Analyze and Report Rolled-Up Costs for Discrete Manufacturing Work Definitions with Multiple Outputs Using OTBI

You can now analyze the rolled-up costs if you use discrete manufacturing in your enterprise and have multiple outputs yielded from your work definition. This helps you validate the costs of your manufactured items and validate the costs allocated to different outputs based on cost allocation.

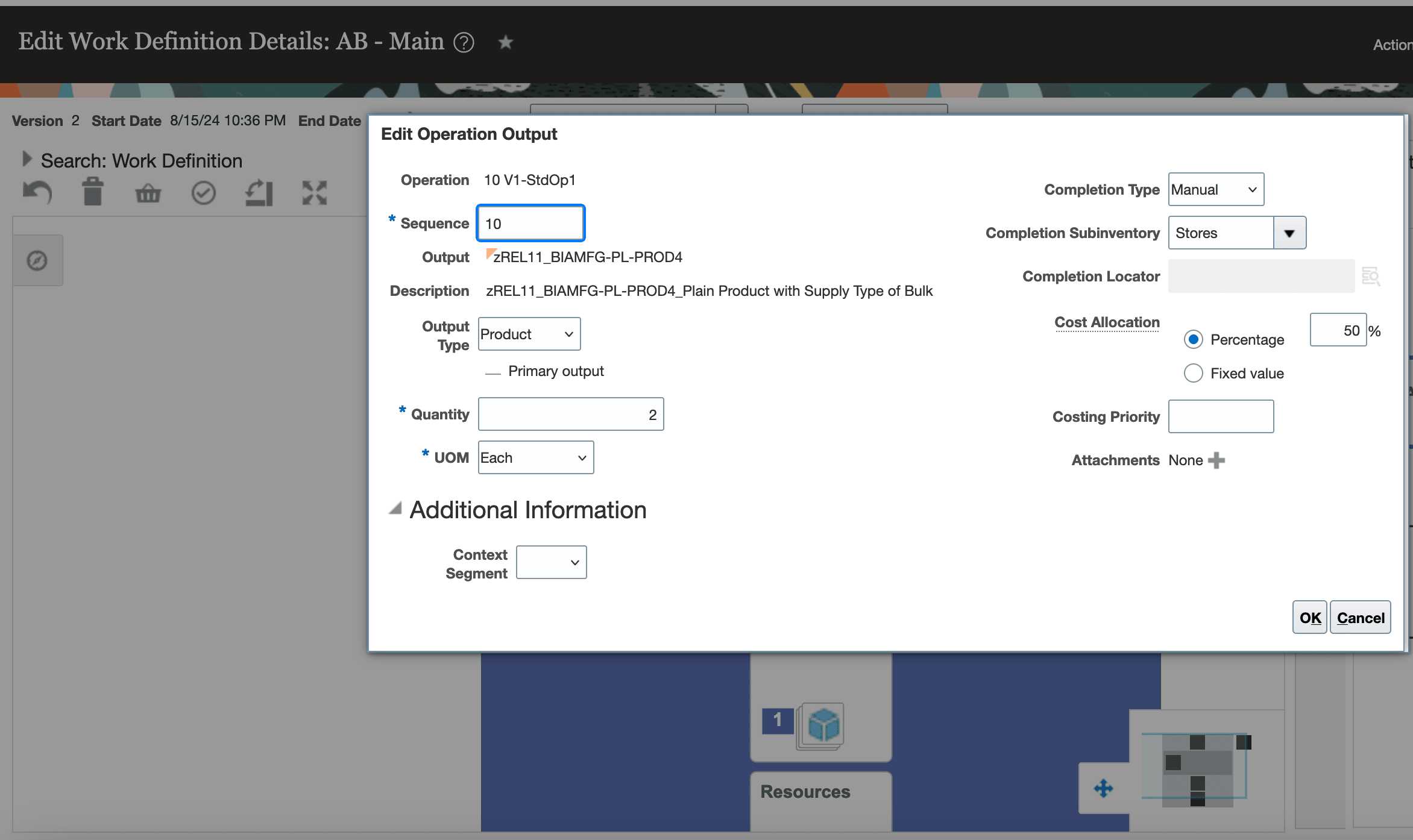

For example, if you've defined a work definition that has additional output (co-product) yielded in the first operation of your work definition:

