Redwood: Create Supply Plans and Edit Supply Plan Options using a New User Experience

You can now use the Redwood guided process to create a new supply plan. The plan creation process is significantly streamlined to guide you at every step, helping you make informed choices as you configure the plan to fit your enterprise’s requirements. Additionally, you can also view and edit plan options for an existing Supply plan.

To create a supply plan from the Redwood Supply Chain Planning work area:

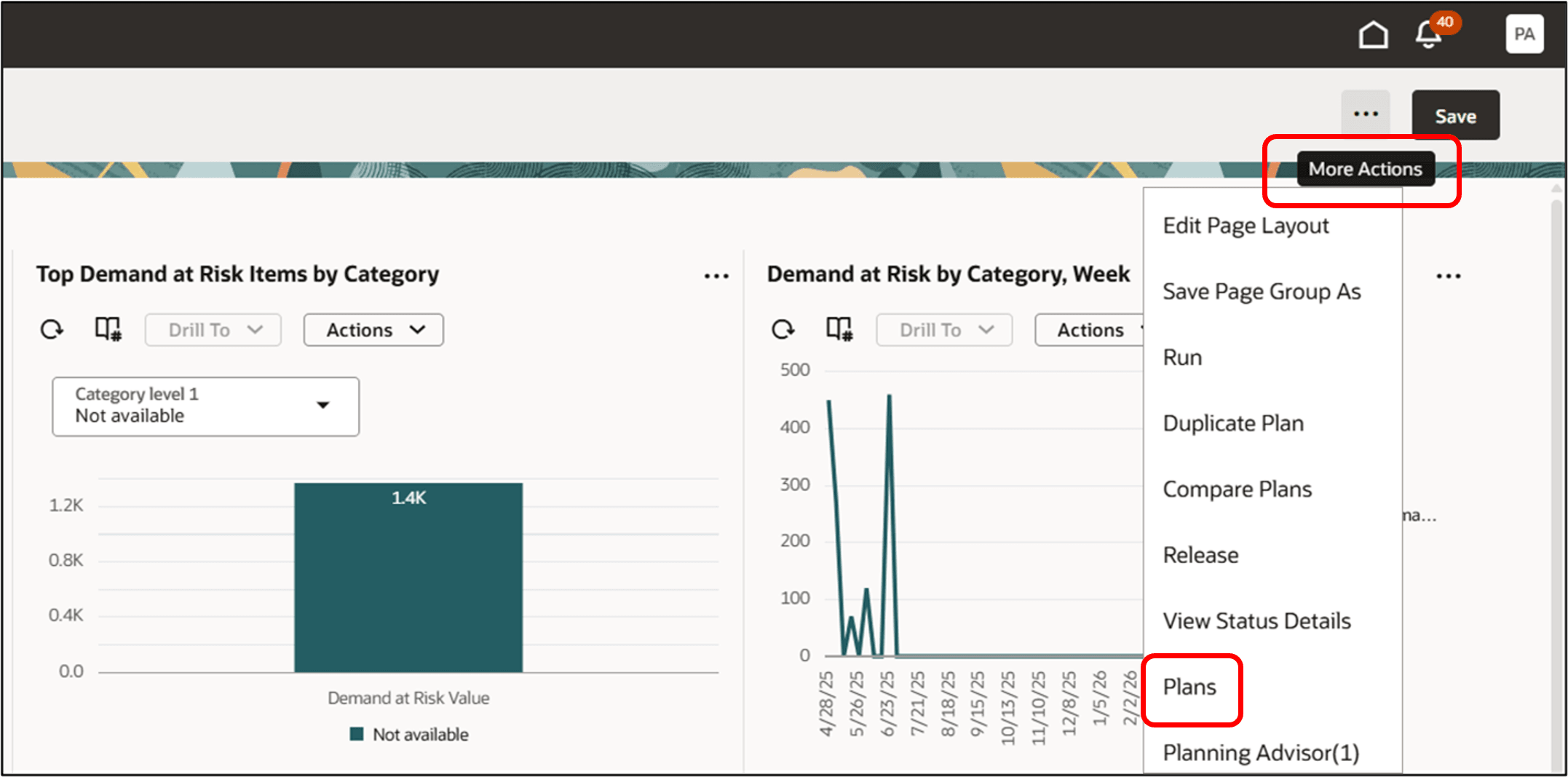

- In the Supply Chain Planning work area, navigate to More Actions > Plans.

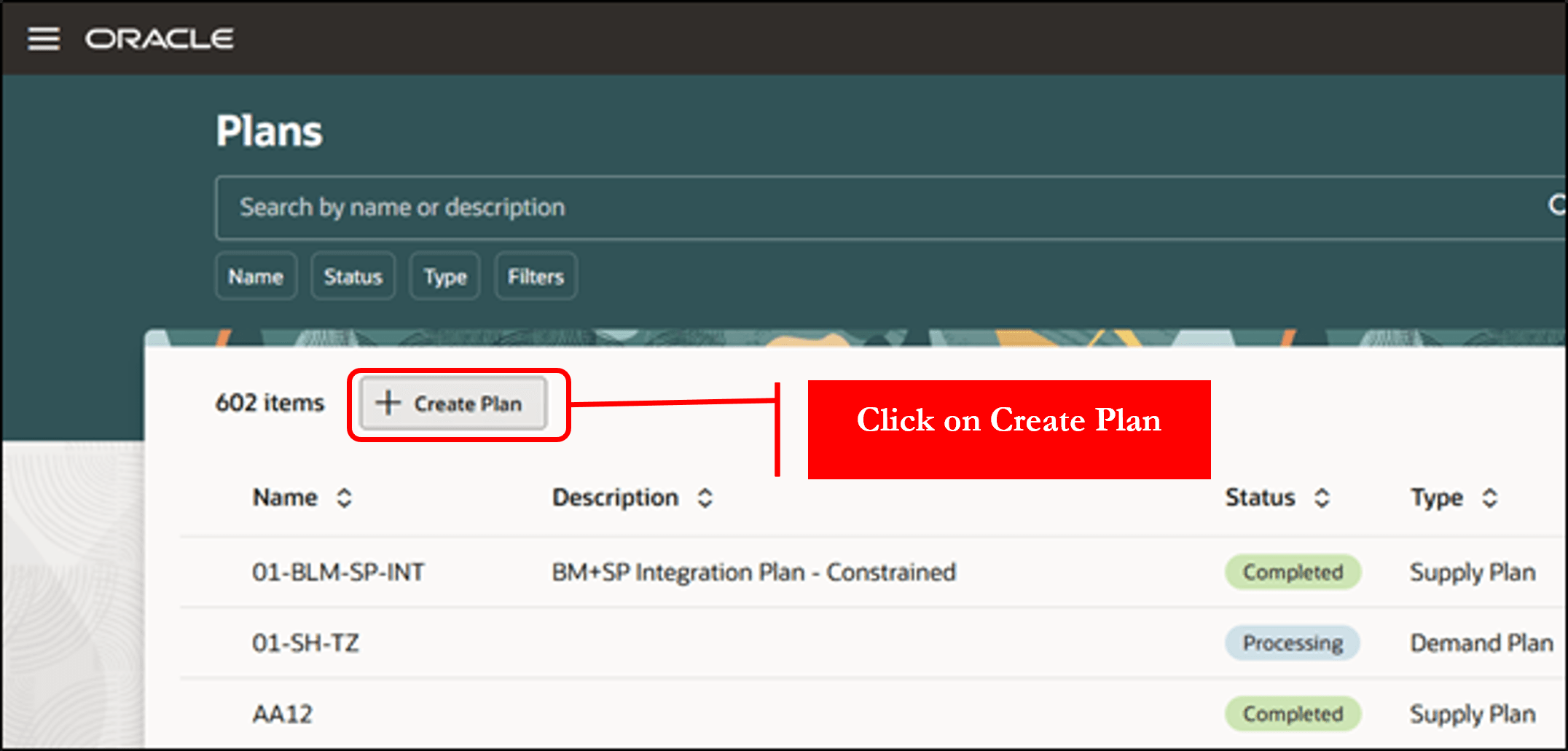

The Plans page opens on a new web browser tab and displays a list of plans that you own or have permission to access. Multiple plan actions are available for each plan based on the plan type.

Select Plans in the Redwood Supply Chain Planning Work Area

- Click Create Plan.

