Manage Work Orders Using the Production Supervisor Workbench

Production supervisors are responsible for orchestrating the scheduled shift work on the factory floor while ensuring that work orders are completed on time without compromising on quality and productivity. With this update, you can supervise production activities in a unified user interface, which enables you to manage work orders and act on critical exceptions to achieve shift goals. You can perform the following work order actions for your work centers:

- Search, filter, and select work orders for execution.

- Perform work order specific actions, such as hold, release, cancel, or reschedule work orders.

- Set priorities for work orders to orchestrate the sequence of execution.

- Set an expedite flag for a work order.

- Access work order operation-specific information including materials, resources, transaction history, and exception information.

As a production supervisor, you can view and manage work orders for work centers that you oversee . To manage production, select Production Supervision from the Tasks menu in the Work Execution area.

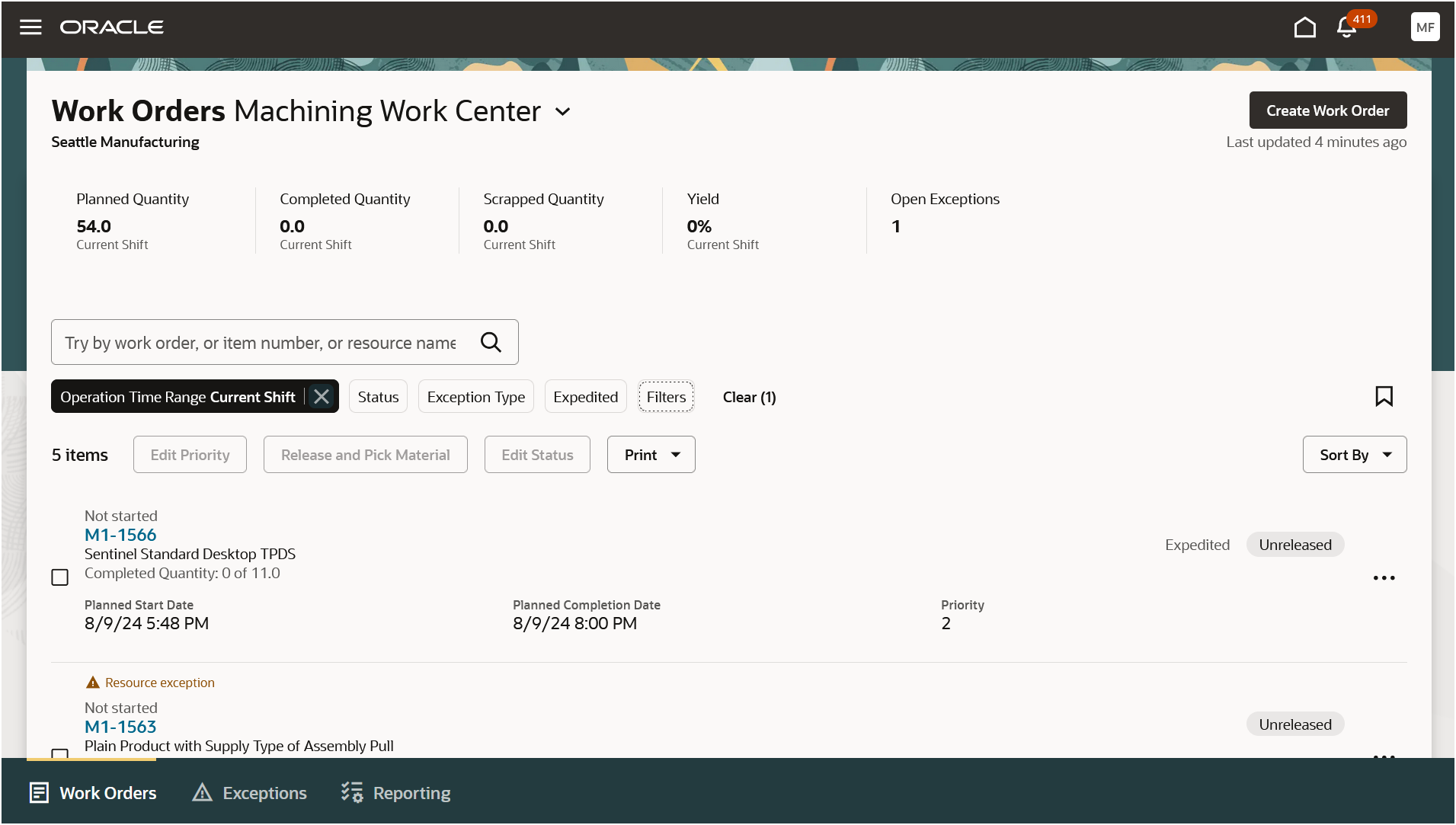

The Work Orders tab shows key operational metrics for the current shift, such as the planned quantity, completed quantity, scrapped quantity, yield, and open exceptions. By default, the list of work orders includes those work orders whose operations are part of the selected work center and the operation time range is in the current shift.

