Use a Supply Plan as a Supply Schedule in a Multiechelon Replenishment Plan

In a multiechelon supply chain network, you may want to plan locations closer to the customer using Oracle Replenishment Planning while the rest of the network is planned with Oracle Supply Planning.

With this update, you can use the supplies from a supply plan or a demand and supply plan that respect manufacturing and supplier constraints for upstream locations as a supply schedule for a downstream location. This supply schedule can then be used as a constraint to drive downstream operations in your multiechelon replenishment plan. This approach ensures seamless, end-to-end planning of your entire network.

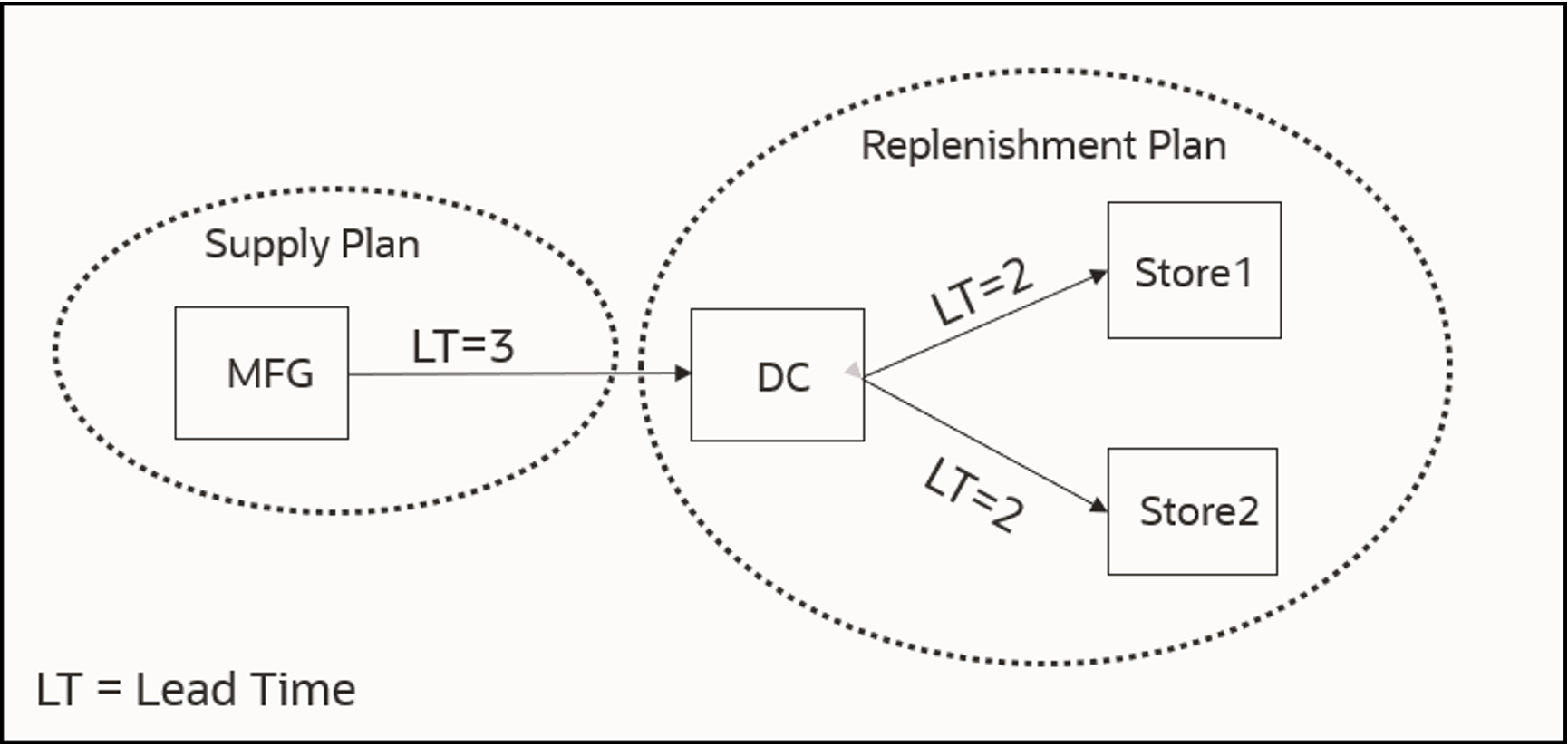

Consider a supply chain with the DC distribution center, Store1 store, and Store2 store that are planned in a multiechelon replenishment plan and the MFG manufacturing location that’s planned in a supply plan.