Create a Plan from the Plans Page

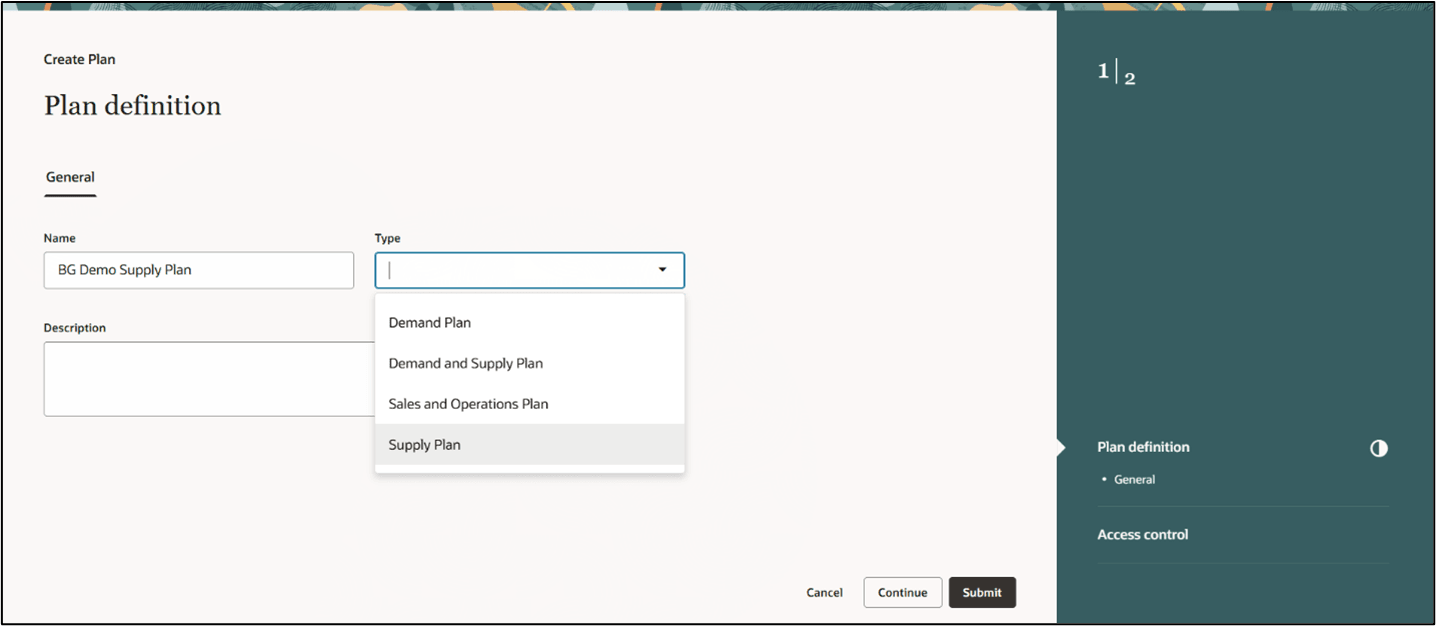

A guided process opens in a new browser tab, displaying Name, Type, and Description fields.

- Enter a Name and Description and select Type as Supply Plan.

Create a Supply Plan in the Guided Process

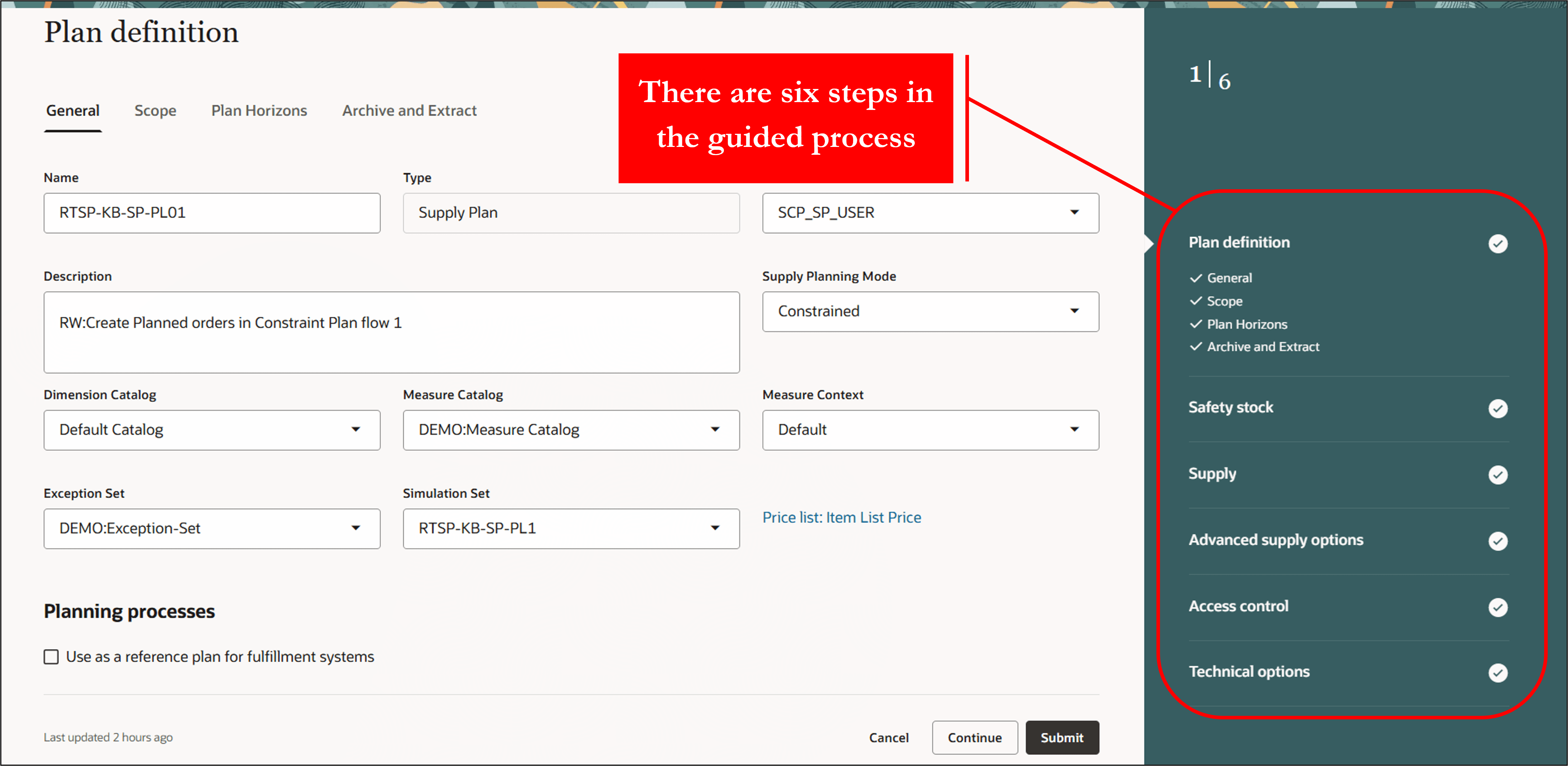

The expanded guided process displays the default plan options applicable to a supply plan. The process consists of six steps.

- Plan definition

- Safety Stock

- Supply

- Advanced supply options

- Access control

- Technical options

The plan options page has two sections: the guided process (right) and the content area (left). The table of contents shows the plan options steps, and the content area displays plan options for the selected step.

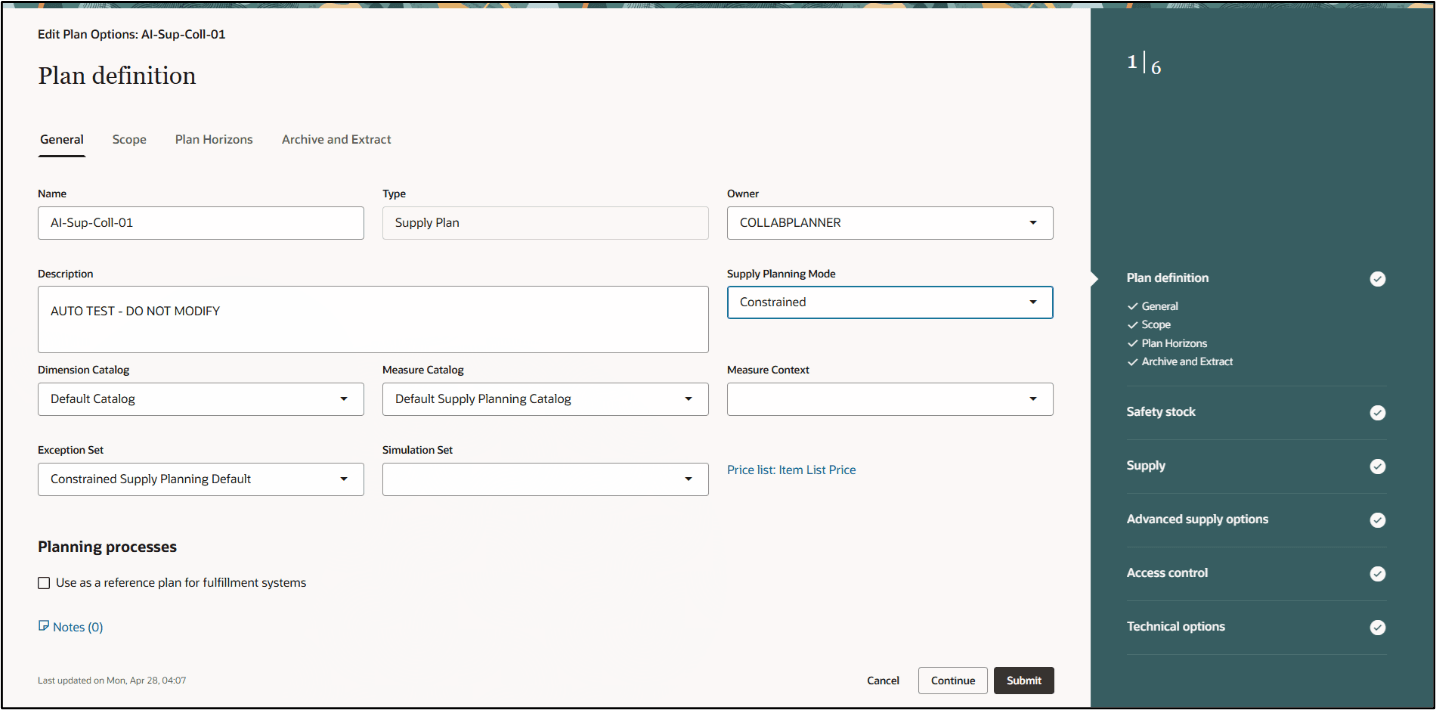

Plan Definition with Guided Process

Plan Definition General Tab Plan Options

- In the Plan definition page, use the General tab to modify the following plan options as needed:

- Name

- Type

- Owner

- Description

- Supply Planning Mode

- Exception Set

- Simulation Set

- Dimension Catalog: A selected list of hierarchies in different dimensions enabled for use in plans.

