Exclude Unfulfilled Demands from Projected Available Balance

When you run the supply planning process to balance supply and demand, it’s possible that some portion of the demand couldn’t be fulfilled because of various material and capacity constraints that may be present in your enterprise. If the demand isn’t fully met, then the projected available balance calculations need to exclude the unfulfilled demand from the calculations because otherwise it will affect your understanding of the true supply and demand picture, in addition to affecting safety stock calculations. With this update, the projected available balance calculations now can exclude the demand that’s unfulfilled by using the Number of Days for Demand Cutoff attribute. This attribute specifies the maximum allowed lateness for a demand, after which it’s dropped from planning calculations.

Dropped Demands

The demands that aren’t satisfied due to the following attributes are called dropped demands:

- Final Date to Satisfy Forecast Demand. This is calculated in constrained supply planning.

- Final Date to Satisfy Forecast Demand = Forecast Demand Date + Number of Days for Forecast Cutoff

- Dropped demands are those demands after the Cutoff Date (starting with Cutoff Date + 1).

- Sales Order Demand Latest Acceptable Date. The Latest Acceptable Date is an item-org sales order attribute, which is specified at the sales order line level.

The Projected Available Balance (PAB) measure calculation is now changed to exclude the demands that are dropped because of implementing the existing feature: Fill Demand with Supplies Only Within a User-Specified Time Window.

Example 1

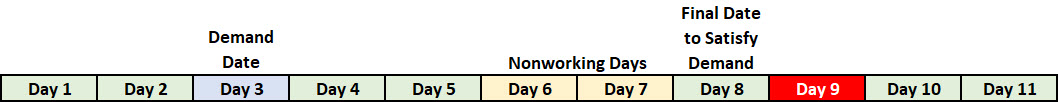

In the following figure:

- Current Date = Day 1

- Forecast Demand Date = Day 3

- Number of Days for Demand Cutoff = 3 Days

Final Date to Satisfy Demand

Final Date to Satisfy Forecast Demand = Day 3 + 3 Days + 2 Nonworking Days = Day 8

This means the planning process can only satisfy this demand on or before Day 8.

New PAB Calculation

With this enhancement, the PAB is calculated using the following equation:

PAB = Previous PAB + On Hand + Scheduled Receipts + Planned Orders - (Total Demand - Dropped Demand)

In addition, the Projected On Hand value is impacted similarly:

Projected On Hand = Previous Projected On Hand + On Hand + Scheduled Receipts - (Total Demand - Dropped Demand)

This feature is relevant only to constrained supply planning.

Example 2

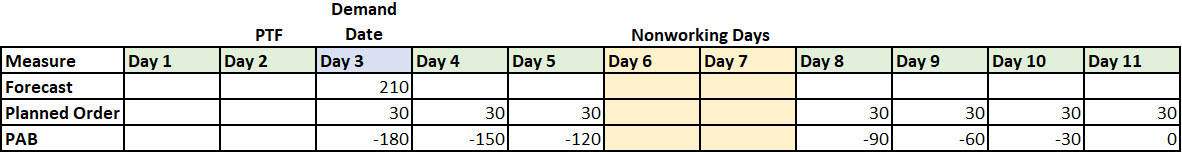

In the following figures:

- Demand Quantity = 210

- Planning Time Fence = Day 2

- Daily Production Resource Capacity = 30 Units

Before Enhancement

PAB Before Enhancement

After Enhancement

PAB After Enhancement

* The Dropped Demand measure used in the new PAB calculation will be available in a future release.

In the PAB After Enhancement figure, the PAB for days 9, 10, and 11 (highlighted in yellow) show the revised PAB as zero for each day, given the new feature.

PAB (Day 9) = PAB (Day 8) + Planned Orders (Day 9) – [Total Demand (Day 9) – Dropped Demand (Day 9)] = -90 + 0 – [0 – 90] = 0

Steps to Enable

You don't need to do anything to enable this feature.

Key Resources

- The following feature, released in update 23A, allows you to specify the maximum number of days an order can be late. Any remaining quantity that’s not fulfilled within this window will be considered unmet.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Supply Chain Planner (ORA_MSC_SUPPLY_CHAIN_PLANNER_JOB)

- Materials Planner (ORA_MSC_MATERIALS_PLANNER_JOB)

These privileges were available prior to this update.