The following figure depicts this supply chain:

Supply Chain

Follow these steps to use the supply plan as a supply schedule for the replenishment plan:

-

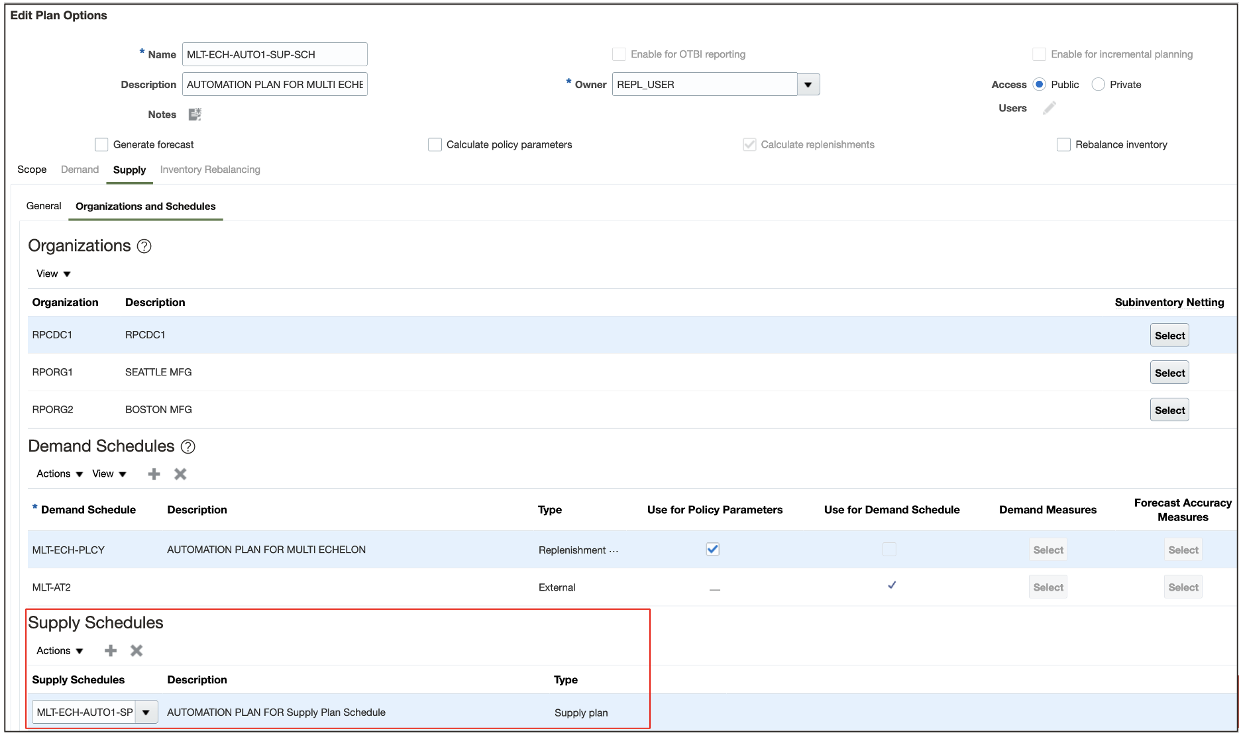

On the Organizations and Schedules subtab on the Supply tab on the Plan Options page for the replenishment plan, in the Supply Schedules section, select the supply plan.

Ideally, the supply plan should be constrained.

Organizations and Schedules Subtab on Supply Tab on Plan Options Page for Replenishment Plan

