Respect the MTQ Within and Across Work Definitions

Transferring material quantities across operations in increments, referred to as a minimum transfer quantity (MTQ), allows for increases in operational efficiency and maximizes overall equipment effectiveness by reducing overall manufacturing lead times. Previously, the capability to define and use an MTQ was available, but it was enabled only for production scheduling. With this update, the tactical supply planning process also considers any defined MTQ when calculating a plan, enabling you to model your manufacturing operations more accurately when planning calculations of material and resource requirements.

Additional Information

In certain industries, manufacturers leverage a common strategy for reducing the lead time for a manufacturing process by starting a downstream operation before the previous operation completes. They identify a minimum quantity to incrementally transfer between operations.

MTQ in Work Definition

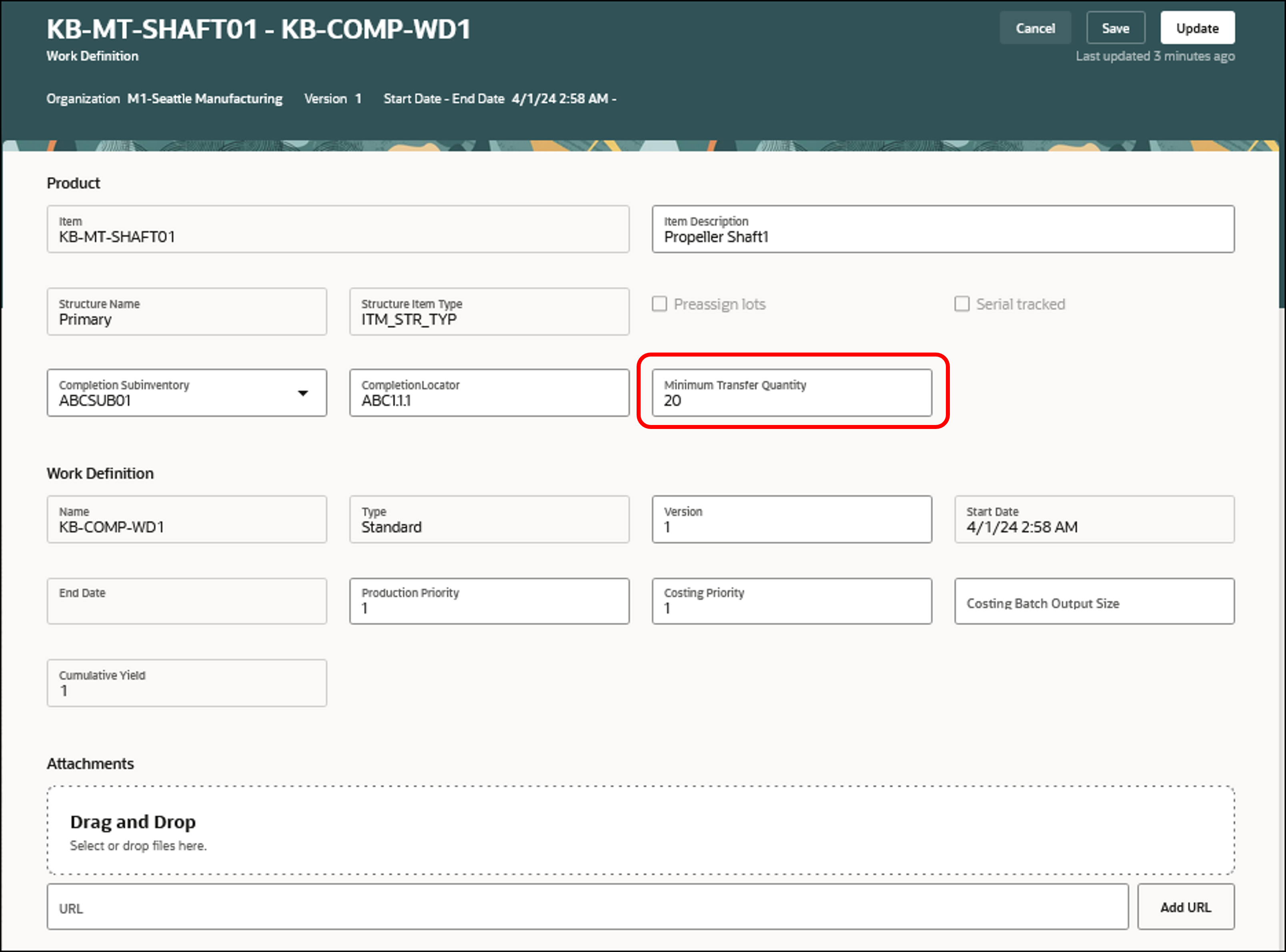

The MTQ is maintained in the Minimum Transfer Quantity field at the work definition header level, which is common across all versions of a work definition. For example, when you change MTQ for version 2, the same change will be reflected in version 1.

