Plan Multiple Outputs from a Discrete Manufacturing Work Definition

Plan Multiple Outputs from a Discrete Manufacturing Work Definition

In discrete manufacturing, consider a scenario where multiple products (co-products or by-products) are being produced along with the primary one, each having its own potential value. For example, several standard-sized metal pieces cut from a single large metal sheet. Oracle Supply Planning and Oracle Production Scheduling now support discrete manufacturing work definitions or work orders that generate multiple output products in addition to the primary one. This update enables discrete manufacturers using Supply Planning and Production Scheduling to efficiently plan and schedule within an environment where manufacturing processes generate items of value with their own demand in addition to the primary product.

You can now plan for the primary and additional products (co-products or by-products) facilitating responses to the discrete manufacturing demands.

This feature is applicable to both Constrained and Unconstrained Supply Plans.

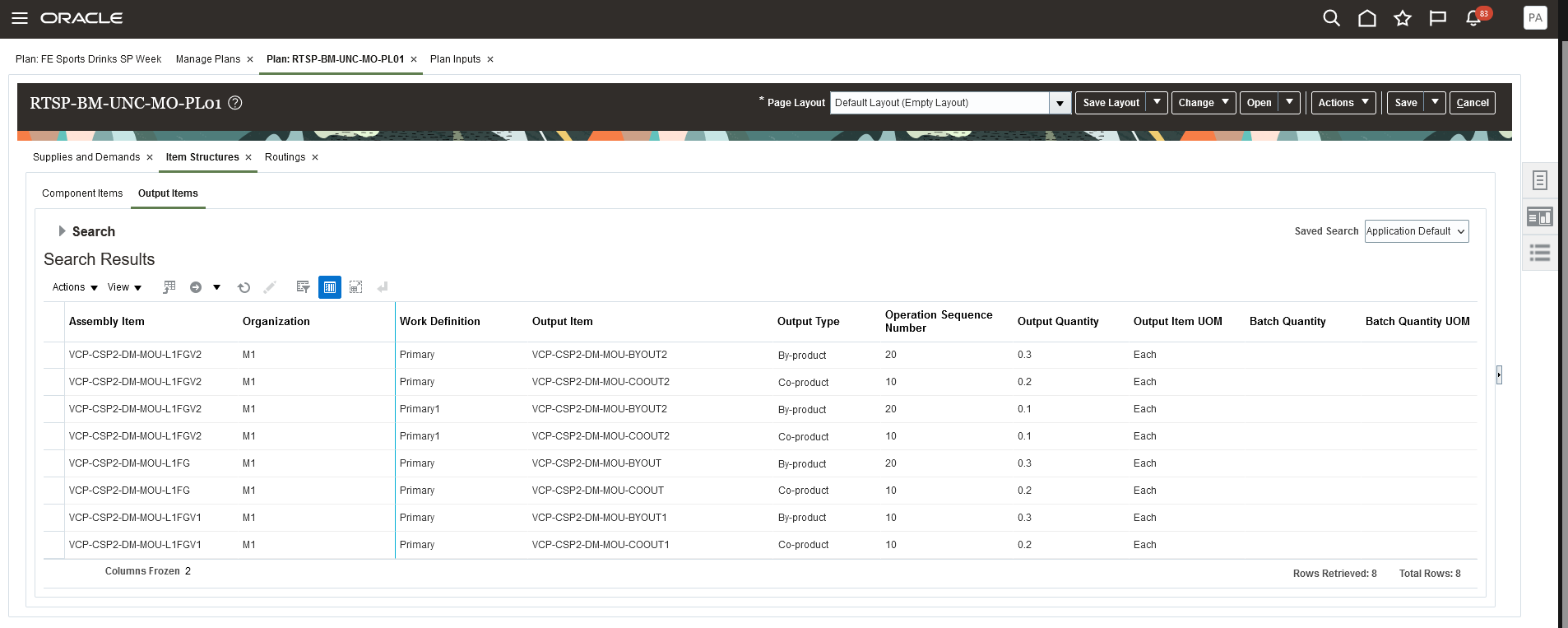

Under the Item Structures option, you can see the various output types such as primary products, co-products, and by-products in the Output Items tab. These products were produced at different operations with a discrete work definition.

