Report Material Transactions for a Work Order Operation Executed at a Workstation

When performing the execution of a work order operation at a workstation, you may need to issue materials that are either serial controlled, lot controlled or non-controlled, and of different supply types. With this update, you can:

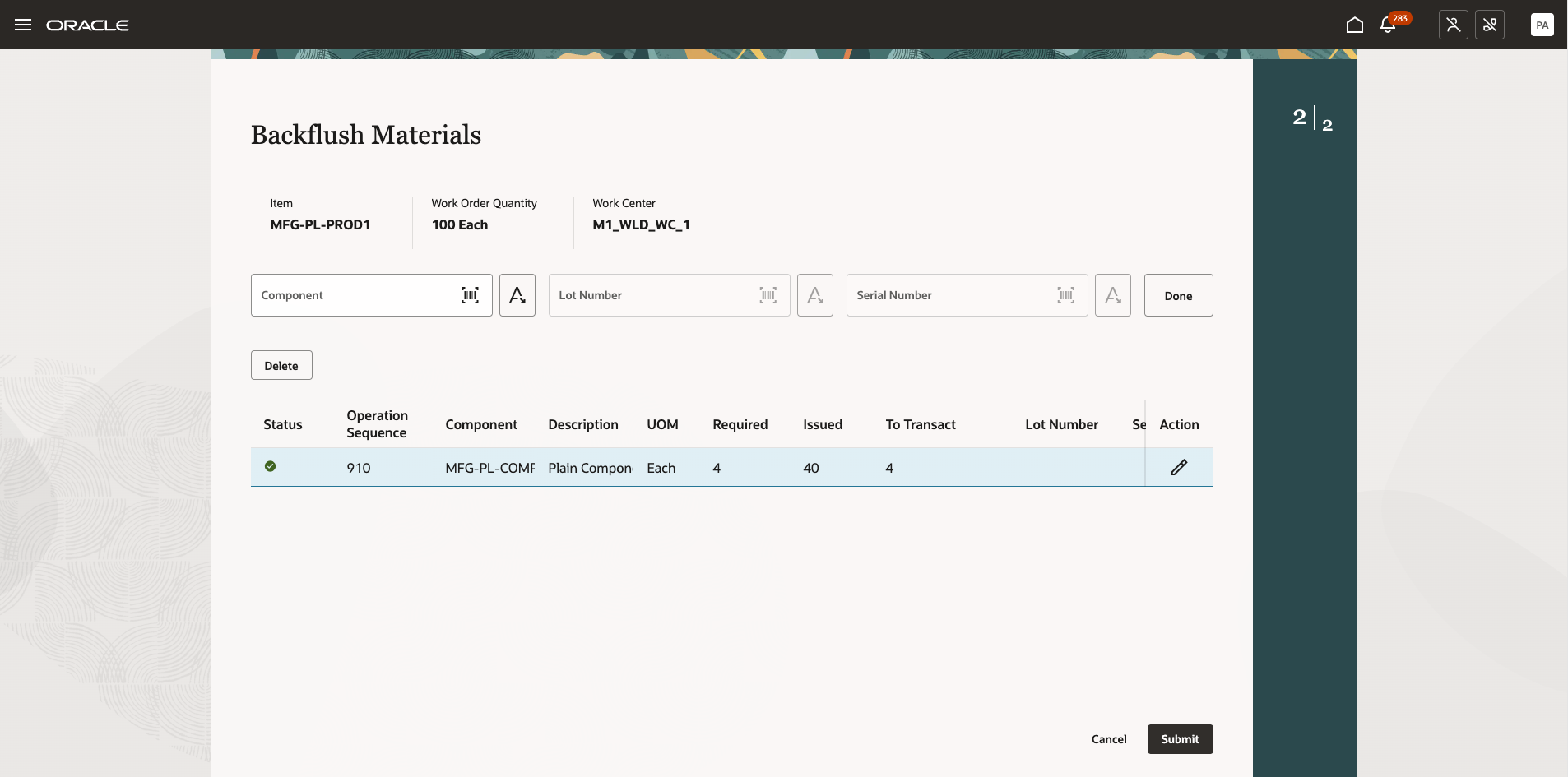

- Scan or enter the lot and serial information of supply types push and operation pull.

- Report material quantities consumed for the work order operation quantity.

- Report ad hoc materials for a work order operation.

- Enter serial and lot information during material backflush for serial-controlled components, before operation completion.

You can enable guided journeys to help user perform this task by providing videos, images, and best practices.

