Complete an Intermediate Operation for a Flow Schedule on a Production Line

Lean manufacturers with longer manufacturing cycle times typically require visibility of the work in progress (WIP) before products are finished on a flow manufacturing production line. Interim production progress updates help provide an accurate picture of the materials used without the need to wait for end of line completions. With this update, you can now complete all production line operations for a flow schedule using the Redwood user experience. The following capabilities in flow manufacturing have been augmented:

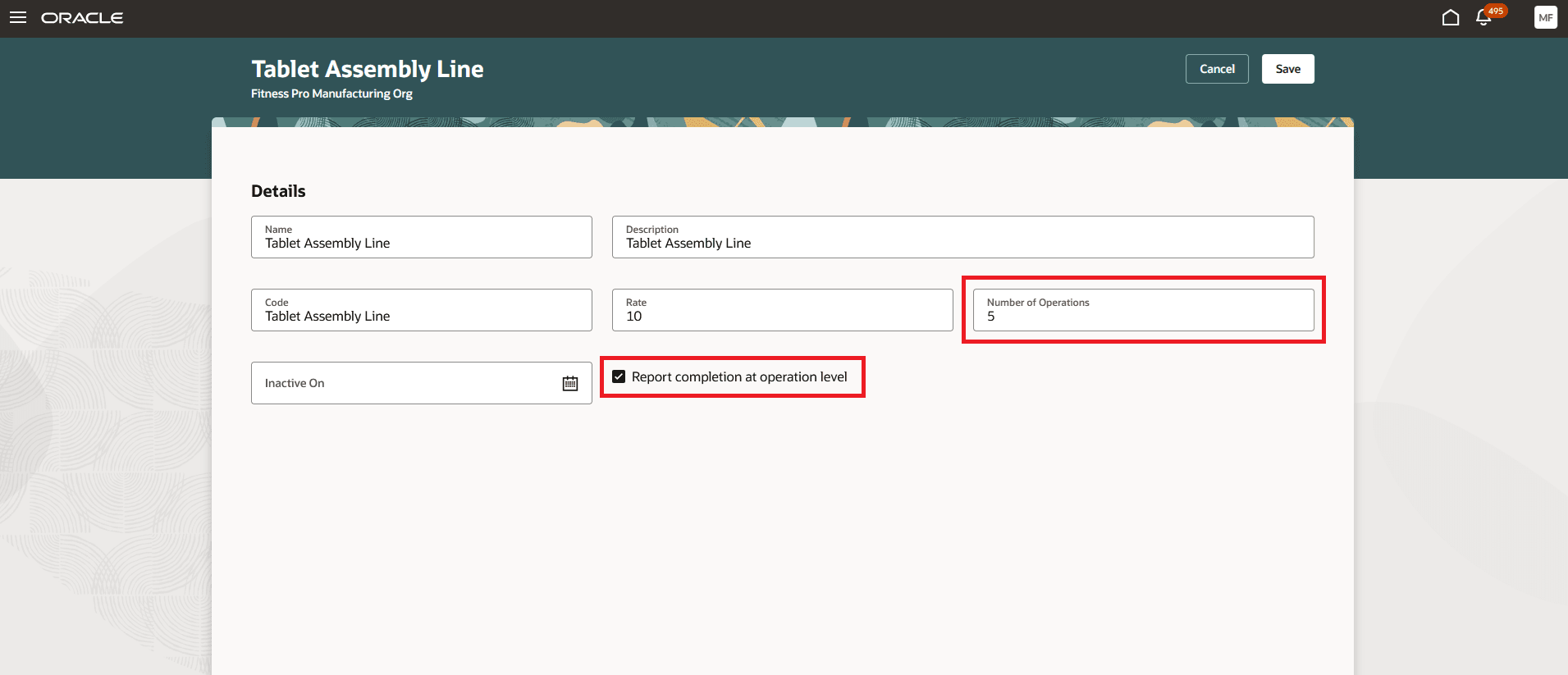

- Create a flow production line with line operations for reporting completions: Specify additional details for a new production line, including the number of operations and whether production reporting can be done at the operation level.