You can search for work orders based on the work order number, product item, serial number, resource, material item, and customer name.

You can use various filters to narrow down the search, such as operation time range, status, exception type, expedited state, and workstation. You can save your work order searches, and optionally set a saved search as the default. The default search results are automatically loaded the next time.

You can also change the sort order of work orders based on priority, planned start date, or planned completion date. Expedited work orders always appear at the top of the list, irrespective of the sort order.

Work Orders Tab Showing the List of Work Orders

Exceptions logged by operators are highlighted against the work order row for the immediate attention of the supervisor. You can also see the execution status, work order status, and the expedited state of work orders.

You can perform the following actions from the Work Orders tab:

- Create a rework work order.

- Edit priority for one or more work orders.

- Release and pick materials for one or more work orders.

- Edit status for one or more work orders.

- Print work order traveler report for one or more work orders.

- Print material list report for one or more work orders.

- Print label report for one or more work orders.

- Expedite or de-expedite a work order.

- Reschedule a work order.

- View work order details for a work order.

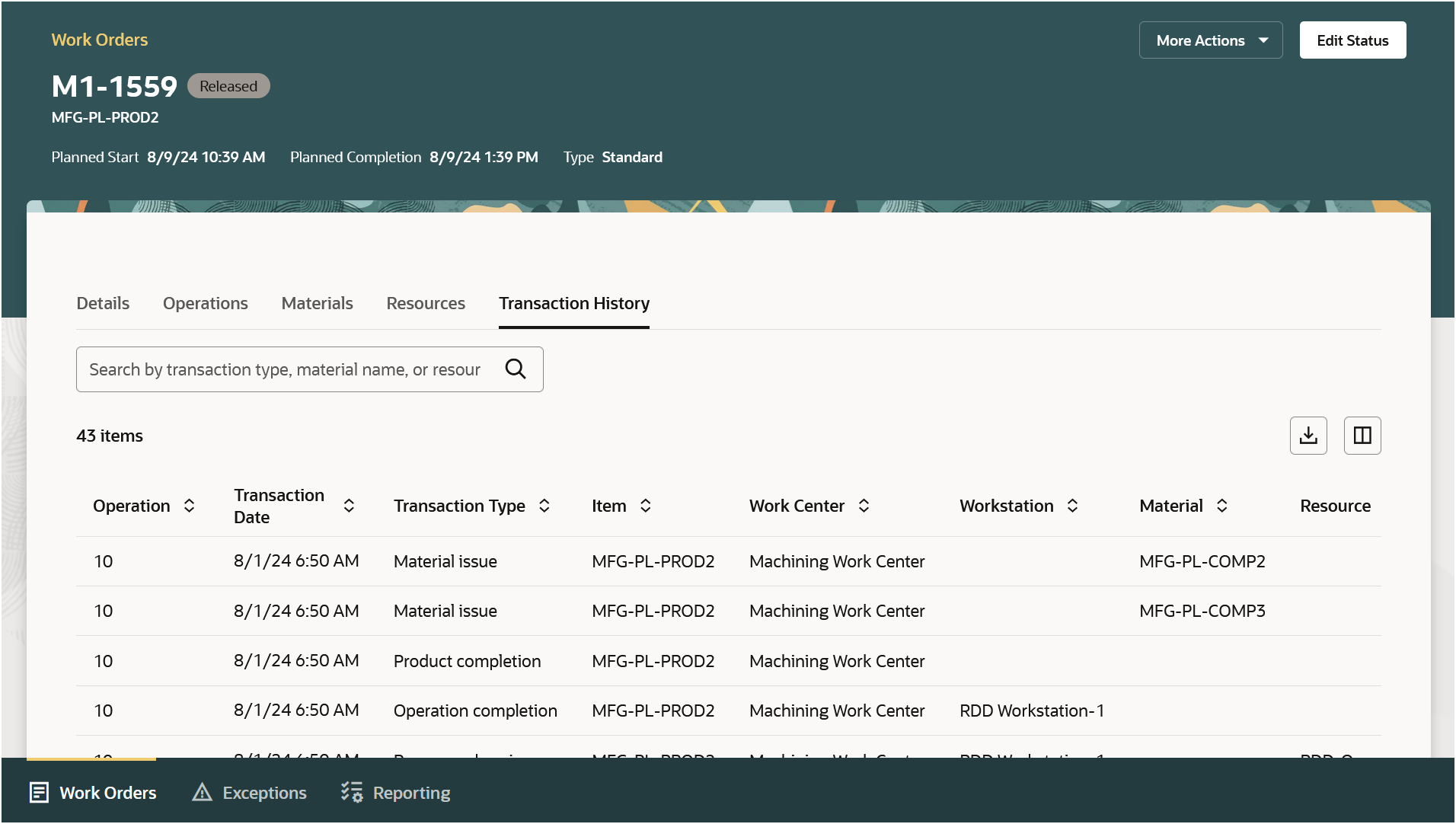

You can navigate to the details page of any work order for more information. Work order details include work order header details, details of operations, material requirements, resource requirements, serial number details, lot number details, and the transaction history of operations that belong to your work center.

Work Order Details: Transaction History Tab

In addition, you can perform the following actions from the work order detail pages:

- Edit status.

- Edit priority.

- Pick materials.

- Print work order traveler.

- Print label.

- View work order and operation descriptive flex fields.

- View exception details and close exception line.

- Reschedule operation.

- Reserve material.

- Substitute material.

