Plan and Schedule Supplies Respecting Minimum Transfer Quantity Between Operations

Plan and Schedule Supplies Respecting Minimum Transfer Quantity Between Operations

You can use the minimum transfer quantity to schedule production with reduced makespan by overlapping operations within and across work orders.

Prior to this update, all units of the prior operation in a work order had to be completed before the next operation could start, resulting in longer than necessary production times.

With this update, you can consider the minimum transfer quantity of an item's work definition to schedule sequential operations or work orders that overlap. The next operation or work order is started after the minimum transfer quantity has been produced in the prior operation or work order.

The consideration of minimum transfer quantity between operations reflects shop floor reality more closely and leads to shorter makespans, higher throughput, and resource utilization.

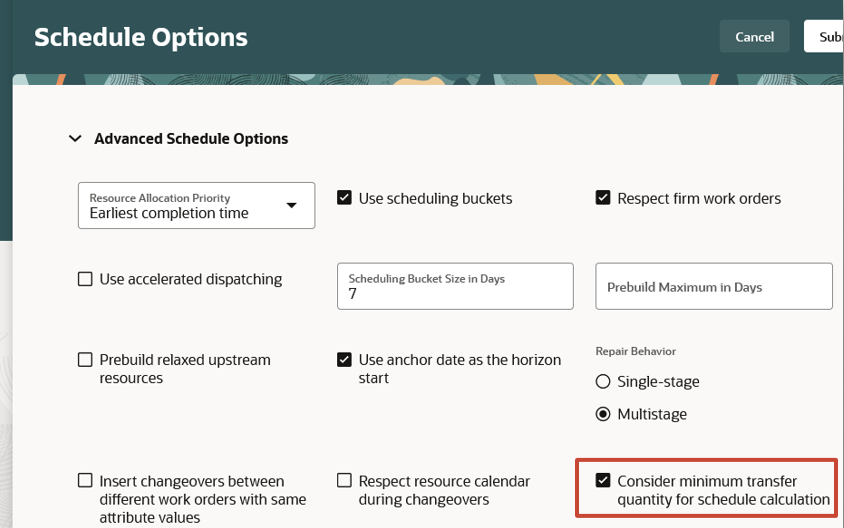

Schedule Options

On the Schedule Options page, you can now specify whether the minimum transfer quantity will be considered during schedule calculation. If you select the Consider minimum transfer quantity for schedule calculation check box, then operation overlaps will be possible within and across work orders.