Specify Number of Line Operations and Indicate if Production Reporting Can Be Done at the Operation Level

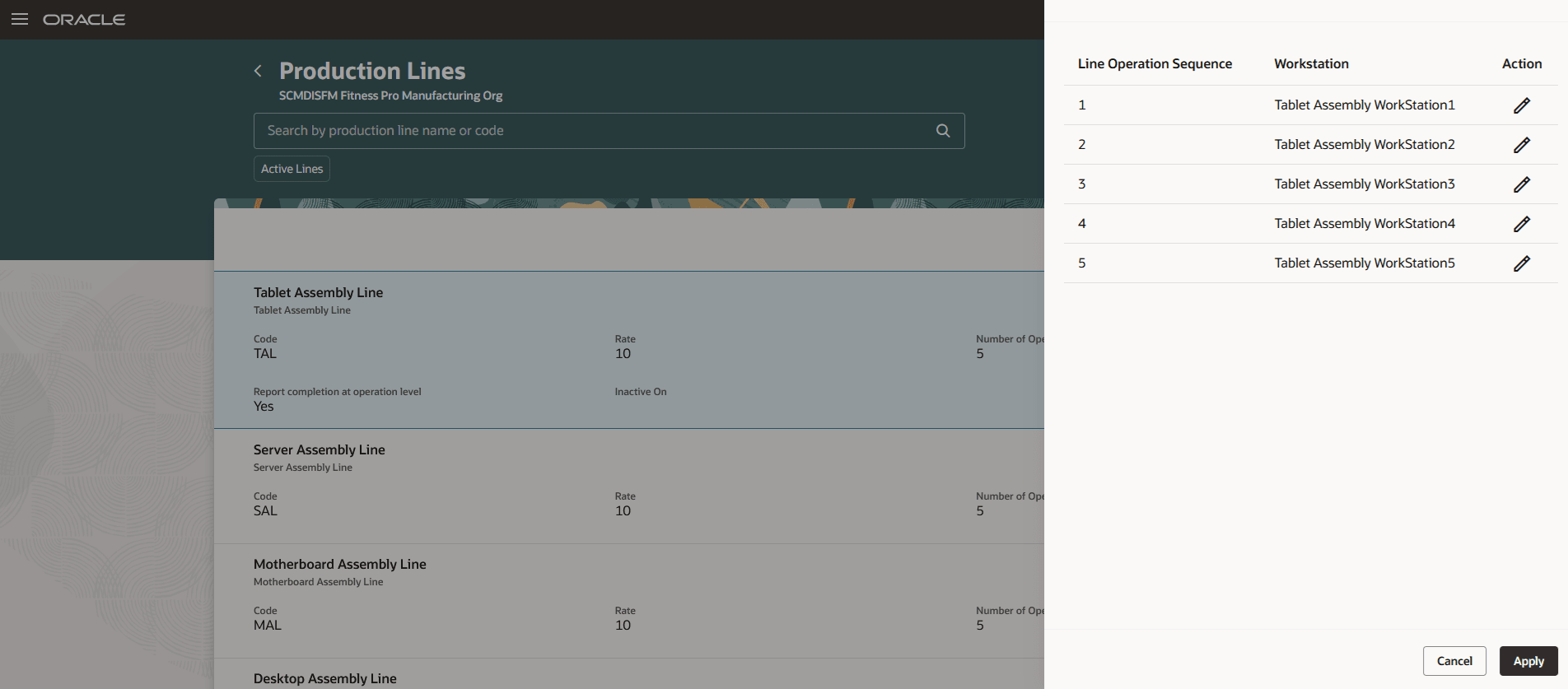

- Manage line operations and associate workstations: Based on the number of operations, optionally associate a specific line operation sequence to a workstation to report completion of a count point operation through the operator workbench. You can use the line operations and workstations for the purposes of supply planning and production scheduling.