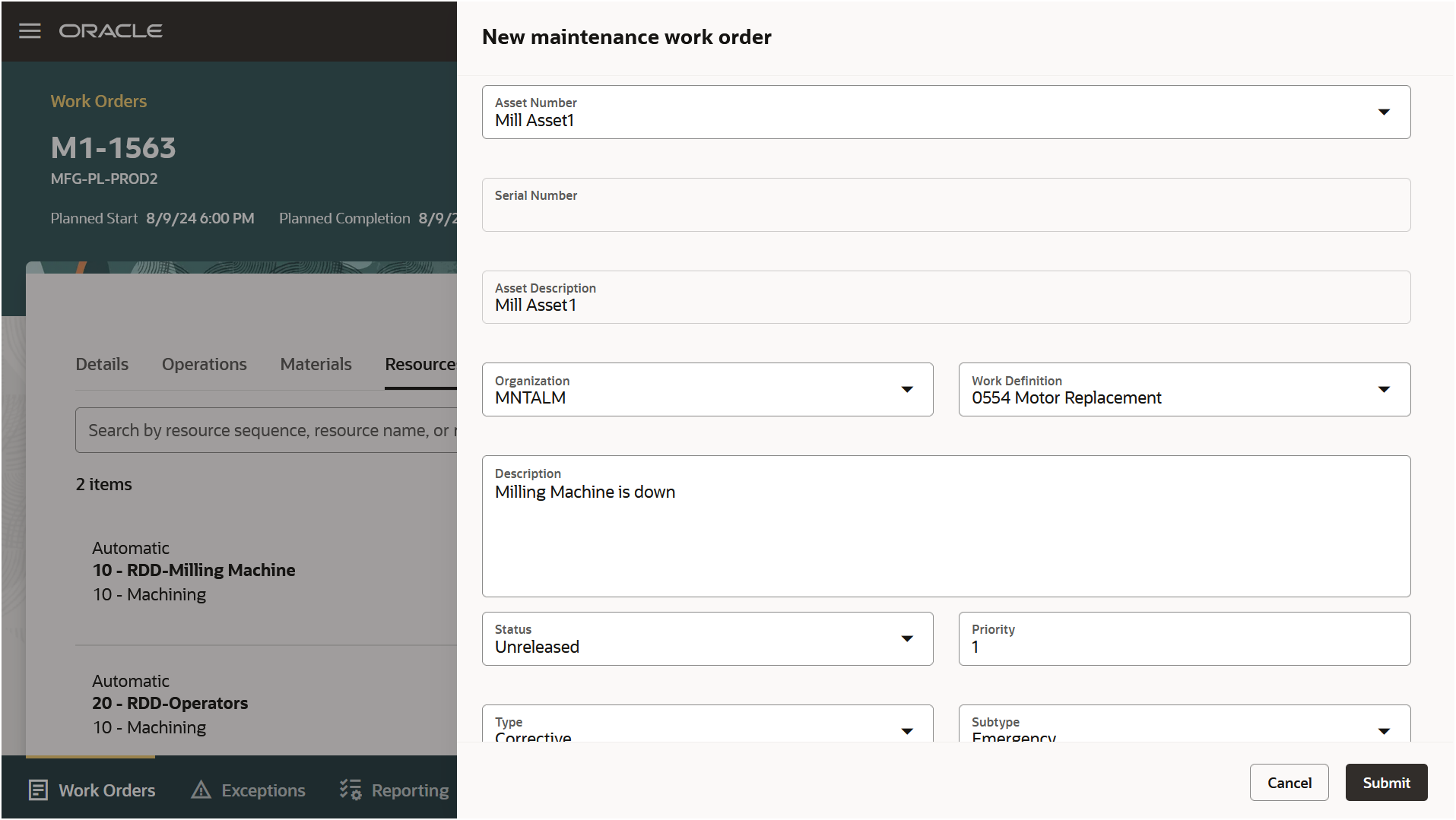

- Create maintenance work order.

New Maintenance Work Order Drawer

You can enable guided journeys to help the user perform this task by providing videos, images, and best practices.

With this update, production supervisors can efficiently manage scheduled work using a single interface and are able to react faster to address and resolve challenges during production.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- The current update supports discrete manufacturing work orders only.

- Quantity based metrics in the scorecard are displayed only when a common unit of measure is used across the products manufactured in a shift.

- Before using this feature, make sure that you submit the scheduled process to create the index definition and perform initial ingest to OSCS. You can also submit the process if the index is already created and you want to ingest it again. This clears the index and reingests the data.

- Program name: ESS job to create index definition and perform initial ingest to OSCS.

- Index Name to Reingest: fa-scm-mfg-work-order.

- Work orders can be created or executed using the user interface, REST APIs, or File-Based Data Import (FBDI). Not all modes of work order creation or update trigger the near real-time ingest of the index. You can update the index by running a separate scheduled process. This scheduled process doesn't clear the index, but only updates the existing index with the changes from these transactions. Oracle recommends that you ingest these updates at least once a day, or as often as your business requires, to keep the index current.

- Program Name to Run Bulk Ingest: ESS job to run Bulk ingest to OSCS.

- Index Name to Reingest: MFG_WO_BULK_INGEST.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Manufacturing Privileges :

