Perform Inline Inspections When Executing Production at a Workstation

Embedding quality control in manufacturing execution is an important strategy in ensuring high quality products. Operators follow a quality inspection plan and record measurements and quality results against specific characteristics, based on a predefined sampling method.

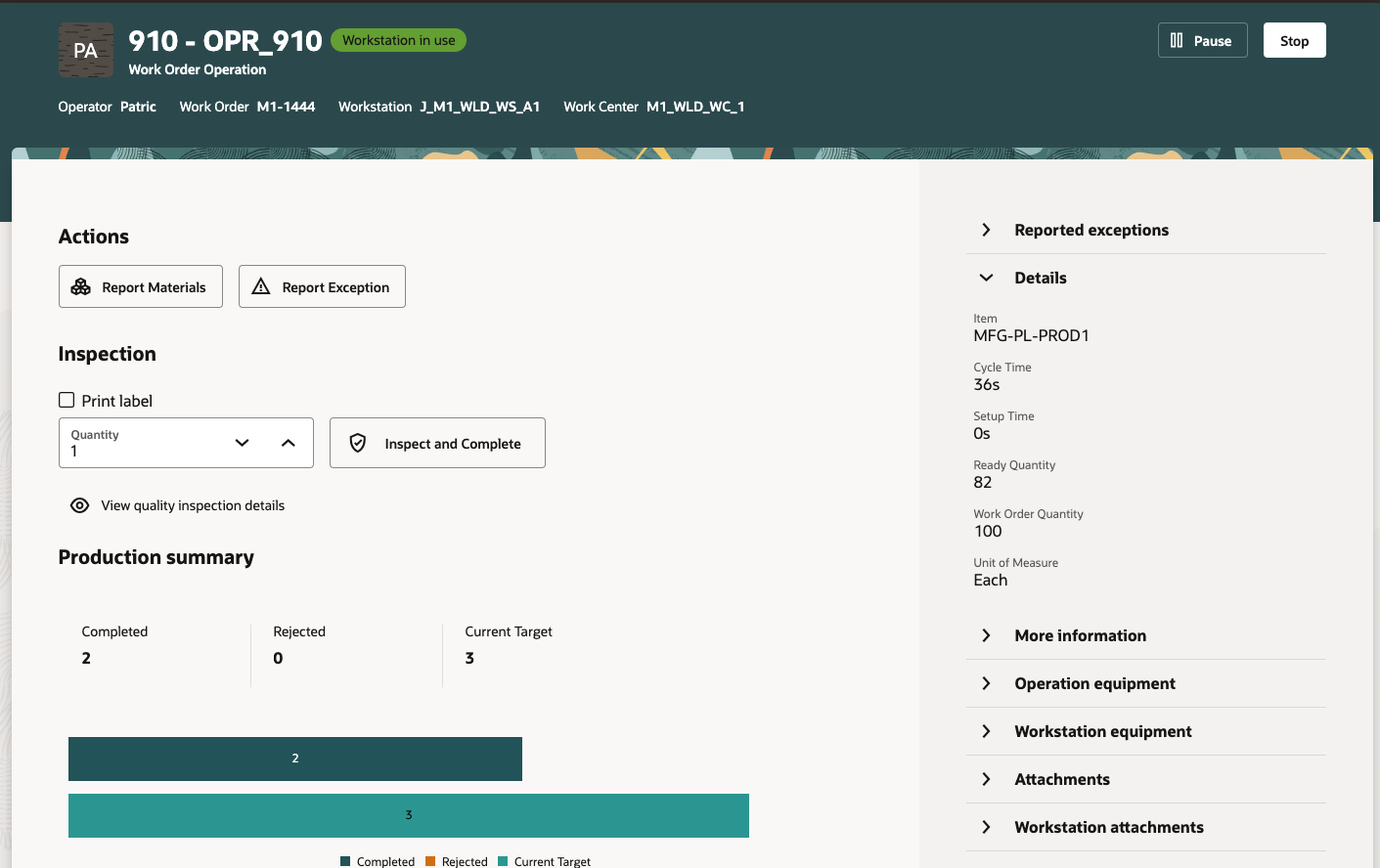

With this update, operators can perform inline inspections on work order operation quantities when executing production at a workstation. Operators record the inspection results against the inspection characteristics for the samples prescribed in the inspection plan. The inspection results are automatically used to transact quantities as completed or rejected without any manual intervention from the operator. This eliminates the need to have other systems to record quality inspection results.

You can enable guided journeys to help the user perform this task by providing videos, images, and best practices.