Manage Line Operations and Associate Workstations

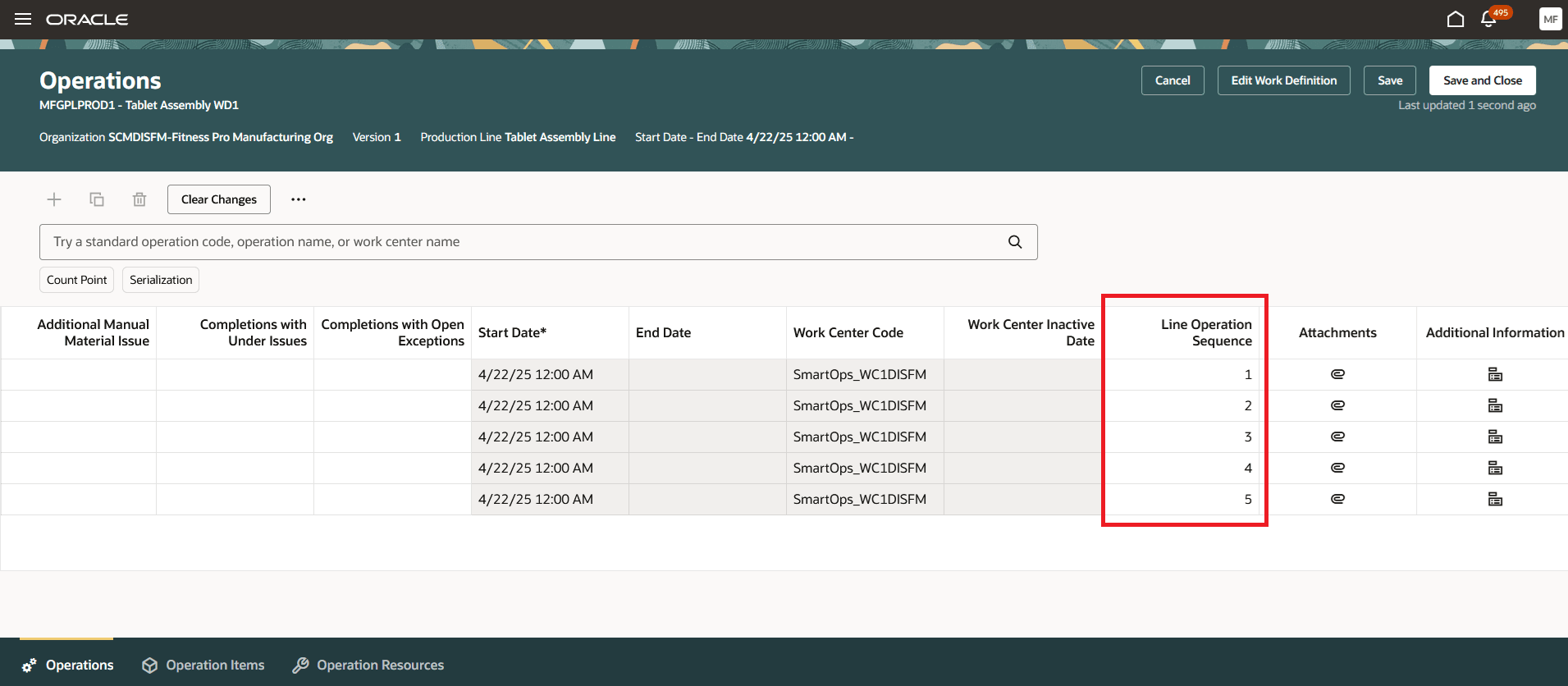

- Create a flow manufacturing work definition associated with the production line operations: Associate the work definition with a production line, where the number of line operations that are enabled for operation-level completion reporting matches the list of work definition operations that are marked as count point.