- Supervise Production (WIP_SUPERVISE_PRODUCTION_PRIV)

- Manage Work Orders by Service (WIP_UPDATE_WORK_ORDERS_SERVICE_PRIV)

- View Production Shift Details (WIP_GET_PROD_SHIFT_DETAILS_PRIV)

- Print Work Order Traveler (WIP_PRINT_WORK_ORDER_TRAVELER_PRIV)

- Print Components List (WIP_PRINT_COMPONENTS_LIST_PRIV)

- Print Product Labels (INV_PRINT_LABEL_REQUESTS_PRIV)

- View Production Exceptions (WIP_VIEW_PRODUCTION_EXCEPTIONS_PRIV)

- Other Privileges:

- Manage On-Hand Quantity (INV_MANAGE_ONHAND_QUANTITY_PRIV)

- View On-Hand Quantity Using Responsive Inventory (INV_VIEW_ONHAND_QUANTITY_USING_RESPONSIVE_INVENTORY_PWA_PRIV)

- Manage Inventory Reservation and Picks (INV_MANAGE_INVENTORY_RESERVATION_AND_PICKS_PRIV)

- Create Maintenance Work Orders by Service (MNT_CREATE_WORK_ORDERS_BY_SERVICE_PRIV)

- Manage Quality Issue (ENQ_MANAGE_QUALITY_ISSUE_PRIV)

- Get Item Rest (EGP_GET_ITEM_REST_PRIV)

- HCM Privileges:

- Access HCM Common Components (HRC_ACCESS_HCM_COMMON_COMPONENTS_PRIV)

- Manage Search Views (HRC_MANAGE_SEARCH_VIEWS_PRIV)

- Use REST Service - Guided Journey Responses (ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

- Use REST Service - Guided Journeys Read Only (ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

In addition to the preceding privileges, you should have the following data security configured for your role and user:

- Manufacturing plant data security: Set the security context value for the manufacturing plant to the manufacturing organization.

- Item class data security: Set the View Item Basic action to allowed.

- Maintenance organization data security: Set the security context value for the inventory organization to the maintenance organization responsible for maintaining the assets.