Collect Operational Process Data from Connected Equipment When Executing Production at a Workstation

Manufacturing processes involve performing complex operations under strict operating conditions to ensure quality standards and regulatory compliance. If your manufacturing process has connected equipment that can provide readings for the process operational parameters, you can automate process data collection by recording the data from associated sensors in the connected equipment. For example, operational parameters can include temperature and pressure sensor readings. Operational parameters can also include compliance data, such as emission levels.

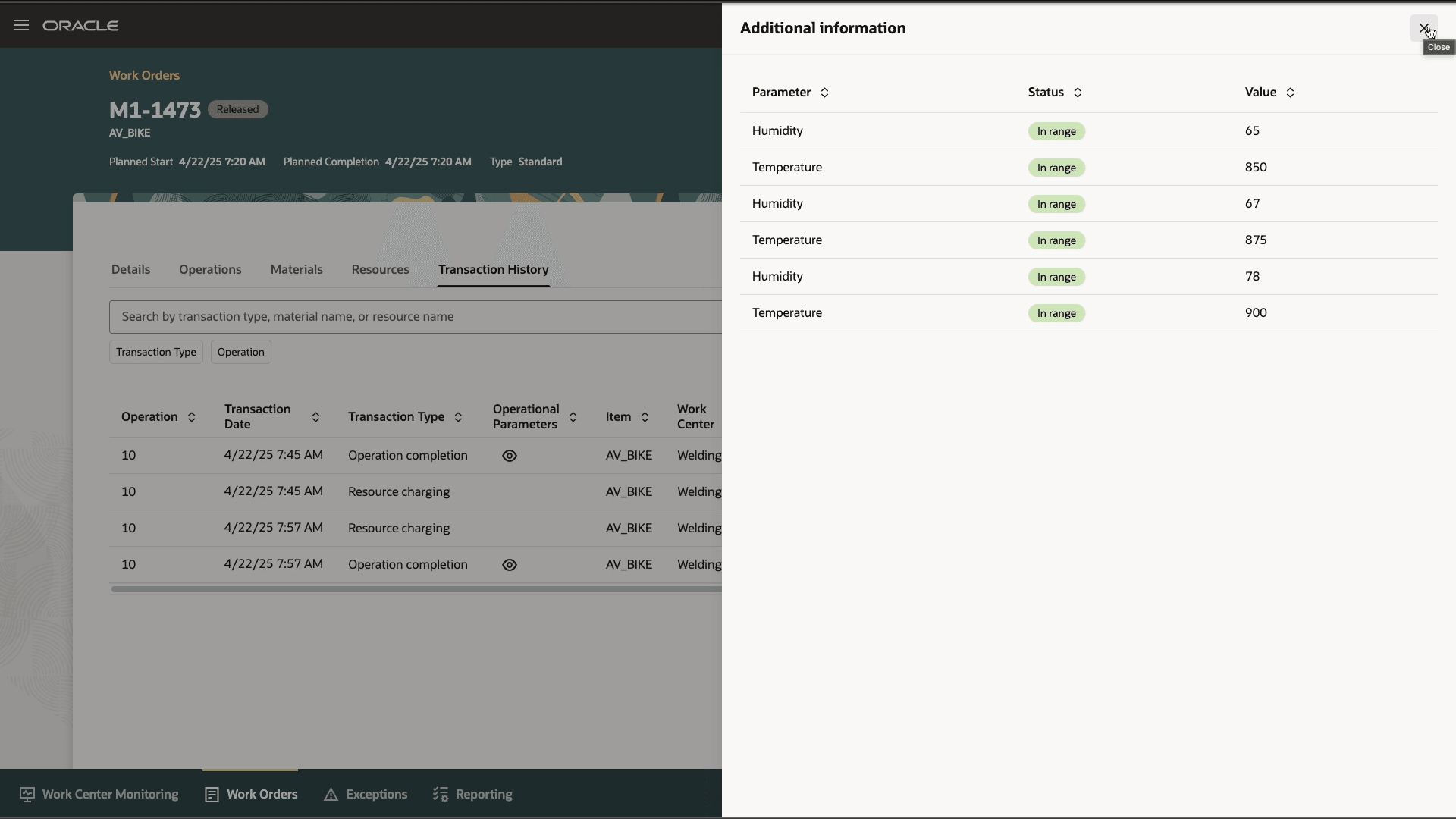

With this update, you can automatically capture process data for a work order operation during operation completion. The process operational parameters data is stored as part of the production record and can be leveraged for analytics and intelligence, such as to predict potential failures and downtime. You can also view the automatically collected operational parameters in the Production Transaction History tab in the production supervisor workbench.