Output Type Displayed for the Item Structure in the Output Items Tab

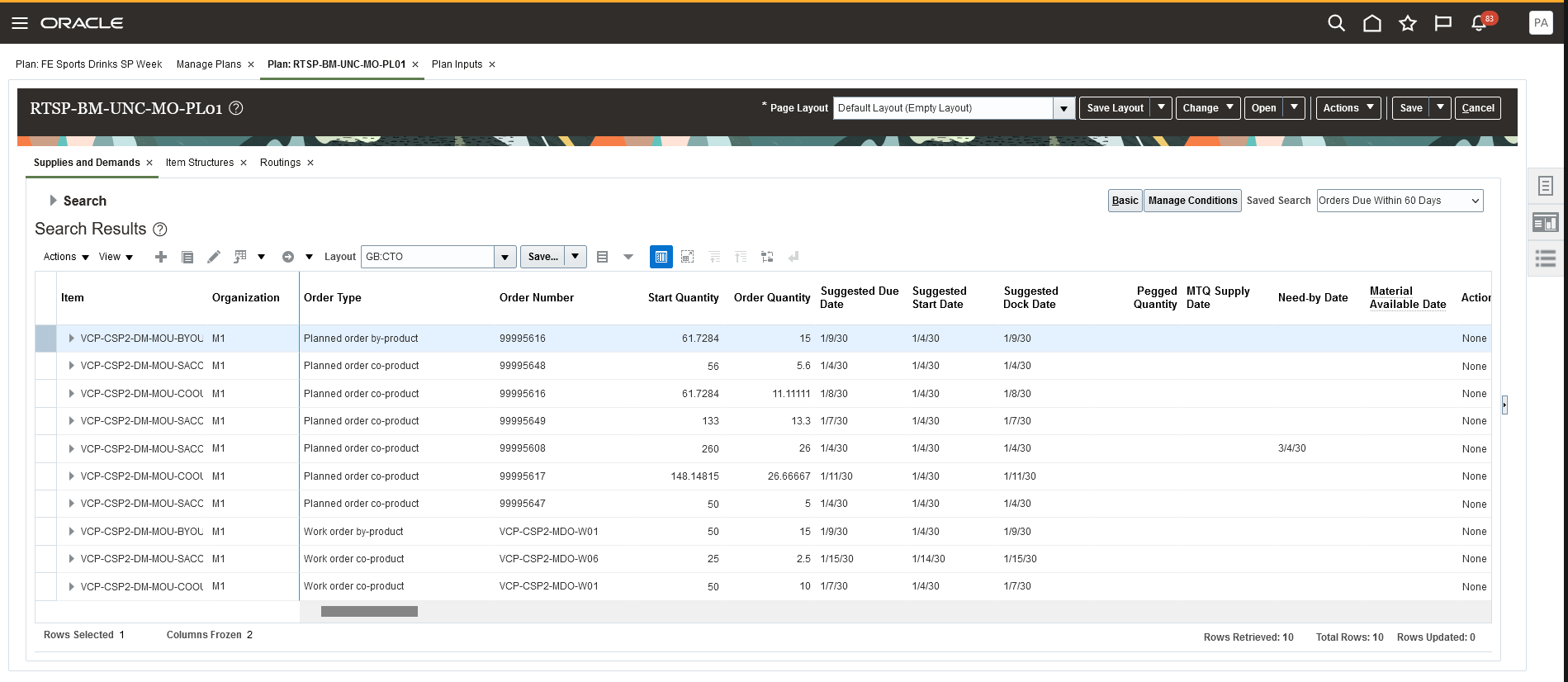

To support the output supplies in discrete manufacturing, these order types are used in the Supply Planning work area:

- Planned Order co-product

- Work Order co-product

- Planned Order by-product

- Work Order by-product

Various Order Types Used for Output Supplies

From planning perspective, Supply Planning recommends new supplies for co-products and by-products in proportion to the output quantities of the primary item.

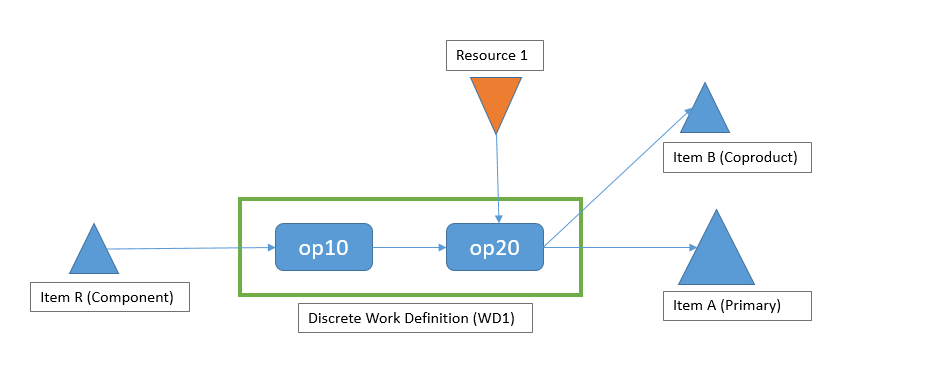

For example, in a unidirectional discrete work definition shown below, item B is generated as a co-product output while producing the primary item A using discrete work definition WD1. Operations op10 and op20 are associated with the discrete work definition WD1. Operation op20 produces both the primary and secondary output items. Resource 1 is utilized at operation op20. Primary item A consumes the component item R in its Item Structure with usage quantity as 2.