- Measure Catalog: A collection of predefined and user-defined measures for use in plans.

- Measure Context: Measure contexts are categorized into three types:

- Default: Predefined and user-defined measures with only predefined dimensions and stored levels.

- Project: Predefined measures include project dimensions. User-defined measures can include project dimensions either during creation or through Change Granularity.

- Planning Attributes: Predefined measures can be deployed with planning attribute dimensions. User-defined measures can include planning attributes during creation or through Change Granularity.

Click the Scope tab to continue.

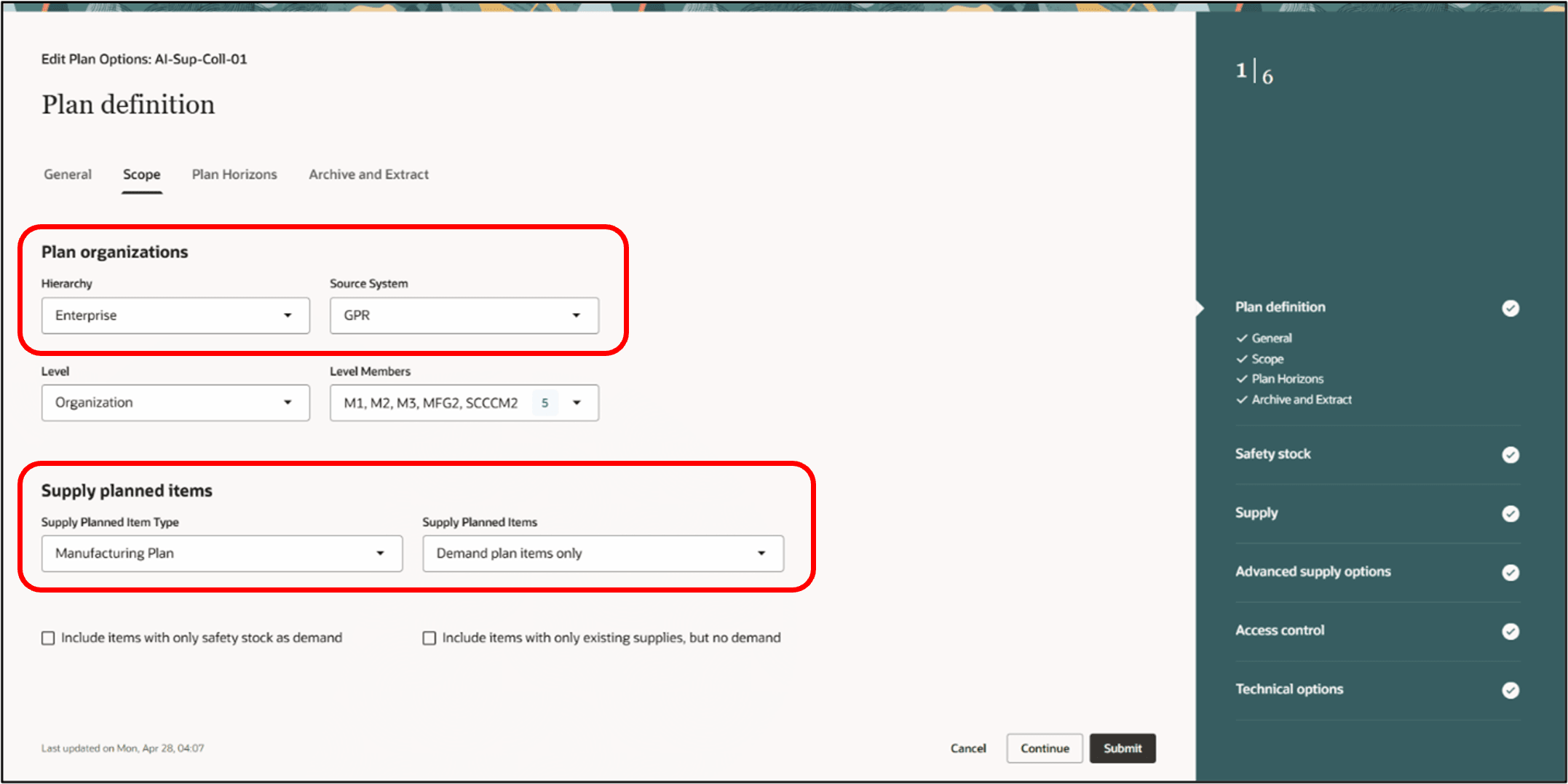

- On the Scope tab, configure plan organizations and items, and define filters by specifying Hierarchy, Level, and Level Members.

Plan Definition Scope Tab Plan Options

Click the Plan Horizons tab to continue.

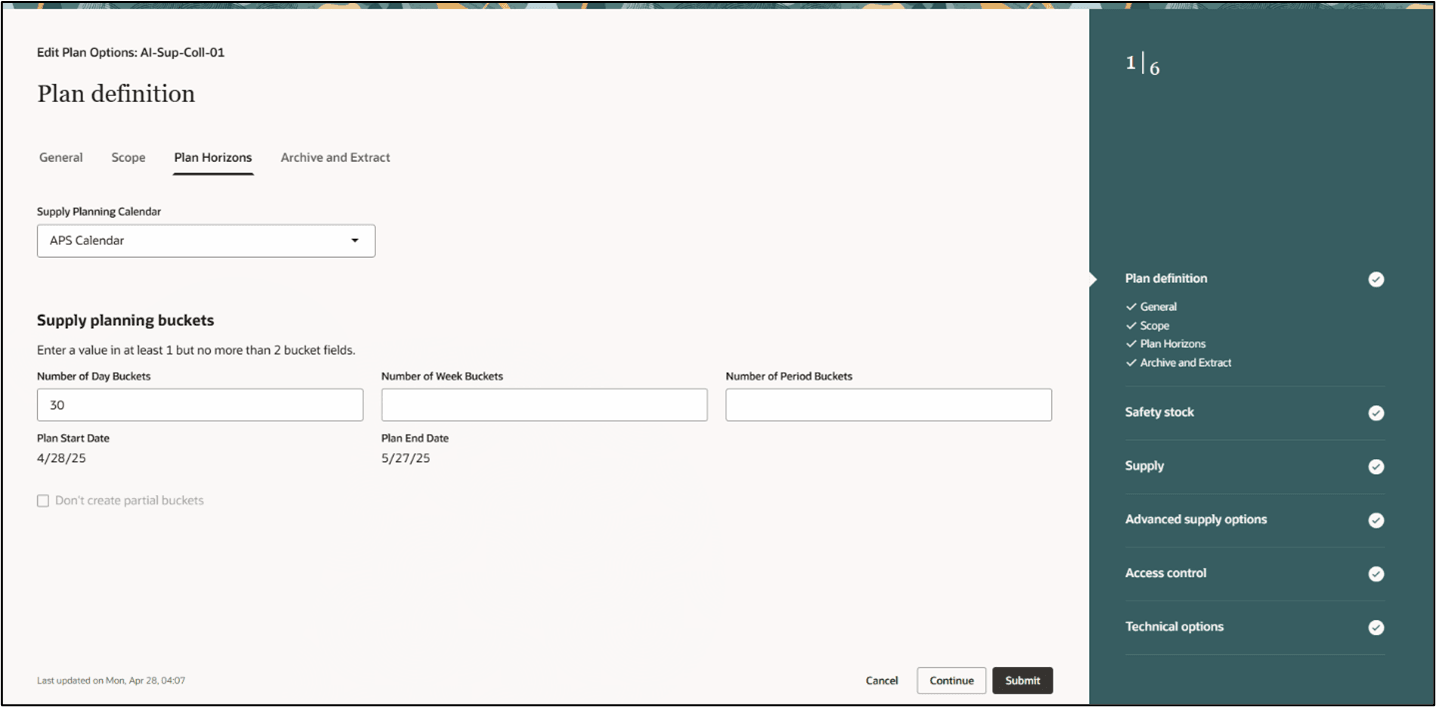

- On the Plan Horizons tab, select the Supply Planning Calendar and Supply Planning Buckets plan options, and Don't create partial buckets checkbox.

Plan Definition Plan Horizons Tab Plan Options

Click the Archive and Extract tab to continue.

