Improved Manual Scheduling by Firming Operations

This capability helps to efficiently fine-tune schedules before a release. Users can allow or disallow offloading an operation to alternate resources or fix the start time of a work order operation for consideration in subsequent solves. With these features, you can manually adjust the schedule for a single production stage to your satisfaction, then firm the schedule on that stage, and finally proceed to align the upstream and downstream stages via a solve action. Refining the schedule will be more efficient and reduce scheduling cycle times.

Work Order and Work Order Operation Properties Impacting Schedule Calculation

There are several work order and work order operation properties that impact schedule calculation. Some of these simply describe the work order and its operations, such as the item produced by the work order, the work order quantity, the resource hours needed by the various operation resource sequences, and the materials and quantities required by each work order operation. Other properties provide additional guideposts that the solve action must consider. These include the work order firm status, the work order operation firm status, and the work order operation offloading allowed flag, with the latter two being available only in Oracle Production Scheduling. In the following sections, the interaction of these properties and how the solve action considers them will be explained.

How these properties’ values are set

The work order firm status, the work order operation firm status, and the work order operation offloading allowed flags are visualized in the tabular schedule views and are set as follows:

- Work Order Firm Status: This status is displayed in the Work orders table. Initially, after schedule refresh, it will be toggled on for all work orders that are firm in SCM Work Execution and for all released work orders that start inside the fixed time fence, if the Firm released work orders that begin during the fixed time fence period check box in the schedule options UI is enabled. It will be toggled off for all other work orders. In the Work orders table, the user can toggle this switch on or off, and the value will be shown accordingly.

- Work Order Operation Firm Status: This status is displayed in the Dispatch list table. Initially, after schedule refresh, status will show as Firm for all operations of a firm work order and be empty for all operations belonging to unfirm work orders. If the user sets the fixed start time using the work order operation edit functionality via the side drawer (this is the mechanism how operation-level firming is performed), then this will show Fixed start time for those work order operations that were changed, regardless of the work order firm status.

- Work Order Operation Offloading Allowed: This status is also displayed in the Dispatch list table. Initially, after schedule refresh, it is defaulted as toggled off for all operations of a firm work order, and toggled on for all operations belonging to unfirm work orders. Using the edit functionality in the side drawer or via in-line editing in the Dispatch list, the user can toggle this switch on or off.

