Manage Work Order Operation Queues for Workstations When Supervising Production

Production supervisors manage and oversee the work scheduled for a shift. With this update, production supervisors can now manage the work order operation queues at workstations for their work centers.

As a production supervisor, you can perform the following actions:

- Assign work order operations at workstations.

- Unassign work order operations at a workstation.

- Edit and re-sequence the work order operation queue at a workstation.

- View expedited work order operation details in the workstation queue.

- Track the progress of work order operation execution at a workstation.

- Track any open exceptions at a workstation for a work order operation.

You can view the list of assigned operations by drilling down into a workstation card from the monitoring dashboard. The operations appear in the sequence that the supervisor expects the operator to follow during work execution. Each assigned operation shows a badge indicating the current execution status of the operation, namely Not Started, Started, or In Progress. Any open exceptions are also displayed alongside the operation. Expedited work order operations appear near the top of the list, positioned just below any In Progress operations.

NOTE: You can use the Work Order Operation Assignment parameter in the Smart Operations Configurations task to enforce the execution sequence at workstations.

You can expand an assigned operation to access additional details, such as operation ready quantity, completed quantity, rejected quantity, scrapped quantity, planned start date, planned completion date, and priority.

Assigned Work Order Operations for a Workstation

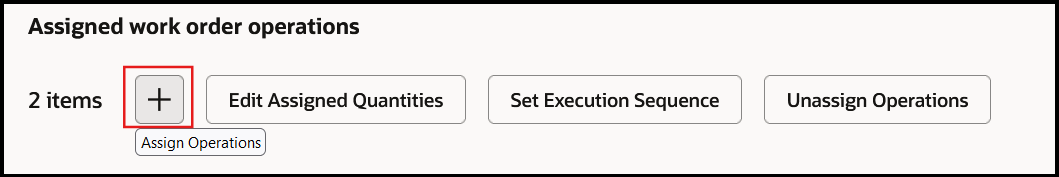

You can add work order operations to a workstation queue using the Assign Operations action. To be eligible for assignment, work orders must be in released status and the operation must be an in-house count point operation that belongs to the context work center.