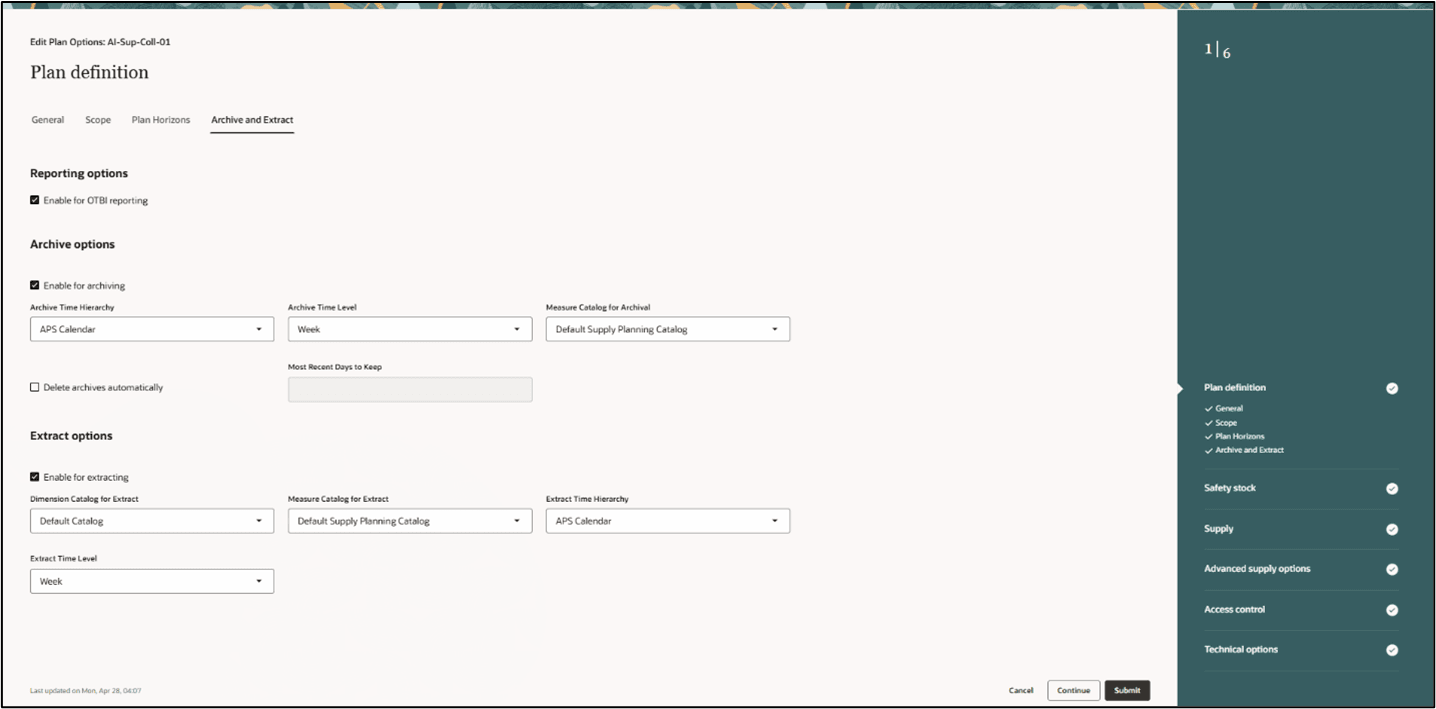

- On the Archive and Extract tab, you can archive and extract plan measures. Archiving saves multiple versions of a plan's measures over time, while extracting lets you pull data for offline reports or external system integration.

Plan Definition Archive and Extract tab Plan Options

Click Continue to go to the Safety Stock step.

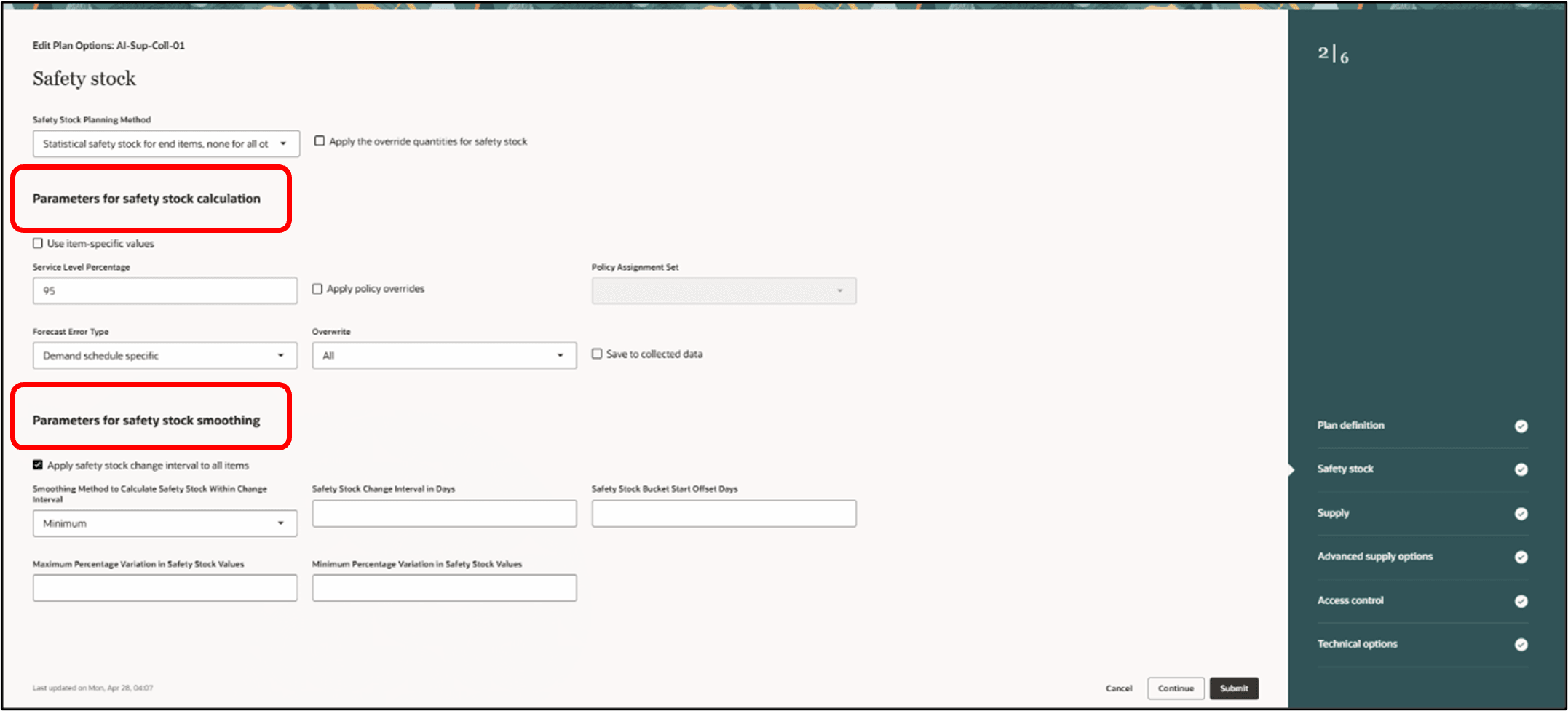

- Use the Safety Stock step to configure calculation and smoothing parameters, select a Safety Stock Planning Method, and apply override quantities.

Safety Stock Plan Options

- Parameters for safety stock calculation: Define key parameters, including Service Level Percentage and Forecast Error Type.

- Parameters for safety stock smoothing: Planners often aim to minimize safety stock fluctuations, as daily changes can be difficult to manage. Even minor adjustments can significantly impact projected available balances due to order modifiers. Safety stock smoothing plan options help control daily and weekly variations, improving stability.

Click Continue to go to the Supply step.

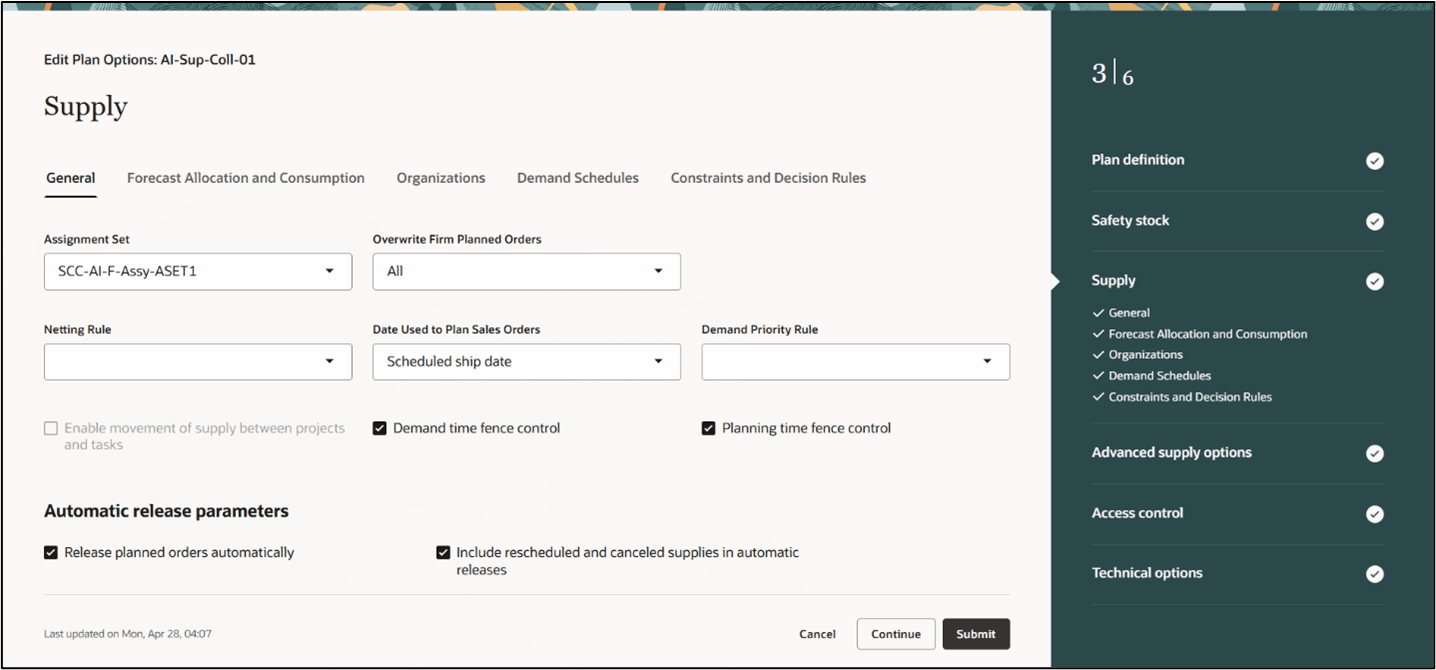

- In the Supply step, go to the General step and select an Assignment Set.