The Minimum Transfer Quantity field:

- Is updatable. It can be null or any positive numeric value.

- Is applicable for work methods Discrete, Process, and Contract Manufacturing.

- Isn’t applicable for Maintenance manufacturing (because the work order quantity = 1, and typically nothing is completed into inventory from a Maintenance work order).

- Is applicable for work definition types of Standard and Rework.

- Isn’t supported in a Transform work definition.

- Is supported in all modes: UI, REST, ADFdi, and FBDI.

Work Definition with Minimum Transfer Quantity Field

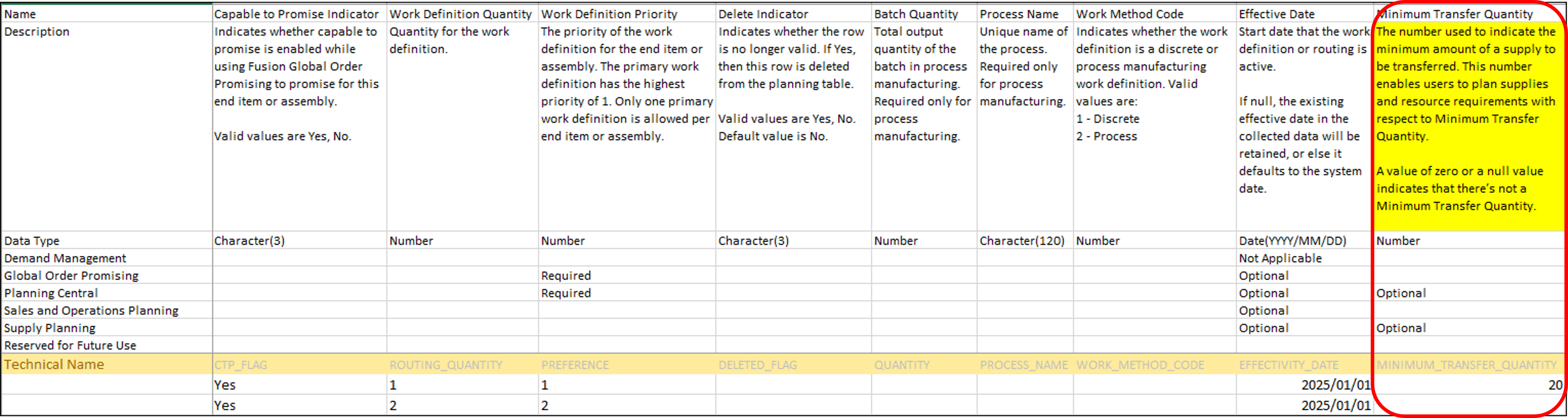

MTQ Uploaded by Using FBDI

The MTQ can also be uploaded by using the Minimum Transfer Quantity column on the Routings tab of the Routings file-based-data-input (FBDI) template.

Routings FBDI Template with Minimum Transfer Quantity Column

- Minimum Transfer Quantity is an optional field.

- The value specified as the Minimum Transfer Quantity in the Routings tab will be applied to all operations.

- A value of zero or a null value in this field indicates that there isn’t an MTQ. This means that an operation must fully complete before the next operation can start.