Associate Line Operation Sequences to Work Definition Operations

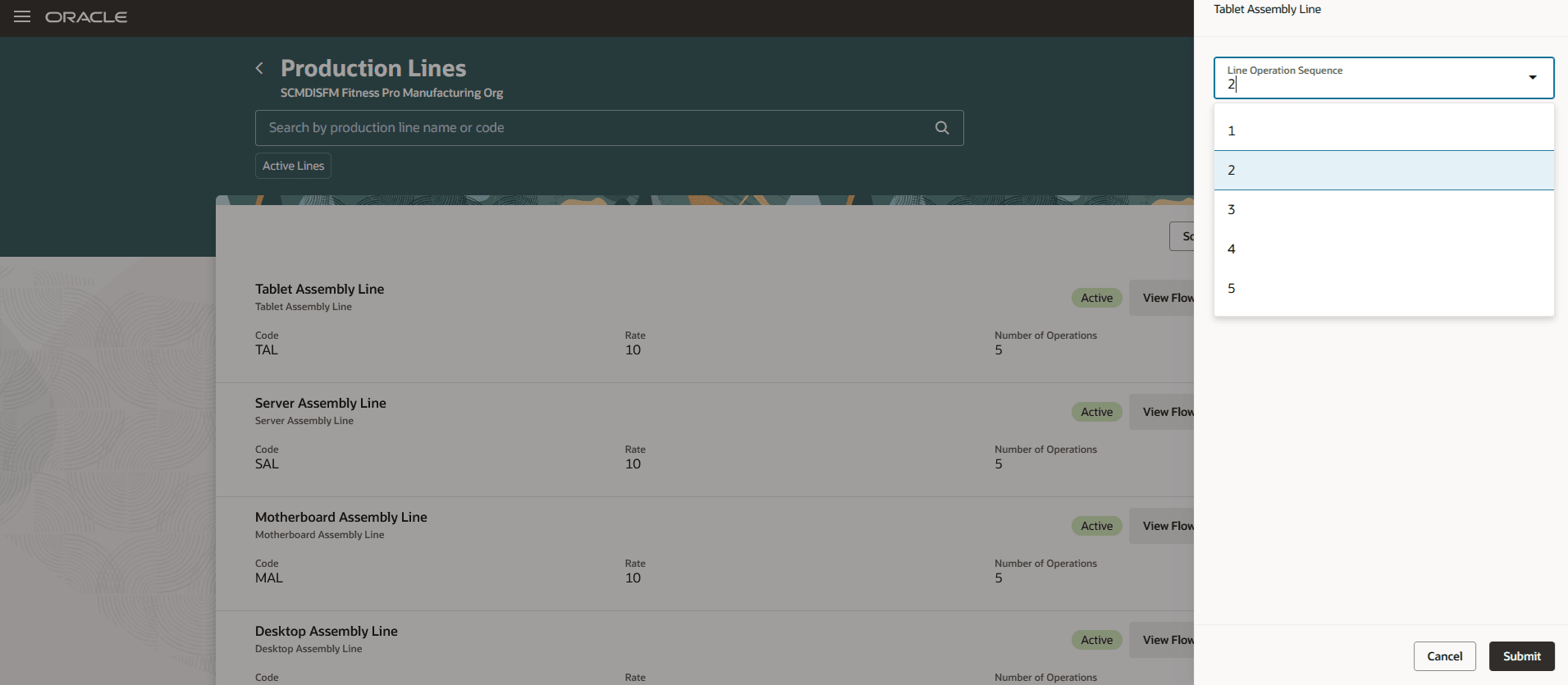

- Complete all operations on a flow production line: Report completion and scrap quantities at an intermediate count point operation on a flow production line. You can also access line operation attachments and additional information during operation execution and record the materials consumed, resources charged, and additional information to complete the line operation.

