Include Operation Yield in Cost Planning and Cost Accounting for Estimated Losses During Work Order Execution

You can now include the impact of operation yield when calculating the standard cost of items using cost roll up and when accounting discrete work orders. Operation yield indicates the yield expected out of an operation. A value of 1 indicates that there isn't any loss. However, any value less than 1 indicates a planned loss in that operation.

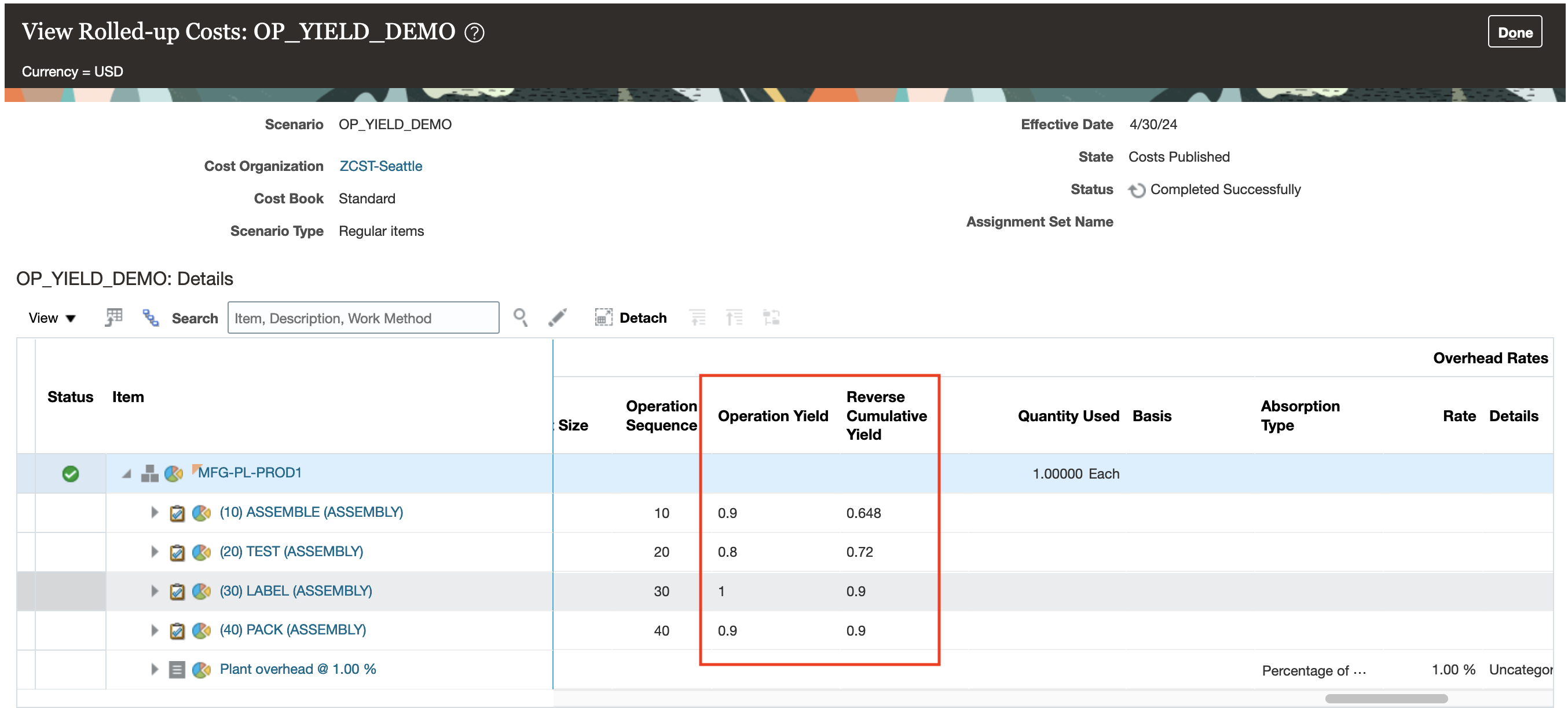

Let's consider an example of a work definition with 4 operations and the operation yields defined. The cumulative yield and reverse cumulative yield are calculated as shown in the table below.

| Operation | Operation Yield | Cumulative Yield | Reverse Cumulative Yield |

|---|---|---|---|

| 10 | 0.9 | 0.9 | 0.648 |

| 20 | 0.8 | 0.72 | 0.72 |

| 30 | 1.0 | 0.72 | 0.9 |

| 40 | 0.9 | 0.648 | 0.9 |

For standard costed items, the Roll up Costs process will include the operation yield defined at each operation to scale up the quantities of components and resources required. The View Rolled Up Costs page shows the Operation Yield defined in the work definition and also the Reverse Cumulative Yield for each operation.