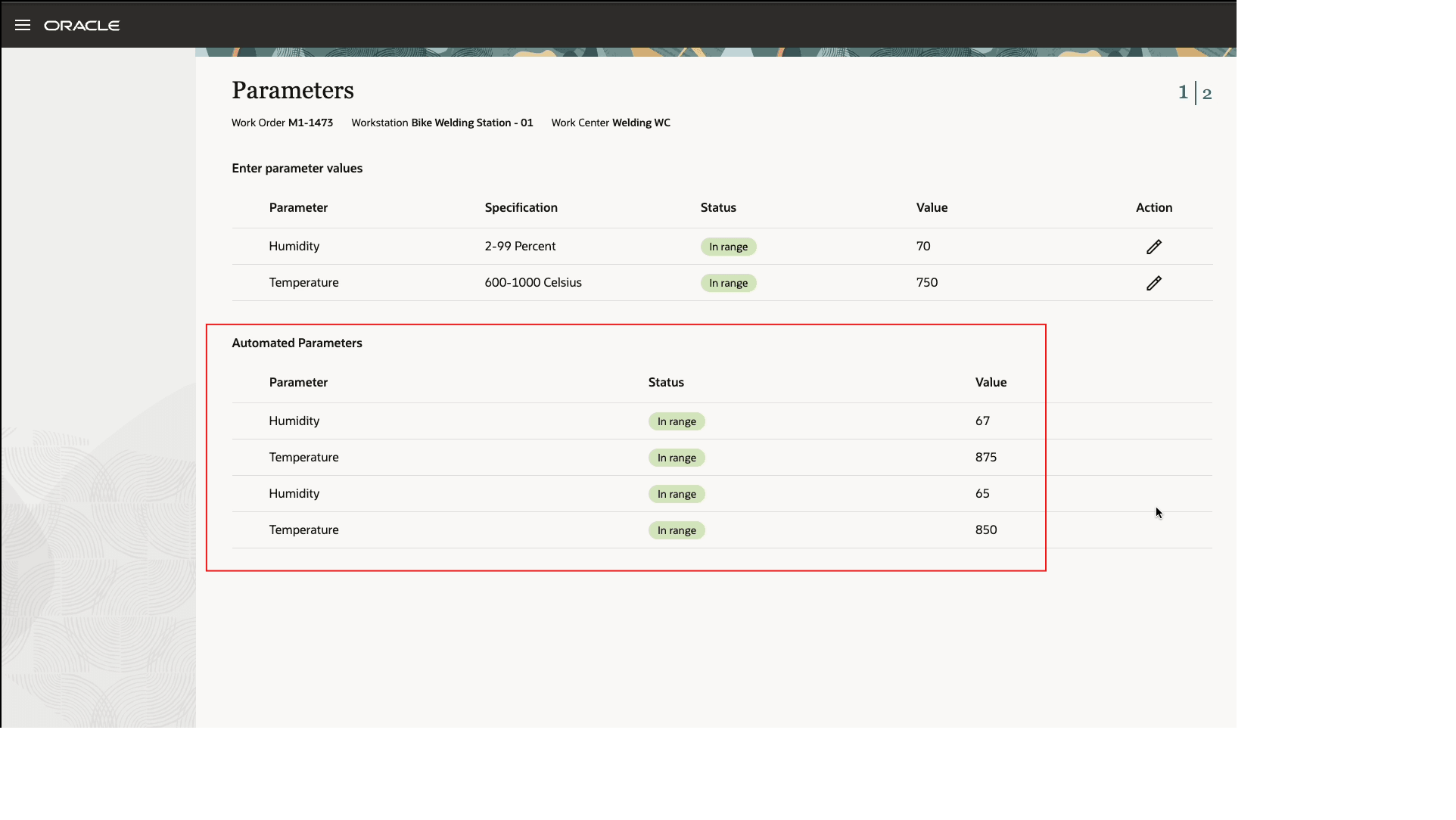

View Automatically Collected Operational Parameters When Completing Quantities in the Operator Workbench

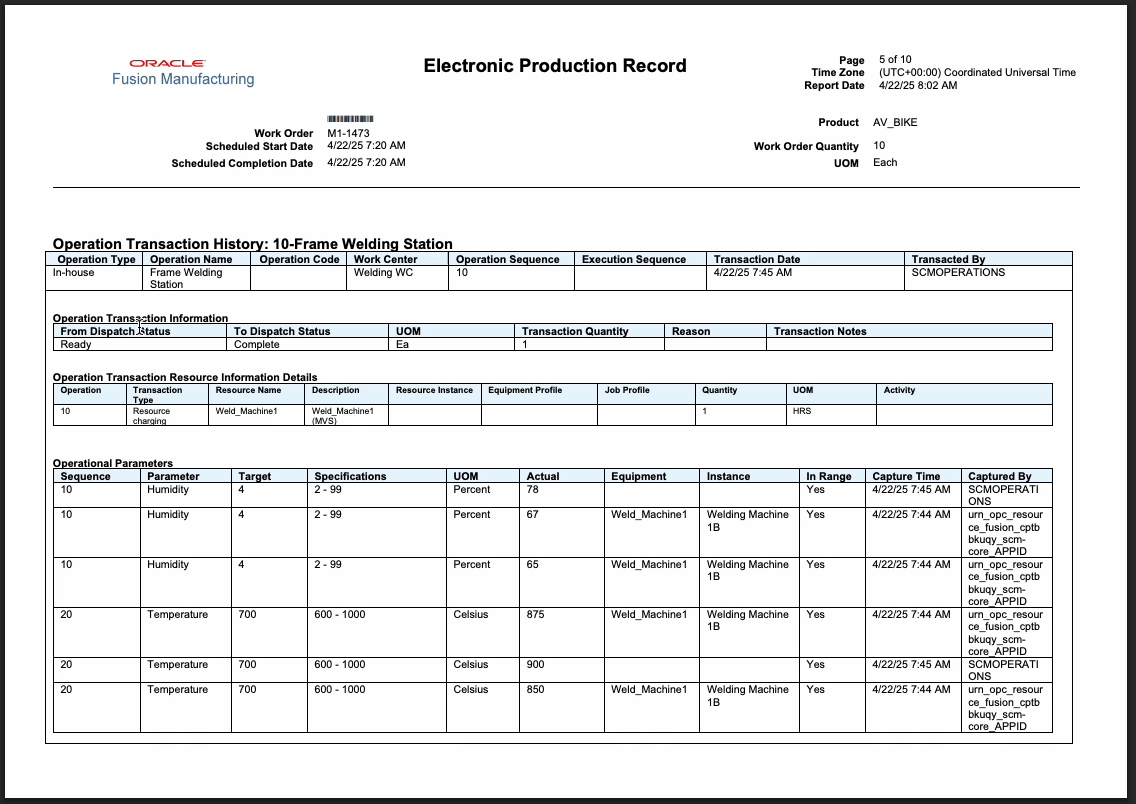

Operational Parameters in the Electronic Production Record

View Operational Parameters in the Production Supervisor Workbench

Manufacturers can maintain contextual data with no manual intervention and take real-time decisions in case of process deviations, preventing unscheduled maintenance.

The collected process data can be used for future analytics and intelligent recommendations on process improvements and optimizations.