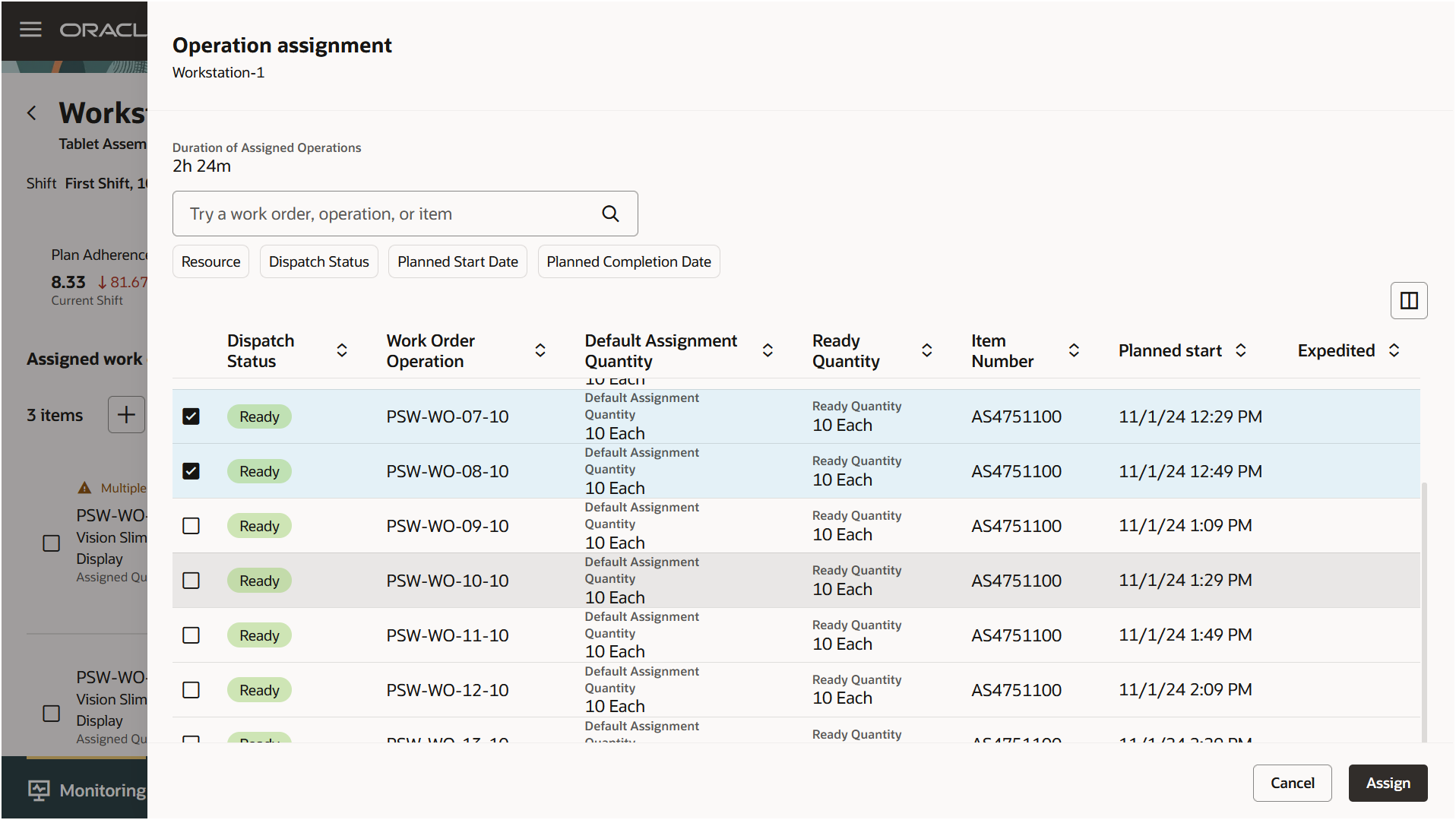

You can assign any number of operations to a workstation. The Duration of Assigned Operations metric represents the total duration of all assigned operations in a workstation queue. The metric helps you assess the present workload on the workstation queue when assigning operations.

When assigning operations, you can search for operations, use search filters to narrow your search, and enable additional display columns relevant to your business in the operation assignment drawer.