Consider the defined usage quantity as 0.5 for the co-product item B. This indicates that for every 1 unit of primary item A produced, 0.5 units of co-product item B is generated.

Unidirectional Supply Chain Network: Item B is the Co-Product and Item A is the Primary Supply

Based on this scenario, here's how the supply plan will recommend planned orders:

- Item A Demand (Day 5):

- Demand: 100 units on day 5.

- Co-product generation: For every 1 unit of item A produced, 0.5 units of item B are generated.

- Supply plan recommendation: Planned order supply of 100 units for item A on day 5 will also generate the planned order co-product supply of 50 units for item B on day 5.

- Item B Demand (Day 7):

- Demand: 60 units on day 7.

- Supply plan recommendation: Planned order co-product supply for item B of 50 units that is produced alongside item A on day 5, will be available to fulfill partially the demand for item B on day 7. The remaining 10 units of planned order supply for item B will be generated on day 7 with no work definition.

- Item R Consumption (Day 3):

- Item R is consumed to produce item A.

- Considering a lead time of 2 days required to produce item A, the consumption of item R for producing 100 units of item A will occur on day 3.

- Supply plan recommendation: Consumption of 200 units of item R on day 3.

A bidirectional discrete work definition produces item A as the primary item and item B as the co-product and another discrete work definition produces item B as the primary item and item A as the co-product. In this scenario, the planning approach is different in constrained and unconstrained supply planning.

In constrained supply planning, both work definitions are planned with the objective of minimizing the inventory. This means that the planning process considers the relationship between the primary and co-product items in both work definitions to optimize the inventory levels.

However, in unconstrained supply planning, the plan assumes one of the items as the primary product and ignores the reverse relationship. This leads to planning with one work definition retaining the primary and co-product relationship, while the other work definitions produce only the primary item without generating the co-product.

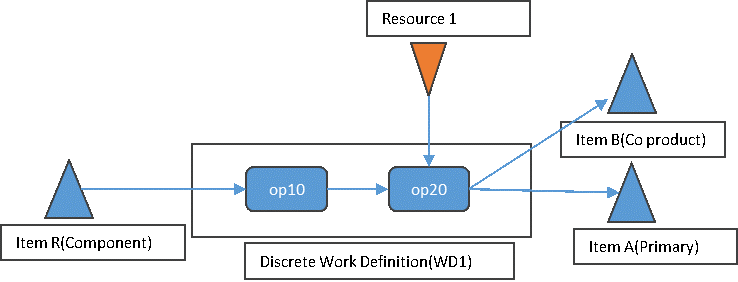

For example, in the bidirectional discrete work definition shown below, in one discrete work definition WD1, item B is generated as a co--product output while producing the primary item A. Operations op10 and op20 are associated with the discrete work definition WD1. Operation op20, produces both the primary and secondary output items. Resource 1 is utilized at op20. Primary item A consumes the component item R in its Item Structure with usage quantity as 2. Consider the defined usage quantity as 0.4 for the co-product item B.

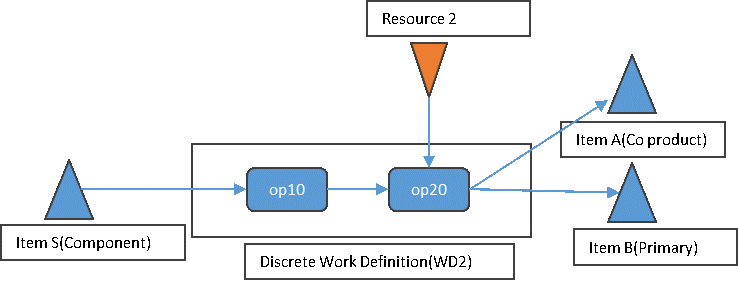

In discrete work definition WD2, item A is generated as a co-product output while producing the primary item B. Operations op10 and op20 are associated with the discrete work definition WD2, and operation op20 produces both the primary and secondary output items. Resource 2 is utilized at op20. Primary item B consumes the component item S in its Item Structure with usage quantity as 2. Consider the defined usage quantity as 0.6 for the co-product item B.