View Rolled Up Costs page shows the operation yield and reverse cumulative yield numbers

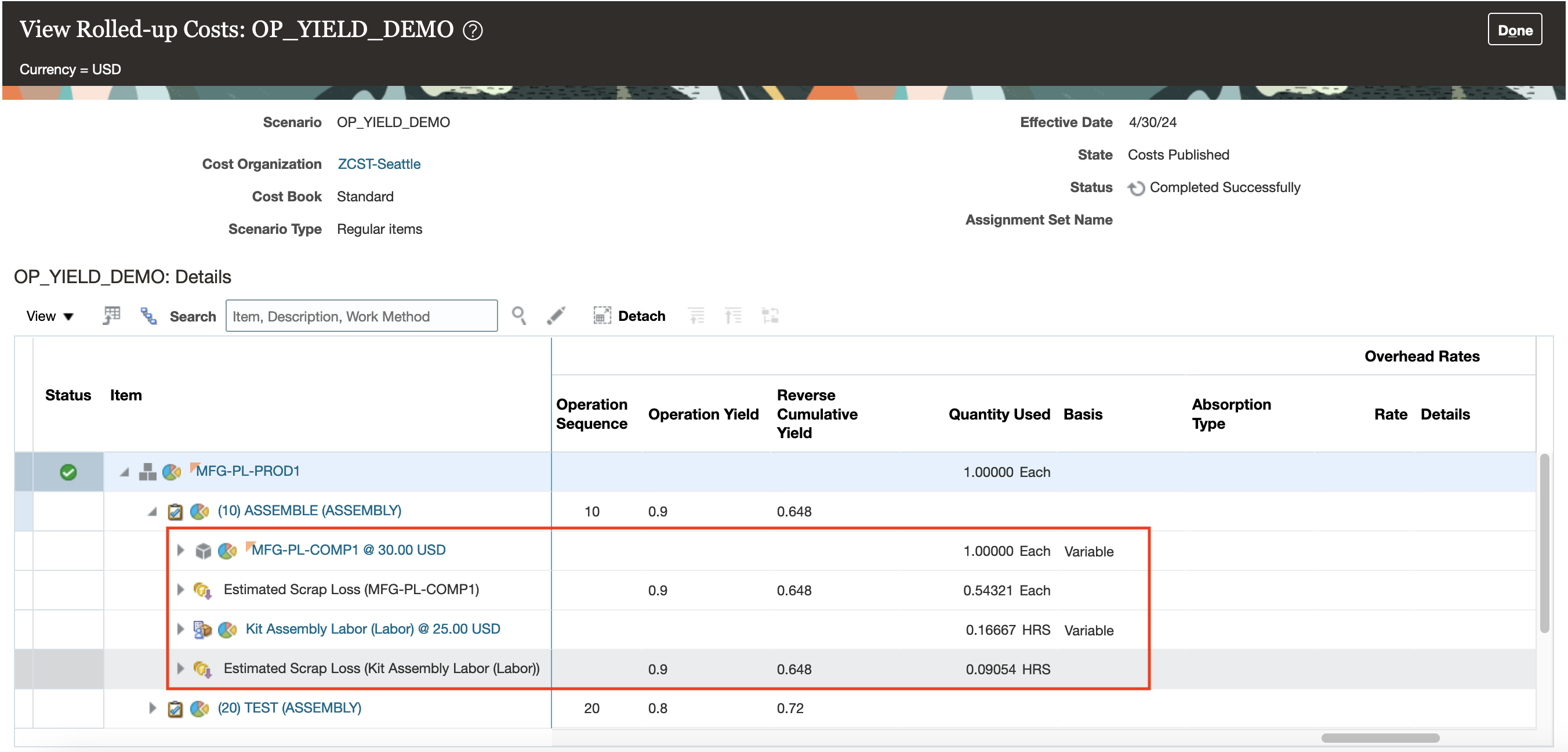

The rolled up cost will show you the extra items and resources used to factor in the operation yield as Estimated Scrap Loss. The Reverse Cumulative Yield is used to calculate the extra quantities that need to be considered based on the operation yield defined in the work definitions.