Here's the demo of these capabilities:

Steps to Enable

To enable this feature you need to log a Service Request (SR).

- Select Product Module - Oracle Fusion Manufacturing Cloud Service.

- Select Category - Work Execution.

- Select Subcategory - Manage Work Orders.

- Select Component: Installation Issue (INSTALL).

- Copy and paste this text into the description area of the SR: Enable the SCM Core Service-Smart Operations.

This feature requires the SCM Core Service-Smart Operations service to be provisioned on your instance. Please note that this service can be enabled only on pods that are available in Oracle Public Cloud regions. Once this service is enabled, you can access the user guide and implementation guide of Manufacturing Cloud to learn more about this feature and how to set it up.

The high-level setups required to use this feature are as follows:

1. Use the Opt In UI to enable this feature. For instructions, refer to the Optional Uptake of New Features section of this document. This feature is a child feature of the feature "Record Process Data for an Operation When Executing Production at a Workstation" and is no longer optional from 26A.

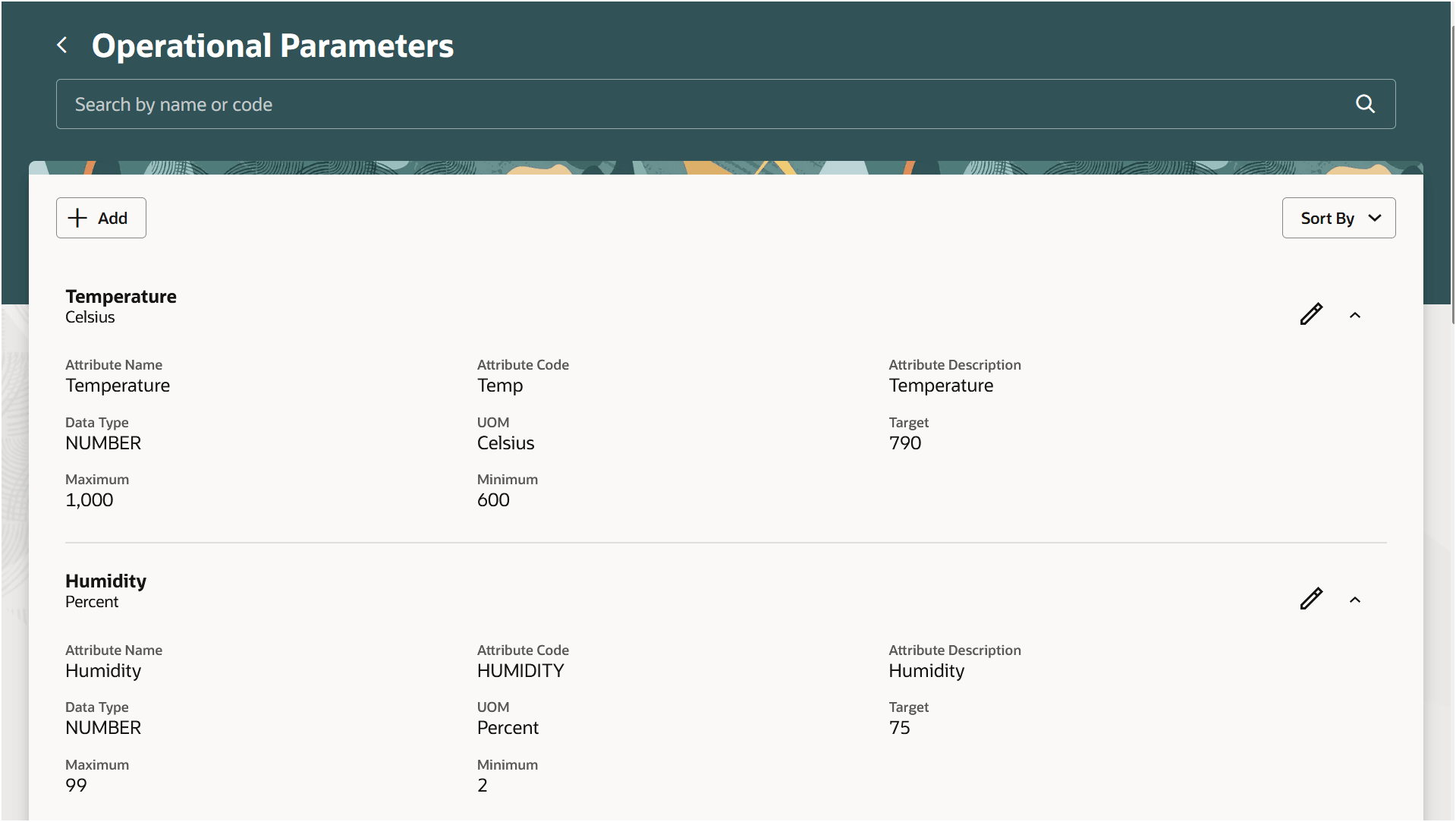

2. Define Operational Parameters.

- Navigate to the Work Definition work area and select the task Operational Parameters.

- Create the parameters by specifying details such as the parameter name, data type, target value, minimum and maximum value.

- Save the parameter.