The MTQ, whether defined in the work definition header or uploaded using the FBDI template, is inferred and implemented at the following levels:

- Operation Sequence (Resource)

- Operation

- Planned Order (Make)

- Work Order

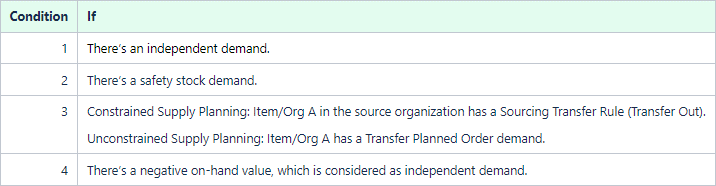

Conditions Where MTQ Isn’t Honored

Oracle Fusion Cloud Supply Planning doesn’t support MTQ across organizations (transfer order).

In addition, MTQ is ignored if any of the following conditions is true:

Conditions Where MTQ Isn’t Honored

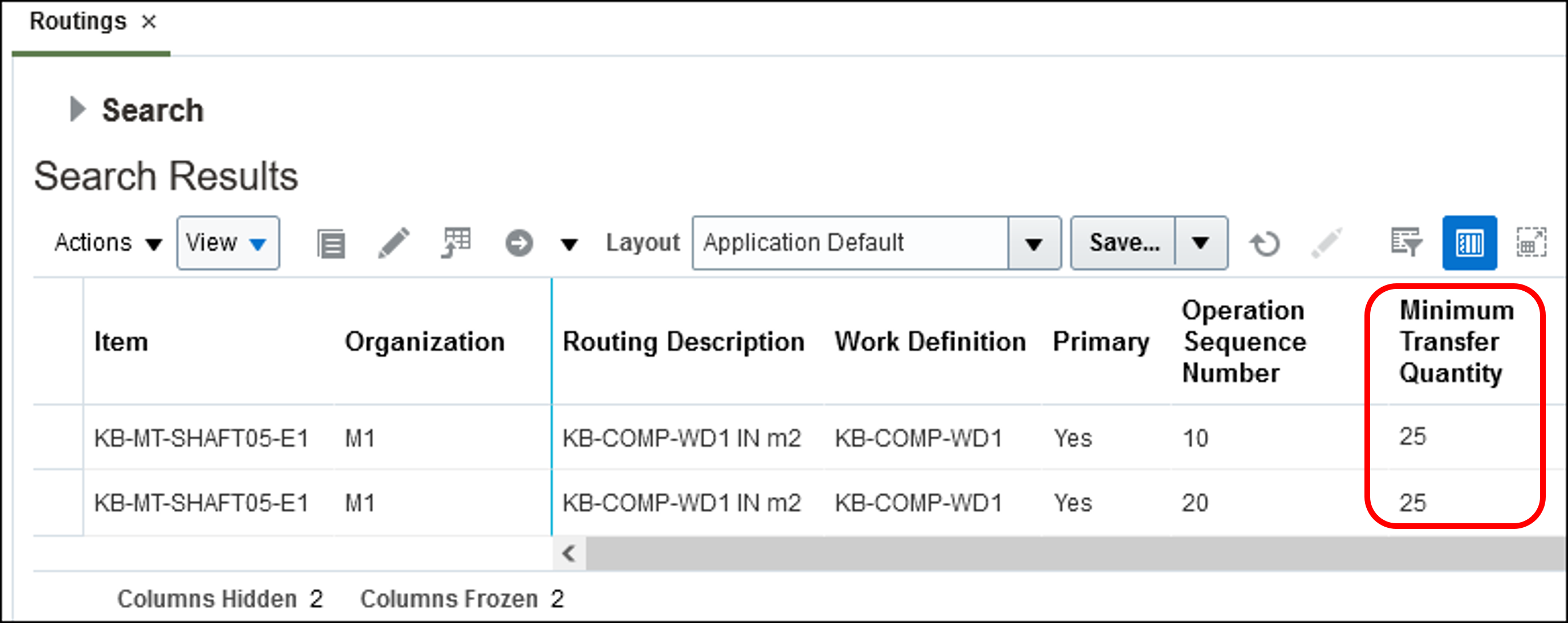

Where MTQ Appears in Supply Planning

A new column named Minimum Transfer Quantity in the Routings table displays the collected MTQ value.