Bidirectional Supply Chain Network: Item B is the Co-Product and Item A is the Primary Supply

Bidirectional Supply Chain Network: Item A is the Co-Product and Item B is the Primary Supply

Based on this scenario, here's how the constrained supply plan will recommend planned orders:

- Item A Demand (Day 5):

- Demand: 100 units on day 5 and 30 units on day 7.

- Supply plan recommendation: Planned order supply of 100 units for item A on day 5 will generate the planned order co-product supply of 40 units for item B on day 5 and planned order co-product supply of 36 units for item A on day 7 will be used.

- Item B Demand (Day 7):

- Demand: 100 units on day 7.

- Supply plan recommendation: Planned order co-product supply for item B of 40 units that is produced alongside item A on day 5, will be available to fulfill partially the demand for item B on day 7. The remaining 60 units of planned order supply for item B are generated on day 7 on work definition(WD2) resulting in planned order co-product supply of item A of 36 quantity on day 7.

- Item R Consumption (Day 3):

- Item R is consumed to produce item A.

- Considering a lead time of 2 days required to produce item A, the consumption of item R for producing 100 units of item A will occur on day 3.

- Supply plan recommendation: Consumption of 200 units of item R on day 3.

- Item S Consumption (Day 5):

- Item S is consumed to produce item B.

- Considering a lead time of 2 days required to produce item B, the consumption of item S for producing 60 units of item B will occur on day 5.

- Supply plan recommendation: Consumption of 120 units of item S on day 5.

Based on the provided scenario, here's how the unconstrained supply plan will recommend planned orders, considering work definition (WD2) primary item and the co-product relationship is broken.

- Item A Demand (Day 5):

- Demand: 100 units on day 5 and 30 units on day 7.

- Supply plan recommendation: Planned order supply of 100 units and 30 units for item A on day 5 and day 7 respectively which in turn will also generate the planned order co-product supply of 40 units and 12 units for item B on day 5 and day 7 respectively.

- Item B Demand (Day 7):

- Demand: 100 units on day 7.

- Supply plan recommendation: Planned order co-product supply for item B of 40 units and 12 units which is produced alongside item A on day 5 and day 7 respectively, will be available to fulfill partially the demand for item B on day 7. The remaining 48 units of planned order supply for item B are generated on day 7 on work definition (WD2) as if only primary item is produced from WD2.

- Item R Consumption (Day 3):

- Item R is consumed to produce item A.

- Considering a lead time of 2 days required to produce item A, the consumption of item R for producing 100 units and 30 units of item A will occur on day 3 and day 5 respectively.

- Supply Plan Recommendation: Consumption of 200 units of item R on day 3 and 60 units on day 5.

- Item S Consumption (Day 5):

- Item S is consumed to produce item B.

- Considering a lead time of 2 days required to produce item B, the consumption of item S for producing 48 units of item B will occur on day 5.

- Supply plan recommendation: Consumption of 96 units of item S on day 5.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- The primary product is completed at the final operation within the discrete manufacturing work definitions.

- The output items can be associated with any operations within discrete manufacturing work definition.

- Items within a specific discrete manufacturing work definition can be associated as either Output or Component types for the operation.

- In unconstrained planning, items (including primary and output items) are planned sequentially. This approach may lead to situations where the total supply of output items is not minimized. Whereas, in constrained planning, the primary objective is to minimize the overall inventory of primary and output items.

- When multiple output products exist within discrete manufacturing work definitions, the planning time fence of the primary product is considered for supply planning.

- File-Based Data Imports can be utilized to upload discrete manufacturing work definitions in Supply Planning for sources other than Oracle Fusion Cloud Manufacturing.

- From a planning perspective, the co-product and by-product supplies will always be generated and rescheduled in alignment with the primary item supplies as defined in the discrete work definitions.

- The firm/unfirm status of planned order co-product/by-product or work order co-product/by-product supplies will be driven by the primary item's planned order or work order status.

- In a supply plan, you can exclusively release the supplies for the primary item, initiating the creation of work orders for the primary item in the source. These work orders include co-products or by-products as output items as defined in the work definitions.

- Planned order co-product/by-product supplies are recommended based on the yield if it’s defined at the operation of the discrete work definitions.

- Shrinkage of the item isn't considered if that item is defined as the co-product or by-product output type in the discrete work definitions.

Key Resources

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Monitor Demand and Supply Planning Work Area (MSC_MONITOR_DEMAND_AND_SUPPLY_PLANNING_WORK_AREA_PRIV)

- Monitor Supply Planning Work Area (MSC_MONITOR_SUPPLY_PLANNING_WORK_AREA_PRIV)

This privilege was available prior to this update.