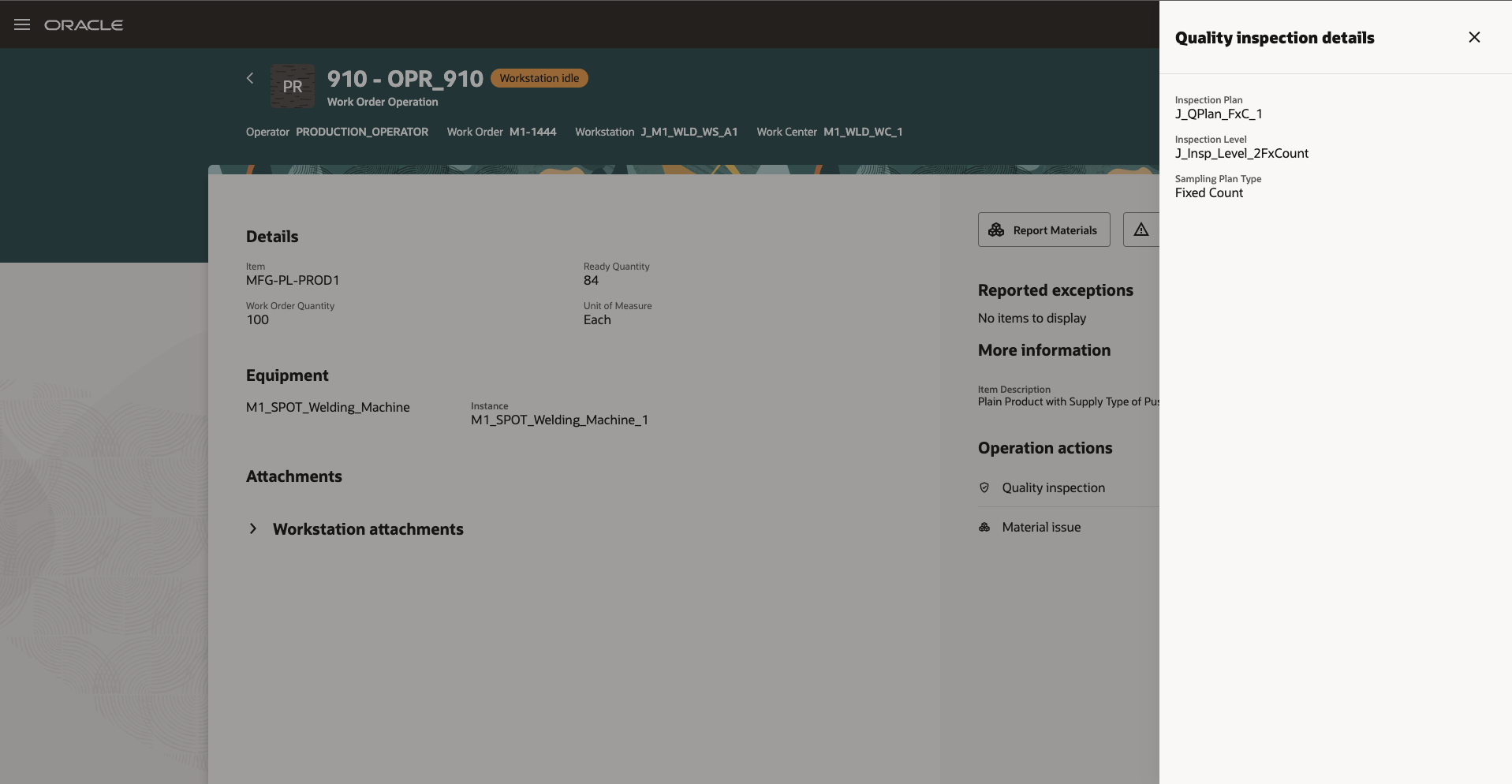

View Inspection Plan Details

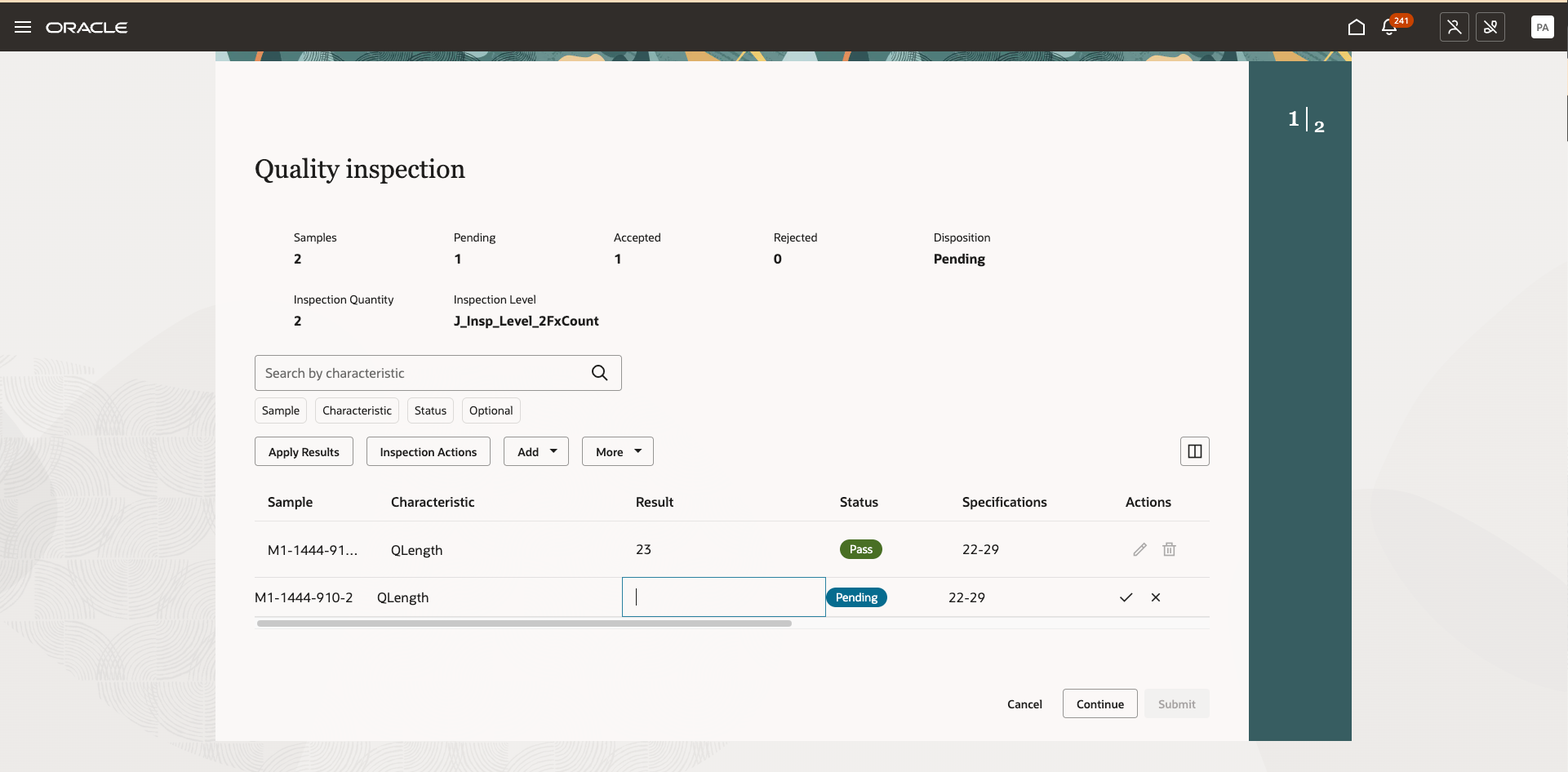

Enter Inspection Results

Quantities Automatically Reported

Manufacturers can maintain traceability without impacting user productivity and eliminate time consuming offline inspection cycles. The production workflows become more efficient, and there is valuable contextual data that can be leveraged for further analysis on continuous improvement.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 25B

You must opt in the Complete Work Order Operations with Details at Workstations feature (24D) to automatically enable this feature.

Tips And Considerations

- When quantities are rejected after inspection, further disposition of the rejected items should be done from the Review Dispatch List page by the operator or production supervisor.

- For serialized operations, only one serial number can be inspected at a time.

- Ad hoc WIP inspections cannot be performed at a workstation at this time. Use the dispatch list or the Create Inspection task in the Work Execution work area to report ad hoc WIP inspections.

Key Resources

- Watch the Perform Inline Inspections When Executing Production at a Workstation demo.

- Refer to the Oracle Fusion Cloud SCM: Using Manufacturing guide, available on the Oracle Help Center.

- Refer to the Oracle Fusion Cloud SCM: Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privileges can perform quality inspection at a workstation:

- Execute Production at a Workstation (WIP_EXECUTE_WORKSTATION)

- Edit Inspection Results (QA_EDIT_INSPECTION_RESULTS_PRIV)

- View Inspection Results (QA_VIEW_INSPECTION_RESULTS_PRIV)

Guided Journeys : Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

These privileges were available prior to this update.