Routings Table with Minimum Transfer Quantity Column

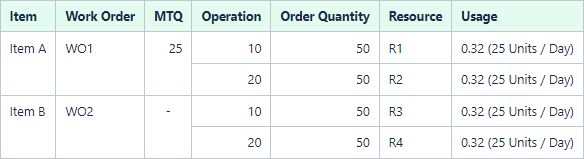

MTQ at the operation level is defaulted from the work definition level, hence all MTQs are 25 in the example shown in the preceding figure.

Behavior of MTQ Within and Across Routings

Oracle Supply Planning allows users to model MTQ between operations within a routing as well as across routings. This implies that a downstream operation can start after completion of the first slice of MTQ at the upstream operation.

There are two versions of MTQ:

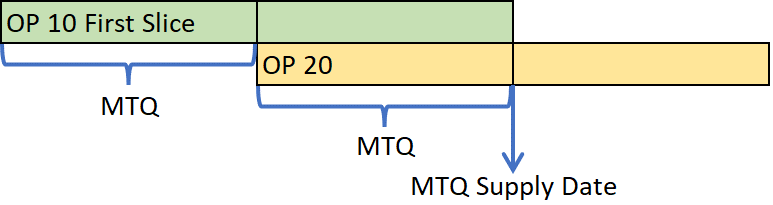

- Intrarouting MTQ – In this case, the MTQ is defined between operations within one routing.

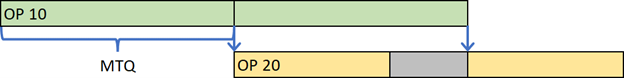

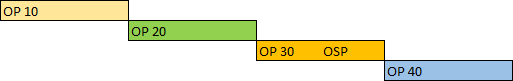

Intrarouting MTQ

MTQ Supply Date is the time when the first slice of MTQ of the upstream process is available for the downstream process.

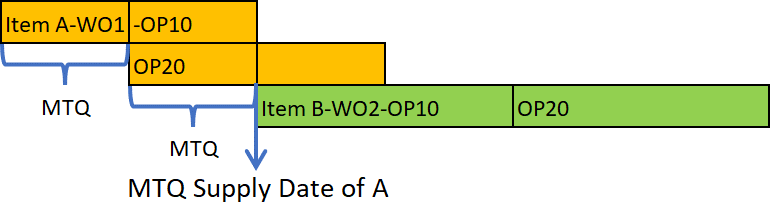

- Interrouting MTQ – In this case, the MTQ is defined between operations across routings.

Interrouting MTQ

Supply Planning Views Containing MTQ Supply Date

The MTQ Supply Date is a new column that’s available on the following pages. It’s hidden by default.

- Supplies and Demands

- Demand Fulfillment

- Late Demand Analysis

- Demand at Risk Due to Insufficient Lead Time

- Late Supply Pegged to Forecast

- Late Supply Pegged to Sales Order

Intrarouting MTQ

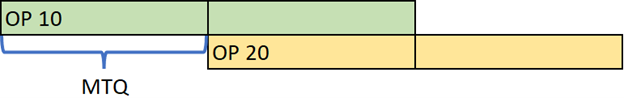

This section presents the planning behavior with respect to MTQ between operations within one routing (intrarouting).

The following figures show how constrained supply planning plans successive operations of a work definition with MTQ given different relative rates for the operations.

Upstream and Downstream Processes Have the Same Rate

Upstream Process Is Faster Than Downstream Process

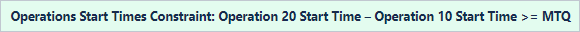

Start Times Constraint

When the downstream process is faster than the upstream process, then supply planning doesn’t create and report any gap in the second operation, as shown by the gray section in Operation 20 in the following figure.

