Consider Minimum Transfer Quantity in Work Order Scheduling and Lead Time Calculation

In the prior update, you can optionally define a minimum transfer quantity for an item in its work definition to model overlapping and sequential operations. Now you can create and perform certain update actions on work orders that trigger unconstrained scheduling or rescheduling with consideration for the minimum transfer quantity to overlap operations and operation resources. By using a work definition with a minimum transfer quantity and selecting the default scheduling method, you can perform forward, backward, and midpoint scheduling for a work order through the UI, using a REST API, and File-Based Data Import.

Overlapped Operations When Minimum Transfer Quantity = 200 and Work Order Quantity = 1200

In addition, you can consider the minimum transfer quantity in the manufacturing lead time calculation of an item based on its primary work definition and lead time lot size.

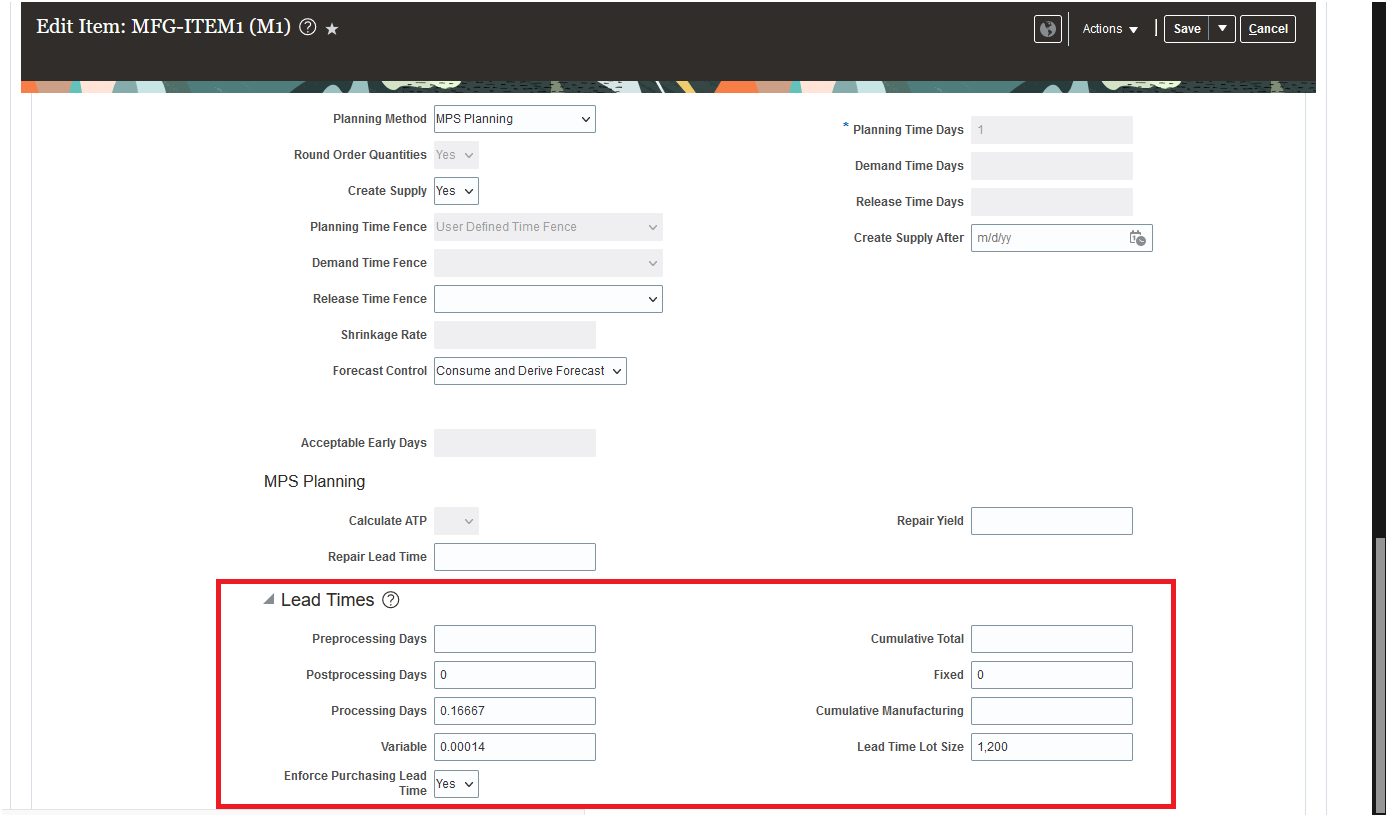

Manufacturing Lead Time Values for an Item with Minimum Transfer Quantity = 200 and Lead Time Lot Size = 1200

By considering a minimum transfer quantity in work order scheduling, you can accurately model factory operations that results in reduced lead times, and maximize resource utilization.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 24D

The 11.13.24.04.0 feature - Define a Minimum Transfer Quantity When Modeling Overlapping Operations or Work Orders must be opted in to automatically enable this feature.

Tips And Considerations

- You can define a minimum transfer quantity for all work definition types, work order types, and work methods in Manufacturing.

- Minimum transfer quantity doesn't apply for a standard operation or operation resources with a Fixed basis type. They are scheduled in contiguous blocks without overlap.

- For more information about minimum transfer quantity, refer to the 24B feature: Define a Minimum Transfer Quantity When Modeling Overlapping Operations or Work Orders.

- It's recommended to specify the lead time lot size in the manufacturing lead time calculation for an item with minimum transfer quantity defined in its work definition.

Key Resources

- Watch the Consider Minimum Transfer Quantity in Work Order Scheduling and Lead Time Calculation Demo.

- Refer to the 24B feature: Define a Minimum Transfer Quantity When Modeling Overlapping Operations or Work Orders

- Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center

Access Requirements

Users who are assigned a configured job role that contains these privilege can access this feature:

- Manage Work Definitions (WIS_MANAGE_WORK_DEFINITIONS_PRIV)

- Calculate Manufacturing Lead Times (WIS_CALCULATE_MANUFACTURING_LEAD_TIMES_PRIV)

- Manage Work Order Headers (WIP_MANAGE_WORK_ORDER_HEADERS_PRIV)

- Manage Work Order Operations (WIP_MANAGE_WORK_ORDER_OPERATIONS_PRIV)

These privileges were available prior to this update.