Inspect Flow Schedules at End of the Production Line

As a critical step in a lean manufacturing environment, final inspection can ensure products produced meet the specified quality standards without slowing down the production process. You can now record final inspection results while completing the product in a flow schedule at the end of the production line using the Complete with Details action. A predefined inspection plan is automatically selected and enforced at the last operation based on the corresponding work definition for the flow schedule. You are prompted to enter the inspection results and complete the flow schedule quantity as completed or scrapped according to the system-automated inspection disposition.

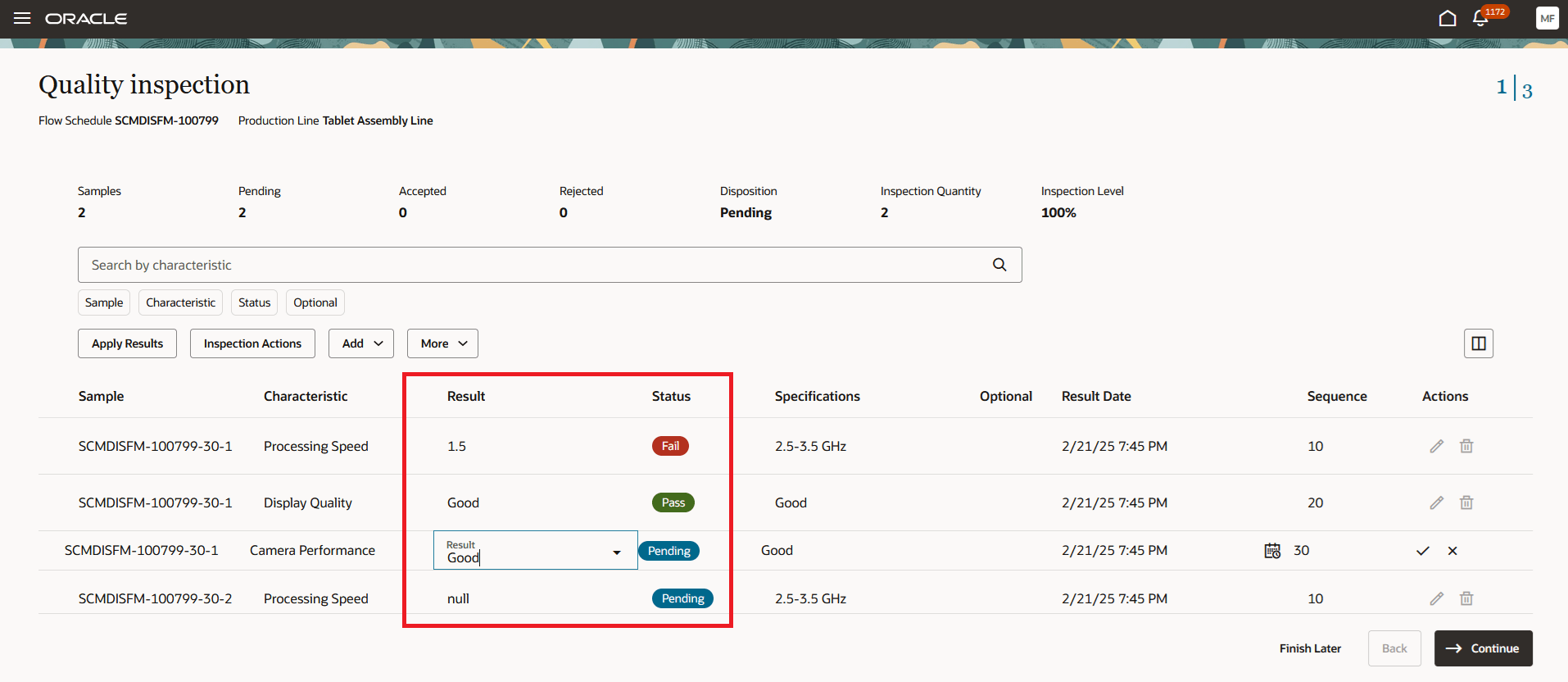

Enter Inspection Results for a Flow Schedule

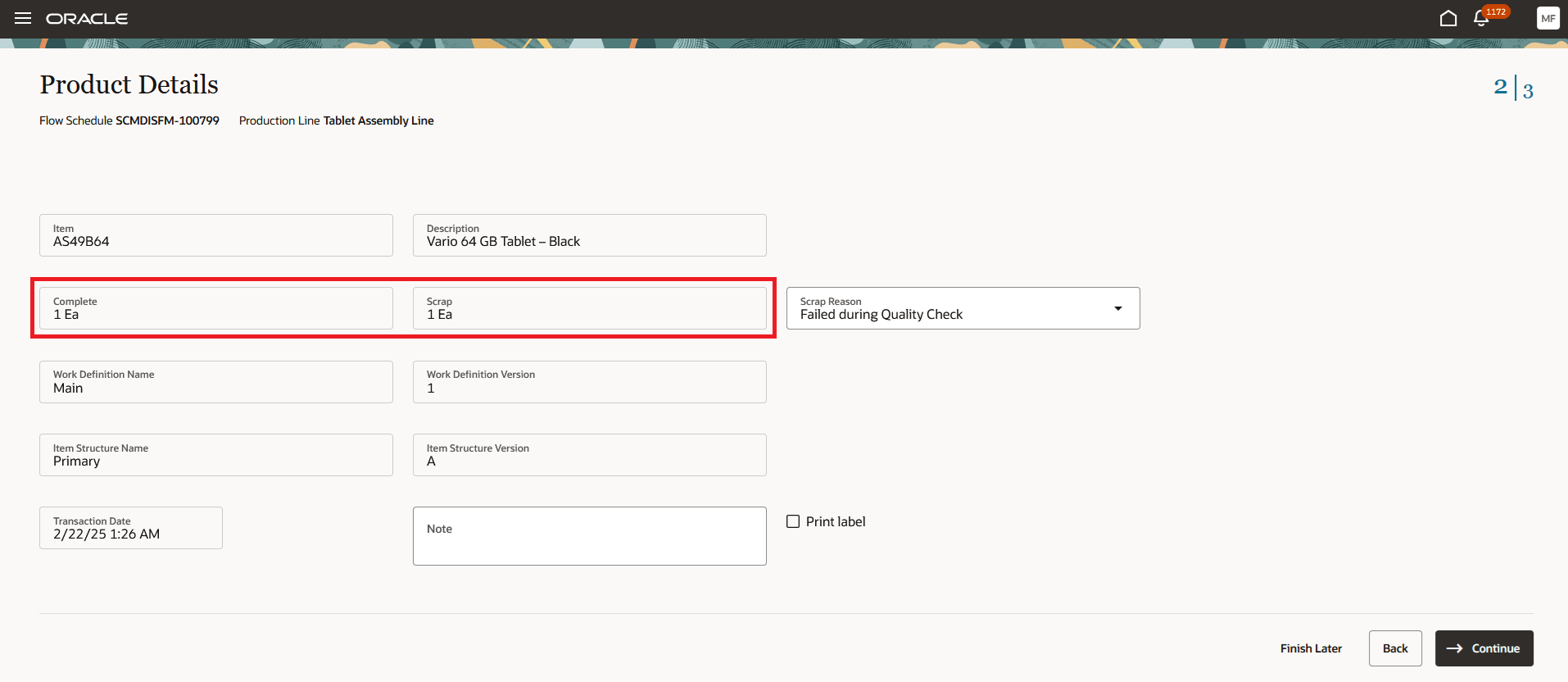

The flow schedule quantity is reported as completed or scrapped according to the system-automated inspection disposition. You can optionally enter a scrap reason. In case a flow schedule is created from a sales order in a back-to-back scenario, the scrap quantity is considered disposed, and this automatically relieves the reserved quantity.