Discrete Manufacturing Work Definition with Co-product

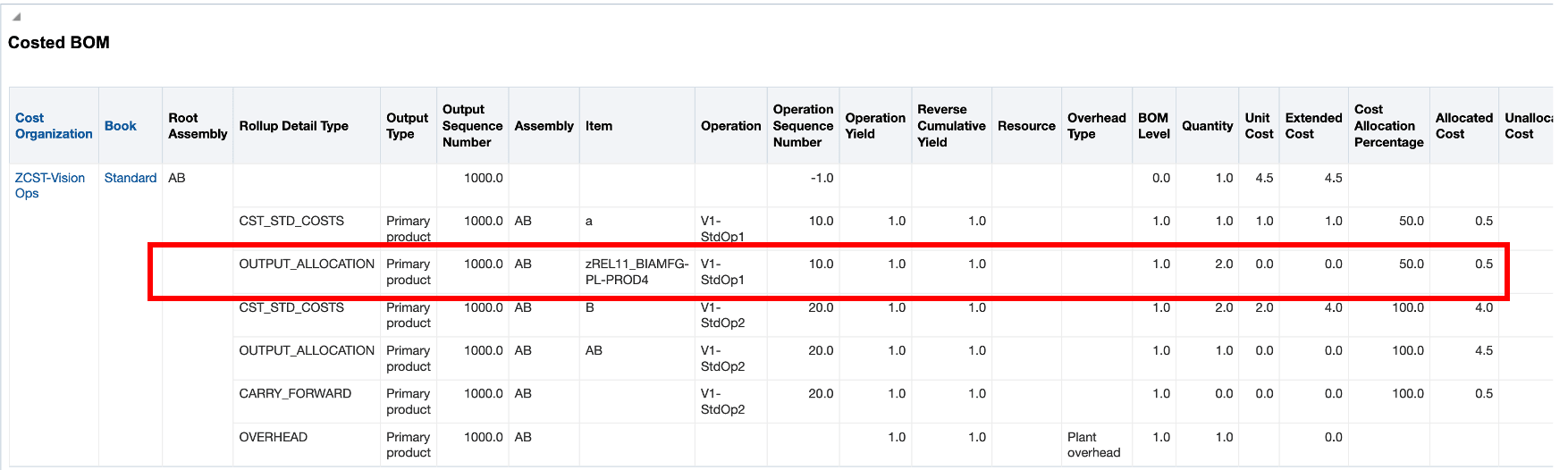

After you run the Roll up Costs process, the co-product cost is calculated as 50% of the total cost incurred till the operation where it is yielded. This is displayed in the Costed BOM report.

Costed BOM Report Displays Output Allocation for Multiple Outputs

Some of the benefits of this feature include:

- Increases efficiency to quickly validate your enterprise's planned production costs as you deal with multiple outputs manufactured from 1 work definition.

- Strengthens your decision making process by analyzing the manufacturing costs for different scenarios to minimize your production costs.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

This feature is useful for customers who are using the multiple outputs for discrete manufacturing feature introduced in update 24C.

Key Resources

- Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management Guide, available on the Oracle Help Center.

- For OTBI, refer Oracle Fusion Cloud SCM: Using Supply Chain Cost Management Guide and Oracle Fusion Cloud SCM: Subject Areas for Transactional Business Intelligence in SCM, available on the Oracle Help Center.

Access Requirements

Users who are assigned BI Administrator role and also have permission to open, view, and edit repository files using the Administration tool or the Oracle BI Metadata web service.