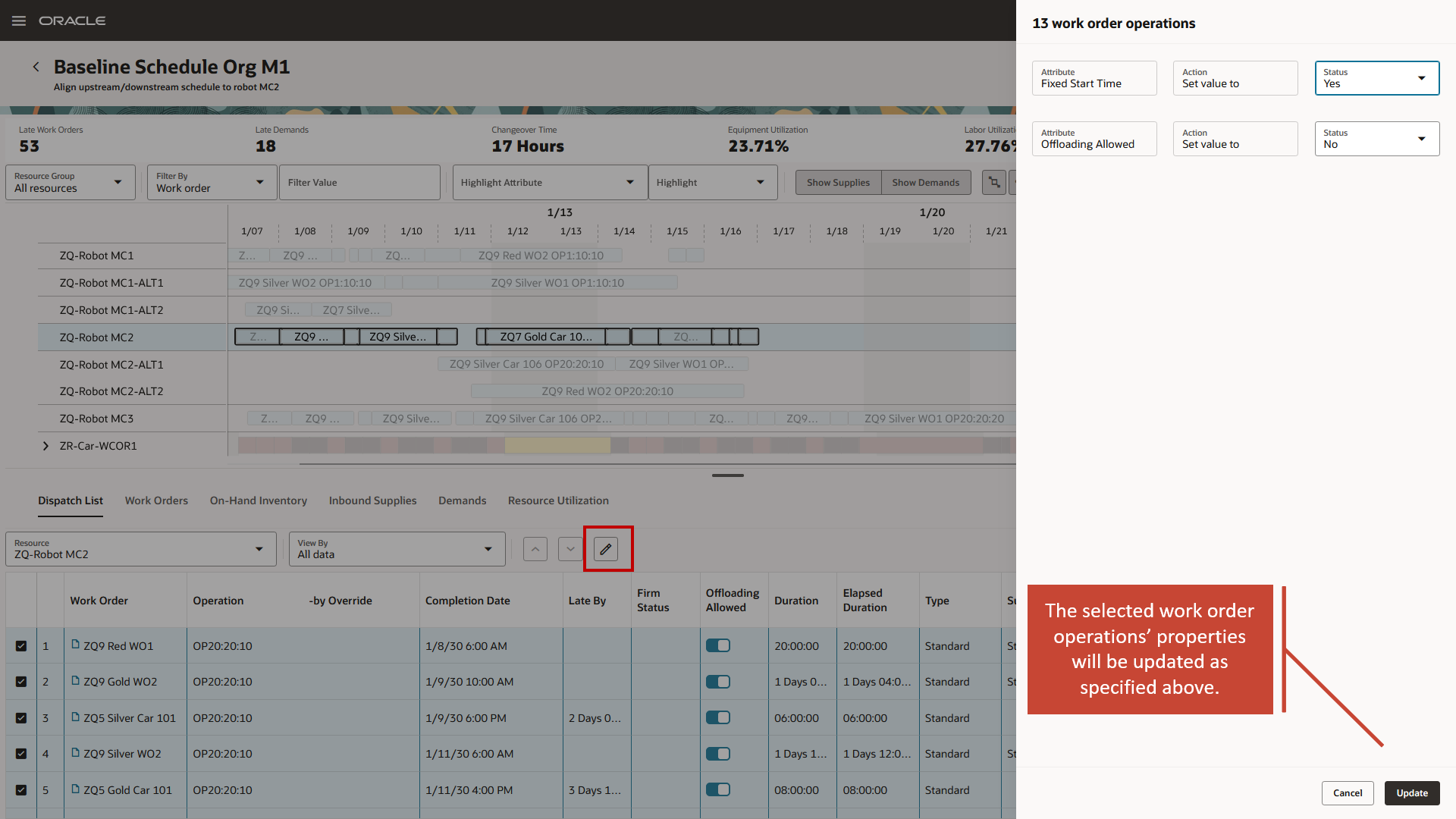

With this update, you can control at the work order operation level whether offloading shall be allowed or not, and whether the current start time shall be considered as firm start time. Previously, the underlying work order operation properties were defaulted during the schedule refresh as explained above. If a work order in Manufacturing was firmed or already transacted, then the operation was set to not allow offloading, and the operation firm status was set to firm. Now you can select operations in the Gantt chart or the Dispatch list and click the Edit icon in the Gantt toolbar or above the Dispatch list to open a side drawer and change these work order operation properties for the selected operations in one action (see the following figure).

Select one or more Operations in Gantt Chart or Dispatch List and Click the Pencil Icon to Edit Operation Properties.