Assign Operations Action

Operation Assignment Drawer

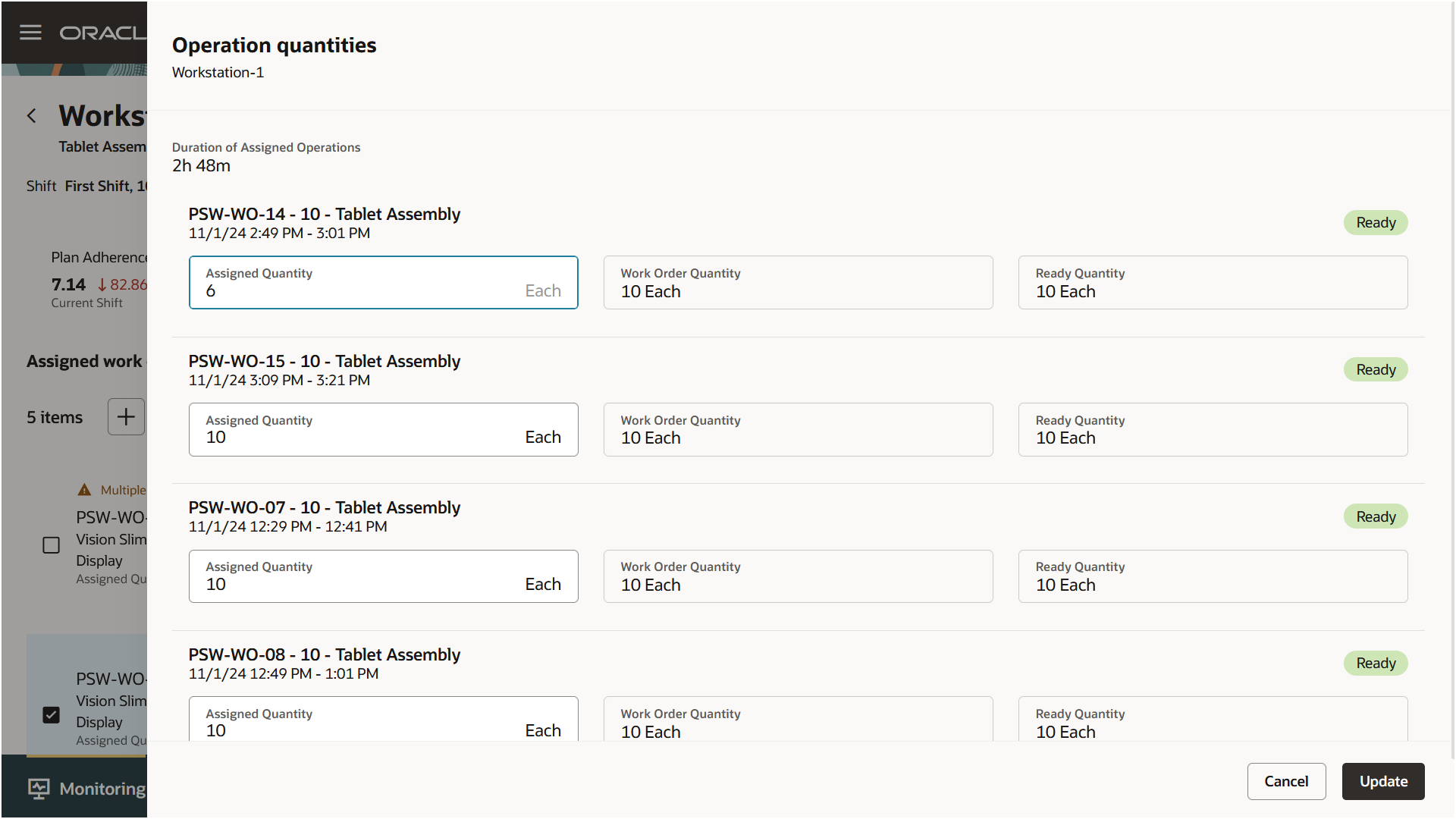

When operations are first assigned to a workstation queue, the entire operation quantity is assigned by default. You can select and edit the assigned quantities of one or more operations using the Edit Assigned Quantities action. You may want to reduce assigned quantities for an operation if you are planning to distribute the execution of an operation across multiple workstations. You cannot edit the quantities of an operation that is in progress. When assigning quantities, the total work order quantities and ready quantities are also displayed for your information.