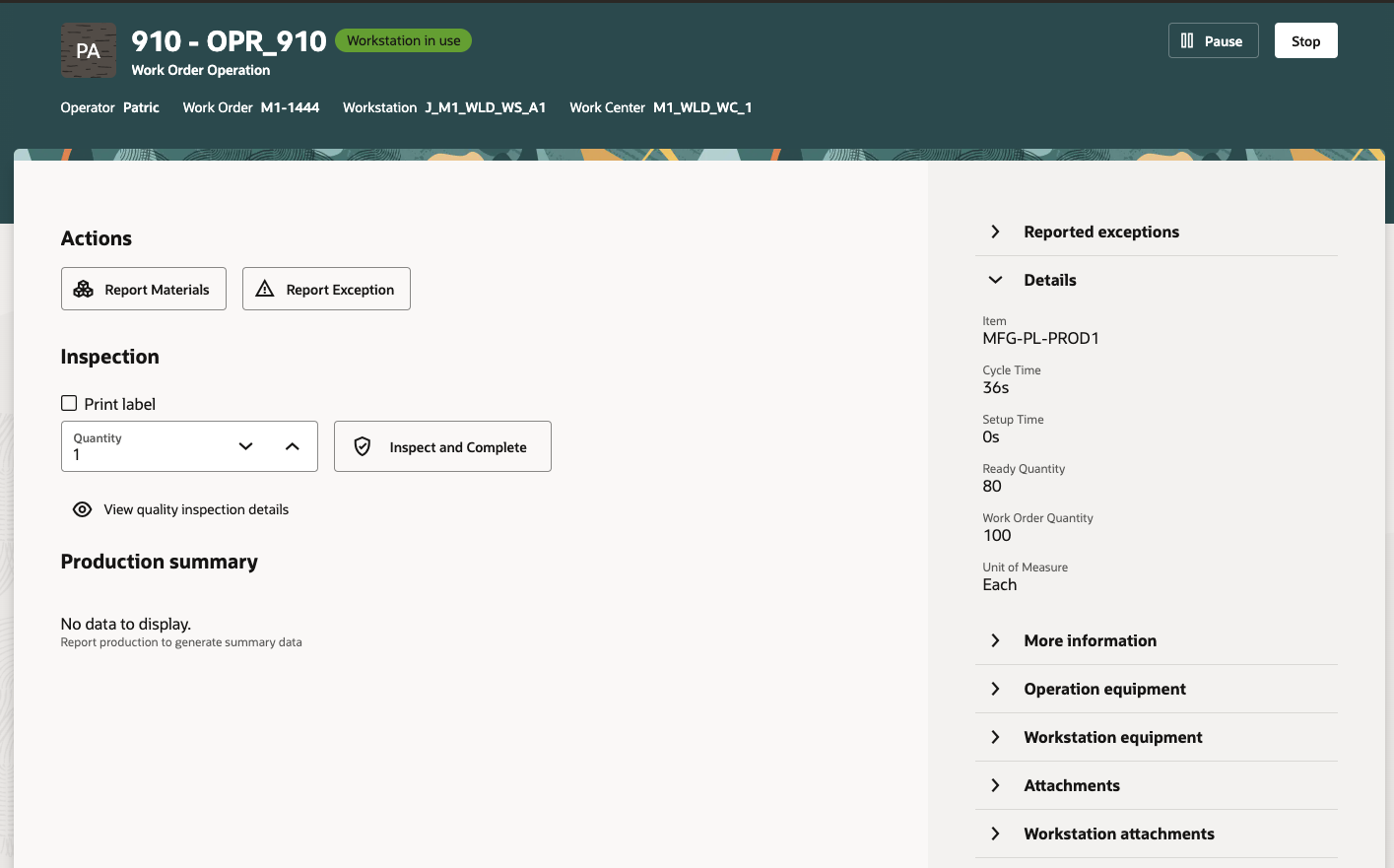

Report Material at a Workstation

Report Backflush Materials During Execution

Manufacturers can maintain accurate traceability of controlled or non-controlled components. Manufacturers can ensure compliance with quality and production standards without spending additional time on manual record management.

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 25B

You must opt in the Complete Work Order Operations with Details at Workstations feature (24D) to automatically enable this feature.

Tips And Considerations

- You can't report materials for work order operations in organizations with project tracking, country of origin tracking for inventory, or with warehouse management integration at this time.

- You can't view material reservations while reporting material transactions at this time.

- You can report material from the workstation before starting a work order operation execution, during execution, or while completing the quantities that require materials to be backflushed.

Key Resources

- Watch the Report Material Transactions for a Work Order Operation Executed at a Workstation Demo.

- Watch the Report Material Transactions for a Work Order Operation Using a Redwood User Experience Demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges can use this feature:

- Report Material Transactions (WIP_REPORT_MATERIAL_TRANSACTIONS_PRIV)

- Execute Production at a Workstation (WIP_EXECUTE_WORKSTATION)

- Edit Inspection Results (QA_EDIT_INSPECTION_RESULTS_PRIV)

- View Inspection Results (QA_VIEW_INSPECTION_RESULTS_PRIV)

Guided Journeys : Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

These privileges were available prior to this update.

In addition to the preceding privileges, you should have the following data security configured for your role and user:

-

Manufacturing plant data security: Set the security context value for the manufacturing plant to the manufacturing organization.

-

Item class data security: Set the View Item Basic action to allowed.