Define Operational Parameters

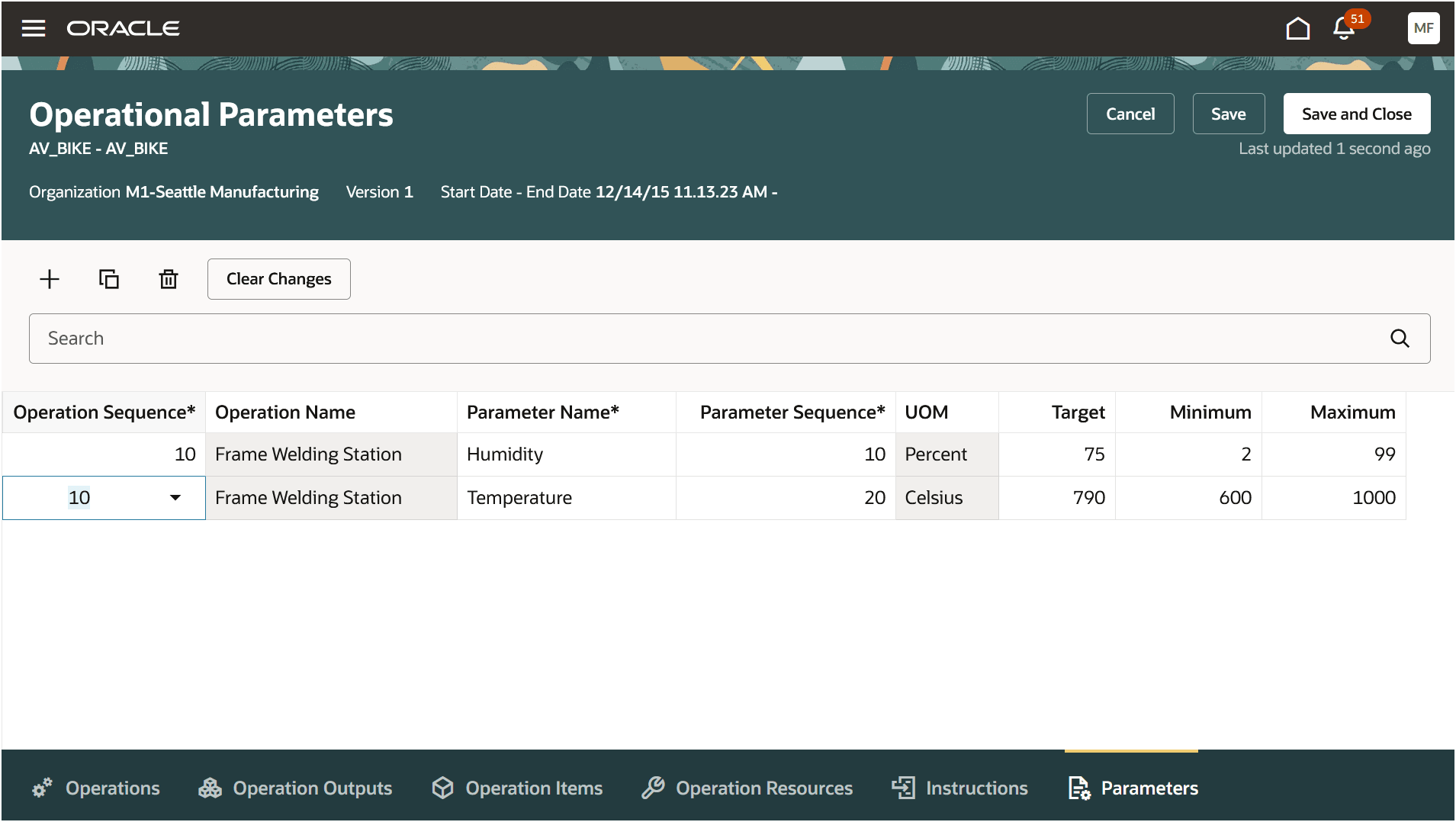

3. Associate Operational Parameters with the work definition.

- In the Work Definition work area, select the Manufacturing Work Definitions task and navigate to the Parameters tab

- Associate the parameters with the operation sequence

- Save the work definition.

Associate Operational Parameters to the Work Definition Operation

Tips And Considerations

- Operational parameters are organization agnostic and can be used in the work definition for items in any organization.

- Operational parameters are added to work definitions in the "Parameters" tab. An operational parameter can be added once per work definition operation.

- The data types supported for operational parameters are string and number. You can provide upper and lower limits and a target value for the number data type.

- During execution of work order operations, a connected equipment can send values for operational parameters defined in the work order operation.

- When an operator or connected equipment reports a completion, rejection, or scrap transaction, the operational parameters collected prior to the operation transaction are stamped with the operation transaction context.

- If operational parameter collection is followed by quality inspection and quantities are split between reject and complete disposition, then operational parameters are stamped with the completion transaction reference only.

- An operational parameter can be sent more than once from a connected equipment during execution of work order operations.