Edit Operation Quantities Drawer

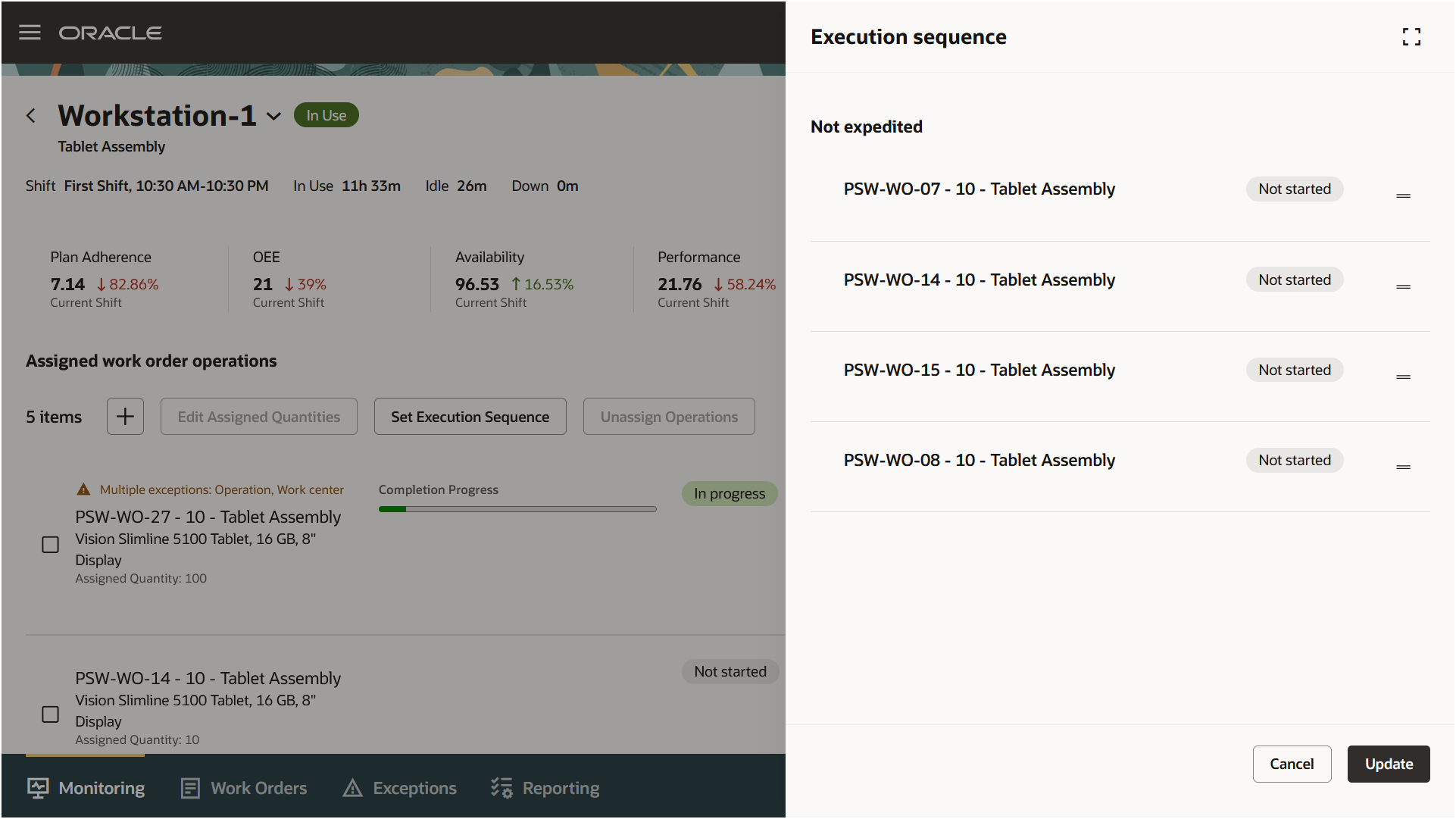

You can rearrange the sequence of work order operations in a workstation queue using the Set Execution Sequence action. You can modify the order of operations, as long as they are not marked as In Progress. You can only rearrange operations within expedited or non-expedited groups, but not across these two groups.

Set Execution Sequence

You can unassign one or more operations from a workstation queue using the Unassign Operation action. Unassigning an operation from a workstation makes the operation available for assignment in another workstation's queue. You cannot unassign an operation that is marked as In Progress.

With real-time management of workstation queues, production supervisors can efficiently manage sequencing of operations for their work centers. Supervisors can quickly adapt to changes in resource availability or customer requirements. They can optimize the utilization of resources to achieve maximum productivity.

Here's the demo of these capabilities:

Steps to Enable

Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document.

Offering: Manufacturing and Supply Chain Materials Management No Longer Optional From: Update 25C

This feature Manage Work Order Operation Queues for Workstations When Supervising Production is a child feature of Monitor Workstation Performance When Supervising Production feature.

The Opt-in for Manage Work Order Operation Queues for Workstations When Supervising Production is based on the parent feature Monitor Workstation Performance When Supervising Production. The parent feature has an Opt-in: When the parent feature is enabled, the child feature also gets enabled.

Tips And Considerations

Use the Smart Operations Configurations task to enforce the assignment and sequencing of operations at workstations. When Work Order Operation Assignment is set to Enforce Assignment, operators must pick from the operations assigned by the production supervisor. If the value is set to Enforce Assignment and Sequence, operators must pick the assigned operations in the sequence set by the production supervisor. If the value is set to Not Enforced, operators can also pick other operations.

Key Resources

- Watch the feature demo for Manage Work Order Operation Queues for Workstations When Supervising Production.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Supervise Production (WIP_SUPERVISE_PRODUCTION_PRIV)

- Manage Workstation Queue (WIP_MANAGE_WORKSTATION_QUEUE_PRIV)

- Manage Assignment of Operators to Workstation (WIP_MANAGE_WORKSTATION_OPERATORS_PRIV)

- Get Manufacturing Plant Set Up Data by Service (WIS_GET_MFG_PLANT_SETUP_SERVICE)

- View Workstations (WIS_VIEW_WORKSTATIONS)

- Execute Production at a Workstation (WIP_EXECUTE_WORKSTATION_PRIV)

- View Production Exceptions (WIP_VIEW_PRODUCTION_EXCEPTIONS_PRIV)

- View Production Shift Details (WIP_GET_PROD_SHIFT_DETAILS_PRIV)

- Configure OTBI Reports on Landing Page (WIS_CONFIGURE_OTBI_REPORTS_LANDING_PAGE_PRIV)

Visualization Configurations:

- View Service Manager Dashboard (SVC_VIEW_SERVICE_MANAGER_DASHBOARD_PRIV)

- View Service Representative Dashboard (SVC_VIEW_SERVICE_REPRESENTATIVE_DASHBOARD_PRIV)

Guided Journeys : Role Codes:

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

The Configure OTBI Reports on Landing Page privilege, Manage Workstation Queue privilege, and Manage Assignment of Operators to Workstation privilege are new in this update. All other privileges and roles were available prior to this update.