Downstream Process Is Faster Than Upstream Process

Interrouting MTQ

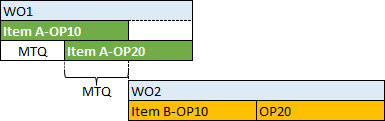

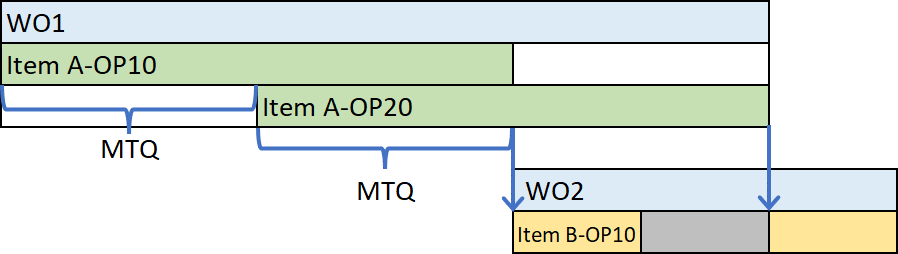

This section presents the planning behavior with respect to MTQ between operations across routings (interrouting).

Upstream Process Is Faster or the Same Rate as the Downstream Process

Example

Interrouting MTQ Behavior: Upstream Faster Than or the Same Rate as Downstream

Interrouting: Downstream Slower Than Upstream or Same Rate

Downstream Process Is Faster Than the Upstream Process

Example

Interrouting: Downstream Faster than Upstream

Oracle Supply Planning doesn’t create and report any gap in Operation 10 of Work Order 2, as shown by the gray section in the preceding figure.

MTQ Supply Date

Oracle Supply Planning considers the date that the first MTQ segment is available from upstream to downstream as the MTQ Supply Date.

Oracle Supply Planning uses MTQ Supply Date for planning downstream processes, pegging, and generating exceptions.

The upstream full supply completion date is the Supply Due Date.

