

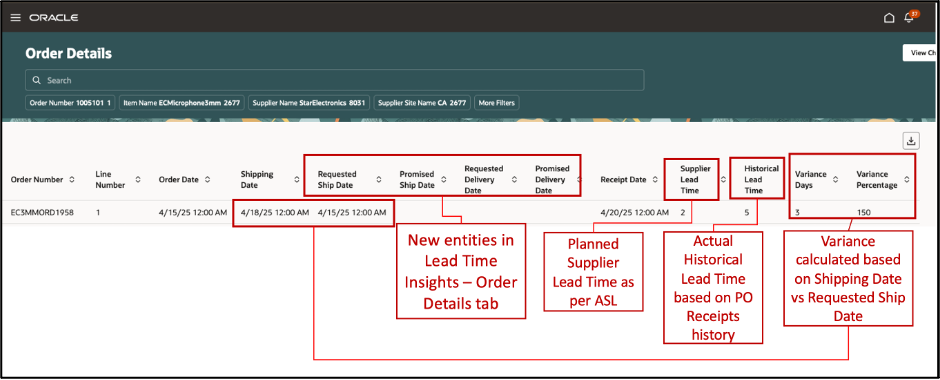

- For items that have the BMT as Yes and consider the Order to Ship cycles, the lead time variance (Variance Days in the following screenshot) is Ship Date – Requested Ship Date.

- For regular Buy orders that consider the Order to Receipt cycles for the lead time calculations, the lead time variance is calculated as Dock Date – Requested Dock Date.

- The Historical Lead Time days are the sum of the variance days and the Supplier Lead Time maintained in the ASL; for example:

- If the average Variance Days is 3 days and the Supplier Lead Time is 2 days, the Historical Lead Time is 5 days.

- The variance calculated shows both positive and negative values. Positive variance for delayed shipments and negative variance for shipments that were received earlier than planned.

- There are four new base entities collected from the purchase order history information. These entities are also introduced as columns on the Order Details page of the Lead Time Insights recommendation type:

- Requested Delivery Date (for PO Line)

- Promised Delivery Date

- Requested Ship Date (for PO line)

- Promised Ship Date

New Entities in the Lead Time Insights Recommendation Type

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

- Refer to the training content for 23B-Gain Insights on Lead Times for Purchased Items for enablement details.

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- Manage Lead Time Insights (MSC_MANAGE_LEAD_TIME_INSIGHTS_PRIV)

This privilege was available prior to this update.