Manage Flow Schedules for Manufacturing Execution on a Production Line

Flow manufacturing applies to a subset of manufacturers that run uninterrupted production lines at a constant rate to make similar products, generally in bulk and with a repetitive process. Production is managed through flow schedules that are created and scheduled based on the line rate and available working hours.

You can create a flow schedule based on the selected flow manufacturing work definition to make a standard or configured product on a production line at a certain rate. You can manually schedule and sequence flow schedules for a mix of products to level load a production line and synchronize production activities with daily customer demand.

You can also fulfill back-to-back supply requests from Order Management with flow schedules, through Supply Chain Orchestration (SCO). SCO sends a flow schedule create request to manufacturing to fulfill back-to-back supply requests. SCO also manages any changes that happen either on the back-to-back sales order or on the flow schedules to keep the demand and supply in sync.

Managing flow schedules provides the following capabilities:

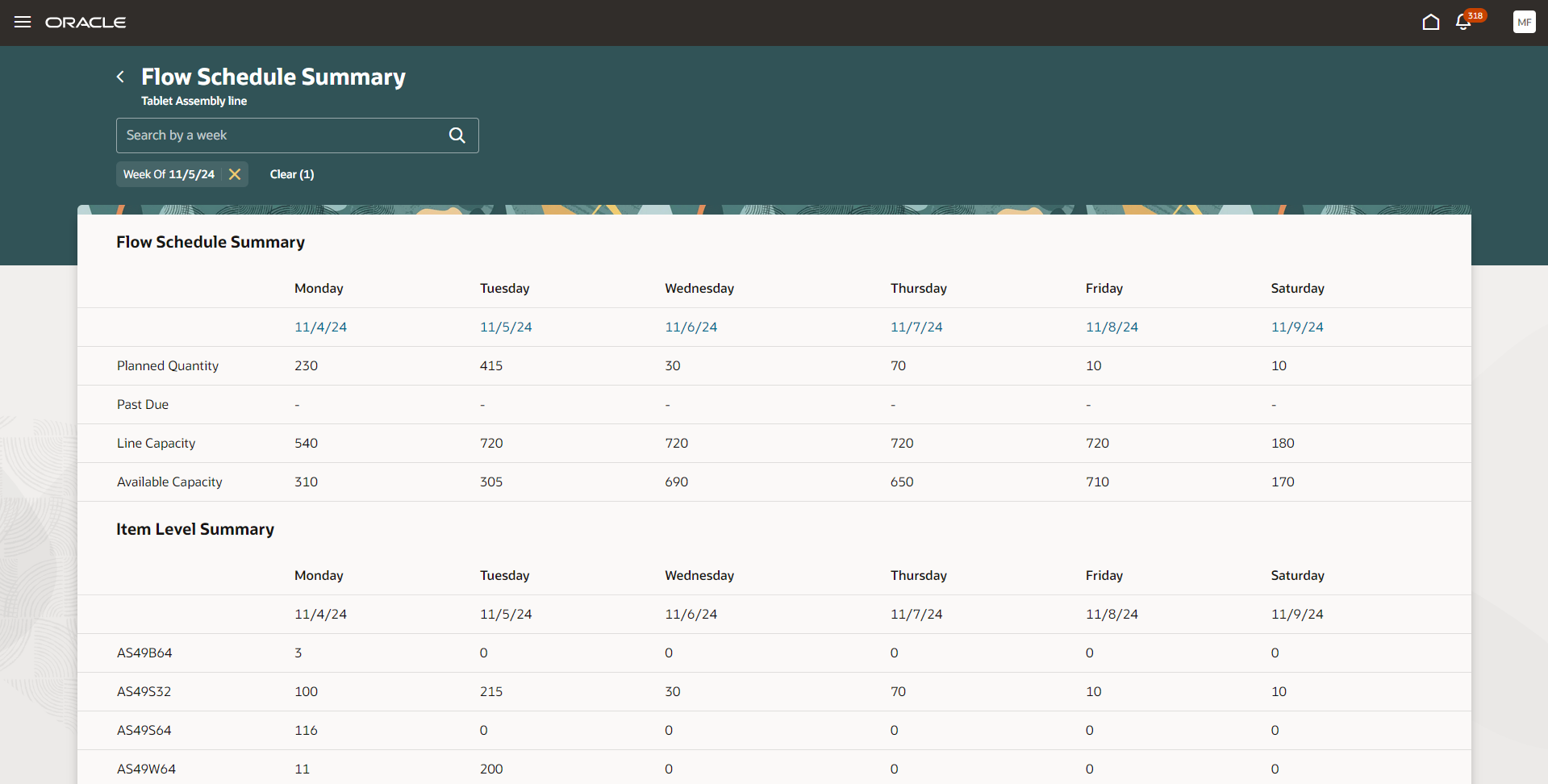

- View a summary of flow schedules for a production line - Compare planned quantities by item against daily line capacity to identify any overload situation that needs to be resolved.