Supply General Tab Plan Options

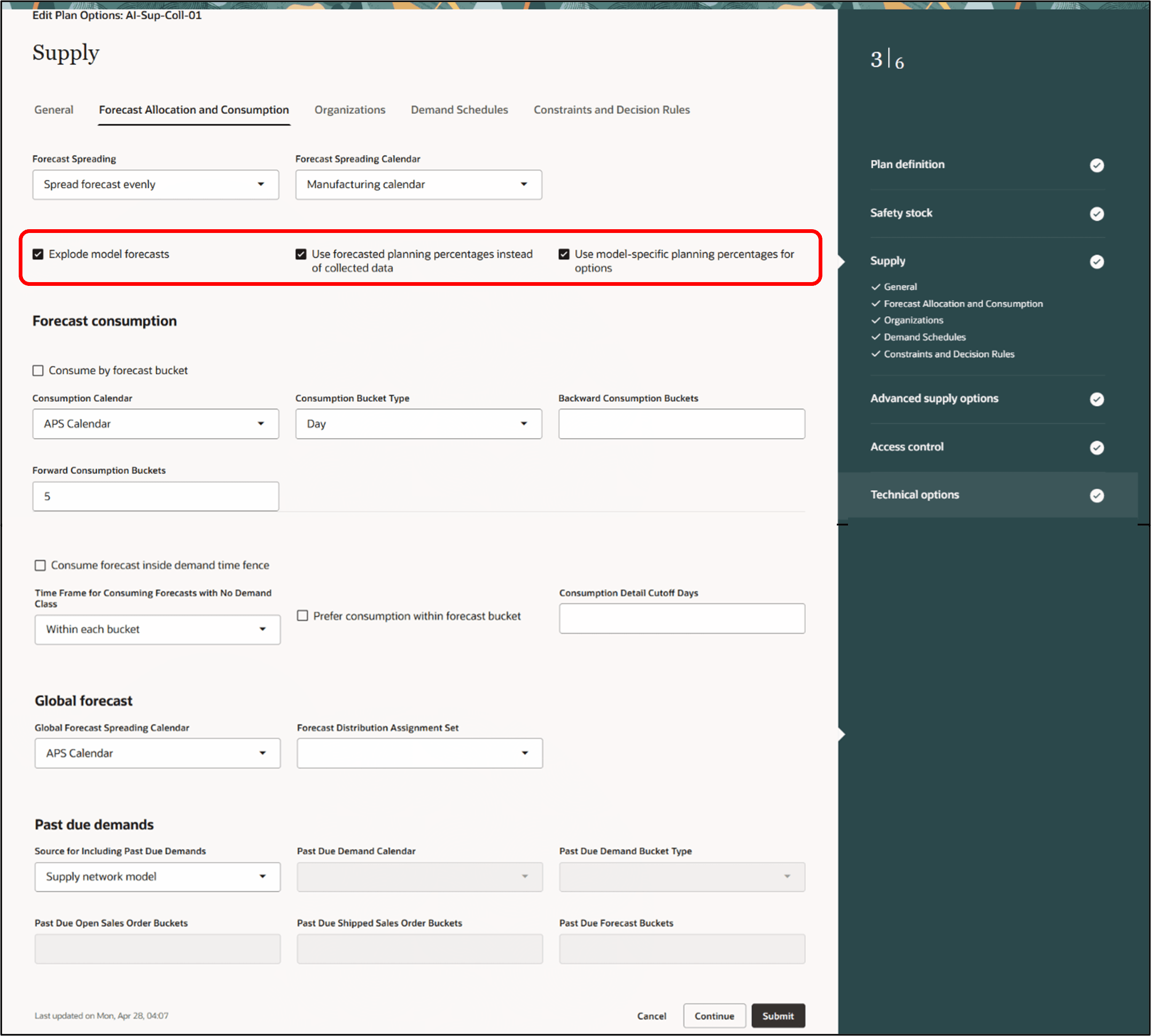

Click the Forecast Allocation and Consumption tab to continue.

- On the Forecast Allocation and Consumption tab, select the options for forecast spreading and model forecasts. You can also update forecast consumption, global forecast, and past due demands.

When exploding model forecasts with forecasted planning percentages, you can use model-specific planning percentages for options.

Forecast Allocation and Consumption Plan Options

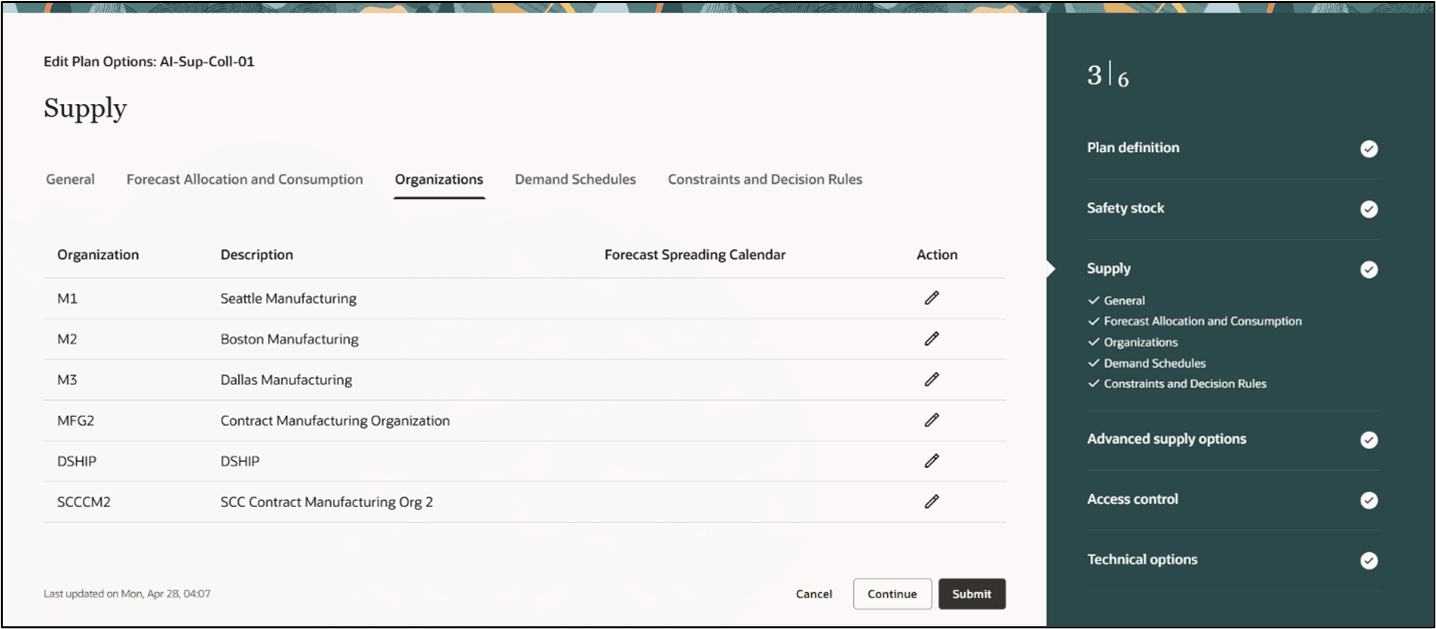

Click the Organizations tab to continue.

- The Organizations tab includes the Organization, Description, Forecast Spreading Calendar, and Action columns. Use the Edit icon in the Action column to update the organization parameters.