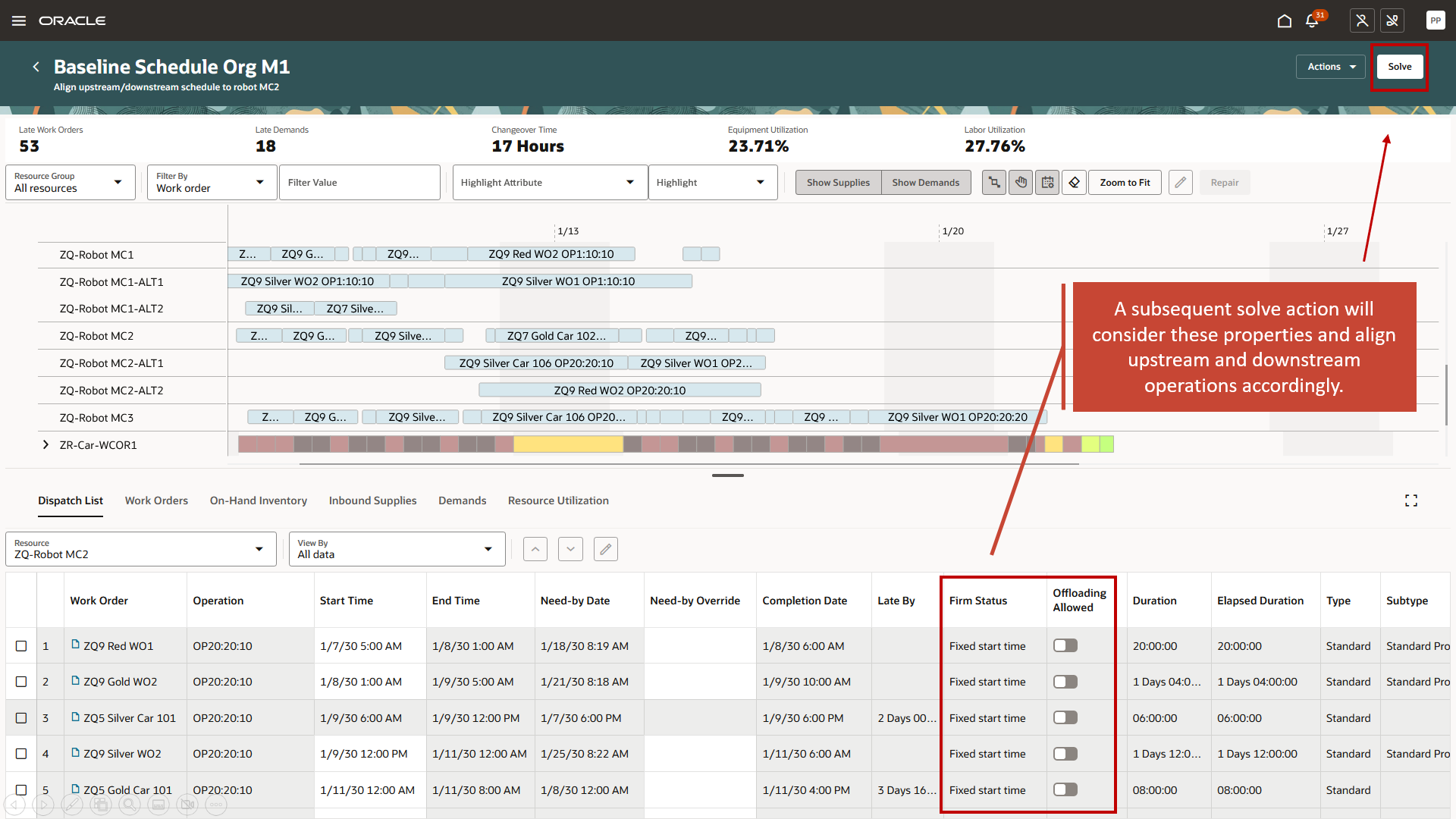

In this example, the user is satisfied with the schedule on resource ZQ-Robot-MC2, selects all operations on that resource and sets their properties Fixed Start Time to Yes and Offloading Allowed to No. After clicking Update, the corresponding values will be changed in the backend, and the subsequent solve action will consider them accordingly. Note that the data in the dispatch list is not automatically refreshed; after switching between resources in the dispatch list or running a solve, the current values for Firm Status and Offloading Allowed will also be displayed in the dispatch list.

Subsequent Solve Action Considers these Operation-Level Properties.

The solve action will respect the schedule on resource ZQ-Robot-MC2 and align upstream and downstream production, if possible.

Best practice

After performing manual scheduling changes like offloading or resequencing, the subsequent repair action implements such changes, ensuring that appropriate production rates are applied (as alternate resources might be faster or slower than the current resource) and correct changeovers are inserted. These adjustments impact the start and end times of the moved operations and possibly adjacent ones. Therefore, a manual scheduling change can be considered complete only once the repair action has been run.

Changes to the properties listed in the previous section only impact the solve action, not the repair action. While editing these properties is possible at any time, it is advisable to only change the Work Order Operation Firm Status and Work Order Operation Offloading Allowed once all manual scheduling changes have been fully implemented via a repair action.

How these properties interact and are considered during solve and repair

While the work order operation firm status and the work order operation offloading allowed properties are independent of one another, they both interact individually with the work order firm status. The following tables explain the solve and repair behavior for the various combinations.

The following table covers whether work order operation dates can be changed by the solve or repair actions depending on the work order firm status and operation firm status.

| Work Order Firm Status | Operation Firm Status | Solve | Repair |

|---|---|---|---|

|

Toggled on (Firm) |

Fixed start time |

Solve respects dates inside fixed time fence (see note below) and tries to respect dates outside the fixed time fence, but will change the latter if necessary |

Work order operation dates can be changed by user via manual scheduling and subsequent repair |

|

Toggled on (Firm) |

Firm (inherited from work order firm status) |

Solve respects dates inside fixed time fence (see note below) and tries to respect dates outside the fixed time fence, but will change the latter if necessary |

Work order operation dates can be changed by user via manual scheduling and subsequent repair |

|

Toggled off (Not firm) |

Fixed start time |

Solve respects dates inside fixed time fence (see note below) and tries to respect dates outside the fixed time fence, but will change the latter if necessary |

Work order operation dates can be changed by user via manual scheduling and subsequent repair |

|

Toggled off (Not firm) |

Empty |

Work order operations are scheduled flexibly, and their dates will typically change |

Work order operation dates can be changed by user via manual scheduling and subsequent repair |

NOTE: Inside the fixed time fence, the solve action may remove precedence constraints between two operations with operation firm status set to Firm or Firm start time if their firm dates conflict with one another.

You can identify firm work order operations in the Gantt chart by using the Highlight Firm action in the Gantt toolbar. All work order operations with operation firm status Firm or Fixed start time will be highlighted.

The next table explains whether work order operations can be offloaded to alternates resources by the solve and repair actions depending on the work order firm status and operation allow offloading values.

| Work Order Firm Status |

Operation Allow Offloading |

Solve | Repair |

|---|---|---|---|

|

Toggled on (Firm) |

Toggled on (Yes) |

Work order operation may be offloaded to an alternate resource |

Work order operation can be offloaded to an alternate resource, if operation has not been transacted yet |

|

Toggled on (Firm) |

Toggled off (No) |

Work order operation won’t be offloaded to an alternate resource |

Work order operation can’t be offloaded to an alternate resource |

|

Toggled off (Not firm) |

Toggled on (Yes) |

Work order operation may be offloaded to an alternate resource |

Work order operation can be offloaded to an alternate resource, if operation has not been transacted yet |

|

Toggled off (Not firm) |

Toggled off (No) |

Work order operation won’t be offloaded to an alternate resource |

Work order operation can’t be offloaded to an alternate resource |

Here's the demo of these capabilities:

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Supply Chain Planning

Tips And Considerations

If you want to use the Improved Manual Scheduling by Firming Operations feature, then you must opt in to its parent feature: Production Scheduling. If you’ve already opted in to this parent feature, then you don’t have to opt in again.

Key Resources

-

Watch the Improved Manual Scheduling by Firming Operations demo.

- Visit https://redwood.oracle.com/ for more information about the Redwood experience.

Access Requirements

Users who are assigned a configured job role that contains this privilege can access this feature:

- Edit Production Schedule (MSC_EDIT_PRODUCTION_SCHEDULE_PRIV)

This privilege was available prior to this update.