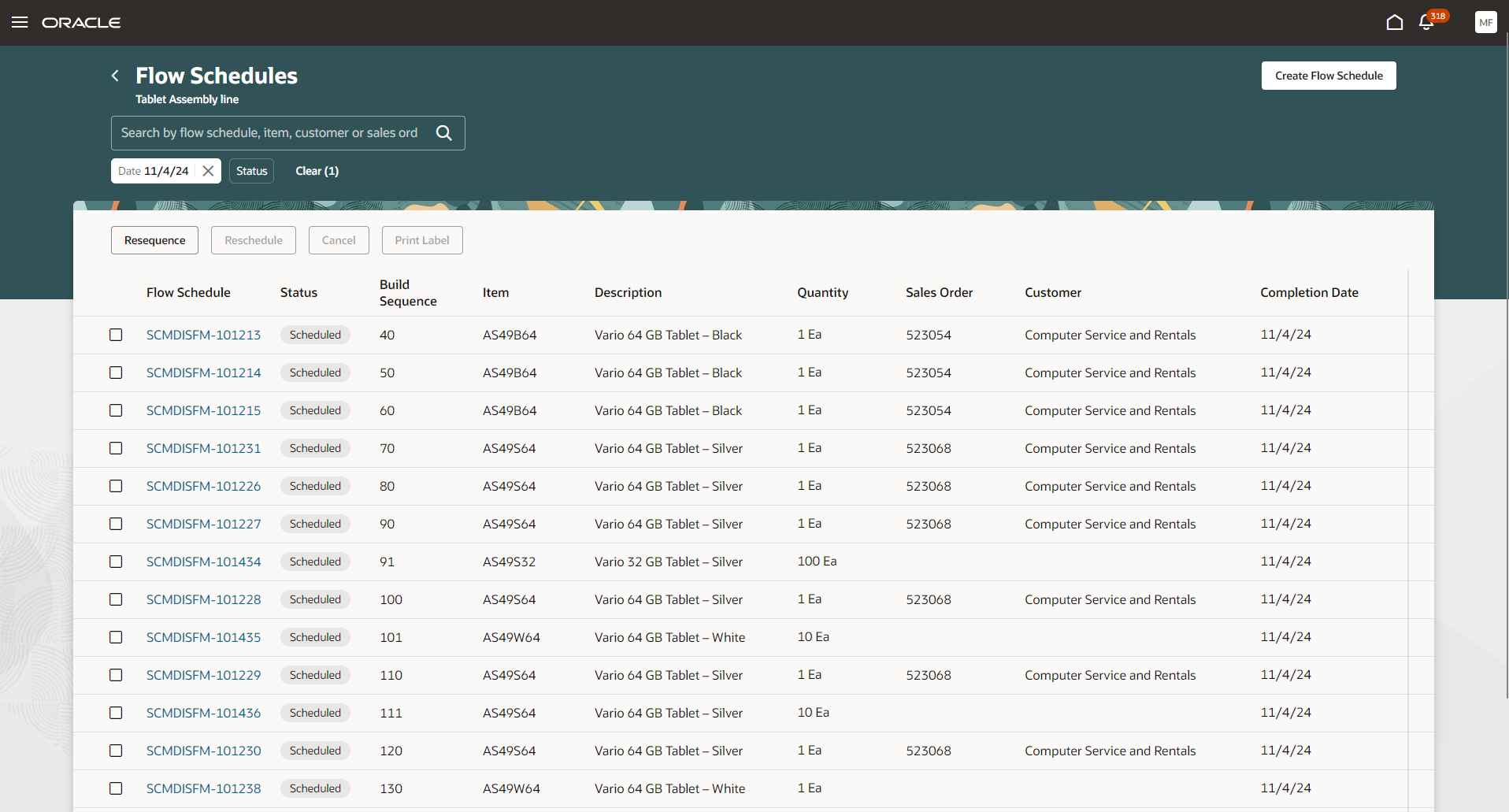

- Manage flow schedules sequenced on a specific day - View, update, or cancel a flow schedule. You can manually create a flow schedule to produce a product. For a flow schedule that's automatically generated as part of a back-to-back order fulfillment flow, you can view the flow schedule details, including the sales order information and requested date. You can also resequence flow schedules to change the order of execution on any particular day to cater to situations such as fulfilling a rush order. You can also reschedule one or more flow schedules to a different date to manage production bottlenecks.

Flow Schedule Summary - Weekly View

Flow Schedule Summary - Day view

Manufacturers can implement flow manufacturing using defined schedules for execution and streamline production execution in line with lean manufacturing principles.

Here's the demo of these capabilities:

Steps to Enable

-

Enable the 24B feature - Search for, Create, and Edit a Standard Item Work Definition Using the Redwood User Experience.

-

Create a flow manufacturing work definition associated with a production line.

Tips And Considerations

- You can design and balance a flow production line to determine the number of slots available for customer orders based the line rate and daily demand. For example, a line rate of 5 units per hour with an 8-hour shift means that there are 40 slots available.

- You can't create flow schedules in the following organizations:

- Contract manufacturing organization

- Organization enabled for inventory tracking by project & task

- Organization enabled for country of origin tracking

- Warehouse management system integration enabled organization

-