Supply Step with Organizations Tab

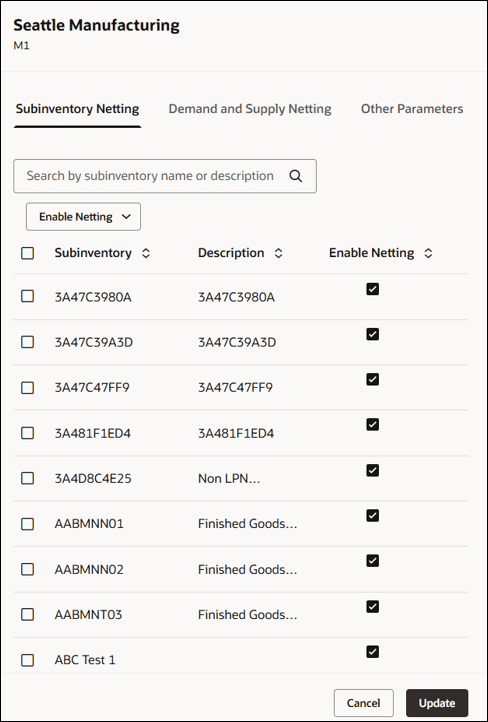

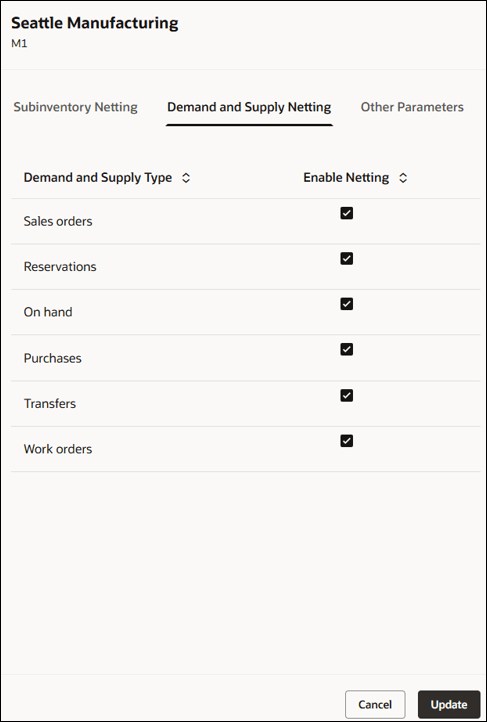

These parameters primarily relate to Subinventory Netting, Demand and Supply Netting, and Forecast Spreading Calendar.

Organization Subinventory Netting

Organization Demand and Supply Netting

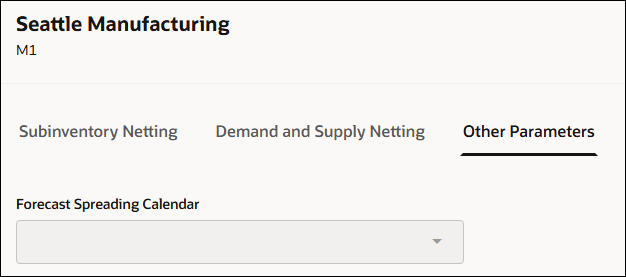

Organization Forecast Spreading Calendar

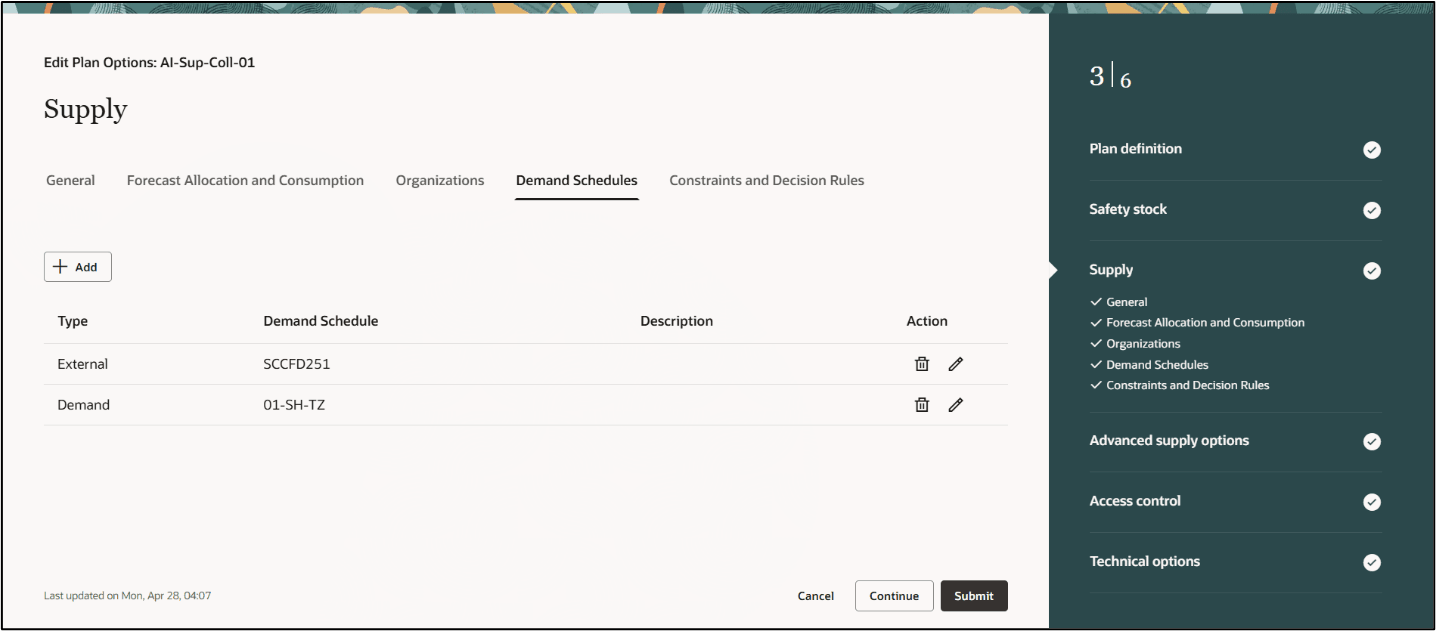

Click the Demand Schedules tab to continue.

- The Demand Schedules tab includes Demand Schedule, Type, Description, and Action columns. Use the Edit icon in the Action column to modify demand schedule parameters. To add a demand schedule, click +Add.

Supply Demand Schedules Plan Options

Demand Schedule Parameters

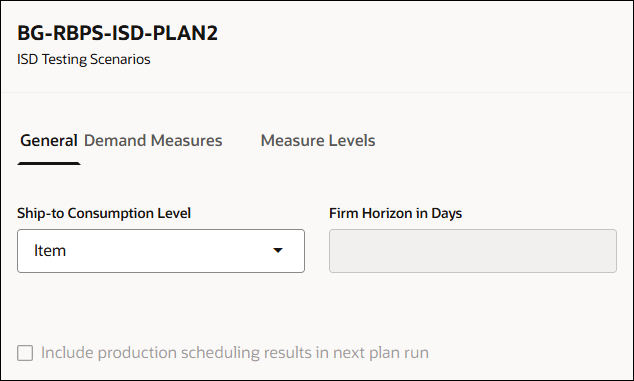

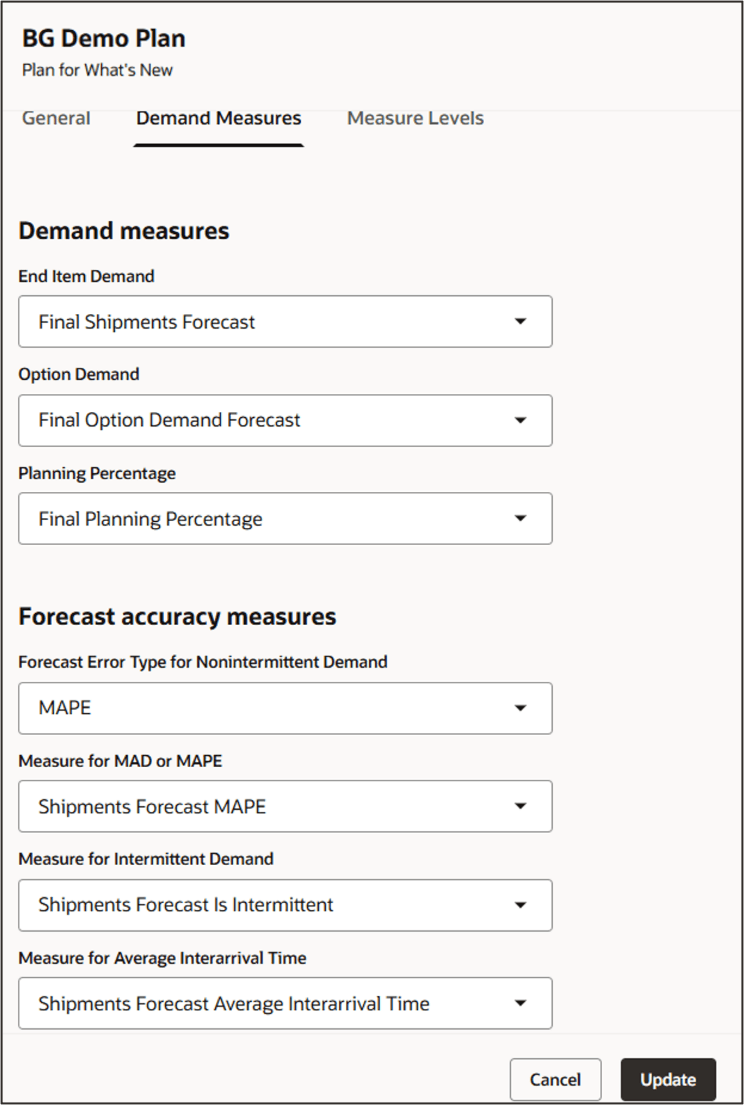

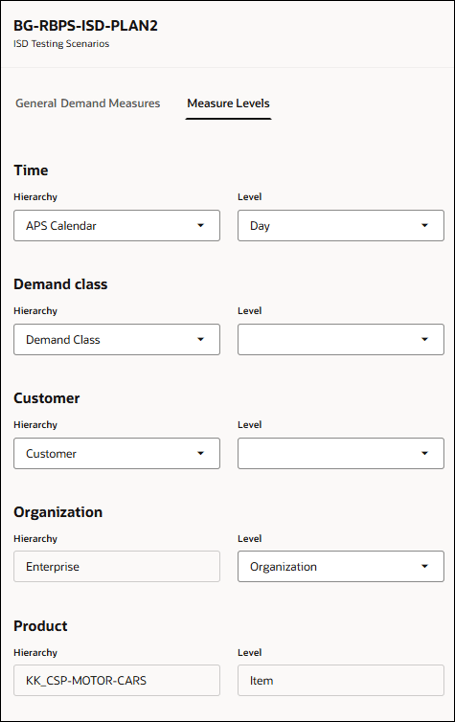

Demand schedule parameters are organized into three tabs: General, Demand Measures, and Measure Levels.