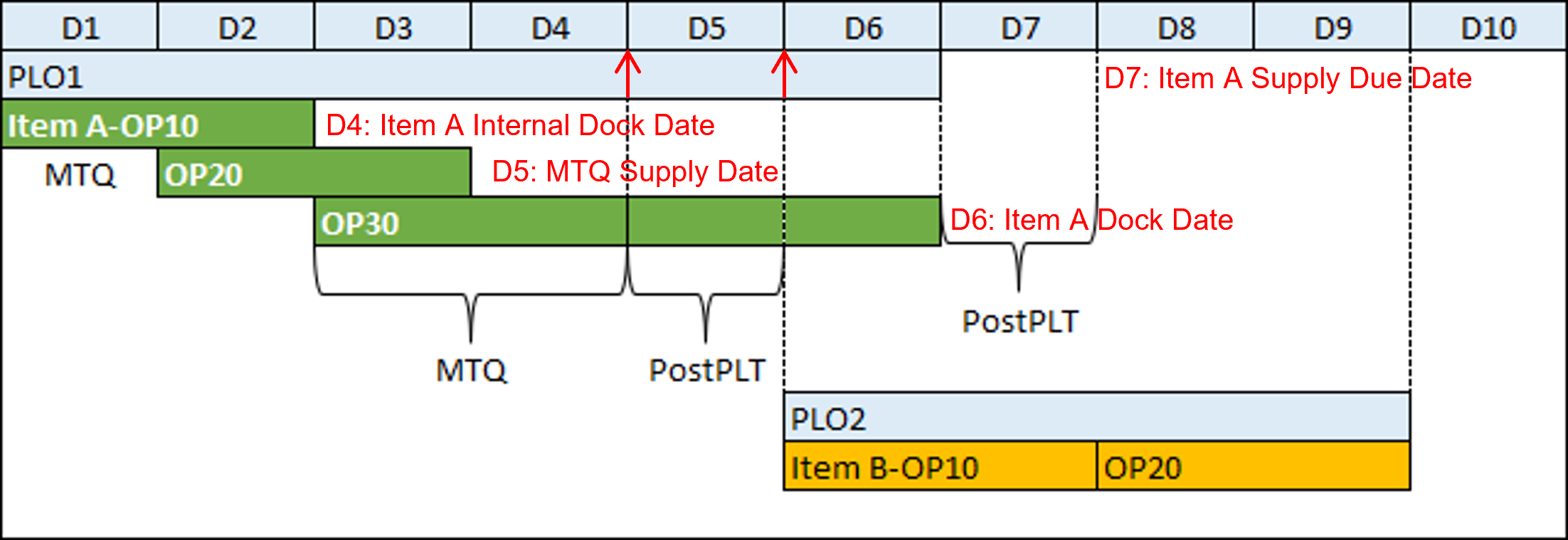

The following figure displays an interrouting case with two items and two planned orders:

PLO1: Item A Planned Order

PLO2: Item B Planned Order

MTQ Supply Date Across Routings

D4: Internal Dock Date = Start date of the last operation plus the time needed to complete one MTQ slice of the last operation.

D5: MTQ Supply Date = Item A Internal Dock Date + Item A Postprocessing Lead Time (PostPLT).

D6: Item A Dock Date

D7: Item A Supply Due Date = Item A Dock Date + PostPLT

Firming Planned Orders and Work Orders with MTQ

If you firm a supply with MTQ and adjust its due date earlier or later, the supply’s MTQ Supply Date moves earlier or later by the same amount.

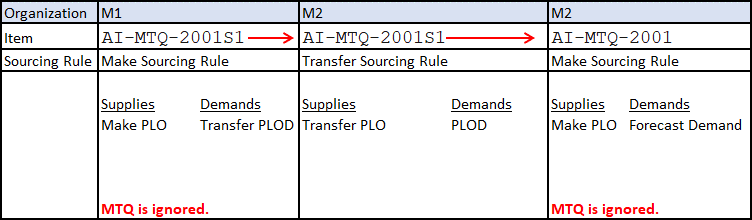

MTQ Isn’t Honored in Cases of Transfer Sourcing Rule

As mentioned earlier, Oracle Supply Planning doesn’t support MTQ across organizations.

The following figure shows the behavior of the planning process with respect to Transfer Sourcing Rule and Transfer Planned Order Demand.

MTQ Support and Transfer Sourcing Rule

- Whenever a supply has to meet demand from outside the organization, MTQ is ignored.

- In this example, the make planned order for Item AI-MTQ-2001S1 in M1 must be completed in its entirety before being transferred in its entirety from M1 to M2.

- Similarly, the make planned order for Item AI-MTQ-2001 in M2 must be completed in its entirety before being used to satisfy forecast demand for AI-MTQ-2001 at M2.

Respecting Finish Time Constraints

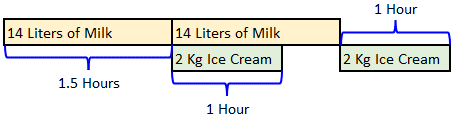

Consider the following ice cream processing example:

An average of 14 liters of milk is needed to obtain 2 kilograms of 30% fat cream.

There’s an order for 2 kilograms of ice cream.

It takes 1.5 hours to process 14 liters of milk, which makes 2 kilograms of ice cream in 1 hour.

Ice Cream Processing Flow

The first transfer quantity of processed milk is available after 9:30 a.m. (the process started at 8:00 a.m.), and then it takes 1 hour to make the first transfer quantity of ice cream, which is available at 10:30 a.m.

The second transfer quantity of processed milk is available at 11:00 a.m. This means making the second transfer quantity of ice cream can’t be started sooner than 11:00 a.m. Consequently, the second batch of ice cream will be ready at least 1 hour after the second batch of processed milk is available.

Finish time of processing ice cream - Finish time of processing milk >= 1 hour.

In such cases, where an upstream MTQ supply feeds a downstream supply that’s also MTQ enabled:

- Constrained supply planning supports such finish time constraints and will produce output that looks like the bottom part of the following figure.