Flow schedules in flow manufacturing are scheduled using the production calendar associated with a manufacturing plant. For plants that have mixed mode manufacturing, such as a combination of discrete, process, or flow manufacturing work methods, and for plants that perform maintenance activities in the same plant, the production line capacity is determined based on the shift definition in the production calendar for work-order based execution. To avoid potential confusion, especially in situations where the production line has a different shift pattern compared to the shift pattern for work-order based scheduling and execution, we recommend that you use work center override calendars for work-order based scheduling and execution.

Key Resources

- Refer to the following demos:

-

Create a production line for flow manufacturing.

-

Create a flow manufacturing work definition associated with a production line.

-

Manage flow schedules for manufacturing execution on a production line.

-

Execute flow schedules on a production line.

-

Access Requirements

Users who are assigned a configured job role that contains these privileges and codes can access this feature:

- Manufacturing Privileges

- Manage Flow Schedules by Service (WIP_MANAGE_FLOW_SCHEDULES_SERVICE)

- Manage Flow Schedules (WIP_MANAGE_FLOW_SCHEDULES)

- View Flow Schedules (WIP_VIEW_FLOW_SCHEDULES)

- Get Flow Schedules by Service (WIP_GET_FLOW_SCHEDULES_SERVICE)

These privileges are new in the 25A update.

- Supply Chain Orchestration

- Process Supply Order Interface (DOS_PROCESS_SUPPLY_ORDER_INTERFACE_PRIV)

- View Supply Orders (DOS_VIEW_SUPPLY_ORDERS_PRIV)

- Manage Supply Request Exceptions (DOS_MANAGE_SUPPLY_REQUEST_EXCEPTIONS_PRIV)

- View Supply Order Exceptions and Status (DOS_VIEW_SUPPLY_ORDER_EXCEPTIONS_AND_STATUS_PRIV)

These privileges were available prior to this update.

- Guided Journeys : Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

These roles were available prior to this update.