Demand Schedule General Parameters

Demand Schedule Demand Measures

To measure forecast accuracy, set the Safety Stock Forecast Error Type to Demand schedule specific.

Demand Schedule Measure Levels

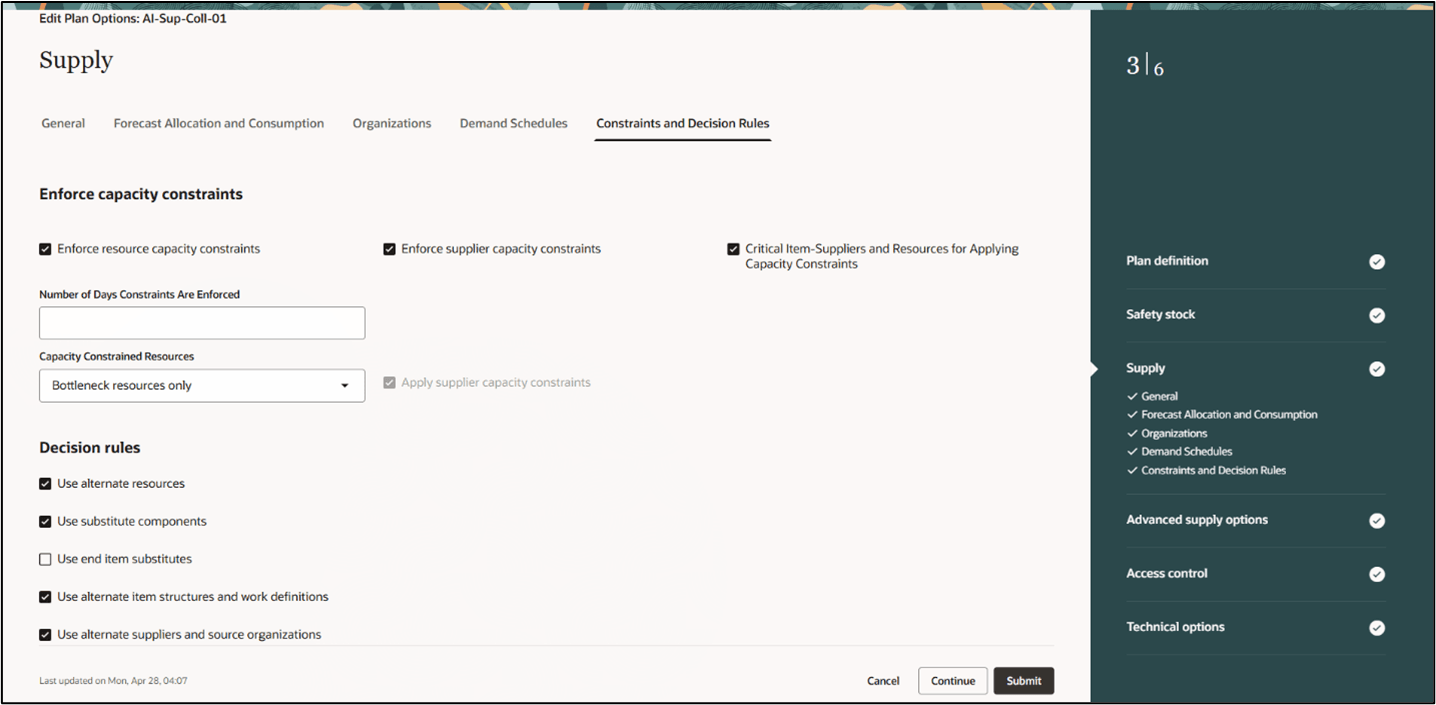

Click the Constraints and Decision Rules tab to continue.

- The Constraints and Decision Rules tab is enabled only for constrained supply plans.

The Constraints and Decision Rules tab includes options to set Enforce capacity constraints and Decision rules.

- Enforce capacity constraints: Use this section to specify constraints for resource capacity, supplier capacity, and other capacity attributes.

- Decision rules: Use this section to specify decision rules such as alternate and substitute sources.

Constraints and Decision Rules Plan Options

Click Continue to go to the Advanced Supply Options step.

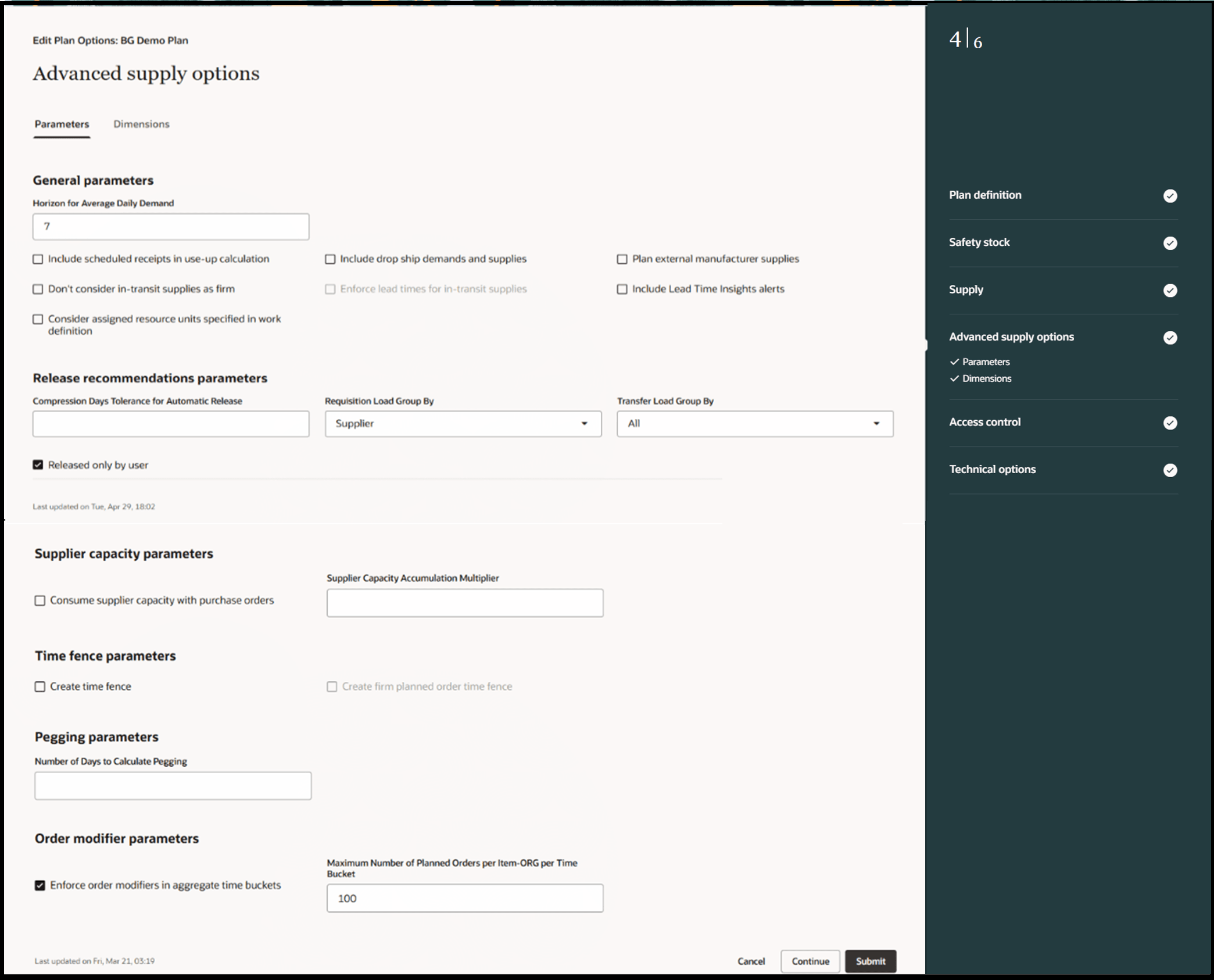

- In the Advanced supply options step, go to the Parameters tab.

Advanced parameters cover release recommendations, supplier capacity, time fences, pegging, and order modifiers. Additionally, you can enforce order modifiers in aggregate time buckets to control the planning cycle time by applying order policies to defined time periods, such as weeks or periods.

Advanced Supply Options Parameters Tab

Click the Dimensions tab to continue.

