Manage and Resolve Exceptions from the Production Supervisor Workbench

Issues during production execution can disrupt manufacturing leading to delays in delivering products or work-in-progress items across the manufacturing workflow. Such issues are reported by production operators and supervisors as production exceptions and may relate to one or more equipment resources or materials at workstations in a work center.

Production supervisors need to constantly watch for such exceptions, so that they can be triaged, addressed, and resolved on time. This helps the production team recover from any delays and continue shift production.

With this update, you can monitor, manage, and resolve open production exceptions in a unified view for one or all work centers. Use the production supervisor workbench to perform the following actions on production exceptions:

- Search, view, and edit open production exceptions for your work center.

- Create new exceptions and close existing exceptions after evaluating the issues.

- Add multiple work order operations to an exception to accurately record the impact of an issue.

- View exceptions in the list of work order page and detail pages to quickly learn about the current issues faced by operators.

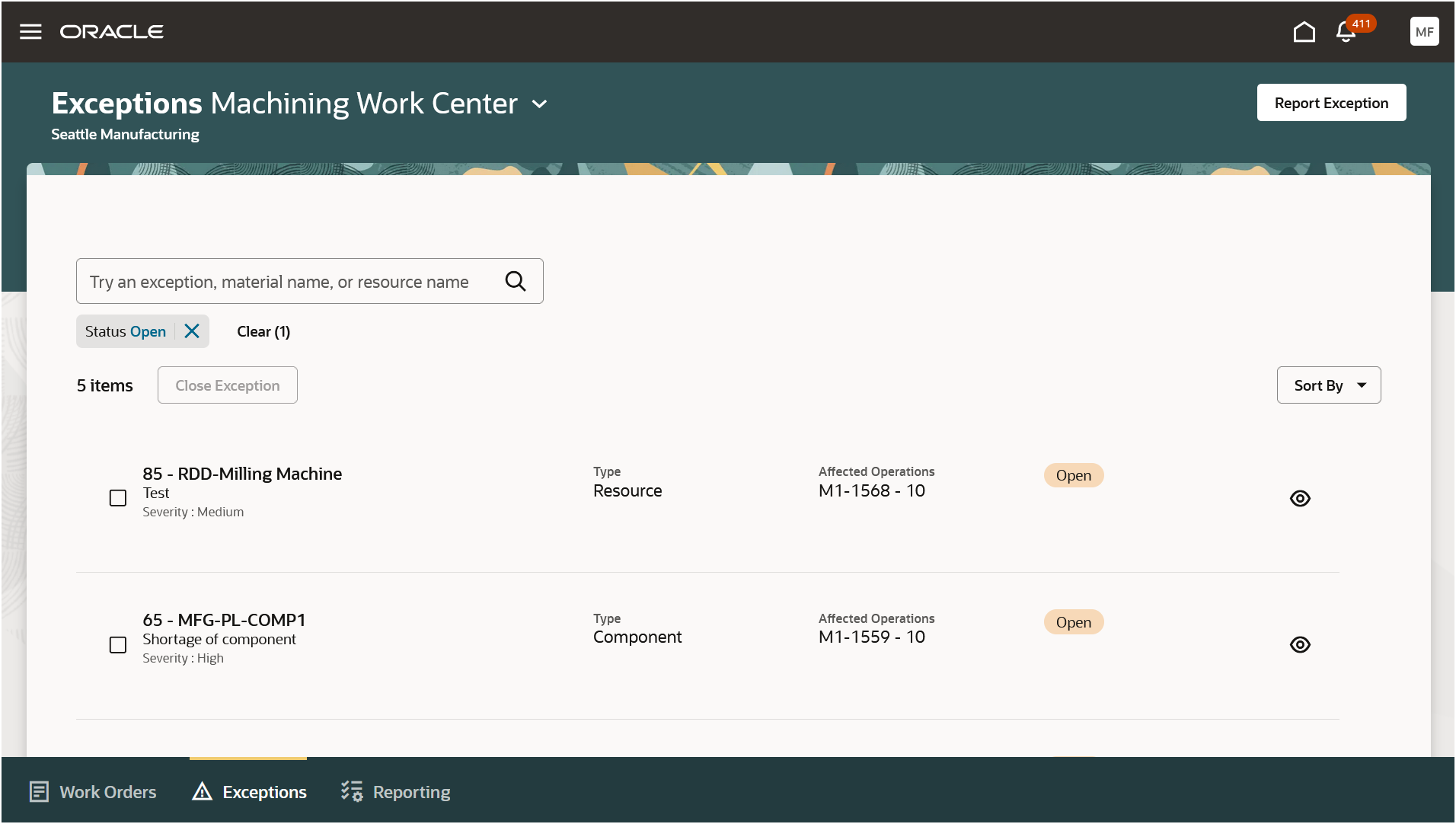

Exceptions List Page

You can take the following actions for the reported exceptions:

- Create a maintenance work order to resolve a resource type exception. The equipment resource instance must have been defined as an asset in Fusion Maintenance.

- Request material substitutes or reserve materials during short supply for component related exceptions.