Advanced Schedule Options

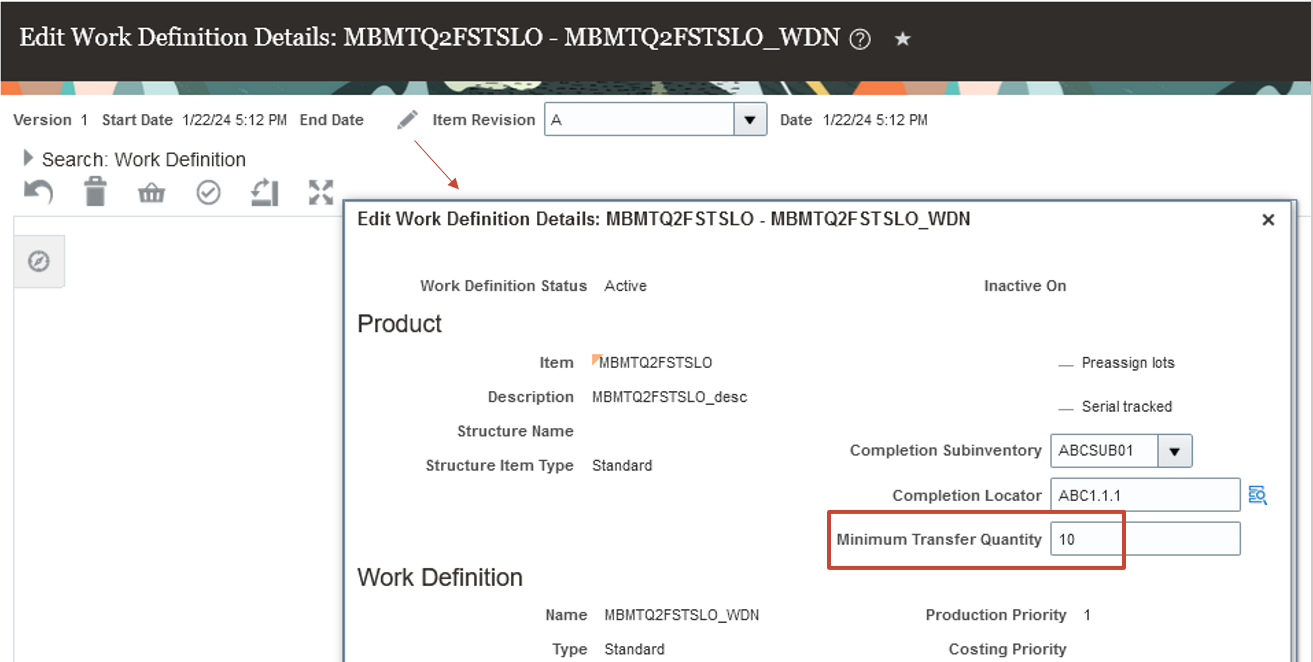

Work Definition

The minimum transfer quantity is maintained on an item's work definition and is consistent across all operation resources, including alternates.

Work Definition Details

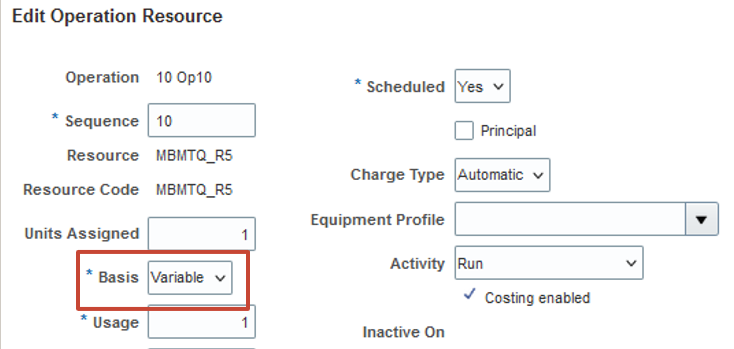

You can enable operation overlap for operation resource sequences by setting the Basis field to Variable in the Edit Operation Resource dialog box. When set to Fixed, operation resource sequences won’t overlap with any upstream or downstream operation.

Edit Operation Resource

If successive operation resource sequences are defined as Variable, they might overlap if other constraints allow it (for example, materials and resource capacity). The overlap can be up to the duration that corresponds to the resource usage time of the upstream operation for one minimum transfer quantity.

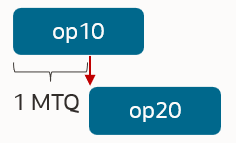

Operations with a Variable Basis Can Overlap

If one of the successive operation resource sequences is defined as Fixed, its operations will always be scheduled sequentially without overlap.

Operations with Fixed Basis Can't Overlap

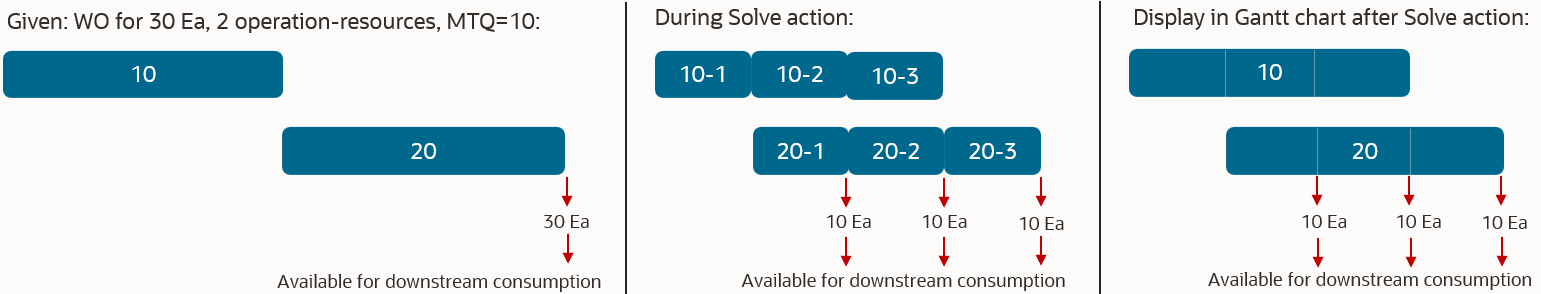

Minimum Transfer Quantity Slices

When a work order uses a work definition that has a minimum transfer quantity defined, and the schedule option Consider minimum transfer quantity for schedule calculation is checked, then Oracle Production Scheduling divides the work order quantity by the minimum transfer quantity to determine how many slices are needed to complete the task. If the work order quantity isn’t a multiple of the minimum transfer quantity, then the last slice will contain an amount less than the minimum transfer quantity. For example, if the minimum transfer quantity is 10 and a work order quantity is 27, the first two slices each contain a quantity of 10, and the third slice contains a quantity of 7. Each slice consists of proportionally scaled operation resource sequences that consume proportional material requirements and resource hours and produce proportional outputs. These outputs are then available for downstream consumption.