The formula for Estimated Scrap Loss for an input = [(1-Reverse Cumulative Yield)/Reverse Cumulative Yield] * Scaled quantity

In the View Rolled Up Costs page, the Estimated Scrap Loss node shows the quantities of input lost due to operation yield. Every input (material and resource) with variable basis type has estimated scrap loss due to the operation yield.

View Rolled Up Costs page shows the estimated scrap loss for each component and resource.

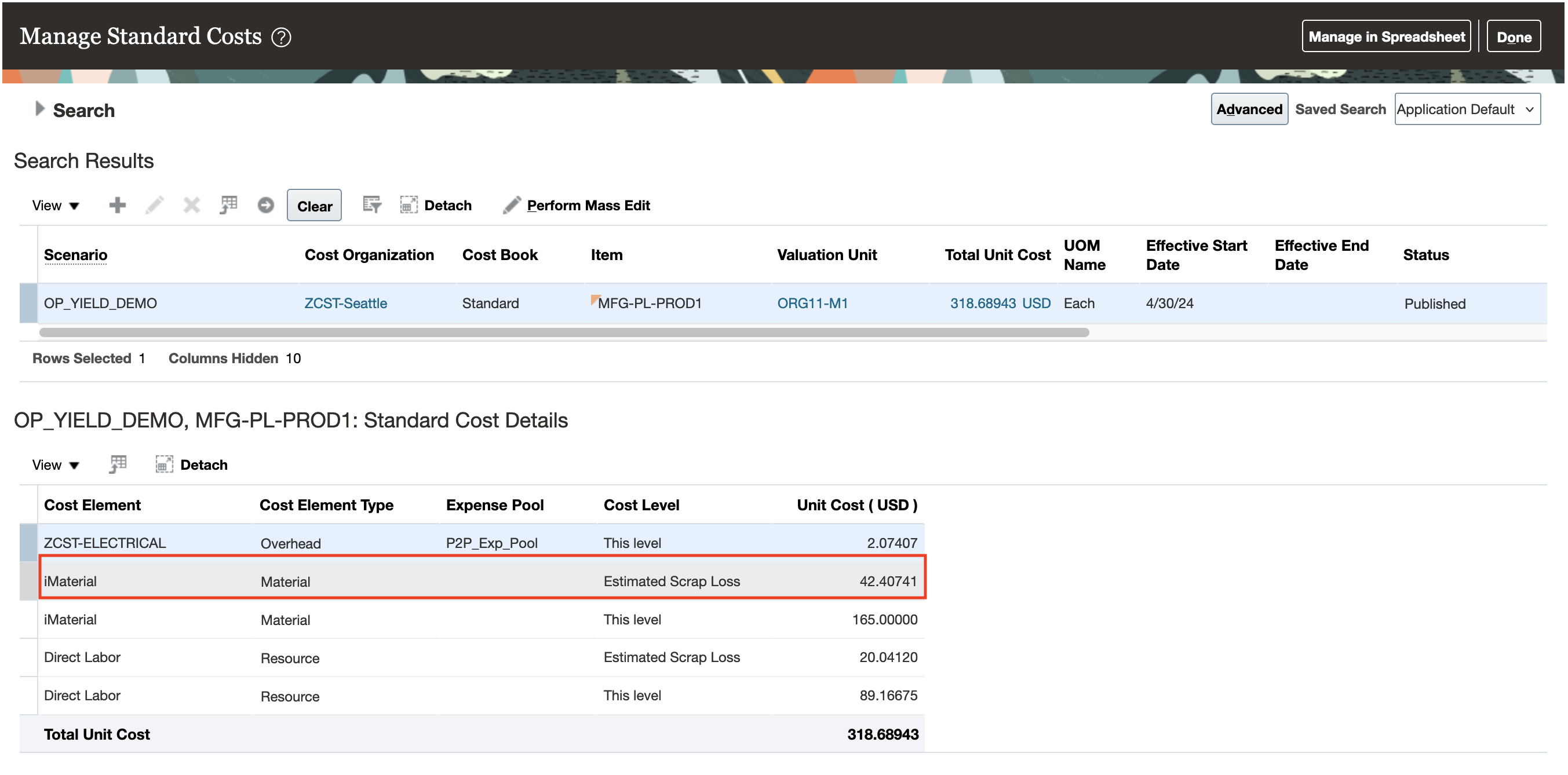

The standard costs that are published will show the Estimated Scrap Loss as a separate cost level.