- Unconstrained supply planning, however, doesn’t support finish time constraints and will produce output that looks like the top part of the following figure.

Respecting Finished Time Constraints

MTQ with Operation Yield

MTQ is inflated by the operation yield, as described in the following example.

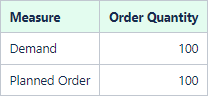

Measure and Order Quantity Values

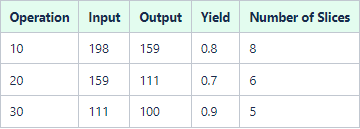

The following table shows the input and output quantities with respect to operation yield:

Operation Input and Output Values

Considering MTQ of 20 units and fixed slices by supply output, the number of slices is calculated as follows:

Number of Slices = 100 / 20 = 5

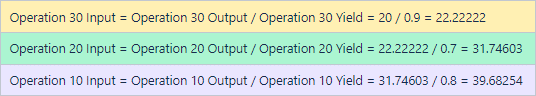

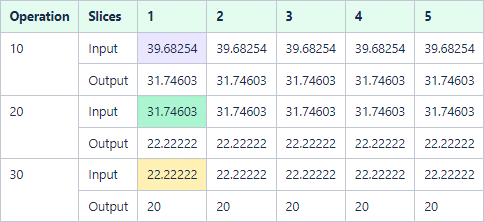

The input quantities at each operation, starting with the last operation with respect to operation yield, are calculated as follows:

Operation Yield Calculations

Operation Yield Impact on MTQ

Planning Support of MTQ with Outside Processing Operations

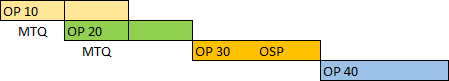

Constrained supply planning doesn’t support MTQ for routings with outside processing operations. The following figure shows that Operation 30 in this example is an outside processing operation (labeled OSP in the figure).

Constrained Supply Planning Output for Routings with an Outside Processing Operation

Unconstrained supply planning also doesn’t support MTQ for outside processing operations. However, unconstrained supply planning does support MTQ for all of the other operations in a routing that includes an outside supply operation, as shown in the following figure:

Unconstrained Supply Planning Output for Routings with an Outside Processing Operation

In this example, Operation 30 is an outside processing operation. But because this is an unconstrained supply plan, MTQ is still supported for all other operations, which means it behaves as follows:

- The supply from the preceding operation (Operation 20) is transferred to the outside processing operation (Operation 30) in one batch at the end of the preceding operation.

- The supply from the outside processing operation (Operation 30) is transferred to the following operation (Operation 40) in one batch at the end of the outside processing operation.