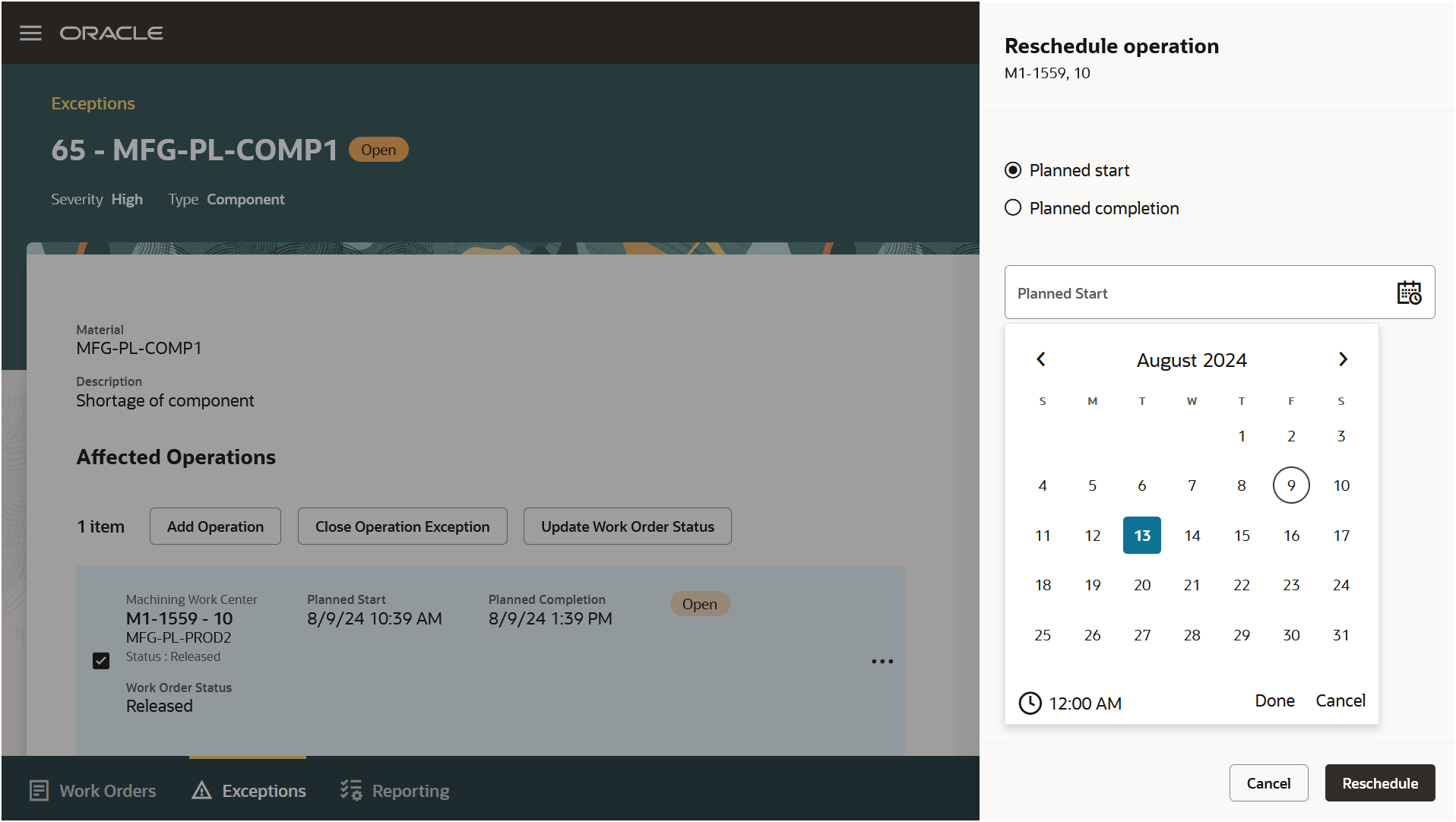

- Reschedule operations impacted by a production exception.

- Update the work order status based on the expected action on resolution.

Reschedule Operation Drawer

You can enable guided journeys to help the user perform this task by providing videos, images, and best practices.

With this update, production supervisors get better visibility into ongoing issues on the shop floor. They can resolve these issues faster using a single interface and increase overall shop floor productivity.

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- The current update supports discrete manufacturing work orders only.

- Supervisors can create exceptions for other work centers to communicate issues that span work centers, but a supervisor’s view of impacted work order operations is restricted to the work center that the supervisor oversees.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Manufacturing Privileges :

- Supervise Production (WIP_SUPERVISE_PRODUCTION_PRIV)

- Manage Work Orders by Service (WIP_UPDATE_WORK_ORDERS_SERVICE_PRIV)

- View Production Shift Details(WIP_GET_PROD_SHIFT_DETAILS_PRIV)

- View Production Exceptions (WIP_VIEW_PRODUCTION_EXCEPTIONS_PRIV)

- Manage Production Exceptions (WIP_MANAGE_PRODUCTION_EXCEPTIONS_PRIV)

- Other Privileges:

- Manage On-Hand Quantity (INV_MANAGE_ONHAND_QUANTITY_PRIV)

- View On-Hand Quantity Using Responsive Inventory (INV_VIEW_ONHAND_QUANTITY_USING_RESPONSIVE_INVENTORY_PWA_PRIV)

- Manage Inventory Reservation and Picks (INV_MANAGE_INVENTORY_RESERVATION_AND_PICKS_PRIV)

- Create Maintenance Work Orders by Service (MNT_CREATE_WORK_ORDERS_BY_SERVICE_PRIV)

- Manage Quality Issue (ENQ_MANAGE_QUALITY_ISSUE_PRIV)

- Get Item Rest (EGP_GET_ITEM_REST_PRIV)

- HCM Privileges:

- Access HCM Common Components (HRC_ACCESS_HCM_COMMON_COMPONENTS_PRIV)

- Manage Search Views (HRC_MANAGE_SEARCH_VIEWS_PRIV)

- Use REST Service - Guided Journey Responses (ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

- Use REST Service - Guided Journeys Read Only (ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

In addition to the preceding privileges, you should have the following data security configured for your user and role:

- Manufacturing plant data security: Set the security context value for the manufacturing plant to the manufacturing organization.

- Item class data security: Set the View Item Basic action to allowed.

- Maintenance organization data security: Set the security context value for the inventory organization to the maintenance organization responsible for maintaining the assets.