Automatic Disposition of Flow Schedule Quantity as Completed or Scrapped

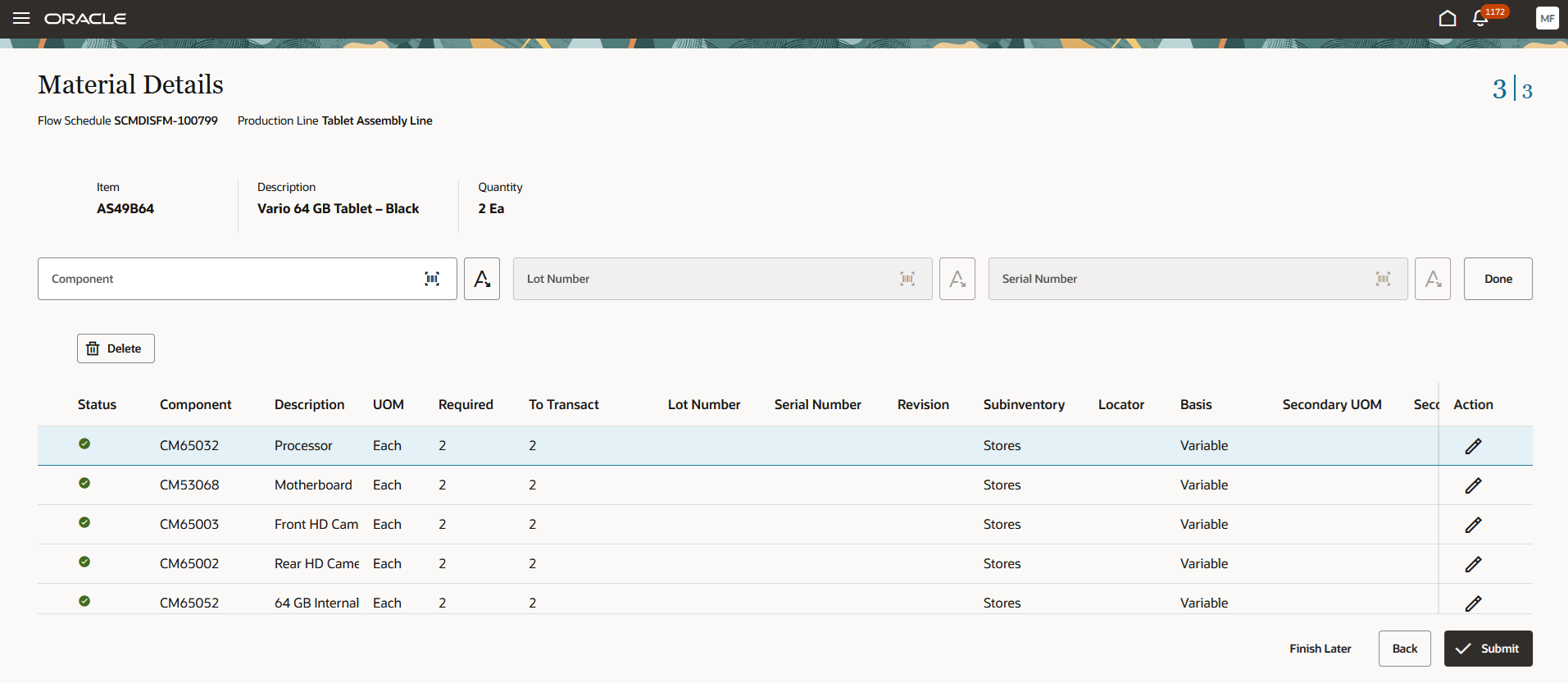

In the Complete with Details flow, you can report the materials consumed for the total quantity that was completed and scrapped.

Report Materials for the Total Quantity That was Completed and Scrapped

Final inspection at the end of the flow line becomes a value-added activity that ensures high quality products are released to customers.

Here's the demo of these capabilities:

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- You can't report a rejected quantity for a flow schedule at this time. Instead, you can report a completed quantity into the specified subinventory and locator, or a scrap quantity to dispose it.

- You can't perform an ad hoc inspection against a flow schedule at this time.

- A common practice is to create a flow schedule to manufacture a product as a single piece flow on a production line and define an inspection plan to inspect the product at a 100% inspection level.

Key Resources

- Watch the Inspect Flow Schedules at End of the Production Line demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges and codes can access this feature:

- Manufacturing Privileges :

- Execute Flow Schedules (WIP_EXECUTE_FLOW_SCHEDULES_PRIV)

- Guided Journeys : Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

These roles and privileges were available prior to this update.