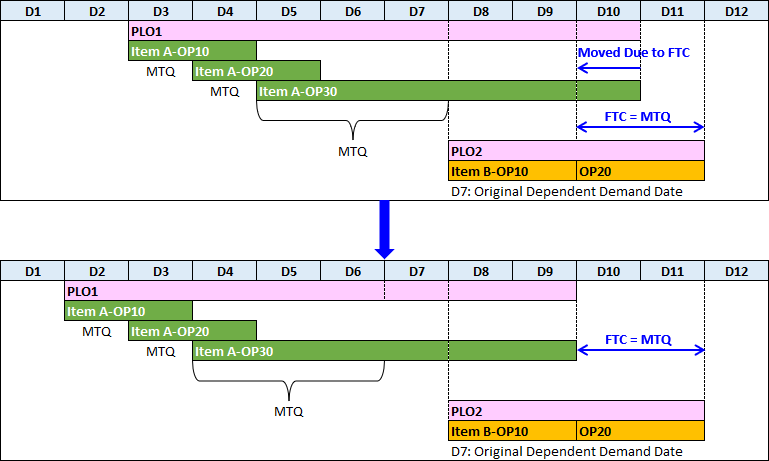

Supply Planning Behavior with Respect to MTQ First Slice Completion Date

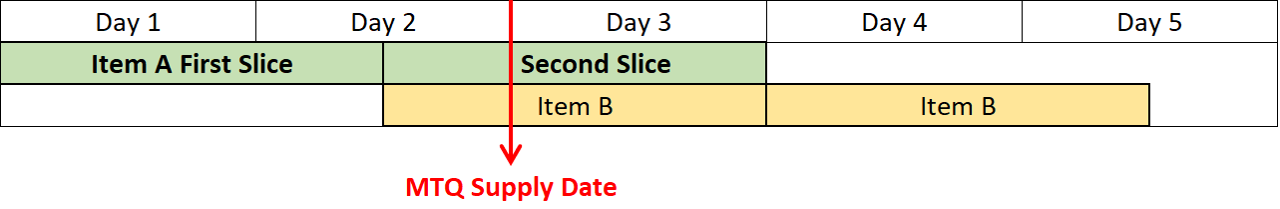

Unconstrained Supply Planning

If the first slice completion date is in the middle of a day, then the MTQ Supply Date is at the end of that day, but the first operation of the downstream process is planned right after the completion of the MTQ first slice.

MTQ Supply Date with Respect to First Slice of Upstream Process in Unconstrained Supply Planning

In this example, the first slice completion date is in the middle of Day 2 (or any time after the beginning of Day 2), then the MTQ Supply Date is at the end of Day 2.

The first operation of the downstream process is planned right after the completion of the MTQ first slice, as shown in the preceding figure.

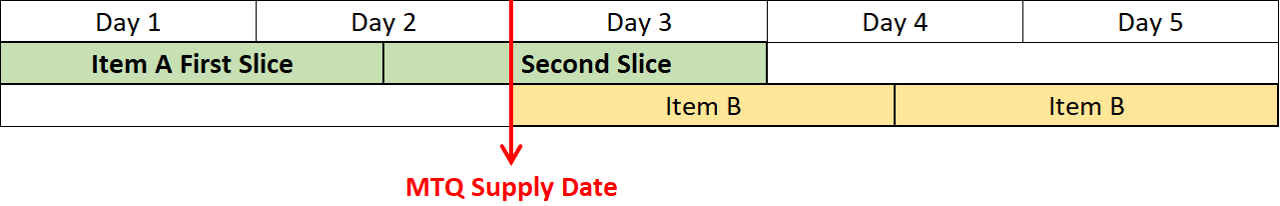

Constrained Supply Planning

If the first slice completion date is in the middle of a day, then the MTQ Supply Date is at the end of that day, and the first operation of the downstream process is planned at the end of that day as well.

MTQ Supply Date with Respect to First Slice of Upstream Process in Constrained Supply Planning

In this example, the first slice completion date is in the middle of Day 2 (or any time after the beginning of Day 2), then the MTQ Supply Date is at the end of Day 2.

The first operation of the downstream process is planned right after the MTQ Supply Date, as shown in the preceding figure.

Note – All dates are reported to the end of the planning bucket. (This is an existing behavior.)

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- Projected Available Balance (PAB) – Because PAB is calculated based on MTQ Supply Date for items with MTQ, it can become and be reported as negative, even though the actual PAB calculated based on the Supply Due Date may not be negative.

- The following exceptions could be affected because they’re generated based on the MTQ Supply Date:

- Late Supply for Forecast

- Late Supply for Sales Order

- Items with a Shortage could be affected because it’s generated based on PAB, which is calculated based on MTQ Supply Date.

- Supply Dates Calculations – All calculations are based on MTQ Supply Date.

- Planning Time Fence – For MTQ items, the MTQ Supply Date respects the planning time fence. As a result, Supply Due Date will respect the planning time fence automatically.

- MTQ is ignored if the order quantity is less than the MTQ.

- Shrinkage Rate – The planning effect of shrinkage rate on MTQ is the same as operation yield.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Supply Chain Planner (ORA_MSC_SUPPLY_CHAIN_PLANNER_JOB)

- Materials Planner (ORA_MSC_MATERIALS_PLANNER_JOB)

These privileges were available prior to this update.