Estimated Scrap Loss details shown in the Manage Standard Costs page

A new transaction called Estimated Scrap is created to absorb the costs due to the additional material used at each operation. An Estimated Scrap transaction is recorded for each completion of an operation that has operation yield associated with it.

Estimated Scrap Quantity = Operation Completion Quantity * (1- Operation Yield)/Operation Yield)

Accounting entries for Estimated Scrap

| Accounting Line Type | Debit | Credit |

|---|---|---|

| Work in Process | X | |

| Estimated Scrap Absorption | X |

If an operation completion transaction is reversed, the estimated scrap gets reversed through an Estimated Scrap Return transaction

| Accounting Line Type | Debit | Credit |

|---|---|---|

| Estimated Scrap Absorption | X | |

| Work in Process | X |

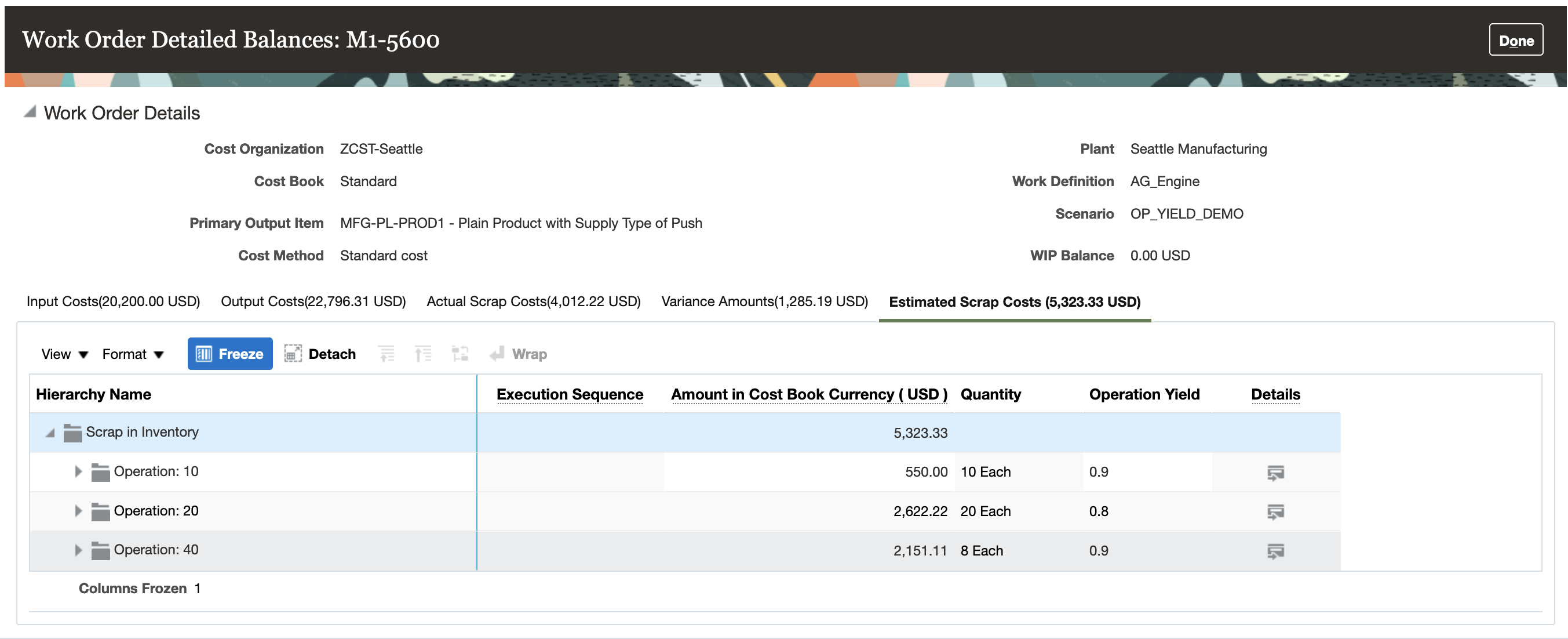

A new tab has been added to Review Work Order Costs - View Detailed Balances page to show the Estimated Scrap that has been absorbed into work in process.