- Operational parameters collected for a work order operation can be viewed in the Electronic Production Record (EPR) and the Production Transaction History tab for the work order in the production supervisor workbench.

- Equipment instance signals received through industrial communication protocols need to be converted to a REST payload that Fusion Manufacturing Cloud can ingest and take actions on. The accepted payload specifications for operational parameters are documented here: REST API for Oracle Fusion Cloud SCM.

Key Resources

- Watch the feature demo for Collect Operational Process Data from Connected Equipment When Executing Production at a Workstation.

- Watch the feature demo for Record Process Data for an Operation When Executing Production at a Workstation.

- Oracle Fusion Cloud SCM: Refer to the Using Manufacturing guide, available on the Oracle Help Center.

- Oracle Fusion Cloud SCM: Refer to the Implementing Manufacturing and Supply Chain Materials Management guide, available on the Oracle Help Center.

Access Requirements

Users who are assigned a configured job role that contains the following privileges and duty roles can use this feature:

- View Operational Events (SMO_VIEW_EVENT_LOGS_PRIV)

- View Operational Events (ORA_DR_SMO_VIEW_OPERATIONAL_EVENTS_MFG_DUTY)

- Manage Operational Rules and Events (ORA_DR_SMO_MANAGE_OPERATIONAL_RULES_AND_EVENTS_MFG_DUTY)

- Manage Operational Parameters (SMO_MANAGE_OPERATIONAL_PARAMETERS_PRIV)

- View Operational Parameters (SMO_VIEW_OPERATIONAL_PARAMETERS_PRIV)

Guided Journeys : Role Codes

- Use REST Service - Guided Journeys Read Only (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEYS_RO)

- Use REST Service - Guided Journey Responses (Role Code ORA_PER_REST_SERVICE_ACCESS_GUIDED_JOURNEY_RESPONSES)