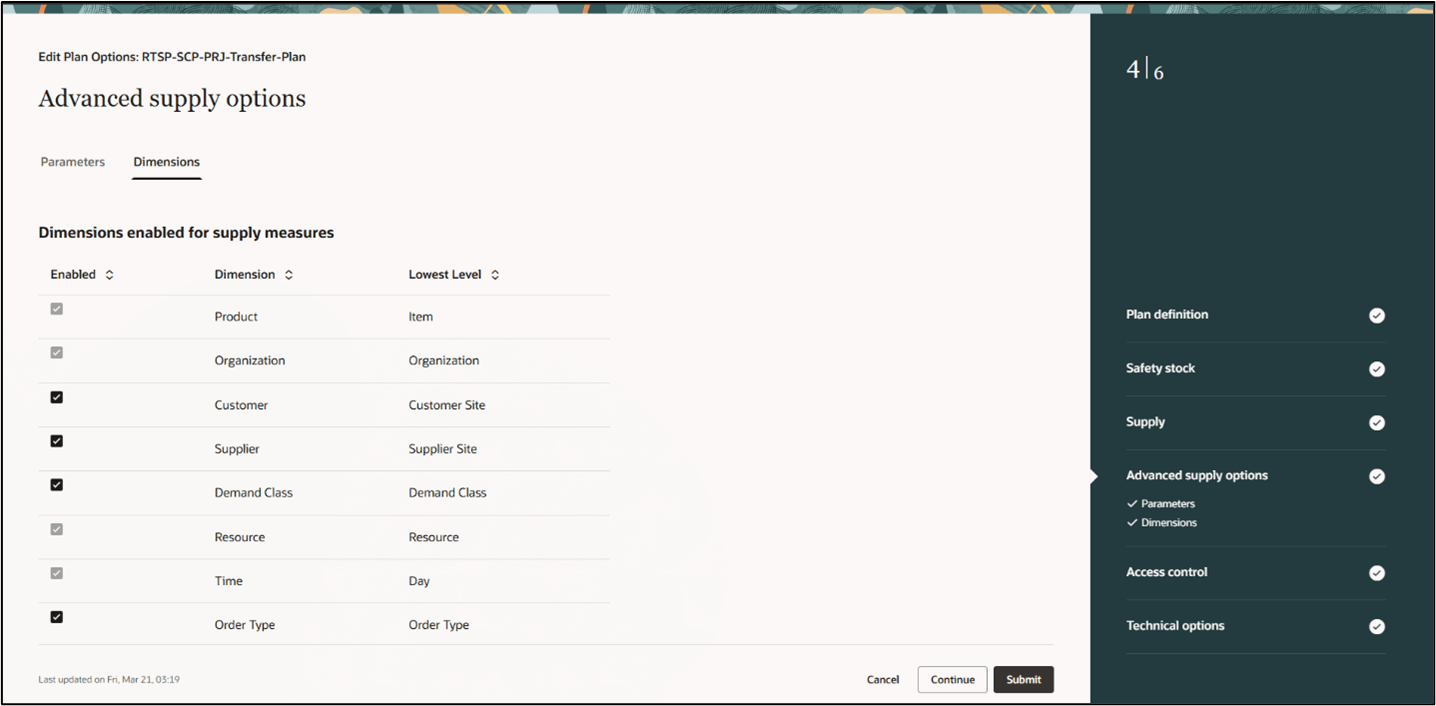

- On the Dimensions tab, enable tracking for supply measures such as Customer, Supplier, Demand Class, and Order Type.

Advanced Supply Options Dimensions Tab

Click Continue to go to the Access control step.

- In the Access control step, you can set access controls for the plan:

- Public: Makes the plan accessible for all users.

- Private: Restricts plan access to only you and specific users you designate.

Access Control Options

Click Continue to go to the Technical Options step.

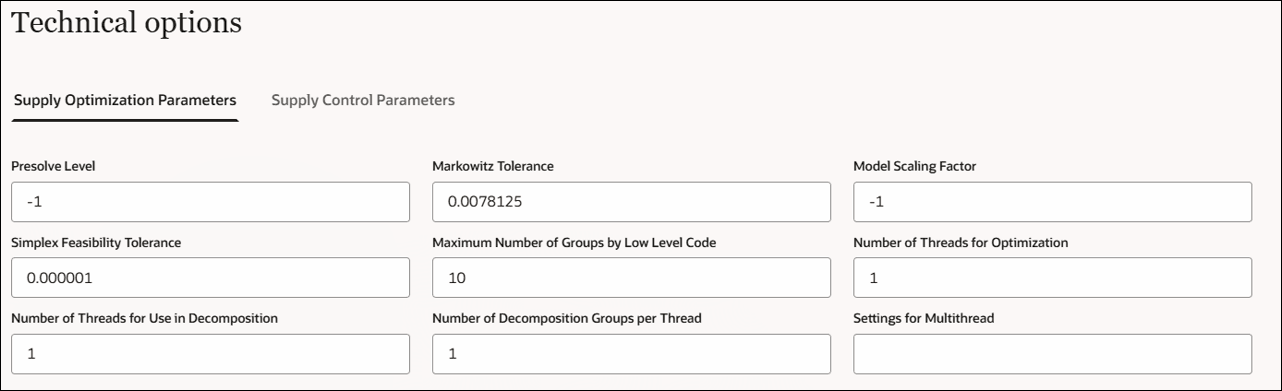

- In the Technical options step, go to the Supply Optimization Parameters tab.

Don't modify these default values unless explicitly advised by your Oracle Help Desk.

Supply Optimization Parameters

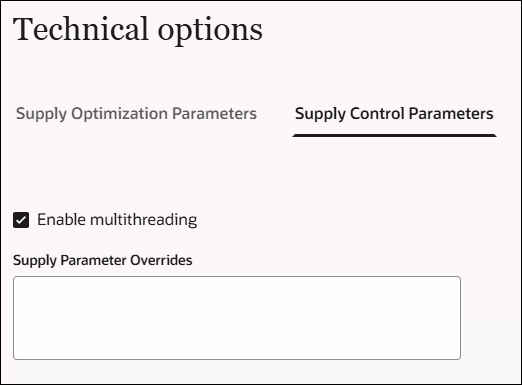

Click the Supply Control Parameters tab to continue.

- On the Supply Control Parameters tab, specify the following:

- Enable multithreading: Use multithreading to reduce the overall runtime of a supply plan.

- Supply Parameter Overrides: You can override the default planning behavior using the Parameter Overrides field. Use this option only when instructed by the Oracle Help Desk, typically to address specific issues raised in a service request.

Supply Control Parameters

- Click Submit to create the supply plan.

A message is displayed when the plan is created. Close the browser tab after creating the plan.

Run the supply plan from the Plans page.

Steps to Enable

There are no new profiles that need to be enabled to access the Plan Options page. However, access to this page is available only from the Redwood Supply Chain Planning Work Area which needs to be enabled. For the steps to enable this work area, please refer to the What’s New documentation in 25B release.

Tips And Considerations

- Measure Context

- The Measure Context option appears in the General tab of the Plan definition only when Attribute Based Planning or Project-Driven Supply Chain opt-in is enabled.

- Default values are assigned based on the plan creation date:

- For plans created before 21C: If the Attribute Based Planning opt-in is enabled, the Measure Context is set to NULL by default. This value is treated as Default for backward compatibility. However, if you select the Measure Context List of Values (LOV), NULL is not available. The LOV options are: Default, Project, and Planning Attributes.

- For plans created in or after 21C: If either the Project-Driven Supply Chain or the Attribute Based Planning opt-in is enabled, the Measure Context is displayed as Default by default. The LOV options are: Default, Project, and Planning Attributes.

- For supply plans with Measure Context set to Project, demand plans with Measure Context values NULL, Default, or Project can be used as a Demand Schedule.

- For supply plans with Measure Context set to Planning Attributes, demand plans with Measure Context values NULL, Default, or Planning Attributes can be used as a Demand Schedule.

- Safety Stock Override

The checkbox Apply the override quantities for safety stock is enabled when any of the following Safety Stock Planning Methods is selected:

- User-specified values for all items

- Statistical safety stock for end items, none for all others

- Statistical safety stock for end items, none for all others, User-specified for all others

- Netting Rule

The netting rule in the General tab of the Supply step is displayed and enabled if Project-Driven Supply Chain or Attribute Based Planning is enabled through opt-in, and the specified netting rule includes project and task attributes.

- A plan qualifies as an Attribute Based Planning plan if the netting rule is not NULL.

- If a netting rule is selected, then the Ship-to Consumption level list of values includes planning attributes.

- Enable Movement of Supply

The Enable movement of supply between projects and tasks option in the General tab of the Supply step is displayed and enabled when Project-Driven Supply Chain or Attribute Based Planning opt-in is enabled, and the netting rule has project and task attributes.

- Forecast Spreading Calendar

The forecast spreading calendar in the Other Parameters tab is enabled when:

- Forecast Spreading is set to Spread forecast evenly in the Forecast Allocation and Consumption tab.

- A Demand and Supply type of forecasts is defined in the Demand and Supply Netting tab.

- Critical Item-Suppliers and Resources

- The Critical Item-Suppliers and Resources for Applying Capacity Constraints option is enabled when either of the following is selected:

- Enforce resource capacity constraints

- Enforce supplier capacity constraints

- Enforce Lead Times

The Enforce lead times for in-transit supplies option is enabled when the Don't consider in-transit supplies as firm checkbox is selected in a constrained plan.

Access Requirements

Users who are assigned a configured job role that contains these privileges can access this feature:

- Supply Chain Planner (ORA_MSC_SUPPLY_CHAIN_PLANNER_JOB)

- Materials Planner (ORA_MSC_MATERIALS_PLANNER_JOB)

These privileges were available prior to this update.