Estimated Scrap in Review Work Order Costs page

The actual scrap transaction reported in work orders are processed with the Operation Scrap Accounting option of Expense, irrespective of the value set up in the cost profile. The timing of the scrap processing transaction depends on the Operation Scrap Valuation option chosen in the cost profile.

| Accounting Line Type | Debit | Credit |

|---|---|---|

| Scrap Expense | X | |

| Work in Process | X |

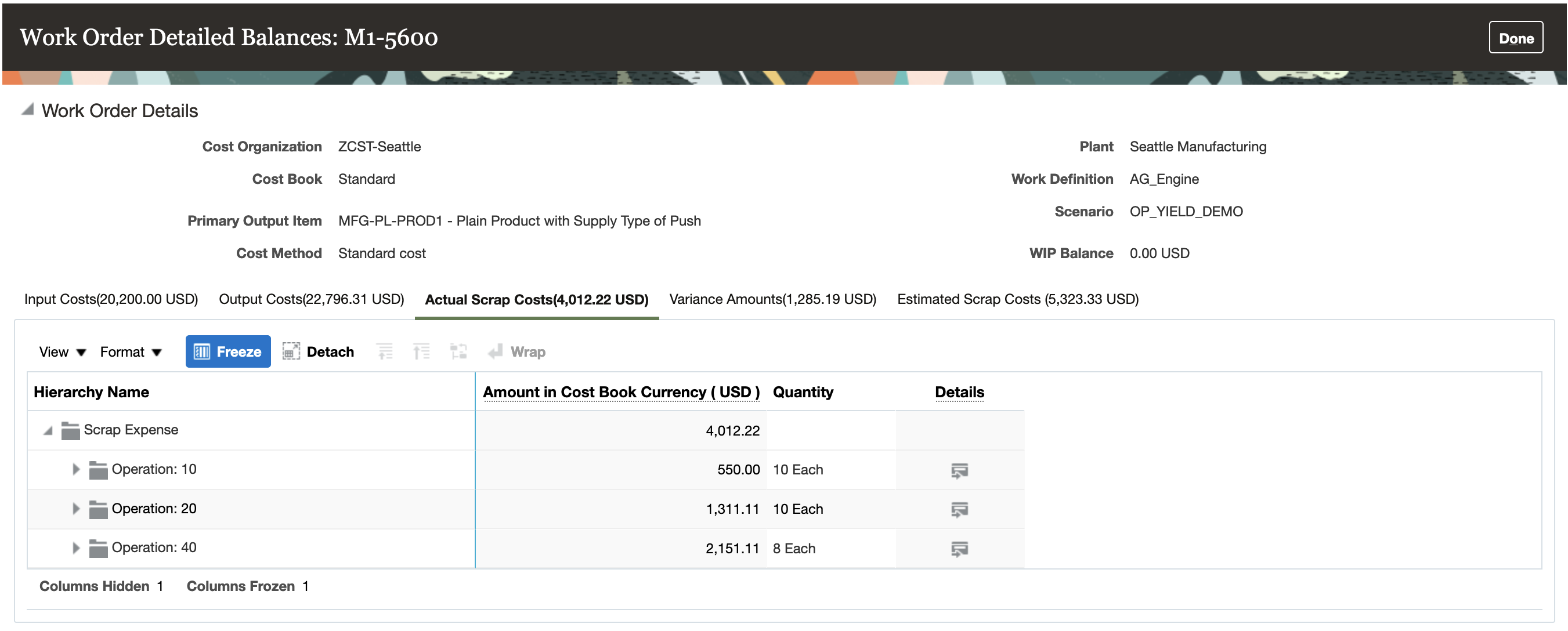

The Actual Scrap Costs tab in the Review Work Order Costs - View Detailed Balances shows the actual scrap reported for the work order.