Note that in the Gantt chart and dispatch list, only the complete operation resources are displayed, not individual slices.

Only Complete Operation Resources Are Displayed in the Gantt Chart

Work Order Dates

In Production Scheduling, the operations in the dispatch list and Gantt chart correspond to operation resource sequences from the work order operations. For each operation resource, the start date corresponds to the earliest start date of its minimum transfer quantity slices, and the end date corresponds to the latest date. These dates will be used when updating work orders upon schedule release. The start and end times of a work order scheduled with a minimum transfer quantity are determined as follows:

- Work order start date = Earliest operation start date

- Work order end date = Latest operation end date

- Operation start date = Earliest operation resource start date of all corresponding minimum transfer quantity slices

- Operation end date = Latest operation resource end date of all corresponding minimum transfer quantity slices

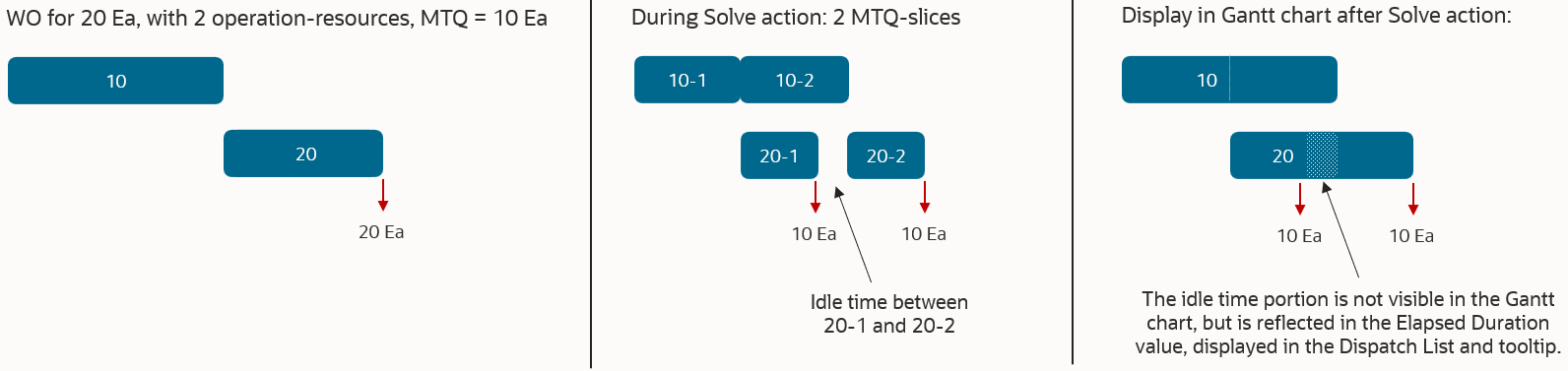

Varying Operation Resource Usage Hours

Typically, operation resource sequences vary in their resource usage, meaning that their resource durations differ as well. So, some operation resource durations within a work definition end up having shorter durations in the production schedule than others. Consequently, a solve action might space out faster operations, resulting in increased elapsed duration. The duration corresponds to the idle time that’s inserted between minimum transfer quantity slices. Note that the idle time of a resource isn’t visible in the Gantt chart; only complete operation resources are displayed. However, the elapsed duration shown in the dispatch list or tooltip will reflect that the elapsed duration is greater than the duration in those situations.

Varying Durations of Operation Resources Within a Work Order

In the previous example, if the upstream operation 10 was faster than operation 20, then no idle time would be inserted into operation 10. Operation 10 is the first operation, so there would be no need to wait for upstream minimum transfer quantity slices to complete. Therefore, all minimum transfer quantity slices of operation 10 would be scheduled together.