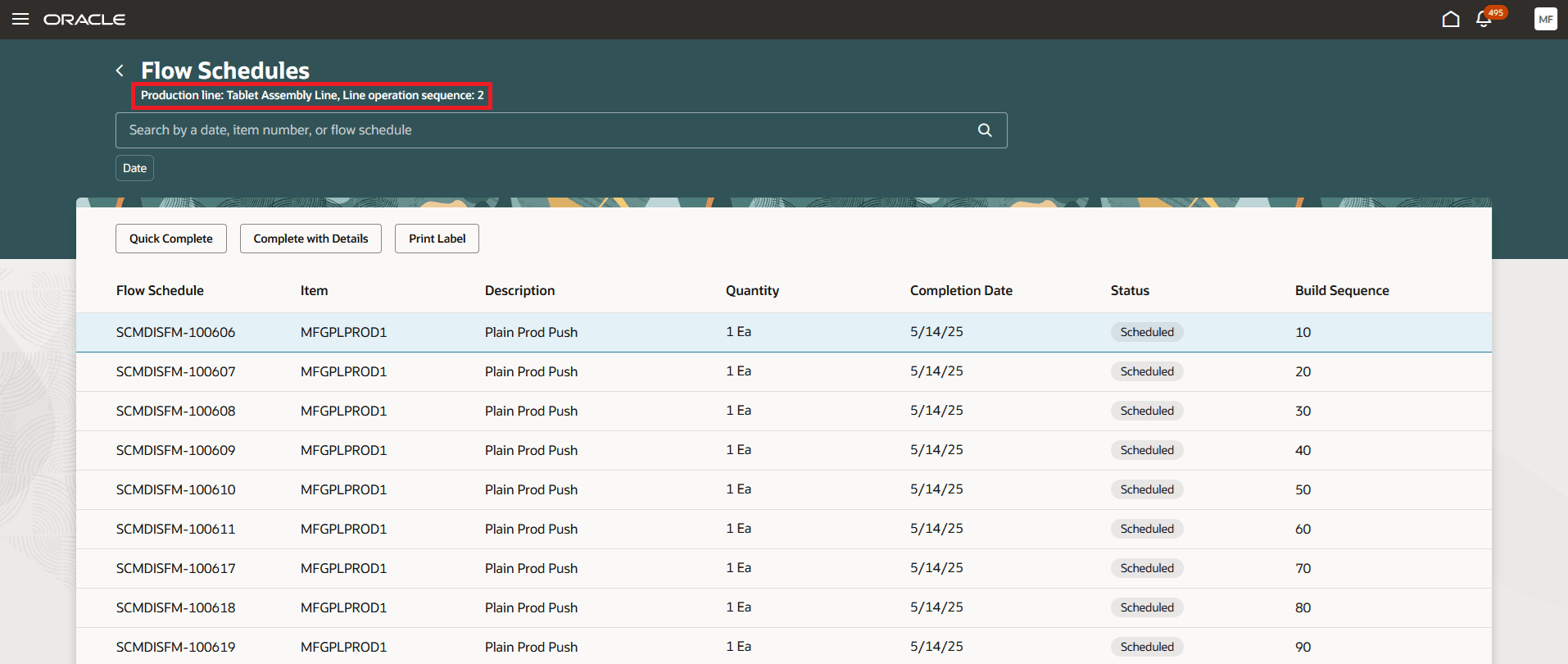

Select a Line Operation Sequence to Report Operation Completion

Select a Flow Schedule to Complete at the Selected Line Operation

Production supervisors can monitor the work in progress (WIP) for the flow manufacturing production line. This helps identify bottlenecks, over or under-stocking of materials, and the progress towards the target completion dates.

Here's the demo of these capabilities:

Steps to Enable

You don't need to do anything to enable this feature.

Tips And Considerations

- You can associate line operation sequence only to count point operations in a work definition.

- You can complete an intermediate operation in addition to the last operation in the flow manufacturing production line. Refer to the 25A feature Execute Flow Schedules on a Production Line for more information.

- You can optionally set up workstations and associate workstation resource instances to help execute flow manufacturing production line operations at workstations. Workstations represent specific locations in a work center.

- You can't partially complete the quantity at any operation in a flow schedule. You must complete the flow schedule quantity at a line operation.

- You can't perform a quality inspection at any operation other than the last operation in the production line.

Key Resources

- Watch the Complete an Intermediate Operation for a Flow Schedule on a Production Line demo.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains these privileges and codes can access this feature:

- Manufacturing Privileges :

- Execute Flow Schedules (WIP_EXECUTE_FLOW_SCHEDULES_PRIV)

This privileges is available from 25A.

- Guided Journeys : Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)

These roles and privileges were available prior to this update.