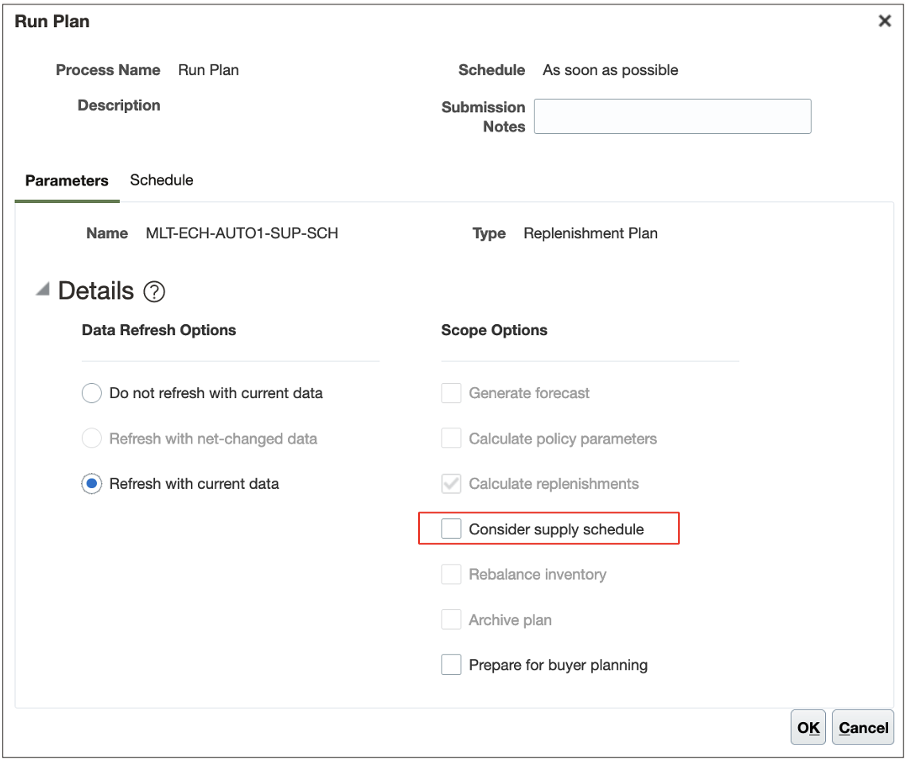

- Run the replenishment plan with the Refresh with current data option selected and Consider supply schedule checkbox not selected on the Parameters tab in the Run Plan dialog box.

This step ensures that unconstrained demand computed by the replenishment plan for DC will be propagated to MFG when the supply plan is run later with the replenishment plan as the demand schedule.

Parameters Tab in Run Plan Dialog Box

The replenishment plan first performs the existing, unconstrained, bottom-up pass to propagate unconstrained demand upstream from Store1 and Store2 to DC. At DC, planned recommendations are created with the source location as MFG. These recommendations are constrained only by lead times and not by the supply constraints at MFG. During the existing, constrained, top-down pass, these planned recommendations at DC drive the fulfillment of demands from Store1 and Store2.

- Run the supply plan with the replenishment plan selected as a demand schedule.

On the Organizations and Schedules subtab on the Supply tab on the Plan Options page, in the Demand Schedules section, select the replenishment plan.

For every planned recommendation at DC, the supply plan creates the corresponding planned transfer order demand at MFG and allocates constrained supplies to these demands.

-

Run the replenishment plan with the Refresh with current data option and Consider supply schedule checkbox selected on the Parameters tab in the Run Plan dialog box.

The selection of this checkbox indicates that you want to drive the replenishment plan with the supplies in the supply plan.

The plan first performs the unconstrained, bottom-up pass to propagate demand upstream. During the constrained, top-down pass, the plan uses the constrained supplies allocated to planned transfer order demands in the supply plan and creates constrained planned recommendations at DC (to be shipped from MFG). These constrained planned recommendations at DC then drive the fulfillment of demands from Store1 and Store2 by creating constrained planned recommendations at these stores.

Here's the demo of these capabilities:

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning

Tips And Considerations

- If you want to use the Use a Supply Plan as a Supply Schedule in a Multiechelon Replenishment Plan feature, then you must opt in to its parent feature: Replenishment Planning. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

- Run the replenishment and the supply plans consecutively so that the plan outputs are based on a uniform picture of supplies and demands. For example, if you run the replenishment plan for the second time a few days after you first run the plan, then any change in demand wouldn’t be synced with the supplies allocated in the supply plan that are based on the previous demand picture. When there’s a significant change in supplies and demands after the first plan run, then it’s recommended to start the entire process from the beginning.

- Constrained planned recommendations are represented in the replenishment plan as planned orders that can be released. There’s no change to the existing order types and release process.

- If the supplies in the supply plan are constrained, then it’s possible that the existing transfer orders from MFG to DC will be rescheduled out.

- After you run the replenishment plan with the Consider supply schedule checkbox not selected on the Parameters tab in the Run Plan dialog box, don’t release the planned recommendations because they aren’t constrained by supplies at MFG.

- If a supply schedule is specified on the Organizations and Schedules subtab on the Supply tab on the Plan Options page for the replenishment plan, and the plan is run with the Consider supply schedule checkbox selected on the Parameters tab in the Run Plan dialog box, then it’s expected that the supply plan has already been run with the replenishment plan selected as the demand schedule. Otherwise, the replenishment plan won’t have visibility into the supply allocation and won’t be able to create constrained planned recommendations at DC.

- If some items at DC are sourced from suppliers, then those items will continue to be planned in the replenishment plan with supplier lead-time constraints and no involvement of the supply plan.

Key Resources

- For more understanding of Replenishment Planning, you can go through the following:

- Introduction to Replenishment Planning Cloud (update 19D) in the readiness training

- Replenishment Planning Training on Oracle Cloud Customer Connect

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Monitor Replenishment Planning Work Area (MSC_MONITOR_REPLENISHMENT_PLANNING_WORK_AREA_PRIV)

- Manage Segments (MSC_MANAGE_SEGMENTS_PRIV)

These privileges were available prior to this update.