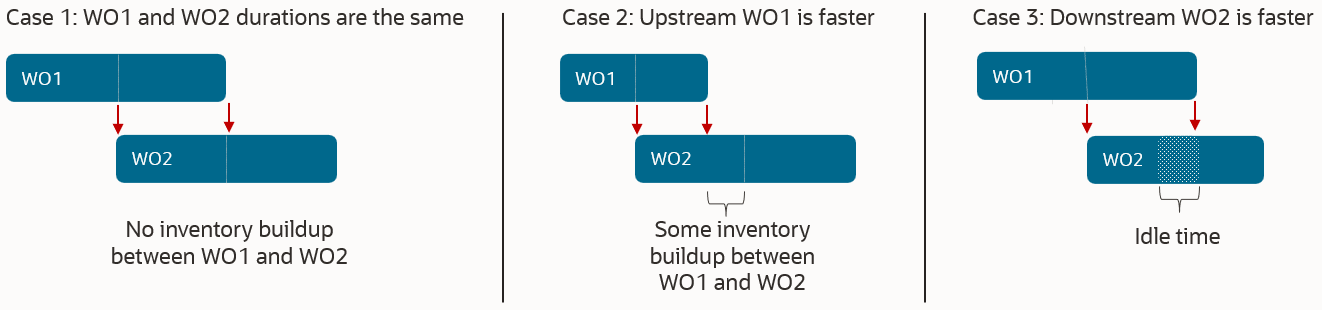

Work Orders with Single Operation Resource Sequences

If work orders have single operation resources, then their minimum transfer quantity slices are scheduled adjacently when the required components are available. If the components are delivered by other supplies, for example, upstream work orders, then the minimum transfer quantity slices might get spaced out. The following example assumes work orders WO1 and WO2, each with a single operation resource. WO1 produces a component that WO2 consumes, and WO quantities =20 and minimum transfer quantities =10. The solve action will consider two minimum transfer quantity slices for each work order, and the schedule result will depend on the WO operation resource durations. If the upstream work order WO1 is faster, then its minimum transfer quantity slices are scheduled adjacently, and component inventory buildup might occur. If the downstream work order is faster, then its minimum transfer quantity slices might be spaced out, resulting in an elapsed duration that’s greater than the duration.

Two Work Orders with a Single Operation Resource

Repair Behavior and Starts After End Constraints of Successive Operations

In general, the repair action that can be triggered after performing manual schedule changes will always only reschedule the operations that were modified. In addition, those operations in the same work order that must be moved to adhere to the starts-after-end constraints of successive operations (for example, "op 10 must complete before op 20 can start") will also be rescheduled. In the context of minimum transfer quantity, this consideration applies to each minimum transfer quantity slice and the related upstream and downstream operation slices individually.

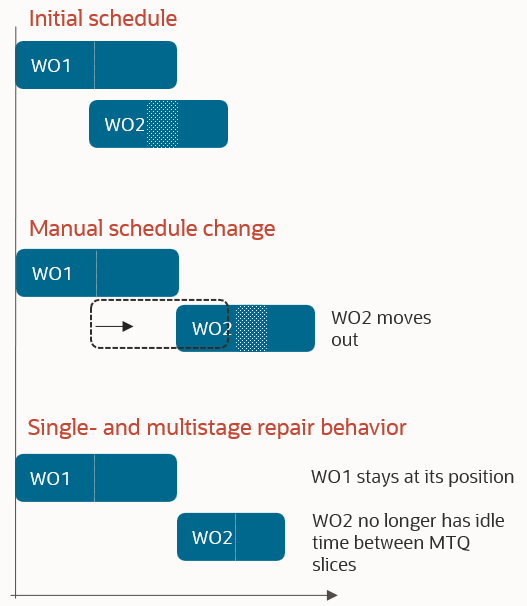

Repair Behavior for Work Orders with a Single Operation Resource

For work orders with only a single operation resource sequence, the repair action will behave as follows:

- Only the moved work order is rescheduled, independent of the single or multistage repair behavior defined in the schedule options.

- The duration of each minimum transfer quantity slice stays the same, but the idle time between the minimum transfer quantity slices might be removed.

The following example involves two work orders, each with a single operation resource, and assumes that the downstream work order’s operation resource is faster. If work order WO2 is moved out during manual scheduling, then the repair action might remove the idle time from the WO2 operation resource.

Repair Behavior for Work Orders with a Single Operation Resource

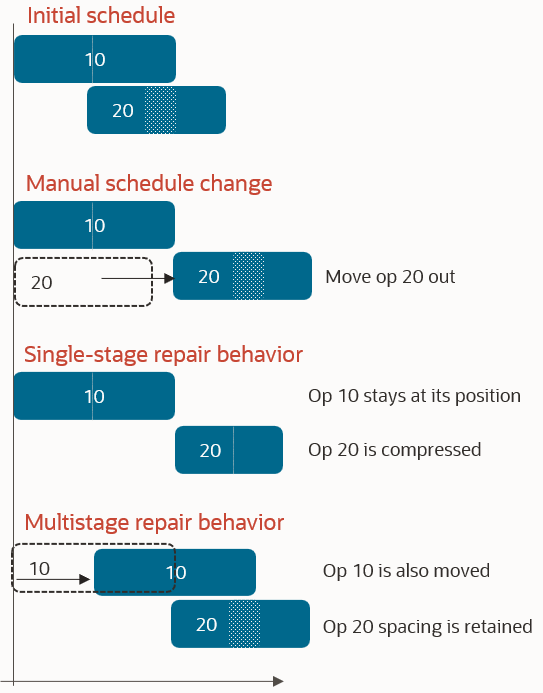

Repair Behavior for Work Orders with Multiple Operation Resources

In cases where a work order has multiple operation resources, the behavior of the repair action depends on the repair mode specified on the Schedule Options page in the Advanced Schedule Options section. If the minimum transfer quantity slices for a faster work order operation were spaced out by the solve action (op 20 in example below), then the repair action might compress such an operation again. This depends on the repair mode set in the schedule options:

- Single stage repair: Spacing is retained only if the precedence rules require it, as they are enforced for each minimum transfer quantity slice.

- Multistage repair: Spacing between minimum transfer quantity slices is generally retained, as the makespan of each individual minimum transfer quantity slice is minimized, resulting in the faster operation slices remaining spaced out.

Repair Behavior for Work Orders with Multiple Operation Resources

Process Work Definitions and Minimum Transfer Quantity

For process work definitions, the minimum transfer quantity should be the same as the batch quantity or multiples thereof. Production Scheduling will consider the work order’s primary output quantity and the minimum transfer quantity to scale the input and output quantities and the duration of each operation’s minimum transfer quantity slice. For example, given a work order with primary output quantity=100, batch quantity=10, minimum transfer quantity=20, and a total duration of 10 hours, Production Scheduling will schedule:

- Five minimum transfer quantity slices, as WO Qty / minimum transfer quantity = 100 units / 20 units = 5

- Each minimum transfer quantity slice has:

- A duration of 2 hours, as WO total duration / # minimum transfer quantity slices = 10 hours / 5 = 2 hours

- An output quantity of 20 units, as WO primary output quantity / # minimum transfer quantity slices = 100 units / 5 = 20 units

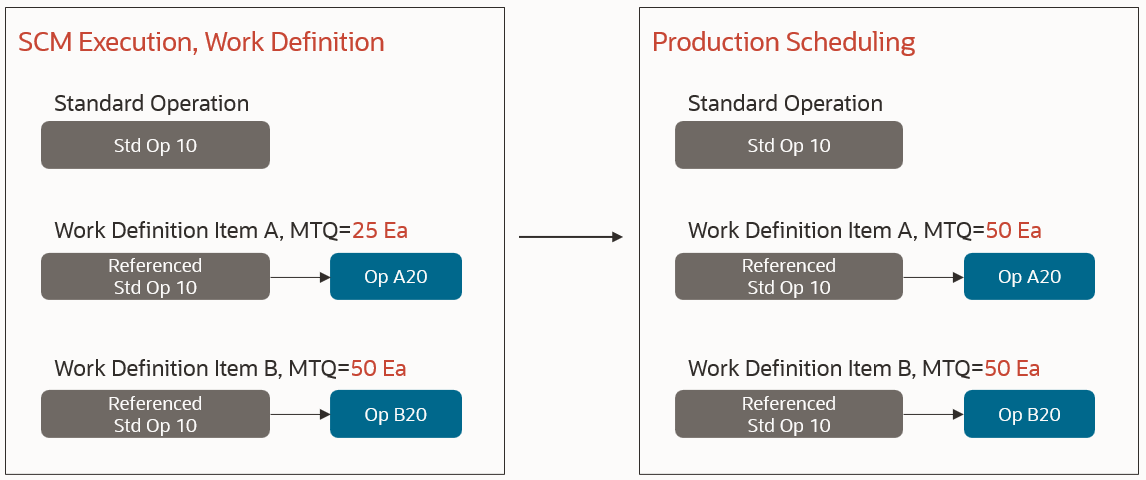

Standard Operations and Minimum Transfer Quantity

We recommend not to use standard operations in multiple work definitions if more than one of these work definitions will have different minimum transfer quantity values. If used in such a situation, then Production Scheduling will use the largest of these minimum transfer quantity values for all work definitions and the work orders that use them.

Standard Operations and Minimum Transfer Quantity

Outside Processing Operations

Note that outside processing operations will be scheduled without consideration of the minimum transfer quantity; that is, they will not overlap with the previous and next operations in the work order.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning

Tips And Considerations

If you want to use the Plan and Schedule Supplies Respecting Minimum Transfer Quantity Between Operations feature, then you must opt in to its parent feature: Production Scheduling. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

Key Resources

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- Edit Production Schedule (MSC_EDIT_PRODUCTION_SCHEDULE_PRIV)

This privilege was available prior to this update.