Actual Scrap details in the Review Work Order Costs page

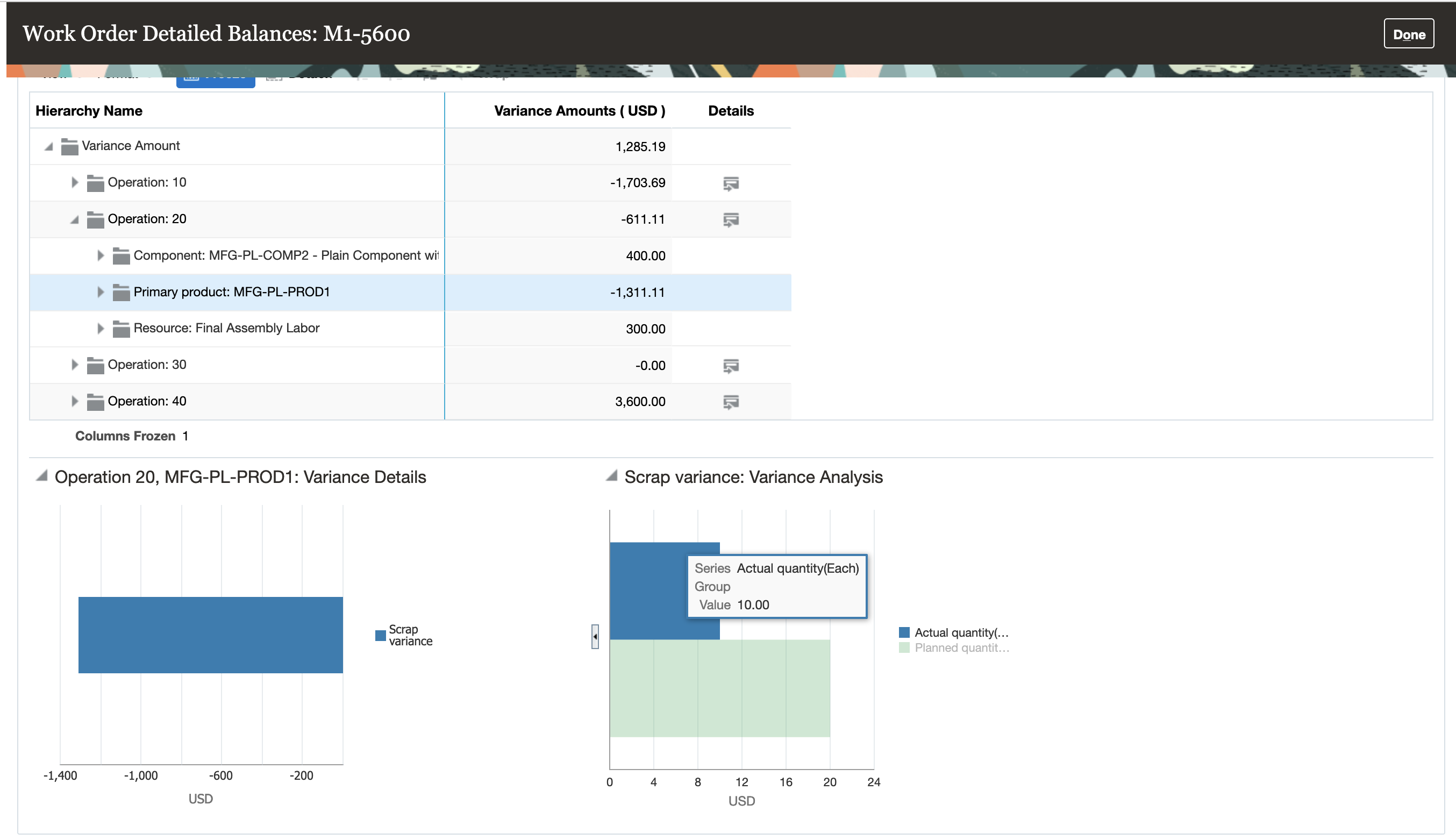

If the primary output is standard costed, a scrap variance is created to account for the variance between the the estimated and actual scrap.

Scrap variance reported if there is a difference between the estimated and actual scrap

By including the effect of operation yield in cost rollup and cost accounting, you will be able to track the estimated scrap and actual scrap to monitor operational efficiencies.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 25A

Tips And Considerations

- Estimated scrap transactions are reported for all cost methods.

- Detailed variance computation will be based on the actual quantity reported in the final operation.

Key Resources

- Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management Guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Using Supply Chain Cost Management Guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Create Cost Distributions (CST_CREATE_COST_DISTRIBUTIONS)

- Review Cost Distribution (CST_REVIEW_COST_DISTRIBUTIONS)